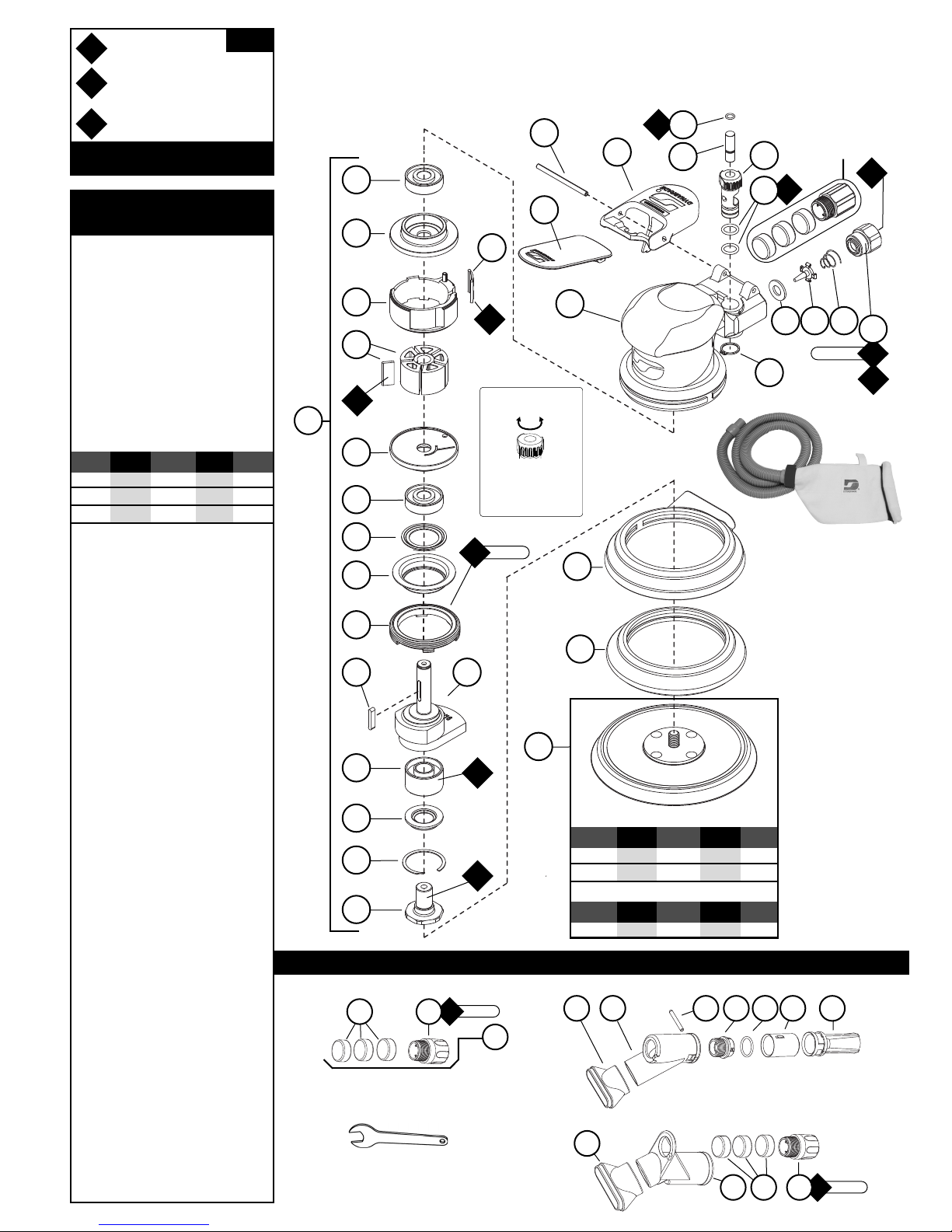

MAINTENANCE INSTRUCTIONS

Important: To keep tool safe, a Preventative Maintenance Program is

recommended. The program should include inspection of the tool and all

related accessories and consumables, including air lines, pressure regulators,

filters, oilers, etc. (refer to CAGI B186.1 for additional maintenance

information). If accessory or tool breakage occurs, investigate failure to

determine the cause and correct before issuing tool for work. Use the following

schedule as a starting point in developing a Preventative Maintenance

Program. If tool does not operate properly (RPM, vibration, start/stop) after

these scheduled checks or at any time, the tool must be repaired and

corrected before returning tool to use.

