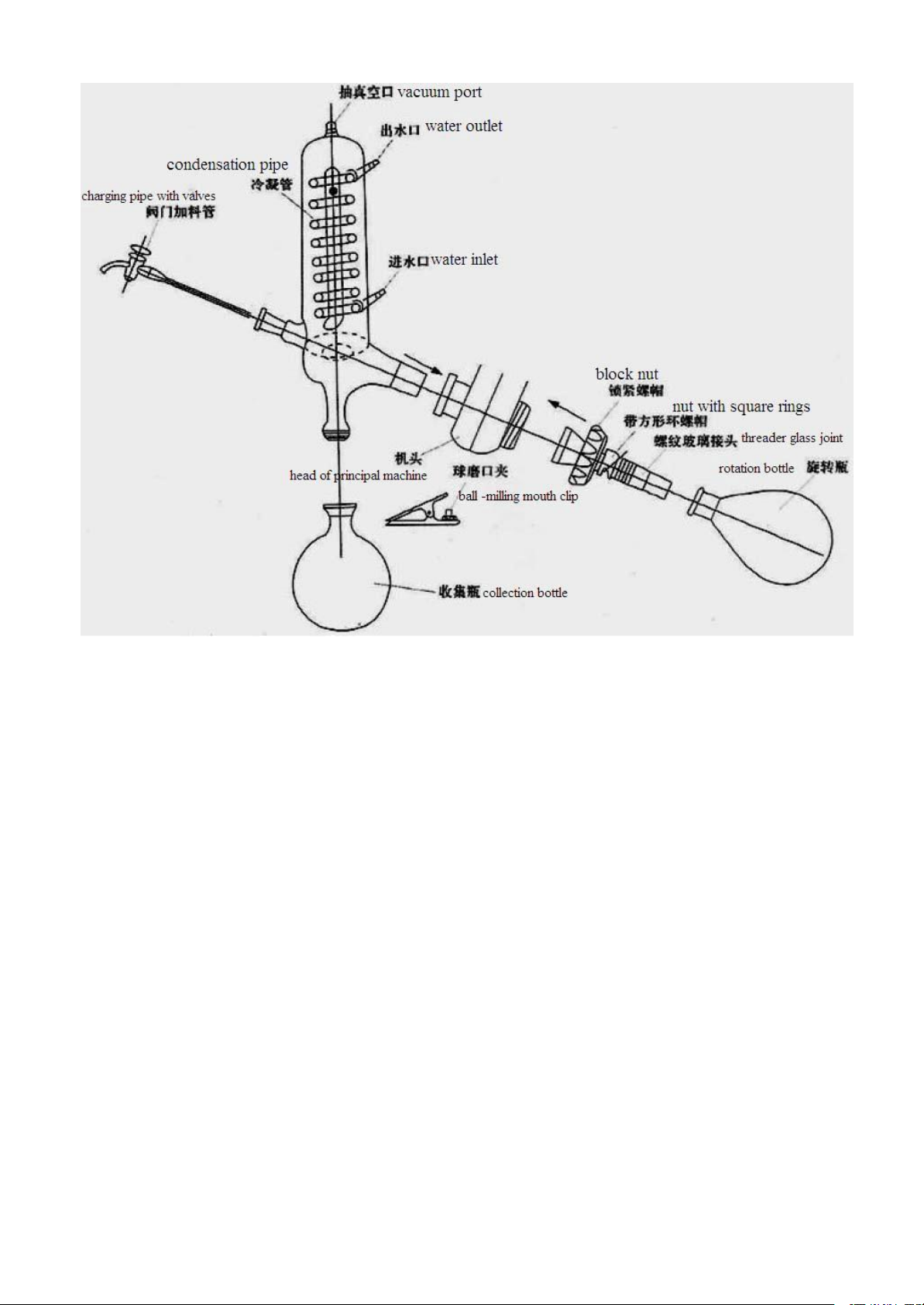

2. 1 As for RE52CS, RE52A and RE52AA types of rotary evaporators, insert the

Embossed-grinding mouth of four-way ball into the PTFE connection tube on the left side of

head of principal machine, and turn a little after inserting tightly to make it to fit well.

2. 2 As for RE5203 type, insert the Embossed-grinding mouth on the side of condensation pipe

into the PTFE connection tube on the left side of head of principal machine, and turn back and

forth after inserting tightly to make it to fit well.

3. As for , RE52A and RE52AA types, realize the interconnection among the condensation pipe,

four-way ball and collection bottle, and joints should be coated with vacuum grease to

strengthen the tightness.

4. Unscrew the black lock nut on the right side of head of principal machine, encase from the

flange of threaded glass joints (see the figure below), and then screw the black lock nut into the

head of principal machine smoothly and tightly.

5. Connect the rotation bottle to the other end of threaded glass joint (Embossed-grinding

mouth), screw on the nut with square rings, and make square rings button the flask rim closely.

In case of needing to back off the rotation bottle, screw off the nut with square rings to make the

bottle exit the Embossed-grinding mouth.

6. Encase D W - RE5203 collection bottle on the ball-milling mouth of condensation pipe,

and clamp with the clip.

7. Water outlets are connected with rubber tubes for discharge.

8. Vacuum port is connected to the vacuum pump through the vacuum tube.

9. After injecting water into the water tank, the heating plug behind the water tank will be

connected to the power line.