3

Installation of drive, intermediate bearings and pull rods

Depending on the fixing height of disconnector, the drive assembly comprises one of two intermediate bearings.

• Only one intermediate bearing is normally used for disconnectors installed under the line (continuous,

branch – for 10.5 m poles.

• Two intermediate bearings are used for disconnectors mounted into the line (on the top of a pole – for

10.5 m and 12 m poles) and for poles mounted under the line (continuous, branching – for 12 m poles).

The first intermediate bearing under the disconnector must be only a pendulum intermediate bearing (with barrel).

The assembly of intermediate bearings can be seen in Fig. 3a and Fig. 3b, respectively.

When assembling and setting the drive, the disconnector is in the switched-on position on the ON stop.

Fix the manual drive T on the concrete pole using the sleeve (Fig. 1 or Fig. 2, pos. 2) at a height of approx. 1350

mm above the ground. Banding the lower part of the drive is done after the complete banding and testing of the

drive function.

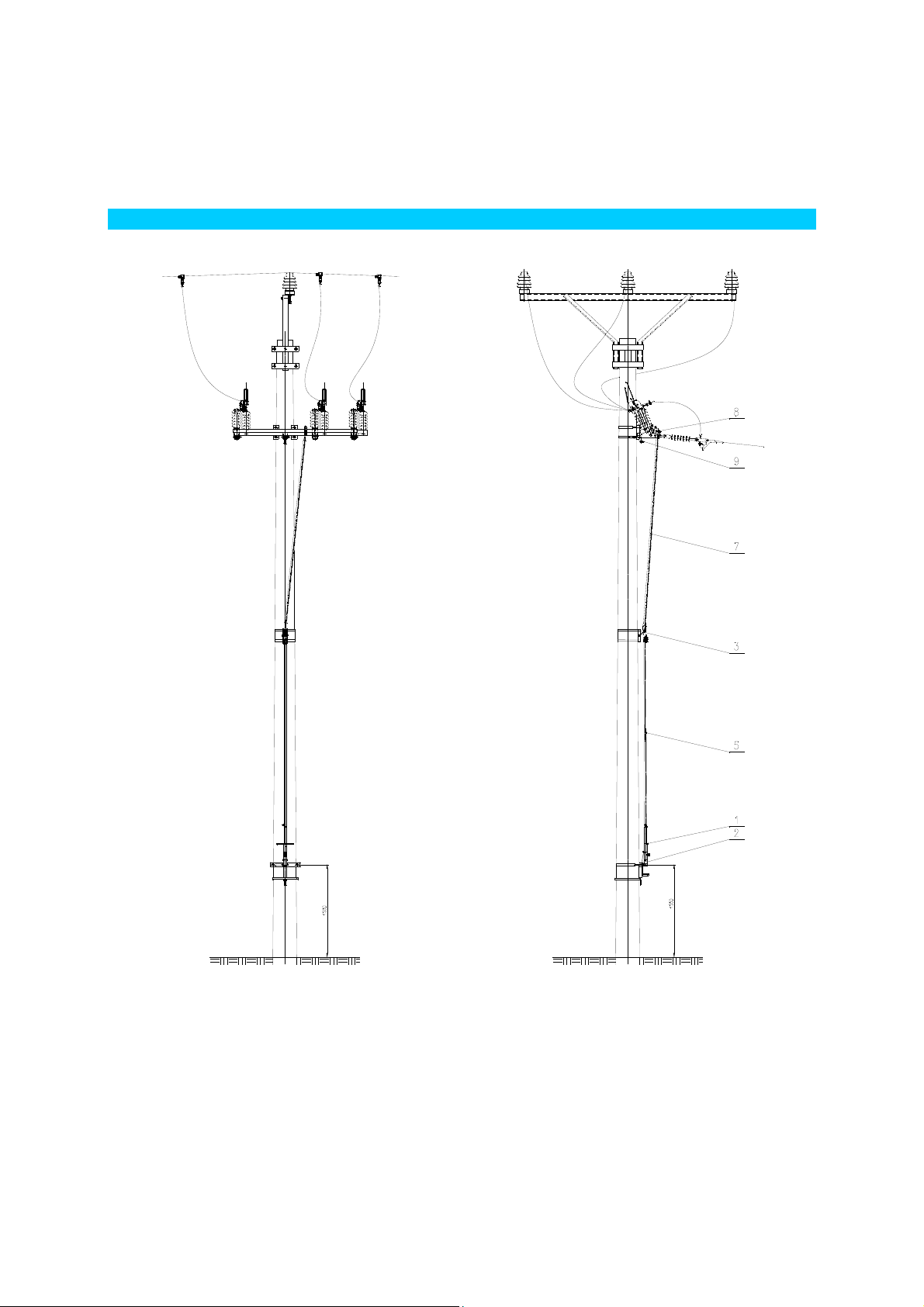

Assembling the drive with one intermediate bearing (Fig. 1)

Connect the upper (flattened on both sides) pull rod tube (pos. 7) to the operating lever on the device (pos. 8)

using the pin.

Fix the intermediate bearing (pos. 3) to the lower end of the upper tube. Position the fixing base of the

intermediate bearing to the pole so that the intermediate bearing lever is tilted up at the angle of 45°.

Fix the intermediate bearing in this position to the pole with two bands.

Slide the lower pull rod tube with the end with hole on the socket of manual drive T (pos. 5) and secure with the

provided screw. Move the drive lever to the switched-on position – the lever directs vertically. After swinging the

lever by approx. 150 mm (see the figure; in this way the necessary pretension of the pull rod in the switched-on

position is reached) measure the necessary length of the lower pull rod tube and shorten it. Shorten the tube

from its upper part – the one without holes!

When shortened, screw the lower pull rod tube (pos. 5) together with the manual drive (pos. 1).

Slide the upper end of tube into the yokes of the intermediate bearing (pos. 3) and tighten the

yokes by the prescribed torque.

