- 2 -

CONTENTS

1PRODUCT TECHNICAL SPECIFICATION....................................................................................................... 4

1.1 FUNCTION DESCRIPTION ................................................................................................................... 4

1.2 ADVICE FOR CUSTOMERS .................................................................................................................. 4

1.2.1 HOT WATER CONSUMPTION ..................................................................................................... 4

1.2.2 ENERGY SAVING......................................................................................................................... 4

1.2.3 EMERGENCY POWER CONSUMPTION ....................................................................................... 5

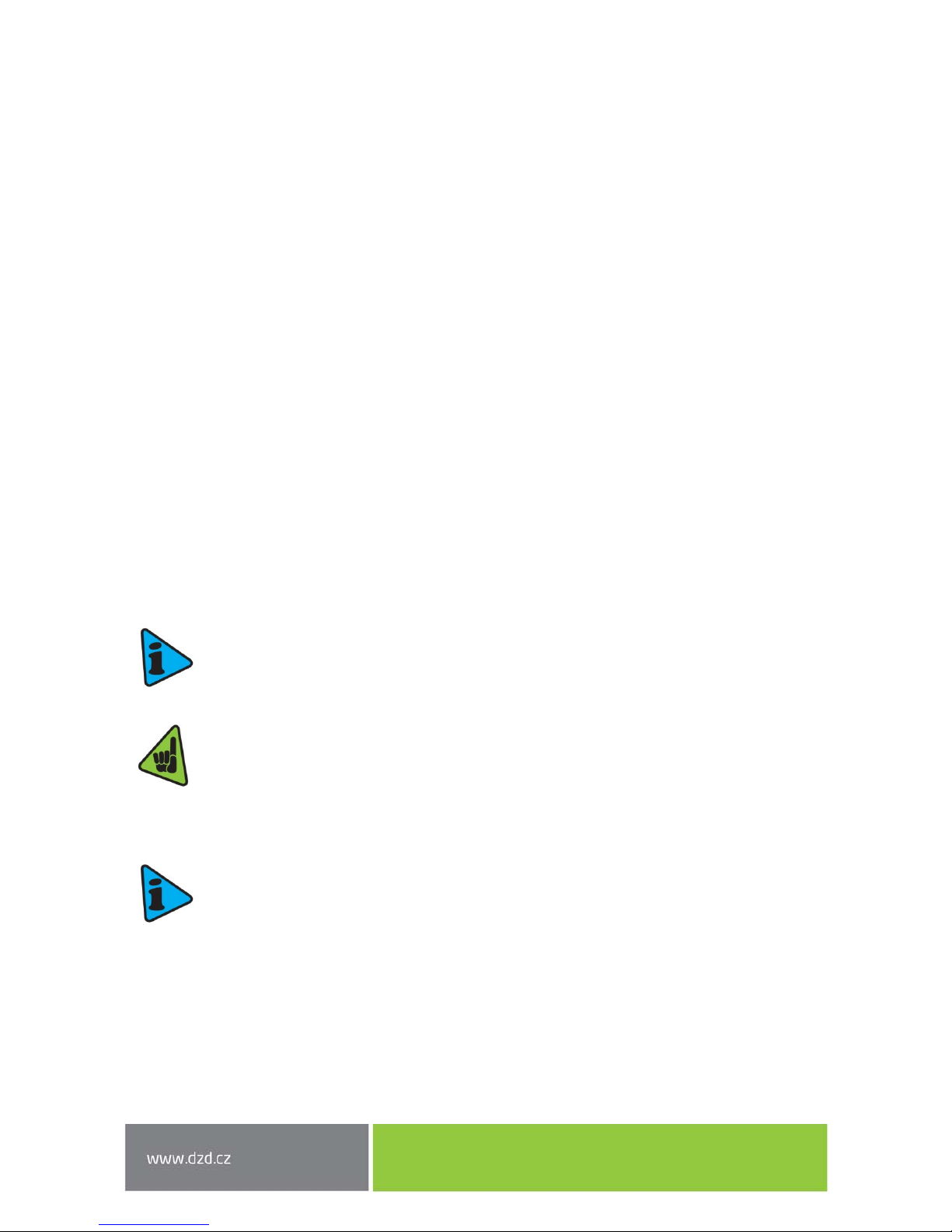

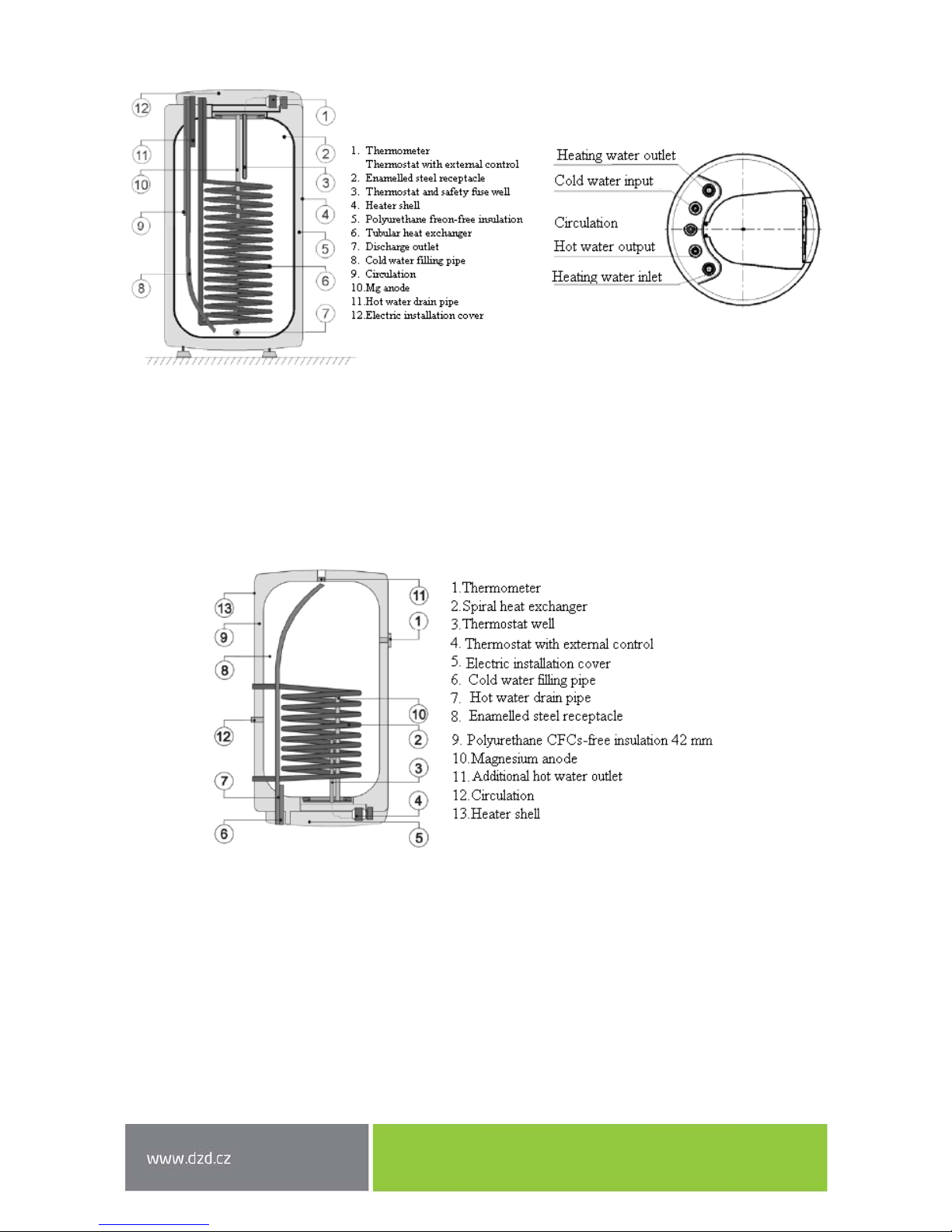

1.3 DESIGN AND GENERAL HEATER DIMENSIONS................................................................................... 6

2OPERATION AND FITTING INSTRUCTIONS............................................................................................... 17

2.1 OPERATING CONDITIONS ................................................................................................................ 17

2.2 WALL MOUNTING............................................................................................................................ 17

2.3 PLUMBING FIXTURE......................................................................................................................... 18

2.4 ELECTRICAL INSTALLATION.............................................................................................................. 21

2.4.1 GENERAL INFORMATION for ELECTRICAL INSTALLATION ....................................................... 21

2.4.2 ELECTRONIC THERMOSTAT WIRING METHODS ...................................................................... 21

2.5 CONNECTION OF INDIRECT TANK TO HOT WATER SYSTEM............................................................ 22

2.6 FIRST COMMISSIONING................................................................................................................... 22

2.7 PUTTING OUT OF SERVICE, DISCHARGE .......................................................................................... 23

2.8 INSPECTION, MAINTENANCE & CARE FOR THE APPLIANCE............................................................ 24

2.9 MOST FREQUENT FUNCTION FAILURES AND THEIR CAUSES .......................................................... 25

3OPERATION OF THEROMSTAT................................................................................................................. 25

3.1 SERVICING........................................................................................................................................ 25

3.1.1 OPERATING DEVICES OF THE TANK ......................................................................................... 25

3.1.2 TEMPERATURE SETTING .......................................................................................................... 27

4IMPORTANT NOTICES .............................................................................................................................. 28

4.1 INSTALLATION REGULATIONS.......................................................................................................... 28

4.2 SPARE PARTS.................................................................................................................................... 28

4.3 DISPOSAL OF PACKAGING MATERIAL AND NON-FUNCTIONING APPLIANCE .................................28