User and maintenance manual

EN

TSC - TDC

1

8702040 – 14/01/2019 – R.7 www.d p.it

INDEX

1 INTRODUCTION..................................................................................................................................................2

1.1 GENERAL

INFORMATION ...........................................................................................................................2

1.2 MANUFACTURER

DATA ..............................................................................................................................2

1.3 CONSULTATION

METHODS .......................................................................................................................2

1.4 PERSONNEL

QUALIFICATIONS .................................................................................................................2

1.5 PERSONAL

PROTECTION

EQUIPMENT ....................................................................................................3

1.6 IDENTIFICATION

PLATE ..............................................................................................................................3

2 SAFETY ...............................................................................................................................................................4

2.1 GENERAL

WARNINGS .................................................................................................................................4

2.2 ADDITIONAL

RISKS .....................................................................................................................................4

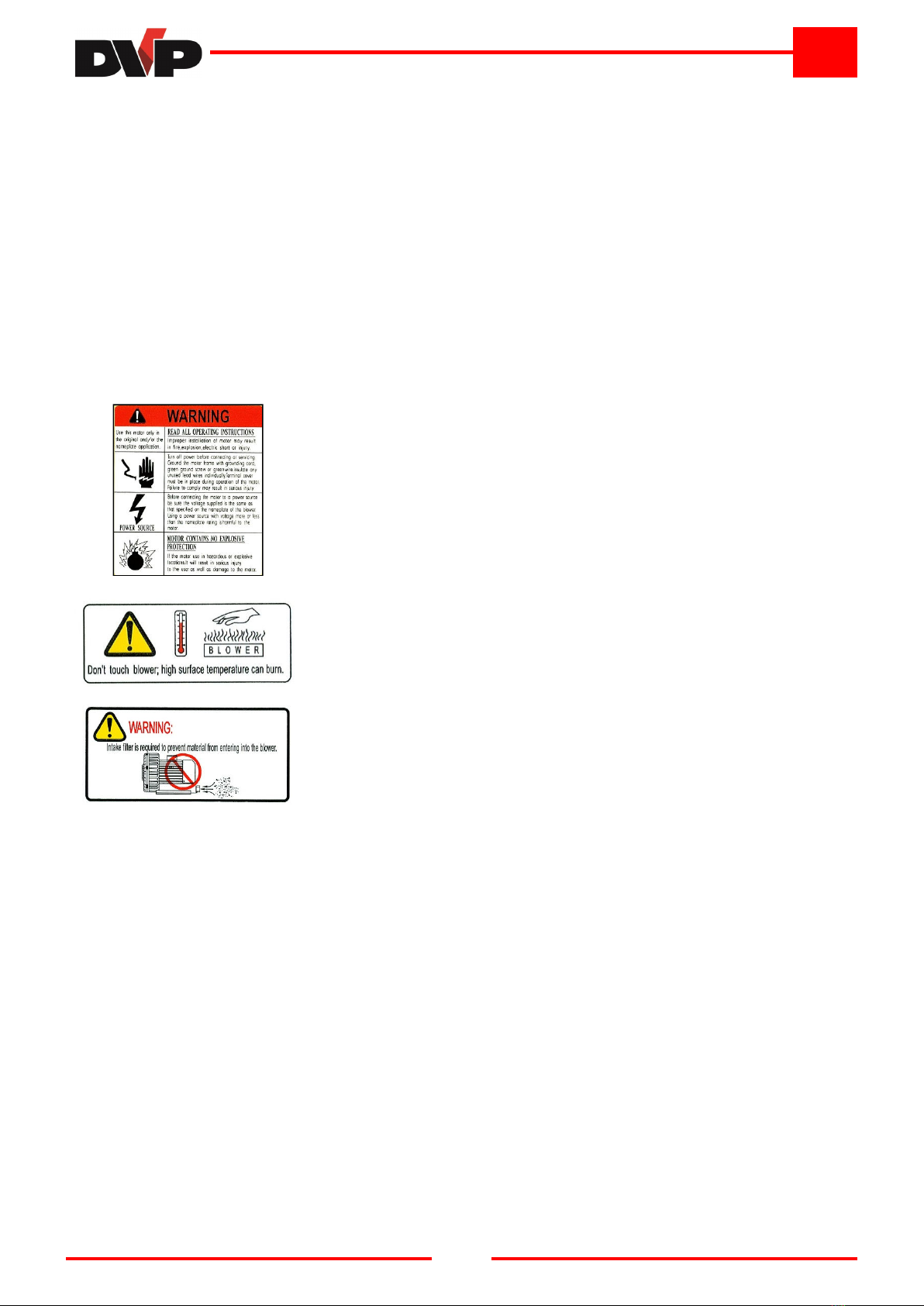

2.3 PICTOGRAMS ..............................................................................................................................................5

