4

CoilMaster 35 -45 - Gas Conversion ProCedure

www.myaic.eu

AIC Europe B.V.

Graafschap Hornelaan 163A

NL-6001 AC Weert

Combustion Adjustment

Conditions:

îBoiler full of water and under pressure

îGas supply open

îPower supply activated through external electrical

box (fuse or circuit breaker)

îBoiler turned on using the On/O switch

Tools and material:

îFlue gas analyser

îScrewdriver, at head, size 3

îWrench, hex head, sizes 2 and 2.5

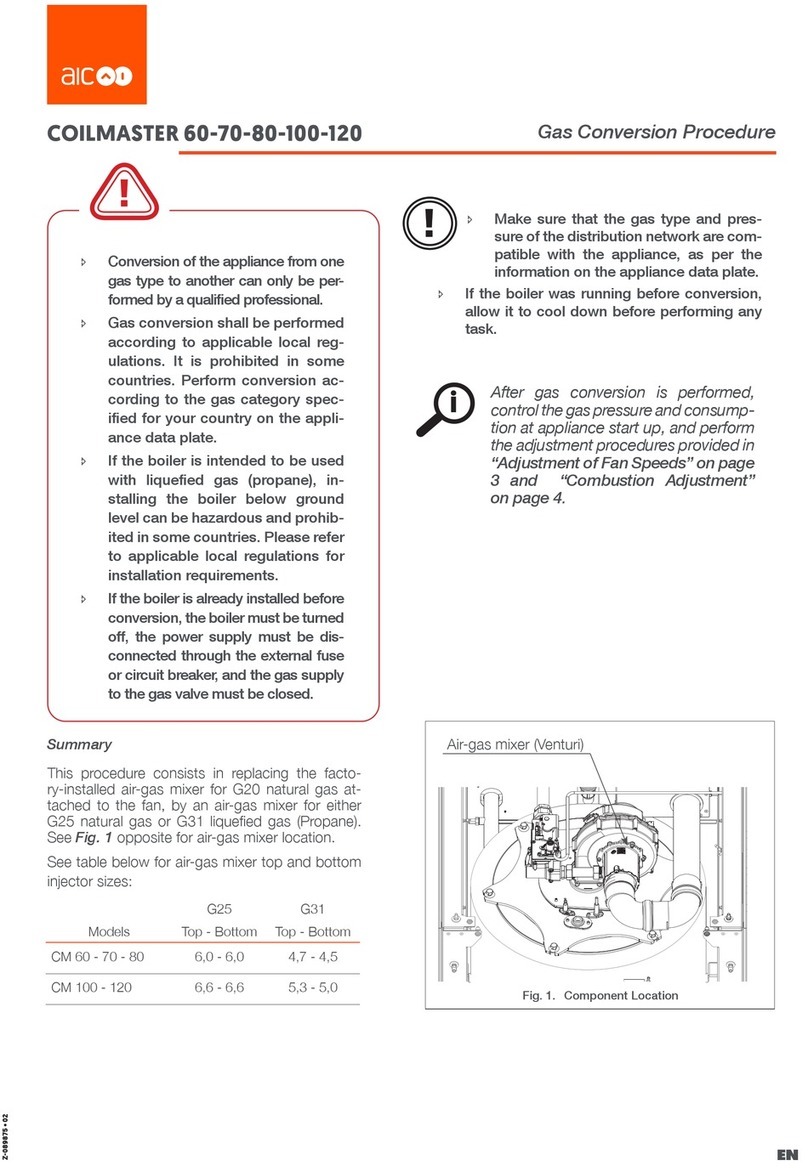

Adjustment Procedure (Figs. 4 & 5):

1. Activate the required heating mode.

2. Allow the boiler to operate for a few minutes.

3. Connect the ue gas analyser probe to the meas-

uring port of the ue gas pipe.

4. Check CO2 contents in the ue gas at max output

as follows:

