CRAFT-STICK | Version 1.12 7

Transport, packaging, storage

5 Transport, packaging, storage

5.1 Delivery and Transport

After delivery, check the device for visible transport da-

mage. If the electrode inverter is damaged, report this

immediately to the transport company or the dealer.

5.2 Packaging

All used packaging materials and packaging aids are re-

cyclable and should be taken to a materials recycling de-

pot to be disposed of.

The delivery packaging is made of cardboard, so please

dispose carefully by having it chopped up and given to

the recycling collection.

The film is made of polyethylene (PE) and the cushioned

parts of polystyrene (PS). These materials should be

taken to a collection point for recyclable materials or to

the local waste disposal company.

5.3 Storage

The electrode inverter must be installed in closed, dry

and well-ventilated rooms with room temperatures bet-

ween 15 and 35 degrees. Do not expose it to moisture or

intense sunlight.

5.4 Installation requirements

The device has been designed for use in covered rooms

and outdoors and must be installed in a dry environment.

The environment in which the electrode inverter is used

should be below +40°C and the humidity should be low.

The environment must be free of dust, acids, salts or

concentrations of iron or metal powders.

Ensure that there is sufficient space in front of the device

so that the operating elements can be easily reached

and viewed. Position the device so that the air inlet and

outlet are not obstructed. Make sure that no metal parts,

dust or other foreign objects can enter the device.

The environmental conditions must be appropriate for

protection class IP21!