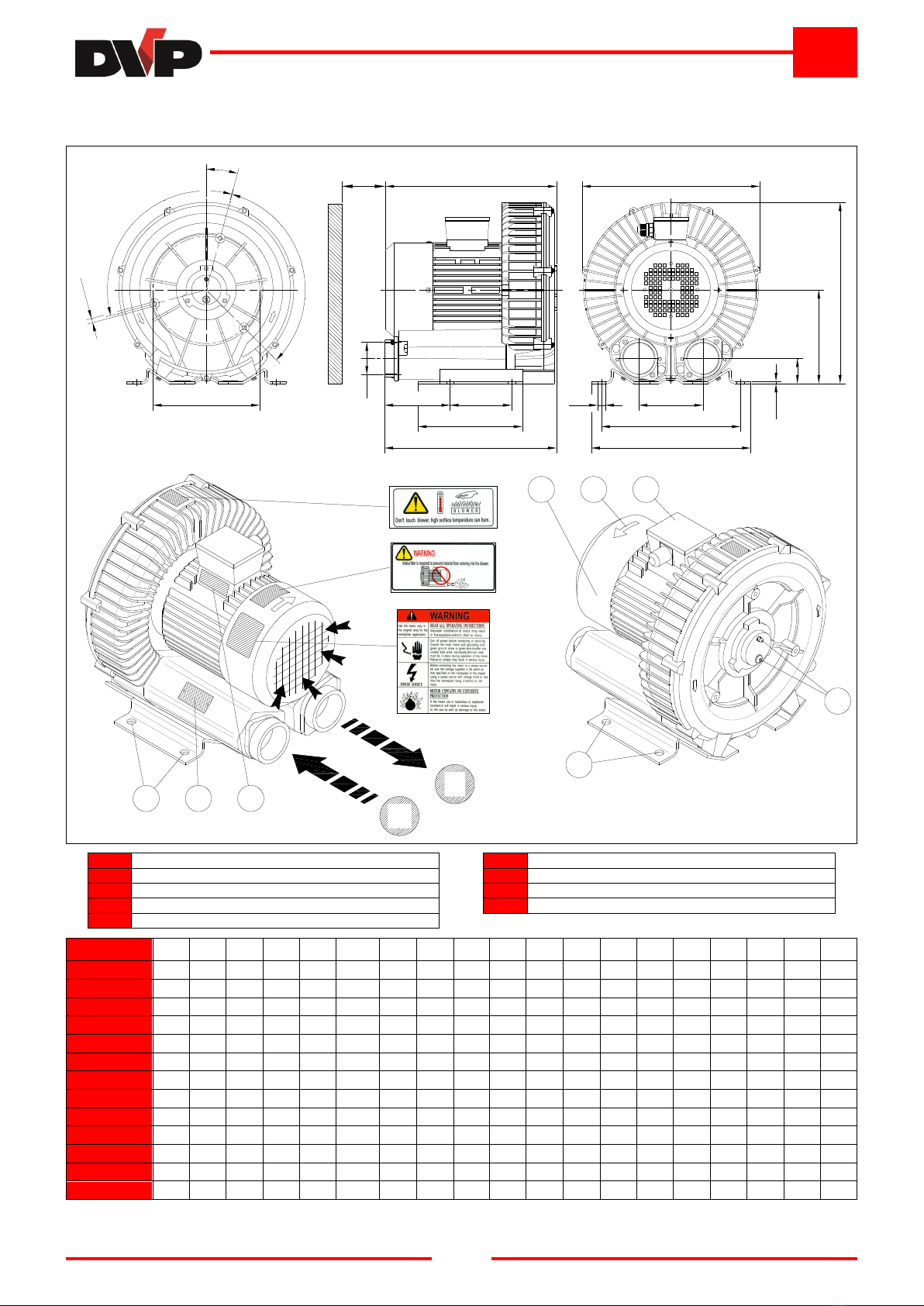

3 TURBINE DESCRIPTION ...................................................................................................................................6

3.1 INTENTED

USE

AND

CONTRAINDICATIONS ............................................................................................6

3.1.1 INTENTED USE ......................................................................................................................................6

3.1.2 CONTRAINDICATIONS ..........................................................................................................................6

3.2 NOISE

EMISSIONS .......................................................................................................................................6

