Suva®HP81 offers the highest efficiency versus

R-502, with slightly better capacity. However, the

higher HCFC-22 content results in compressor

discharge temperatures in the range of 14°C (25°F)

higher than that of R-502, which makes Suva®

HP81 most suited for medium-temperature systems

such as ice machines.

Suva®404A (HP62) offers the best overall proper-

ties when compared with R-502. Capacity and effi-

ciency values should be equivalent to R-502, and

compressor discharge temperatures may be up to

9°C (14°F) lower than R-502, which may equate to

longer compressor life and better lubricant stability.

In addition, the heat transfer characteristics of

all the Suva®HP products appear to be better than

R-502, so any loss of compression efficiency may

be offset by improvements in heat transfer.

Due to the differences in operating characteristics

described above, Suva®HP80 and HP81are typi-

cally selected for different applications. Suva®

HP81 is preferred where higher energy efficiency

and capacity are needed and where the higher dis-

charge temperatures will not create operating diffi-

culties. Both Suva®HP80 and Suva®404A (HP62)

are full-range R-502 replacements, with Suva®

HP80 preferred for retrofitting of existing systems,

and Suva®404A (HP62) preferred for new equip-

ment. Suva®404A (HP62) can also be used for

retrofitting existing equipment where HFCs are

desired. Table 2 shows markets that currently use

each of these refrigerants.