6 Operating principle

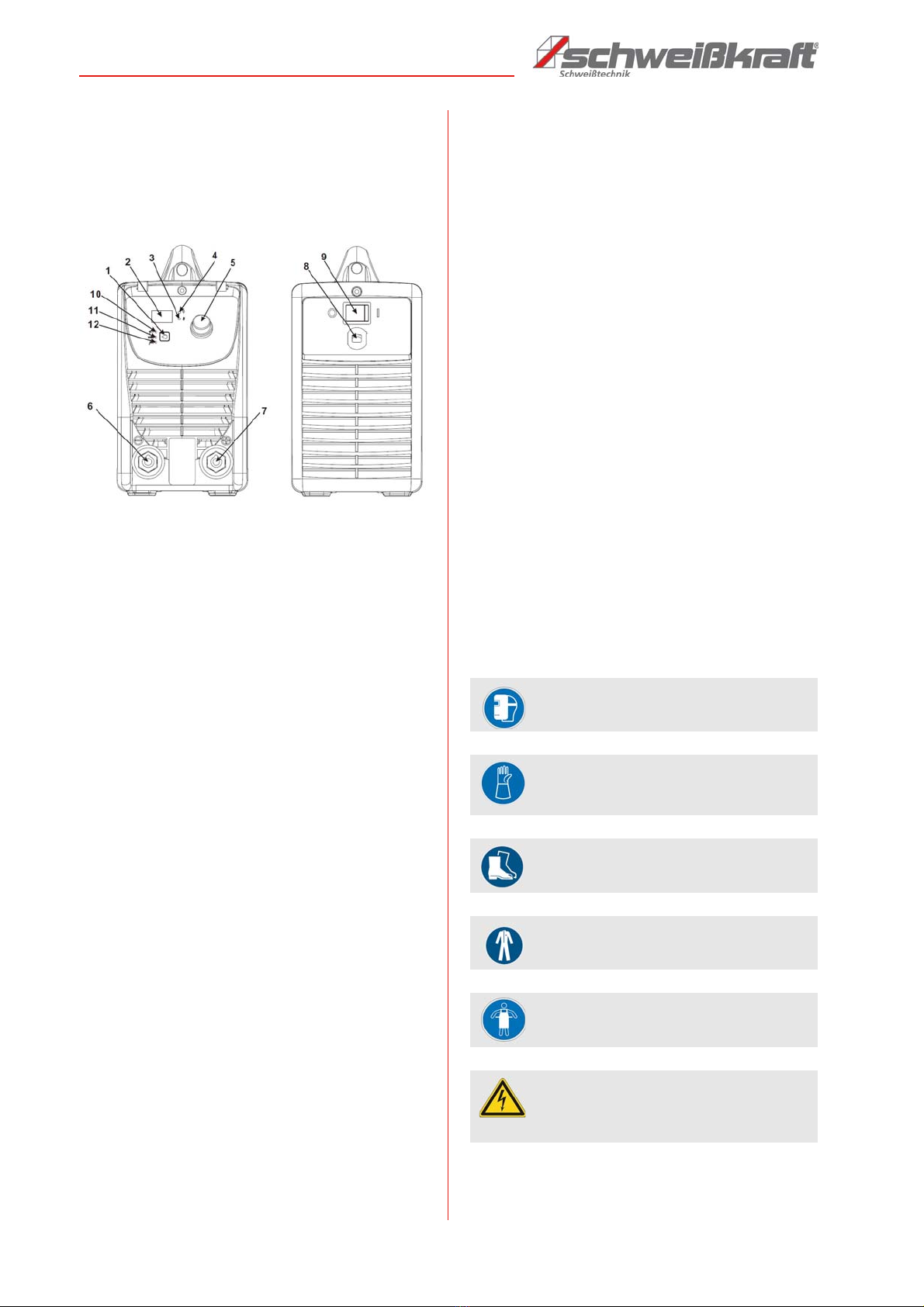

The EASY-STICK 121 welding unit is an electrode inver-

ter for welding with all common rutile, stainless steel and

cast iron electrodes with direct current as well as with

TIG function. The required welding current can be adju-

sted steplessly via a control dial. The Hot-Start function

provides stable ignition of the arc and the Anti-Stick

function prevents the electrode from sticking. These

functions are automatically activated and deactivated.

The Arc-Force control adjusts the dynamics to the wel-

ding process and can be controlled. The unit is cooled

with an air fan. If the permissible temperature of the po-

wer components is overshot, the welding current is auto-

matically switched off. This is indicated by a control lamp

on the control panel. The housing protects the compo-

nents against external influences and direct contact. De-

pending on the application, there are different degrees of

protection against penetration by solid bodies and water.

