Dura-Max DRVL1 User manual

PRIVACY VINYL FENCE INSTALLATION GUIDE

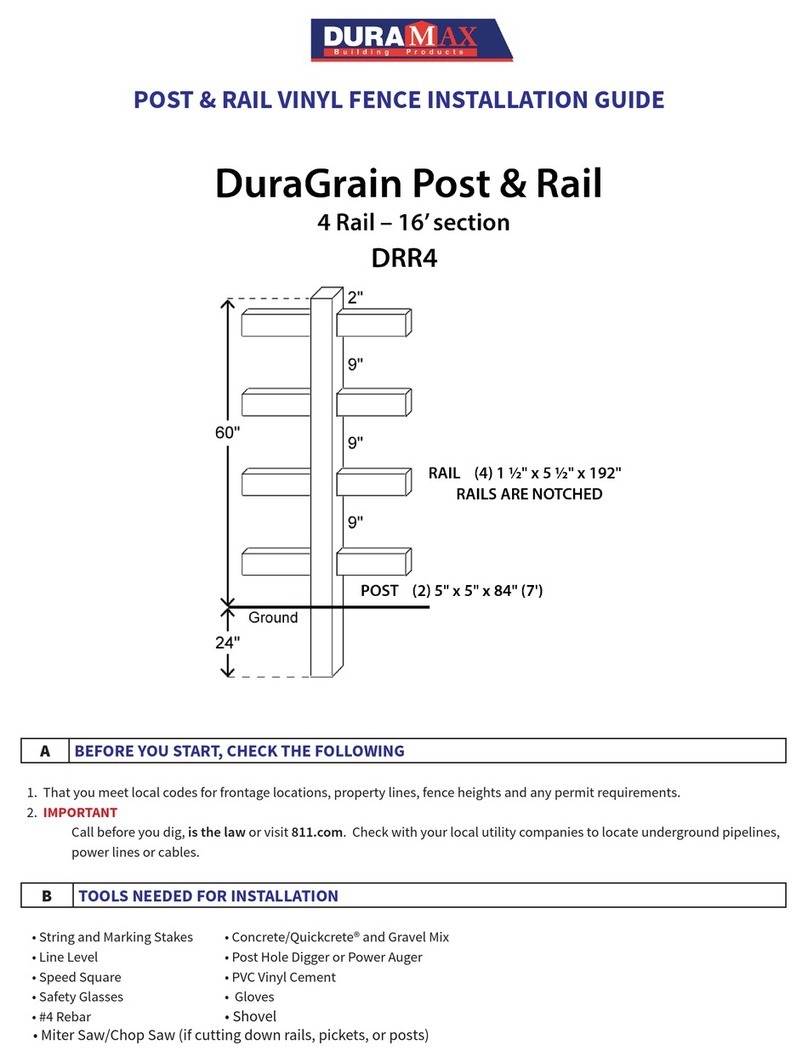

ABEFORE YOU START, CHECK THE FOLLOWING

1. That you meet local codes for frontage locations, property lines, fence heights and any permit requirements.

2. IMPORTANT

Call before you dig, is the law or visit 811.com. Check with your local utility companies to locate underground pipelines,

power lines or cables.

BTOOLS NEEDED FOR INSTALLATION

• String and Marking Stakes • Concrete/Quickcrete® and Gravel Mix

• Line Level • Post Hole Digger or Power Auger

• Speed Square • PVC Vinyl Cement

• Safety Glasses • Gloves

• #4 Rebar • Shovel

• Miter Saw/Chop Saw (if cutting down rails, pickets, or posts)

EACH POST

SOLD

SEPERATELY

5 TYPES OF VINYL POST

Step 1 PREPARE VINYL FENCE LAYOUT

Installation instructions for fence lay-out, setting posts, cap installation and clean up, are common for each fence style we oer.