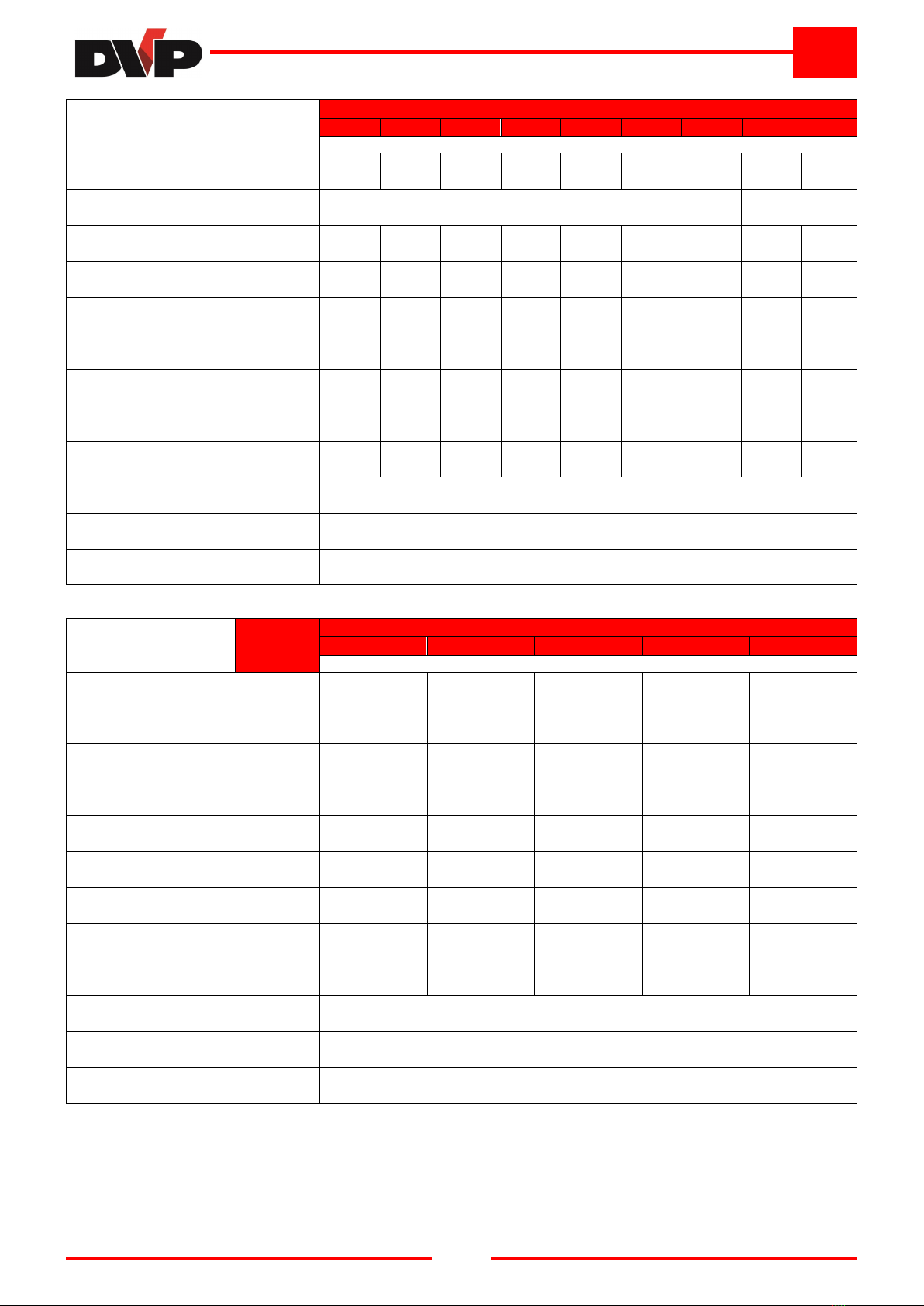

3.3 DIMENSIONS

AND

SPECIFICATIONS ........................................................................................................7

3.3.1 TSC Mod ls ............................................................................................................................................7

3.3.2 TDC Mod ls ......................................................................................................................................... 10

4 INSTALLATION ................................................................................................................................................ 13

4.1 CONTENT

RECEPTION

AND

CONTROL ................................................................................................. 13

4.2 PACKAGING .............................................................................................................................................. 13

4.3 TRANSPORT

AND

HANDLING ................................................................................................................. 13

4.4 STORAGE .................................................................................................................................................. 13

4.5 ENVIRONMENTAL

CONDITIONS ............................................................................................................. 13

4.6 TURBINE

INSTALLATION ......................................................................................................................... 14

4.7 USER

SYSTEM .......................................................................................................................................... 14

4.8 CONNECTION ........................................................................................................................................... 14

4.8.1 INTAKE AND OUTLET CONNECTION ............................................................................................... 15

4.8.2 ELECTRIC CONNECTION .................................................................................................................. 15

5 INSTRUCTIONS FOR USE .............................................................................................................................. 17

5.1 OPERATION .............................................................................................................................................. 17