Table 2

DuPont™ Suva®HP Refrigerant

Market Applications

Product Medium Temperature Low Temperature

Suva

®

HP81 Ice Machines To Be Determined

Food Service

Vending

Supermarket

Suva

®

HP80 Supermarket Supermarket

Transport Transport

Food Service

Suva

®

404A

(HP62) All

Physical Properties

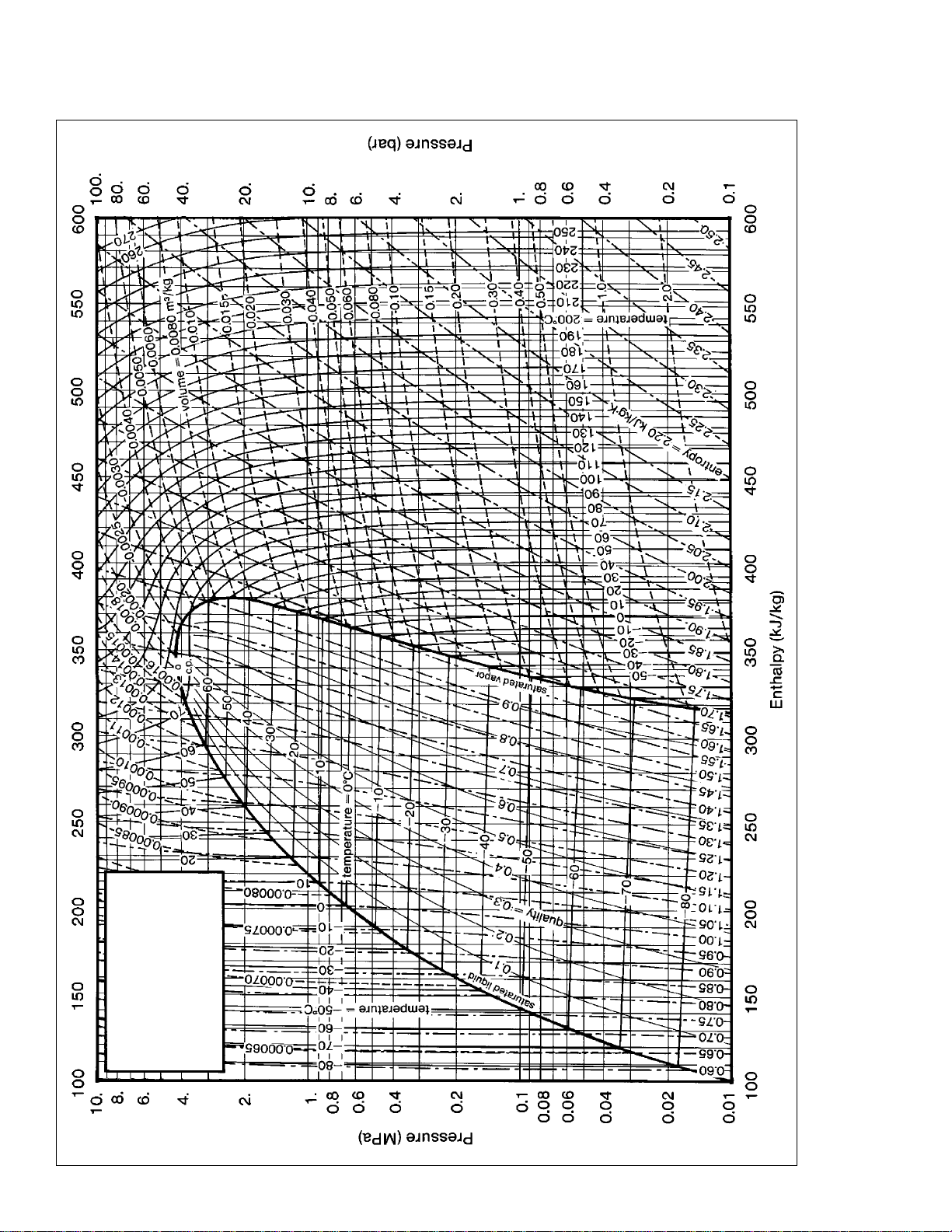

General physical properties of the Suva®HP refrig-

erants are shown in Table 3. Pressure-enthalpy dia-

grams for the Suva®HP refrigerants are shown in

Figures 1–6.

Additional physical property data may be found

in other DuPont publications. Bulletin ART-18

contains viscosity, thermal conductivity, and heat

capacity data for saturated liquid and both saturated

and superheated vapor. ART-18 also contains heat

capacity ratios for saturated and superheated vapor.

Thermodynamic tables in English and SI units are

available in Bulletins T-HP80-ENG, T-HP80-SI,

T-HP81-ENG, T-HP81-SI, T-HP62-ENG, and

T-HP62-SI for Suva®HP80, Suva®HP81, and

Suva®404A (HP62).

Chemical/Thermal Stability

Stability with Metals

Stability tests for refrigerant with metals are typi-

cally performed in the presence of refrigeration

lubricants. Results of sealed tube stability tests

available for R-502/mineral oil and alkylbenzene

lubricants have shown long-term stability in contact

with copper, steel, and aluminum in actual refrig-

eration systems. Mineral oils, alkylbenzene, mix-

tures of mineral oil/alkylbenzene and polyol esters

(POE) are all possible candidates for use with

Suva®HP80 and HP81; POE are proposed lubri-

cants for use with Suva®404A (HP62).

The method followed was generally the same as

ASHRAE 97 with several minor modifications. A

3-mL volume of refrigerant/lubricant solution was

heated in the presence of copper, steel, and alumi-

num coupons in an oven for 14 days at 175°C

(347°F). Both the neat lubricant and a mixture of

lubricant and refrigerant (50/50 volume ratio) were

tested. Visual ratings were obtained on both the

liquid solutions and the metal coupons after the

designated exposure time. The visual ratings range

from 0 to 5, with 0 being best.

After the visual ratings were obtained, sample tubes

were opened and the lubricant and refrigerant (if

present) were analyzed. The lubricant was typically

checked for halide content and viscosity, while the

refrigerant was examined for the presence of de-

composition products. Table 4 summarizes typical

data for Suva®HP refrigerants. Visual ratings are

listed for the neat lubricant, the lubricant/refriger-

ant solution, and the three metals that were present

in the lubricant/refrigerant solutions. Viscosity was

determined on the unused lubricant, the tested neat

lubricant, and the lubricant tested in the presence

of refrigerant. Decomposition products were deter-

mined in some cases. Typical measurements for

decomposition products is in the low parts per

million (ppm) range.

Suva®HP81 tests with various lubricants indicate it

has adequate chemical stability with these lubri-

cants. In addition, we believe that HP80 will have

similar behavior due to the same refrigerants being

used in the formulation. Suva®404A (HP62) tests

with common POE lubricants indicate that chemi-

cal stability of Suva®404A (HP62) with common

metals used in refrigeration systems is acceptable.

2