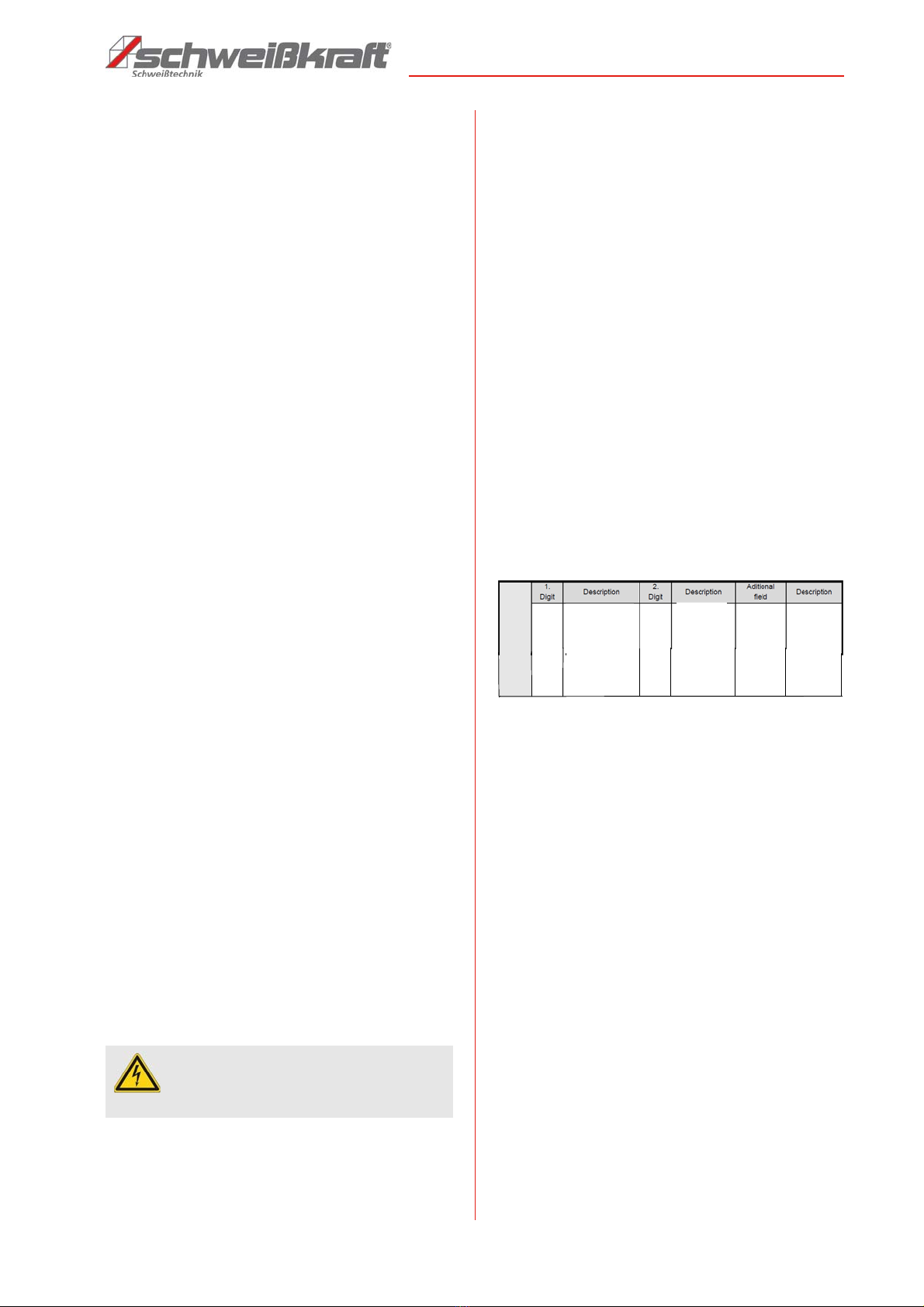

The degree of protection is indicated by the letters IP

followed by two digits: The first digit indicates the degree

of protection against solid bodies and the second digit

the degree of protection against water.

