Combustible materials such as buffing lint, paper, wood, metal dusts, weld fume, or flammable

coolants or solvents represent potential fire and/or explosion hazards. Use special care when

selecting, installing, and operating all dust, fume, or mist collection equipment when such combustible

materials may be present in order to protect workers and property from serious injury or damage due to a

fire and/or explosion.

Consult and comply with all National and Local Codes related to fire and/or explosion properties of

combustible materials when determining the location and operation of all dust, fume, or mist collection

equipment.

Standard Donaldson Torit equipment is not equipped with fire extinguishing or explosion protection systems.

1

Donaldson Company, Inc.

Description

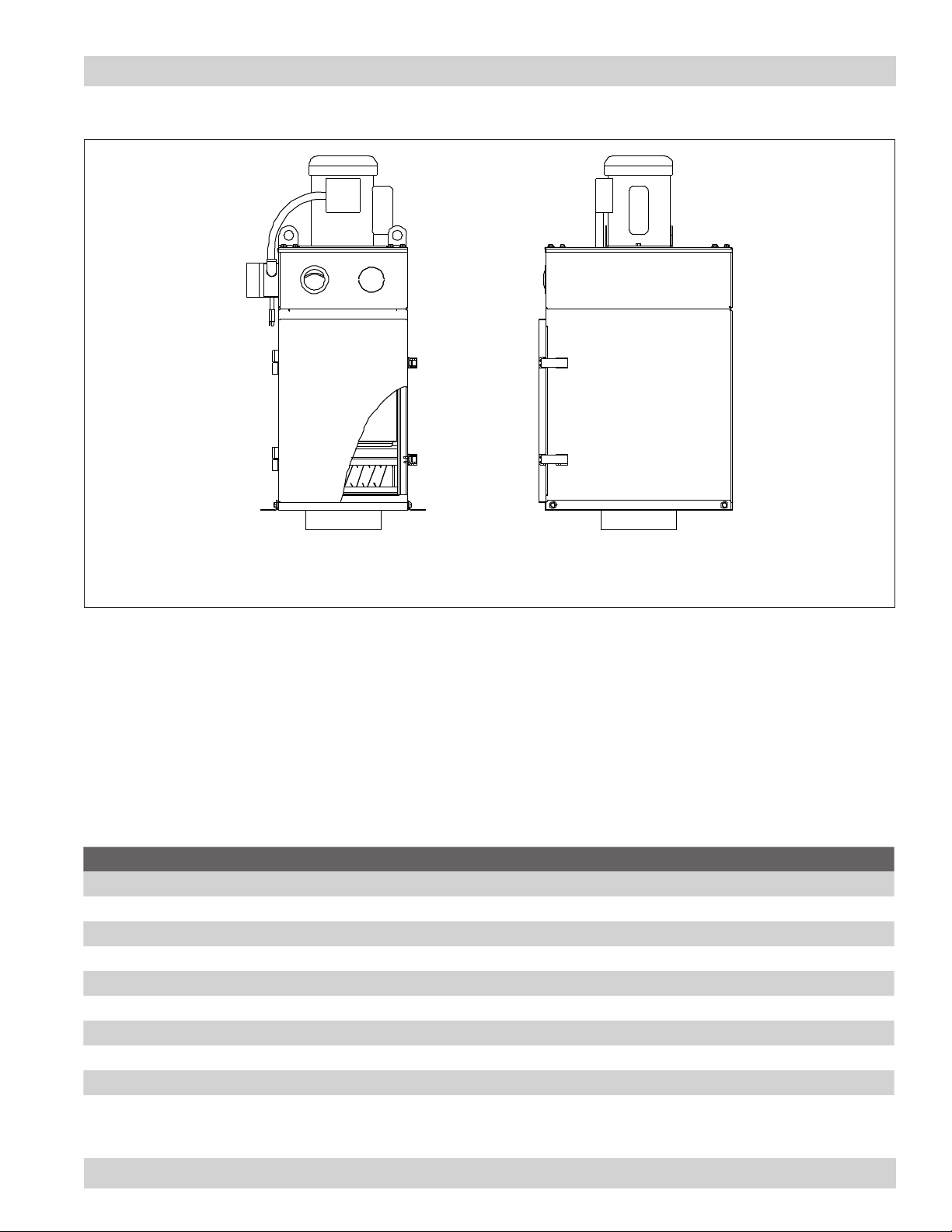