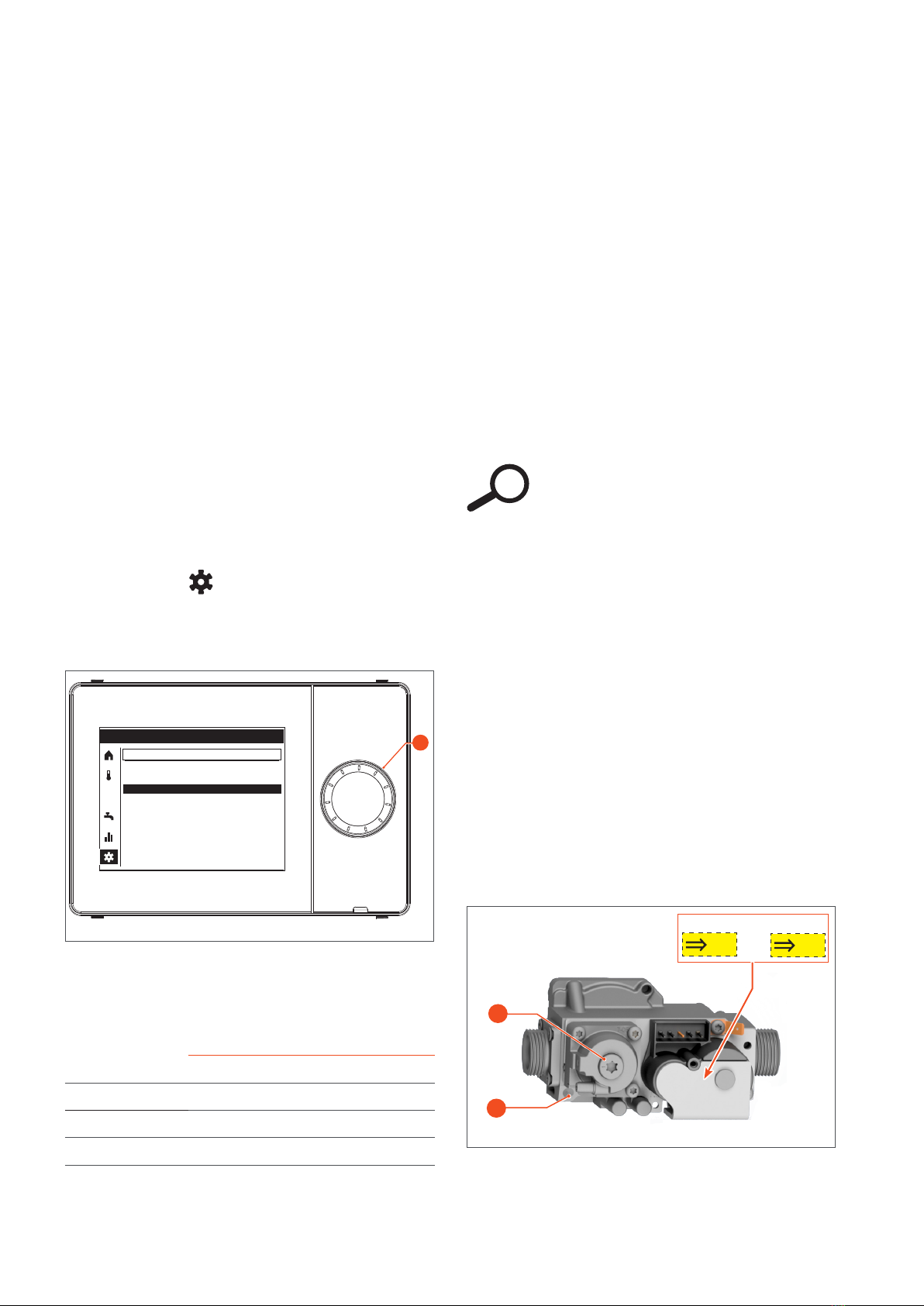

îUsing the rotary selector (1), select and acti-

vate the icon,

îSelect “Special operations (1/3)”,

îSet “Chimney sweep function” to “On”,

îSet “Burner output” to “Full load”.

6. If the value is outside the range, adjust the com-

bustion value by turning the gas valve throttle (2)

in small steps. Allow the value to stabilise before

performing additional adjustments.

- Rotate throttle screw clockwise (to the right)

to decrease the CO2 contents.

- Rotate throttle screw counter-clockwise (to

the left) to increase the CO2 contents.

7. Check CO2 contents in the ue gas at min. output

as follows:

îSet “Burner output” to “Partial load”.

îCheck the CO2 contents, and compare the values

with those in the table at the bottom of the page.

îIf the value is outside the range, adjust the

combustion value by turning the oset screw

(3) in small steps. Allow the value to stabilise

before performing additional adjustments.

The oset screw (3) is factory-sealed.

After adjustment, make sure to reseal it.

8. In “Special operations (1/3)”, set “Chimney

sweep function” to “off”.

9. Press the selector (1) for more than 3 sec. to exit

the setting menu.

10. Restart the boiler to check the ignition behaviour.

Control the correct operation of the boiler by re-

peating steps 1 to 7.

11. Reseal the oset screw (3) using some paint or tape.

Follow-on Task(s):

îOn the gas valve (Fig. 5), place the yellow sticker in-

dicating that a gas conversion has been carried out.

îOn the data plate (back of the boiler), place the white

sticker indicating that a gas conversion has been

carried out.

îReinstall front and top panels, Please refer to the ap-

pliance Installation and Maintenance manual for the

correct procedure.

îRecord the combustion values in the log sheet available

in the installation manual of the appliance.

i

Fig. 4. Combustion Adjustment - Control Panel

3

2

Fig. 5. Combustion Adjustment on Gas Valve

G31

Or

Sticker

27.01.2020 14:42

Special operaons (1/3)

Chimney sweep funcon

On

Back

1

5. Check the CO2 (or O2) contents displayed on the

gas analyser, and compare the values with those in

the table below.

@Min output @Max output

G25 %CO28.4 (±0.1) 8.8 (±0.1)

G31 %CO210.0 (+0.2) 10.5 (+0.2)

G25 %O25.7 (±0.18) 4.9 (±0.18)

G31 %O25.7 (-0.30) 4.9 (-0.30)