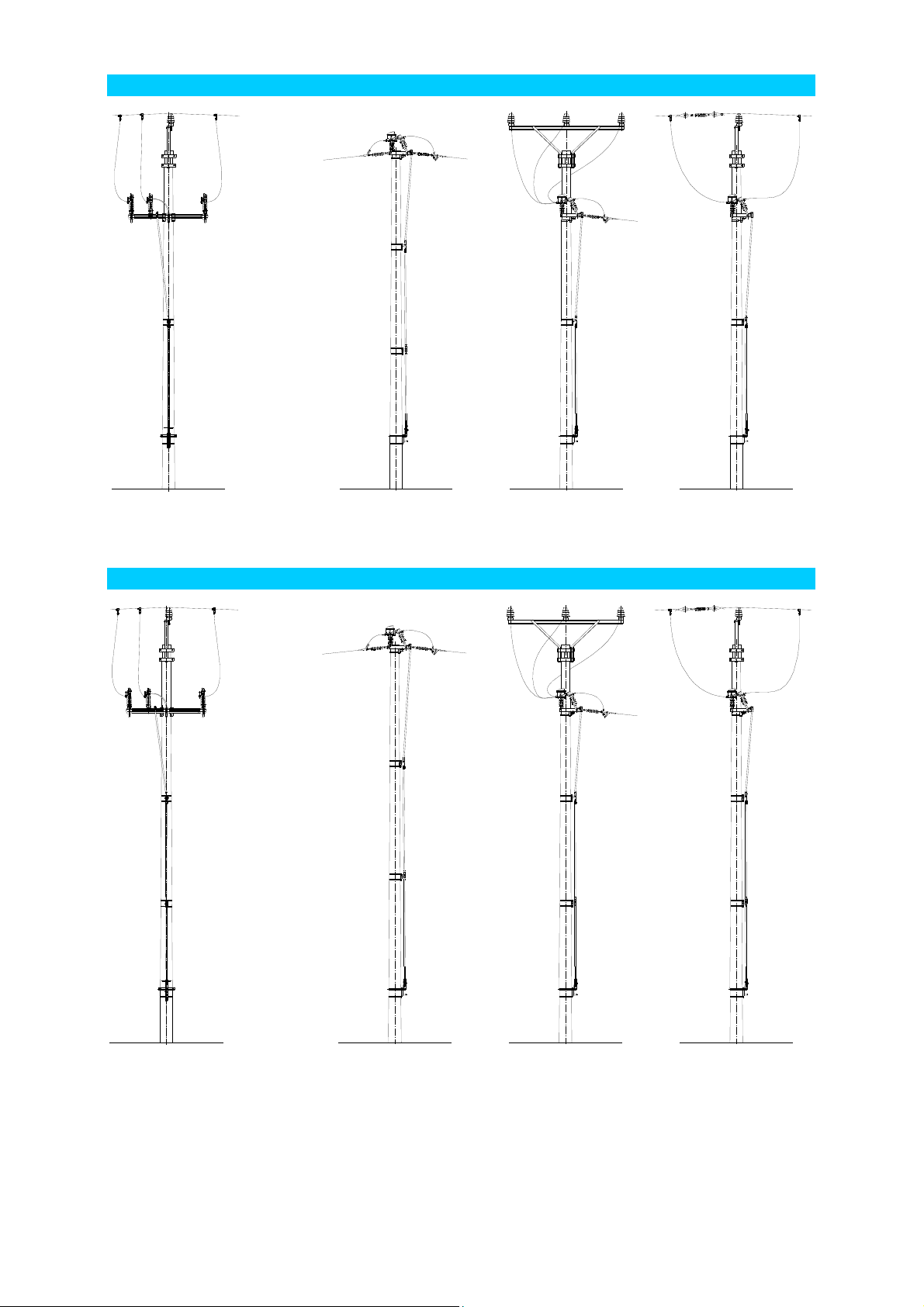

Assembling the drive with two intermediate bearings (Fig. 2)

Using the pin, fix the upper (flattened on both sides) pull rod tube (pos. 7) to the operating lever

on the device.

Fix the upper intermediate bearing (pos. 3) to the lower end of the upper pull rod tube. Position

the fixing base of the upper intermediate bearing to the pole so that the intermediate bearing

lever is tilted up at the angle of approx. 45° and fix it in this position to the pole with two bands.

Slide the lower pull rod tube (pos. 4) with the end with hole on the socket of manual drive T (pos.

1) and fix with the provided bolt and nut. By means of the pin, fix the lower intermediate bearing

(pos. 4) to the upper end of the lower pull rod tube (pos. 4).

Turn the drive to switched-on position. In this position fix the lower intermediate bearing (pos. 4) with two bands –

after fixing, the intermediate bearing lever must be in parallel with the upper intermediate bearing lever (directing

up at the angle of approx. 45°).

Fix the middle pull rod tube (pos. 6) with the flattened end to the lower intermediate bearing (pos. 4). When tilting

the operating lever of the manual drive (pos. 1) 150 mm from the pole (for the necessary pretension in switched-

on position and for elimination of pull rod clearances), measure the necessary length of the middle pull rod tube to

the upper intermediate bearing (pos. 3) and shorten from the upper end.

After shortened, slide the middle pull rod tube (pos. 6) into the yokes of the upper intermediate bearing (pos. 3)

and tighten the yokes by the prescribed torque.

Function test after installation

Operate the drive to the OFF position to disconnect the main contacts. Then operate to the limit ON position. In

the limit ON position, the disconnector must reliably reach the switched-on position (Fig. 4, control points A and

B). Contacts must be fully retracted and the stop on the device must reach the limit position. Intermediate

bearings must not thrust and no deflection of the pull rod tubes must occur (a threat of damage to the drive).

If the limit position of the device is not reached (control point B), make correction by changing the length of the

lower (or middle in the case of the drive with two intermediate bearings) of pull rod tube within the limits of

possible shift on the clamping terminal of the upper intermediate bearing (Fig. 1 and 2, respectively, pos. 3). If a

larger correction is required, the pull rod must be replaced or the drive shifted.

On the disconnector, check that the moving contact is retracted in the main contact properly (Fig. 4, control point

A). If the disconnector does not have the correct clearance in contacts despite reaching the ON position stop,

check that the contact system was not damaged during transport.