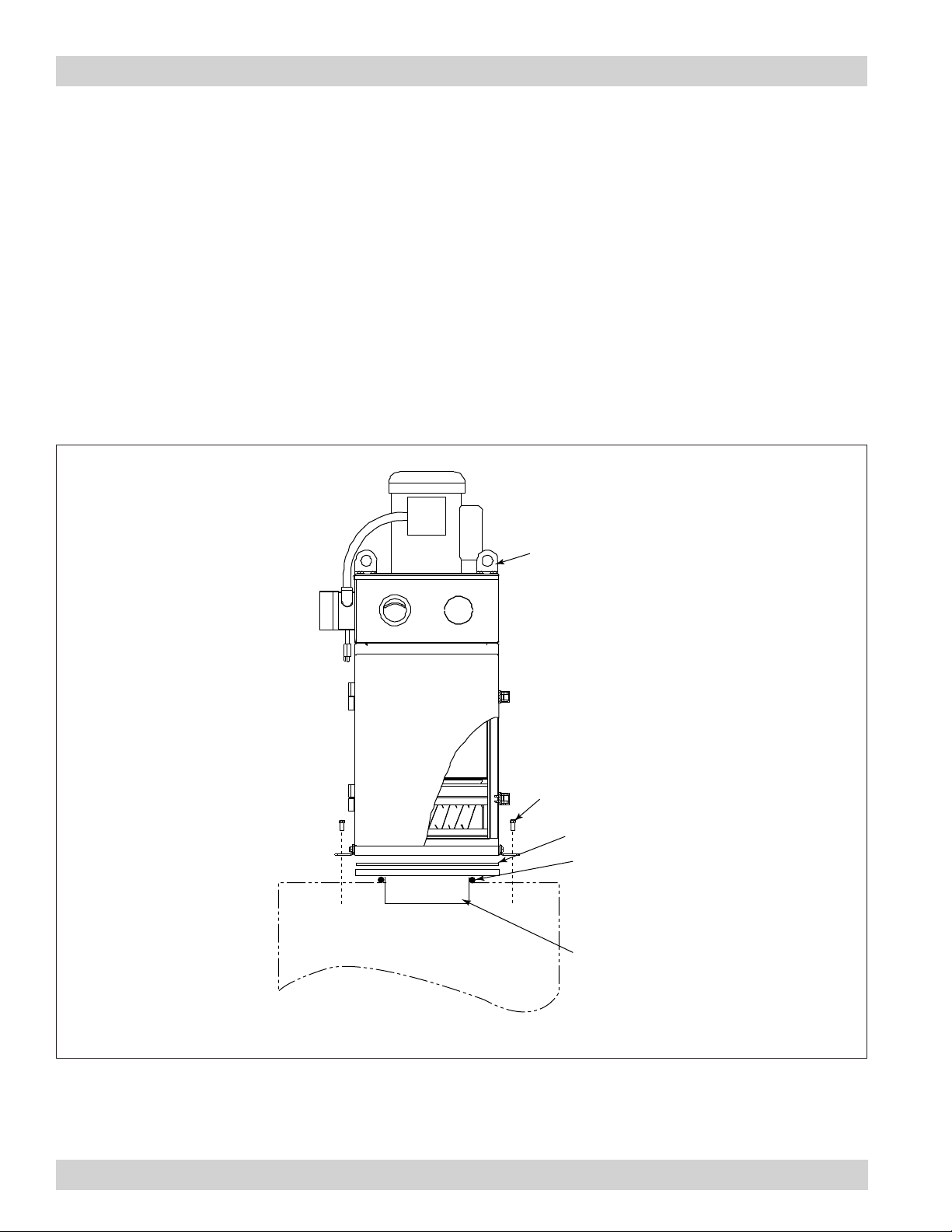

The Mini-Mist Air Filter, Models MM 500 and

MM 1200 are compact, machine-mountable mist

collectors designed to filter wet contaminants from

machining operations and industrial processes. Primarily

used for light- to moderate-duty applications, the Mini-

Mist is an excellent choice for machine repair, tool and

die,

or job shops with small to average production runs.

Three separate filters provide superior filtration of oil,

water-soluble and synthetic coolant mist as well as

small amounts of dust and smoke. Standard models

are designed for 500 to 1200 cfm and feature 1/2 to 1

1/2 horsepower direct-drive blowers. Standard options

include multiple motor options, wall- or machine-mount

brackets, and HEPA filters all designed to increase the

versatility of the unit.