IMPORTANT

Consider soil conditions, slopes, utility locations and property lines when positioning posts. In frost regions, dig the post holes

deep enough to ensure concrete extends below the frost line.

Duramax Vinyl fences are designed for level or sloping terrain. For significant sloping terrain you will need to modify some of the

posts and panel components. Lengthing out the routed holes in the posts and cutting the pickets at the angle of slope will help

with assembly on uneven terrain.

1. Locate property lines.

2. Drive stakes at each end of property lines. Then stretch a string between each stake and

extend the string 2’ beyond property line (Fig. 1a).

3. Mark each end-corner post locations with a stake. For gate posts, refer to gate section for gate

opening size.

IMPORTANT

Use the 3-4-5 rule as shown below

to ensure for square corners (Fig. 1b).

POST LOCATION table summarizes sizes and measurements for posts, fence sections and gates.

On Center Distance - refer to the center of one post to the center of adjacent post

Fence Style Post Size Post Span Fence On Center Distance Gate opening Post

Privacy with Lattice 5”x5” 68” 73” 48” 53”

Privacy 5”x5” 68” 73” 48” 53”

Picket Fence 4”x4” 68” 72” 48” 52”

Ranch Rail 5”x5” 93” 98” 72” 77”

Fig. 1b

Fig. 1a

LAYOUT FENCE AND POSITION POSTS

SET END-CORNER POSTS

1. Dig all End-Corner post holes first, 10” for 5”x5” post and 8” for

4”x4” in diameter and 24” deep (Fig. 2a).

2. Insert End-Corner Posts into holes and set them in concrete filling

hole to 2” below ground level.

3. Make sure all posts are level and plumb.

4. Stake a string line across the top of the End-Corner posts to mark the desired height of the Line posts (Fig. 2b).

5. Now stake out the positions of the Line posts along the string line (Fig. 2b).

IMPORTANT

You will first need to determine the “post on center distance”, the measurement from the center of one post to the center

of the next.

Example for Privacy Fence: Section width = 90” Post size = 5” (5x5) Total “Post On Center distance” = 95”

Step 2 SETTING VINYL FENCE POSTS

Fig.2a

Fig.2b

LAYOUT FENCE AND POSITION POSTS

IMPORTANT

Post depth and width will be determined by local weather and

soil conditions. In frost regions, dig the post holes deep enough

to ensure concrete extends below the frost line. Please check the

building code in your area specifies a frost line depth.

Step 3 FILL END-CORNER POSTS WITH RE-BAR & CONCRETE

Mix concrete according to manufacturers specications. Place and hold the post while pouring concrete 6” at a time, tamping

to eliminate air pockets. Leave enough space at the top of the concrete to allow sod to grow around the post. Set the correct

post height, plumb and level each post.

IMPORTANT

BEFORE FILLING GATE POSTS WITH CONCRETE, MAKE SURE THAT THE GATE HARDWARE IS INSTALLED FOLLOWING THE

INSTRUCTIONS IN THE GATE SECTION.

Before concrete sets, site down the fence line and, if necessary, adjust posts. If posts are too high, place a wooden

block across the top of the post and tap down with a rubber mallet. Allow post concrete to set 24 hours before

installing fence sections.

For added strength End-Corner posts should be filled up to 2” from the top of the post with concrete and rebar.

1. Each end, corner or gate post takes 2 pieces of ½” diameter rebar cut 4” shorter than the post length located at

opposing corners of post (Fig. 3a).

IMPORTANT

Rebar should extend to the ground a minimum of 12”.

2. Now fill the posts with concrete, tapping on the sides of the post to remove

air-pockets in the concrete (Fig.3b).

3. Clean up excess concrete with water before it dries.

Concrete Requirements:

4x4 Line Posts = approx 100 lbs 4x4 End, Corner, Gate post = approx 160 lbs

5x5 Line Posts = approx 140 lbs 5x5 End, Corner, Gate post = approx 260 lbs

Fig.3a

Fig.3b

STEP 4 POST CAP INSTALLATION

Apply a small amount of PVC glue in each coner of the post cap and insert

the external post cap on top of the post by tapping lightly on top of the post

cap until it securely fit the post top. Wipe o any pvc glue residue (Fig.4).