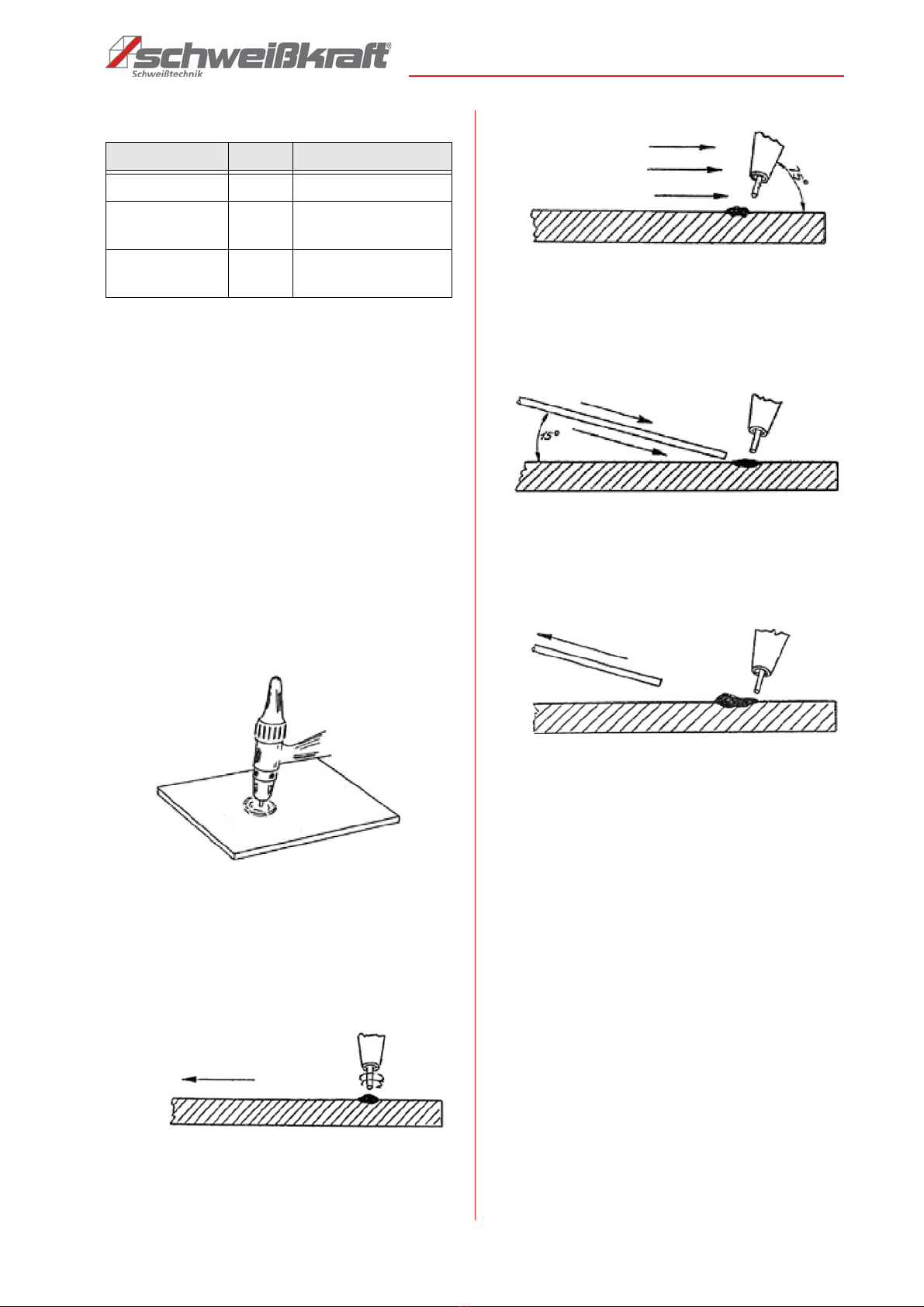

6.1 Principle of electrode welding

Electrode welding is an uncomplicated welding method

with which almost all metals can be welded. This method

can also be used outdoors and with special equipment

even under water. In electrode welding, the arc length is

determined by hand. The distance between the electro-

des determines the arc length. Welding is mainly carried

out under direct current; e.g. rutile electrodes are easy to

weld under minus-pole direct current; basic electrodes

under plus-pole direct current. The electrode is an arc

carrier and also an additional material. It consists of a

core wire and a coating. The coating protects the molten

pool from harmful atmospheric oxygen and stabilizes the

arc. In addition, a slag forms which protects and shapes

the weld seam. Depending on the thickness and compo-

sition of the coating, a difference is made between rutile

and basic electrodes. Rutile electrodes are easier to

weld and have a nice flat seam. The slag is also easier to

remove. It should be noted that many electrodes It

should be noted that many electrodes must be dried

back after prolonged storage, because moisture accu-

mulates from the air over time back after longer storage,

because moisture accumulates from the air over time.

Otherwise, electrode welding is a very common and

easy-to-use welding process.

DANGER! ELECTRICAL VOLTAGE!

Do not use the device outdoors in the rain!

Protect

against solid

objects over

12 mm e.g.

hands, large

tools

21

Protected

against

vertically

falling

dripping

water

S

Tested

when

moving

parts are

at a

standstill

IP2

1