Purpose and Intended Use

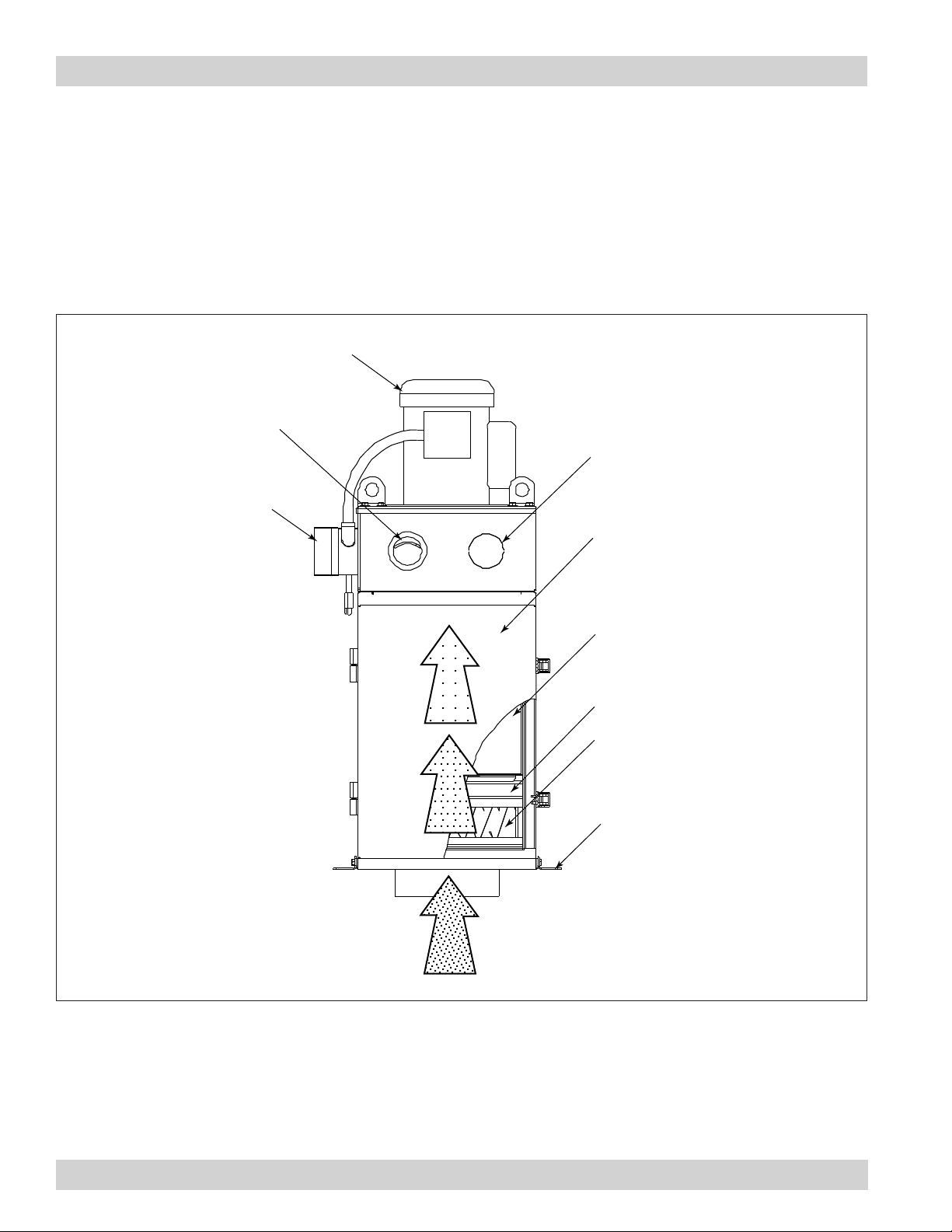

The Mini-Mist Air Filter is primarily used in source

capture applications to remove mist and secondary

contaminants such as dust and light smoke or fume

from machining operations. Two basic means create

mist particles: mechanical action and thermal effects.

Mechanical action refers to the aerosol used for light

lubrication directly from the oil or coolant nozzle.

Mechanical action creates mist greater than one micron

in size. Thermal effects occur when heat vaporizes the

coolant, the vapor cools, and re-condenses into a mist.

Thermal effects create submicron mist particles. Select

the proper module and filter options for the application.

Types of machining fluids and their applications:

• Straightoilprovidesthebestlubricationqualities

but only average cooling properties. Some examples

of machining operations using straight oil are cold

heading, cold forming, hobbing, and gear cutting.

• Water-solublecoolantsconsistpartlyofwater

and provide the best cooling properties. Examples

of applications using water-soluble coolants or

soluble oil include broaching, punching, roll forming,

and stamping because the tool moves slower and

generate less heat.

• Solubleoilorsemi-syntheticcoolantisusedforits

equal qualities of cooling and lubricating because

the tool is moving fast on close tolerances. Boring,

drilling, milling, and lathe turning centers are among

the many applications using soluble oil for cooling

although milling is the most common.

• Syntheticcoolanthassuperiorcoolingproperties.

High-speed operations that generate large amounts

of heat require a good coolant. The two main

applications are abrasive cut-off sawing and wet

grinding including centerless, cylindrical, profile,

rotary table, and surface.

• Theextremesofveryheavyoilsandverylight,thin

oils should be avoided. The very heavy oils, similar

to tar consistency, will not drain. Very light, thin oil,

similar to gasoline consistency, may evaporate.