5.2 START-UP .................................................................................................................................................. 17

5.3 STOP .......................................................................................................................................................... 18

5.4 DECOMMISSIONING

AND

PROLONGED

STOPPAGE ........................................................................... 18

6 MAINTENANCE................................................................................................................................................ 19

6.1 GENERAL

WARNINGS .............................................................................................................................. 19

6.2 INTERVENTION

TABLE............................................................................................................................. 20

6.2.1 INTAKE FILTER CONTROL ................................................................................................................ 20

6.2.2 REPLACING THE INTAKE FILTER .................................................................................................... 20

6.2.3 CLEANING THE MOTOR FAN PROTECTION ................................................................................... 20

6.2.4 GENERAL EXTERNAL CLEANING OF THE TURBINE ..................................................................... 20

6.2.5 CHECKING THE OPERATION OF VACUUM AND/OR PRESSURE REDUCING VALVES ............. 20

6.2.6 CLEANING THE INTAKE AND OUTLET SILENCERS ....................................................................... 21

6.2.7 GREASING THE BEARINGS .............................................................................................................. 21

6.2.8 BEARING REPLACEMENT ................................................................................................................. 21

6.3 SPARE

PARTS ........................................................................................................................................... 21

7 RETURNING THE PRODUCT .......................................................................................................................... 21

8 DISMANTLING ................................................................................................................................................. 22

9 TROUBLESHOOTING ..................................................................................................................................... 22