8

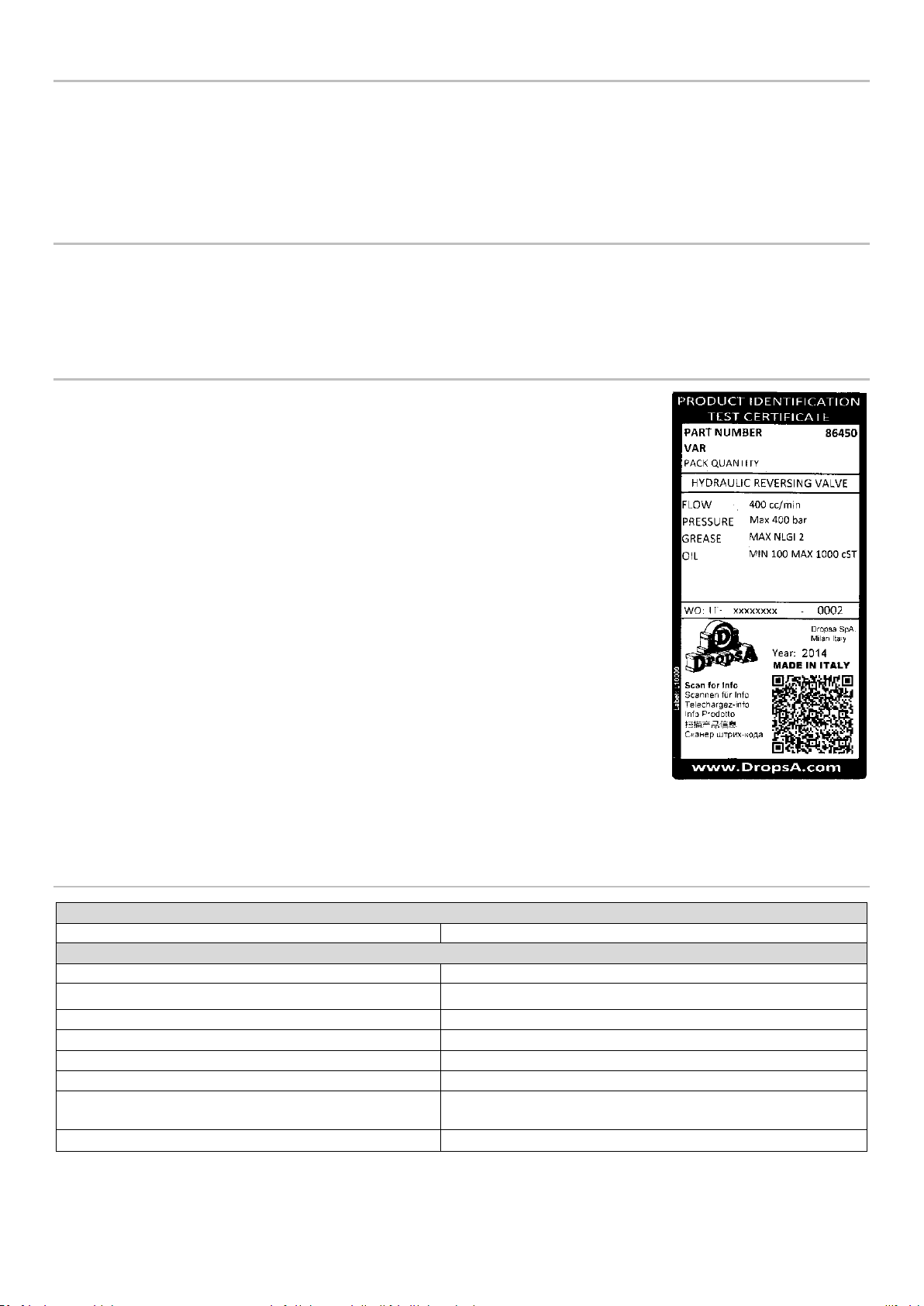

14.1 LUBRICANTS

A comparison table is provided between the classification of NLGI lubricants (National

Lubricating Grease Institute) and the ASTM classification (American Society for Testing and

Materials) for greases for the values that concern the product.

For further information about the technical specifications and the safety measures to adopt,

refer to the product safety sheet (Directive 93/112/EEC) relative to the type of lubricant

selected and supplied by the manufacturer.

