DVJ WHISPAIR™Dry Exhauster | 7

soleplates, the machined top surfaces are used for leveling.

Scrape pads or surfaces clean, and remove burrs on high

points with a flat file.

When blower and driver have been factory mounted on

a common baseplate, the assembly is to be treated as a

unit for leveling purposes. Use the jack screws to establish

grouting space under the base flanges, and to level the base.

Adjust these screws until the indicated variation from level

does not exceed .001” per foot (.08 mm per m) in either

length or width. Any variations should all be in the same

direction, to minimize twist. The maximum allowable twist

is considered to be .001” per horizontal foot (.08 mm per

horizontal m) measured between any two sections of the

base.

Units mounted on soleplates are to be leveled in a similar

manner. The plates should be large enough to provide exten-

sions for leveling in both length and width on the finished

upper surfaces. Fasten the plates solidly to the blower feet,

which are machined flat and parallel to each other, then install

and level the blower carefully, using jack screws, shims or

wedges for adjusting.

When a satisfactory condition of level is obtained, turn the

anchor bolt nuts down snug but not tight. Elimination of twist

here is very important, and minor adjustments can be made

with shims directly under the blower feet.

ALIGNMENT of the drive shafts when the blower unit and

its driver are direct coupled requires careful attention. This

precaution will not only help insure satisfactory coupling

operation, but will minimize chances for damage to either

driving or driven unit from vibration or thrust forces.

In package units with driver and blower mounted on a

common baseplate, the two shafts will have been put in

approximate alignment at the factory. However, baseplate

deflections can occur during shipping and installation. A

close coupling alignment should be obtained during leveling,

so that only small final adjustments will need to be made

after grouting. In a soleplate type installation, the separately

mounted driver must be positioned, leveled and aligned as

part of the installation procedure. Whether it is on soleplates

or on its own base, shims of 1/16” to 1/8” (2-3 mm) thick-

ness placed directly under the driver feet before setting will

permit more accurate final alignment. Spacing between the

two shaft ends as required by the coupling must also be

established. If a motor is being used that has end-play in the

shaft, be sure its rotor is located on magnetic center before

setting this spacing.

When blower is driven through V-belts, the driver must

be mounted on an adjustable base to permit tightening or

removing the belts. In this case the driver shaft height is of

no concern, but it must be parallel to the blower shaft and

level. To position the driver properly, both sheaves need to be

mounted on their shafts, and the shaft center distance must

be known.

The blower sheave, usually the larger one in diameter, must

be of the narrow hub type. Install it so that its inner hub face

is not more than 1/4” (6 mm) away from the bearing housing

end cover. The driver sheave should also be mounted as

close to its bearing as possible. Now position the driver so

that faces of the two sheaves are accurately in line, with

the adjustable base so located as to make 2/3 of its total

movement available in the direction away from the blower.

This positioning provides minimum belt wear and slip, and

allows sufficient adjustment for installation and tightening of

belts. Do not install belts until grouting has set and anchor

bolts are tightened.

Blowers intended for driving by V-belts may be provided with

an extended drive shaft and an additional outer bearing to

handle the side pull of the drive. They may be recognized

by the extended housing for the outer bearing. If necessary,

these units may also be used for direct coupling to the driver.

Blowers intended specifically for direct coupling have no

outer bearing, and may be seriously damaged if used for belt

drive. Consult your Sales Office for approval before belting

these units.

