MK3B WALL CLADDING

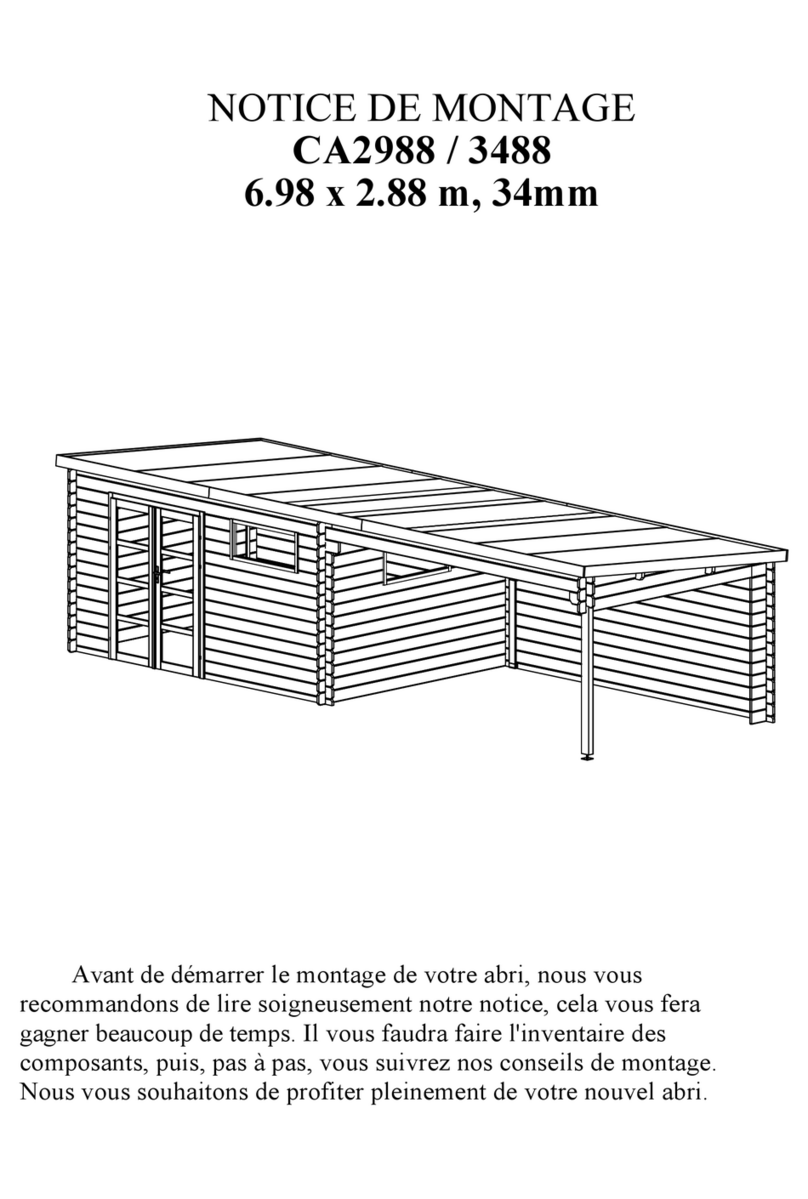

Step 1: Front Wall: Start at the left hand side. Position

the Wall Sheet with the LIP on the left hand

side. Ensuring the LIP is flush with side of the

Stud and the top of the Top Plate, tack in place.

Repeat with Wall Sheet on the right hand side

of doorway.

Step 2: Back Wall: Position the first Wall Sheet with

the LIP on the right hand side. Ensuring the LIP

is flush with the side of the Stud and the top of

the Wall Sheet is flush with the top of the Top

Plate, tack in place. Position the next Wall

Sheet with the LIP on the right hand side. Over-

lap as shown in fig.1 (page 7). Ensuring Wall

Sheet is flush with top of Top Plate, tack in

place. Repeat with remaining two sheets.

Step 4: Nailing Off: Nail one 30mm Clout each side of the Rib (two per Pan) into the Top Plates and Bottom Plates. Nail

Wall Sheets to mid wall Nogs (one per pan). Nail each corner Wall Sheet to Studs using two 30mm Clouts evenly

spaced.

Gable Ends: When nailing Gable Wall Sheets to the Top Plate, use a String Line. At the top of the gable nail one

30mm Clout each side of the Rib (two per Pan) into the Roof Nogs.

Step 3: End Walls: Lean Gable Wall Sheets against

the shed to form gable shape. With the LIP

flush with side of Stud tack in place ensuring

the bottom of the Wall Sheet is 10mm above

the bottom of the Bottom Plate. Tack on re-

maining Wall Sheets. Repeat with other gable

end. If fitting a window, nail in Window Studs

and Nog now. Refer to Window instructions.

8

EDGE

FLUSH

TOP

FLUSH