Section 5

SUGGESTED INSTALLATION

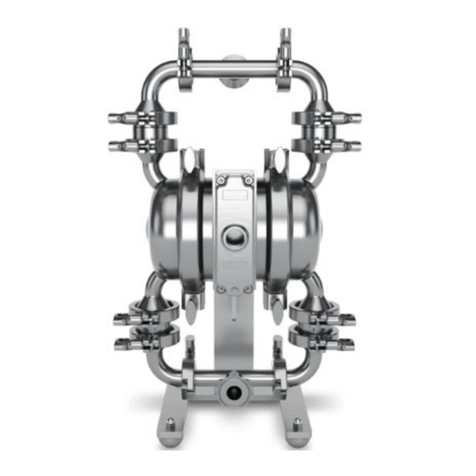

The pipe size should be at least the size of the inlet and

discharge ports of the pump or larger if highly viscous

material is being pumped.The suction hose must be non-

collapsible, reinforced type as the SANIFLO™ VC pump is

capable of pulling a vacuum. It is critical that all fittings

and connections are airtight or a reduction or loss of

pump suction capability will result.

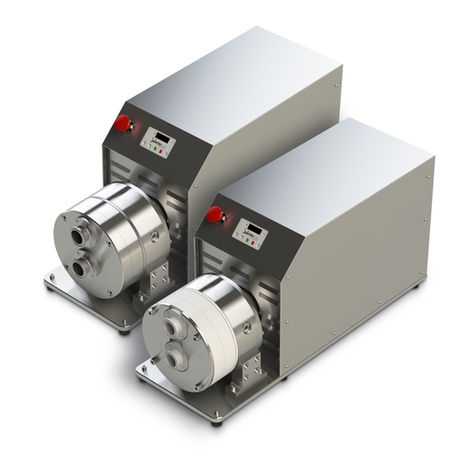

INSTALLATION: Months of careful planning, study

and selection efforts can result in unsatisfactory pump

performance if installation details are left to chance.

Premature failure and long term dissatisfaction can be

avoided if reasonable care is exercised throughout the

installation process.

LOCATION: Noise, safety and other logistical factors

usually dictate where equipment should be situated on

the production floor. Multiple installations with conflicting

requirements can result in congestion of utility areas,

leaving few choices for additional pumps.

Within the framework of these and other existing

conditions, every pump should be located in such a way

that six key factors are balanced against each other to

maximum advantage.

ACCESS: First, the location should be accessible. If it

is easy to reach the pump, maintenance personnel will

have an easier time carrying out routine inspections and

adjustments. Should major repairs become necessary,

ease of access can play a key role in speeding the repair

process and reducing total downtime. Verify that the site

also allows for ease of cleaning and proper drainage

during wash down.

AIR SUPPLY: The HPVC pump is furnished with a one-

half inch (NPT) ball valve as the point of connection for

compressed air. Although air consumption varies with

each application/installation of the HPVC pump; the air

supply should be sized to provide at least 32 CFM @ 75

PSI. Furnished with your pump are an air filter and two

regulatorfilter combinations equipped with automatic

drains. The regulator marked “suction” controls the

amount of pressure available to the vacuum generator.

This pressure should be set at no more than 75 PSI to

ensure maximum efficiency.

The regulator marked “discharge” controls the amount of

pressure used to discharge the product from the pump.

The proper amount of discharge pressure is determined

by several factors including pumping distance, required

flow rate, product viscosity and piping size.

ELECTRICAL : The control panel requires 120/220VAC at

.1 amps.

ELEVATION: Selecting a site that is well within the pump’s

dynamic lift capability will assure that loss-of-prime

troubles will be eliminated. In addition, pump efficiency

can be adversely effected if proper attention is not given

to site location.

PIPING: Final determination of pump site should not be

made until the piping problems of each possible location

have been evaluated. The impact of current installations

should be considered ahead of time to make sure that

inadvertent restrictions are not created for any remaining

sites.

The best choice possible will be a site involving the

shortest and straightest hook-up of suction and discharge

piping. Unnecessary elbows, bends and fittings should

be avoided. Pipe sizes should be selected to keep friction

losses within practical limits. All piping should be

supported independently of the pump. In addition, the

piping should be aligned to avoid placing stresses on the

pump fittings.

If the pump is to be bolted down to a solid location, a

mounting pad placed between the pump stand and the

foundation will assist in minimizing pump vibration.

The proper orientation for this SANIFLO™ VC pump is to

have the vertical column in the vertical position.

SOLIDS PASSAGE CAPABILITIES:

CONNECTING PUMP TO CONTROL PANEL: The control

panel should be connected to the pump as close as

possible without putting the control panel in harms way.

The control panel comes complete with seven feet of hose

to connect the control panel to the pump.The control panel

may be mounted farther from the pump than seven feet,

but this will decrease the capacity of the pump slightly.

Moving the control panel farther away will also increase

the air consumption by approximately five-percent for

every additional ten feet of air tubing. The sanitary cap

which houses the probe and diffuser screen is placed on

top of the vertical tube and secured by a four inch sanitary

clamp.Your pump is now connected to the control panel.

CONNECTING PUMP TO HOPPER: The correct way to

connect the hopper to the pump is from the bottom of

the hopper using sanitary pipe & fittings. NOTE: When

connecting pump to any type of hopper, never place the

flex hose into the hopper from the topside. The hopper

should always be connected to the pump from the bottom

of the hopper.

VC4 7.6 cm (3")

VC6 10.2 cm (4")

VC8 15.2 cm (6")

5WILDEN PUMP & ENGINEERING CO., LLC

WIL-12120-E-01