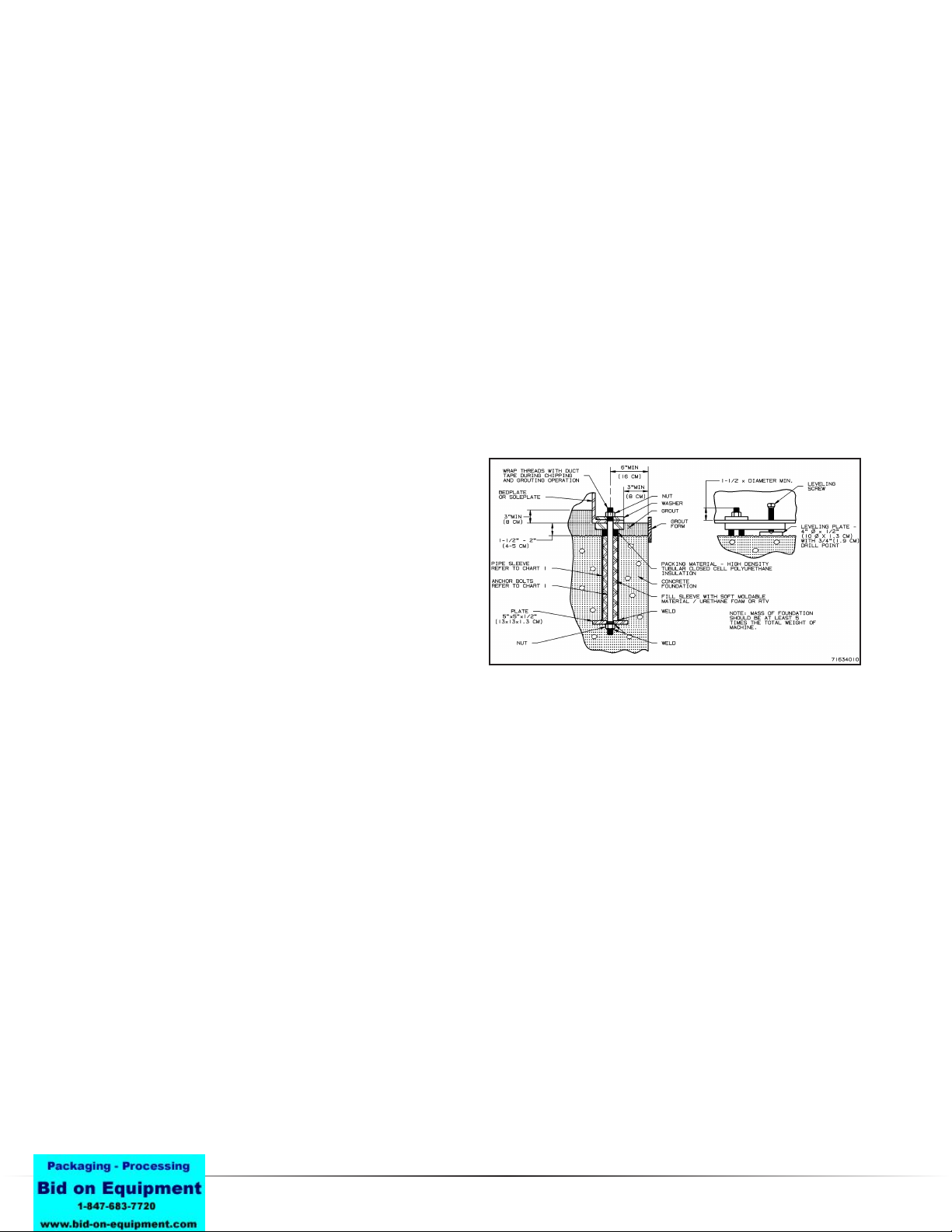

GROUTING follows completion of leveling and preliminary

alignment. Assuming the foundation has been properly cured,

its top surface should first be roughened by chipping to

remove glazed areas and oil or grease removed with a strong

hot detergent or caustic solution.