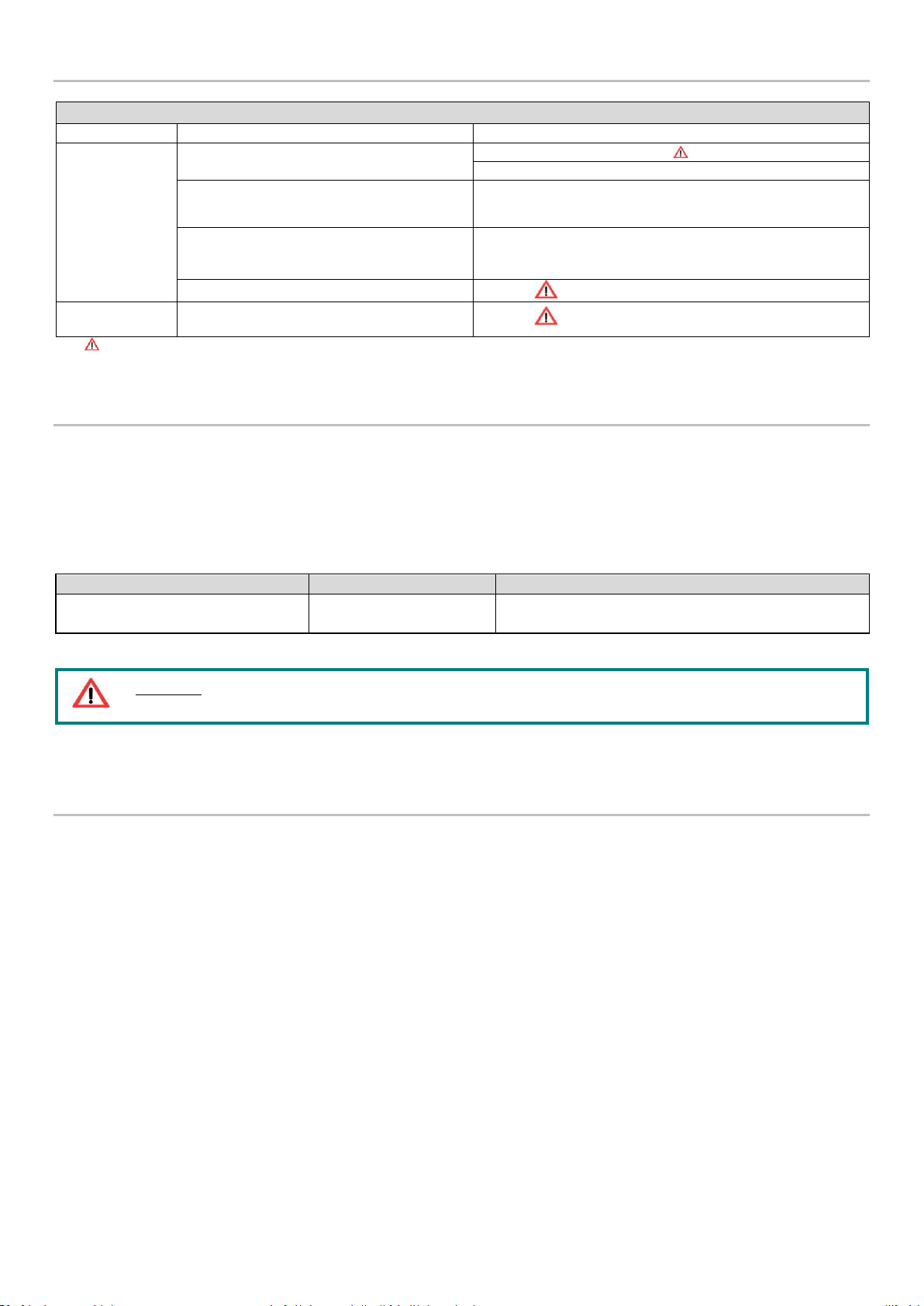

15. PRECAUTION

Compliance with the essential safety requirements and the provisions specified in the machine directive was checked by filling

out prepared check lists that are contained in the technical file.

Three types of lists were used:

Risk assessment (UNI EN ISO 14121-1).

Compliance with the essential safety requirements Machine Directive –EC 06/42).

Electrical safety requirements (EN 60204-1).

The following is a list of dangers which have not been fully eliminated but which are considered acceptable:

During installation there may be small low pressure oil seepage from the pump. Always use appropriate protective

clothing, gloves and take all necessary safety precautions.

Contact with lubricant during maintenance or filling of the reservoir. As per previous point, correct precautions must be

taken to protect from contact with lubricant.

Electric shock. All electrical connections must be carried out by a qualified electrician who has studied the connection

to ensure no electrical danger

Unsuitable Lubricant. Lubricant characteristics are indicated on the pump and in this user manual. In any case contact a

Dropsa Sales and Support engineer (if in any doubts, contact the Technical Department Dropsa SpA).

FLUIDS EXPLICITY NOT ALLOWED

Lubricants with abrasive additives

Wear of the components inside the pump

Lubricants with silicone based additives

Petrol –solvents –inflammable liquids

Fire –explosion –damage to the gaskets

Pump corrosion - damage to people

They would be contaminated

NOTE: The pump is designed to operate with maximum NLGI 2 grade lubricants.

Use lubricants compatible with NBR gasket

The residual lubricant used for assembly and testing is NLGI 2 grade.