NOTE: Post Cap sold separately.

WHITE

PVC VINYL

CEMENT

PVC CEMENT

Top of the Post

External Post Cap

LAYOUT FENCE AND POSITION POSTS

Fig.4

Having set your posts, you are now ready to assemble the fence sections for your specific Privacy Product Item Model as below.

IMPORTANT

Protect the finish of your fence during assembly by assembling on a dry, clean and smooth surface.

NOTE: Rail Style, Picket Panels Style and number of pickets panels may dier depending on the Privacy Product Item Model.

Sold Separately: Post, Post Caps, End Channel

ASSEMBLE AND INSTALL SECTIONS

Layout Fence & Position Post

Refer to STEP 1 to 4

Assemble & Install Sections

Refer to STEP A1 to A4

Post Cap

Top Routed Hole

Bottom Routed Hole

Post

Top Rail

Groove

Privacy T&G (Tongue & Groove)

Pickets

Bottom Rail

Steel Reinforcement Channel

Groove

End Channel

STEP A4

STEP A3

STEP A2

STEP A1

STEP A1: INSTALL END CHANNEL

Center the end channel on the post between the bottom and top rail holes. Position the flat

side of the end channel against the post and secure the channels to the posts using 3, #8 x ¾”

stainless steel self tapping screws (Fig. A1).

ASSEMBLE AND INSTALL SECTIONS

STEP A3: INSERT PRIVACY PICKETS

Starting on one end, insert privacy pickets into

groove on bottom rail and end channels. Continue

across the panel inserting the remaining pickets and

interlocking the (T&G) tongues and grooves of the

pickets securely

(Fig. A3)

.

NOTE: If post spacing is less than 8

’

on center, you

can cut the picket board on one side. The cut side of

picket always goes against the post (Fig. A3b).

Fig.A1

STEP A2: INSTALL BOTTOM RAIL

Slide and insert the Bottom Rail (A), groove side up into the bottom hole of the post. Starting

at end or corner place the next post into the next hole. Now slide the next Bottom Rail into the

bottom hole of the next post (Fig. A2). Repeat these steps until all rails are inserted (B).

NOTE: If post spacing is less than 8’ on center, cut a piece from the end of the t bottom rail to

get the desired length. Steel Reinforcement Channel need to be inserted first before installing

bottom rail.

Steel Reinforcement Channel (AS AN OPTIONAL ITEM ON CERTAIN PRIVACY PRODUCT ITEM

MODEL) need to be inserted first to the rail before installing the bottom rail (Fig. A2B).

STEP A4: INSTALLING TOP RAIL

Install top rail into top hole of post, groove side down, sliding over pickets at an

angle. Lower top rail groove onto pickets, sliding rail as far as possible into the

first post. When privacy picket is fully engaged in top rail, slide rail into second

post (Fig. A4).

NOTE: If post spacing is less than 8’ on center, cut a piece from the end of the top

rail to get the desired length.

Fig.A2

Fig.A3

Fig.A3b

Fig.A4

Property of Duramax Building Products © September 2021

Fig.A2B

Table of contents

Other Dura-Max Fencing & Gate manuals

Popular Fencing & Gate manuals by other brands

CertainTeed

CertainTeed Bufftech Assembly & Installation Guidelines

CertainTeed

CertainTeed CertaWrap Installation guidelines

Orbinox

Orbinox BC Installation, operation & maintenance manual

Fortress Technologies

Fortress Technologies PURE VIEW GLASS BALUSTER AL13 HOME installation instructions

WamBam

WamBam HANDY ANDY Assembly instructions

DIRICKX

DIRICKX ALLIANCE PLUS manual