Grouting serves not only to compensate for surface irregulari-

ties in the foundation and machine base but also to provide

restraint against shifting. Anchor bolts are used

for hold-down only. Therefore, the grout must be adequate

thickness under the soleplate or base flange, must flow into

anchor bolt sleeves and all interior cavities, and must have

minimum shrinkage during the setting period. By virtue of the

open frame design, it is recommended that the bed¬plate

be filled with concrete to a level equal to the top of the main

channels. Special grouting materials designed to counteract

shrinkage are commercially available, and are often preferred

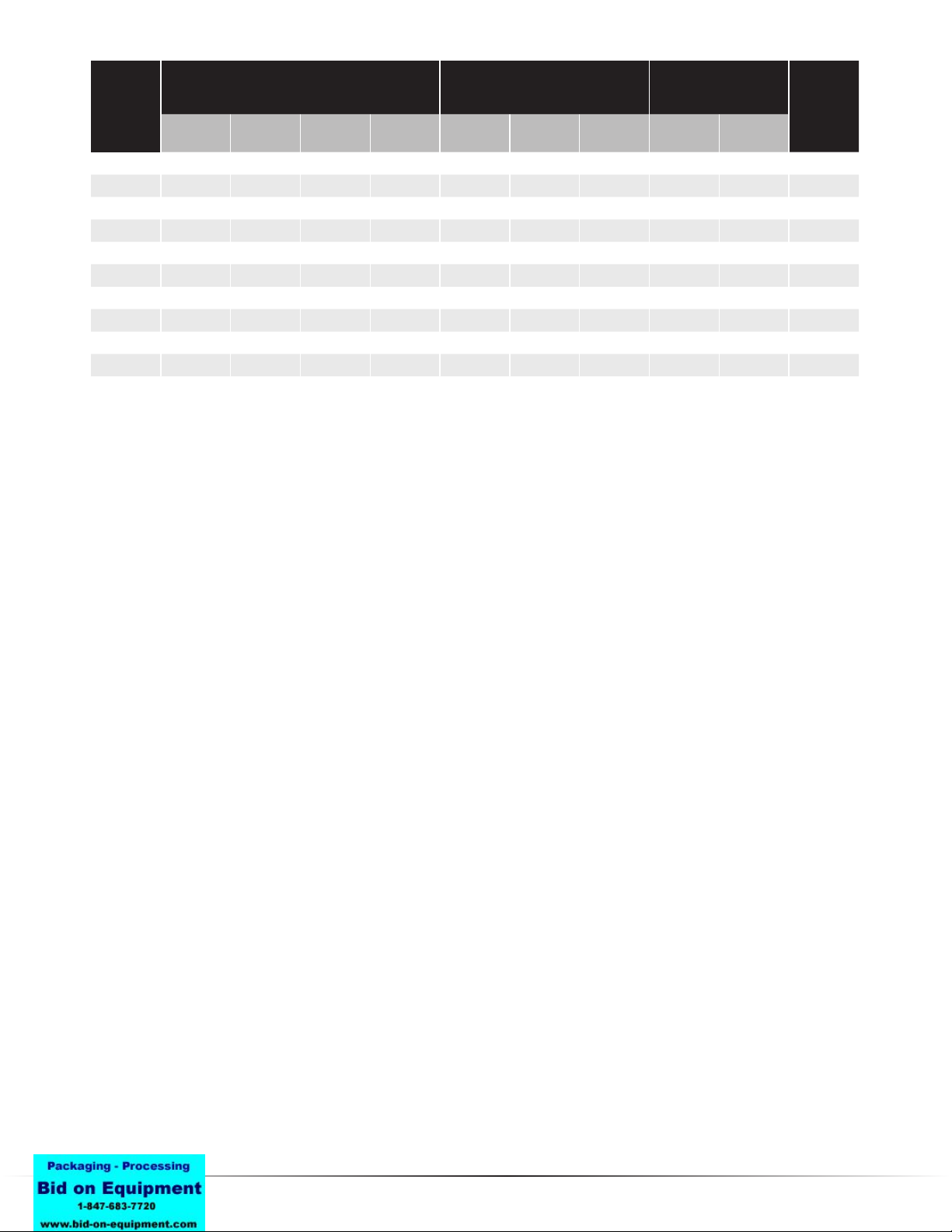

Table 2A - Standard Anchor Bolts in Inches

Table 2B - Standard Anchor Bolts in Centimeters

Unit

Frame

Size

For Soleplates For Baseplates

Bolts Sleeves Bolts Sleeves

Dia. Lgth. I.D. Lgth. Dia. Lgth. I.D. Lgth.

1000 1 25 3 18 3/4 18 2-1/2 12

1200 1 25 3 18 3/4 18 2-1/2 12

1400 1-1/8 25 3 18 3/4 18 2-1/2 12

1600 1-1/8 25 3 25 1 25 3 18

1800 1-1/4 25 3 25 1 25 3 18

2000 1-1/4 25 3 25 1 25 3 18

Unit

Frame

Size

For Soleplates For Baseplates

Bolts Sleeves Bolts Sleeves

Dia. Lgth. I.D. Lgth. Dia. Lgth. I.D. Lgth.

1000 2.4 64 7.5 46 2.0 46 6.5 30

1200 2.4 64 7.5 46 2.0 46 6.5 30

1400 3.0 64 7.5 46 2.0 46 6.5 30

1600 3.0 64 7.5 46 2.4 64 8.0 46

1800 3.0 64 7.5 46 2.4 64 8.0 46

2000 3.0 64 7.5 46 2.4 64 8.0 46