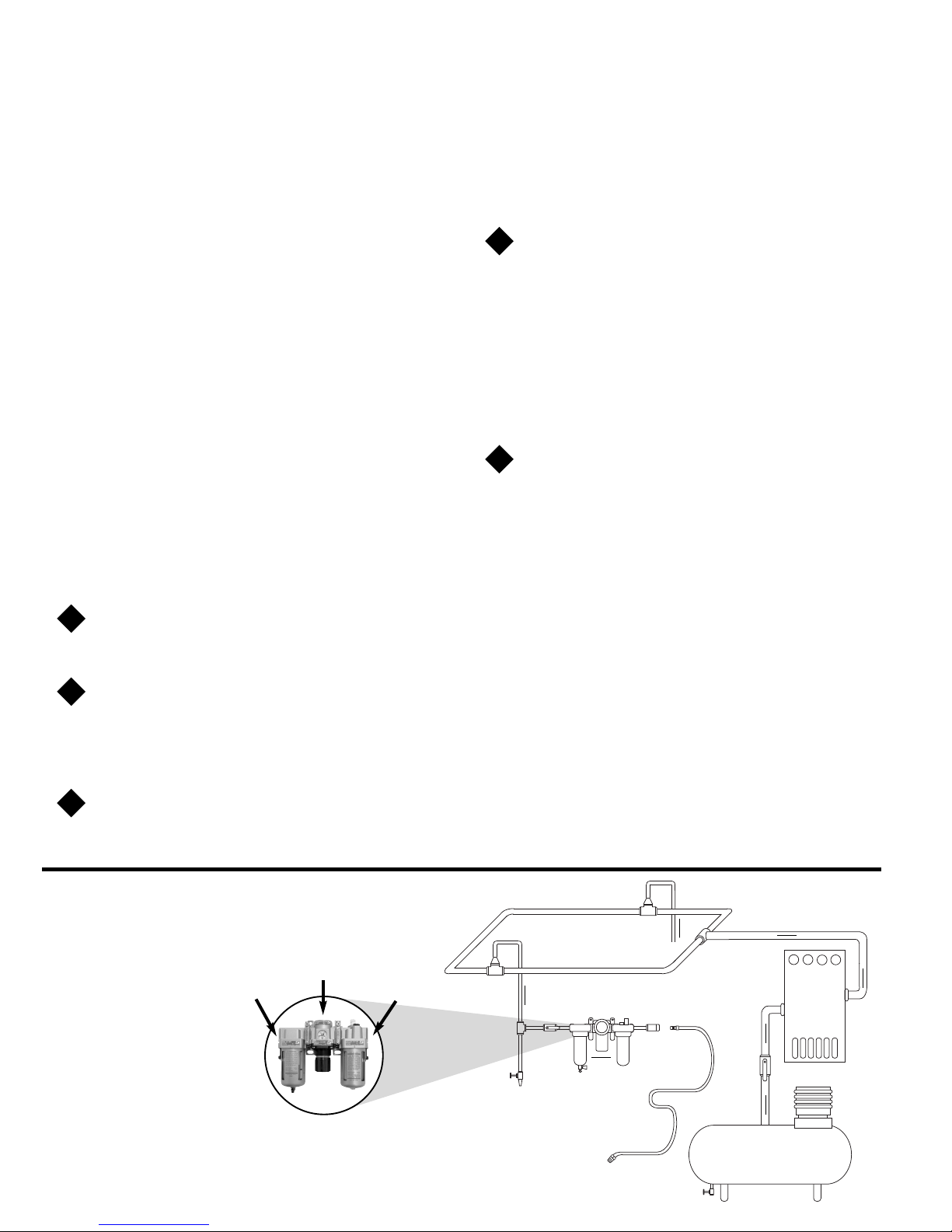

INSTALLATION

• To ensure long life and dependable service, use a Closed Loop Air System

and Filter-Regulator-Lubricator (FRL) as diagramed below.

• Each tool should have its own dedicated hose connected to an air supply

FRL. Quick disconnects should be installed at the FRL in an effort to reduce

contamination into the tool. Securely affix all fittings and hose assemblies.

• It is strongly recommended that all Dynabrade rotary vane air tools be used

with a Filter-Regulator-Lubricator to minimize the possibility of misuse due

to unclean air, wet air or insufficient lubrication. Dynabrade recommends

the following: 10681 Air Line Filter-Regulator-Lubricator — Provides

accurate air pressure regulation, two-stage filtration of water contaminants

and micro-mist lubrication of pneumatic components.

• Dynabrade recommends 1 drop of air lube per minute for each 20 SCFM

(example: if the tool specification states 40 SCFM, set the drip rate

on the filter-lubricator to 2 drops per minute). 95842 Dynabrade Air Lube

is recommended.

MAINTENANCE SCHEDULE

Maintenance schedules depend on the type and style of tool. Refer to page

3 to reference symbols associated with specific maintenance items/areas.

Match maintenance schedules accordingly. See page 4 for any additional

maintenance information.

Note: Turbine style air motors do not require oil.

Daily (every 8 hours):

• Inspect tool and accessories for damage or broken parts. Replace items

as necessary to ensure proper operation and safety.

Lubricate motor as recommended. Use 95842 Dynabrade Air Lube

(10W/NR). Apply 1 drop/minute of air lube per 20 SCFM.

• Check air line pressure with a gage. (MAX. 90 PSIG or 6.2 Bar operating

pressure at the air inlet of the tool.)

Lubricate wick system and right angle gears through gear case

fitting. Apply 3 plunges of 95848 Gear Oil. Use 95541 Lubricant Gun

(Prime lubricant gun before use).

• Check tool for proper operation: If operating improperly or demonstrates

unusual vibration, the tool must be serviced and problem corrected before

further use.

Every 20 Hours/Once a Week (which ever comes first):

For tools without "wick system", lubricate right angle gears through

lubricant fitting. Apply 1 plunge of 95542 Grease. Use 95541

Lubricant Gun. (Prime lubricant gun before use).

• Measure RPM (speed) by setting air pressure to 90 PSIG (6.2 Bar) at

tool inlet, without accessory mounted, while the tool is running. Using

tachometer, check spindle speed of the tool. Unless otherwise stated the

no-load speed may not exceed the rated speed. If tool speed exceeds

maximum rated RPM, service as required and correct before use.

• If tool is running too fast: look for worn, damaged or missing governor, air

control rings and silencer(s). Service as required.

• If tool is running too slow: look for malfunctioning governor, clogged inlet

screen, silencer(s) or air stream. Service as required.

Note: Special care must be taken when servicing governors. Refer to specific

tool manual for governor instructions and/or speed control devices. Governor

assemblies made from molded plastic components are non-serviceable and

must be replaced.

Every 50 Hours:

Lubricate planetary gears through gear case fitting with 3 plunges

of 95544 Grease. Use 95541 Lubricant Gun. (Prime lubricant gun

before use).

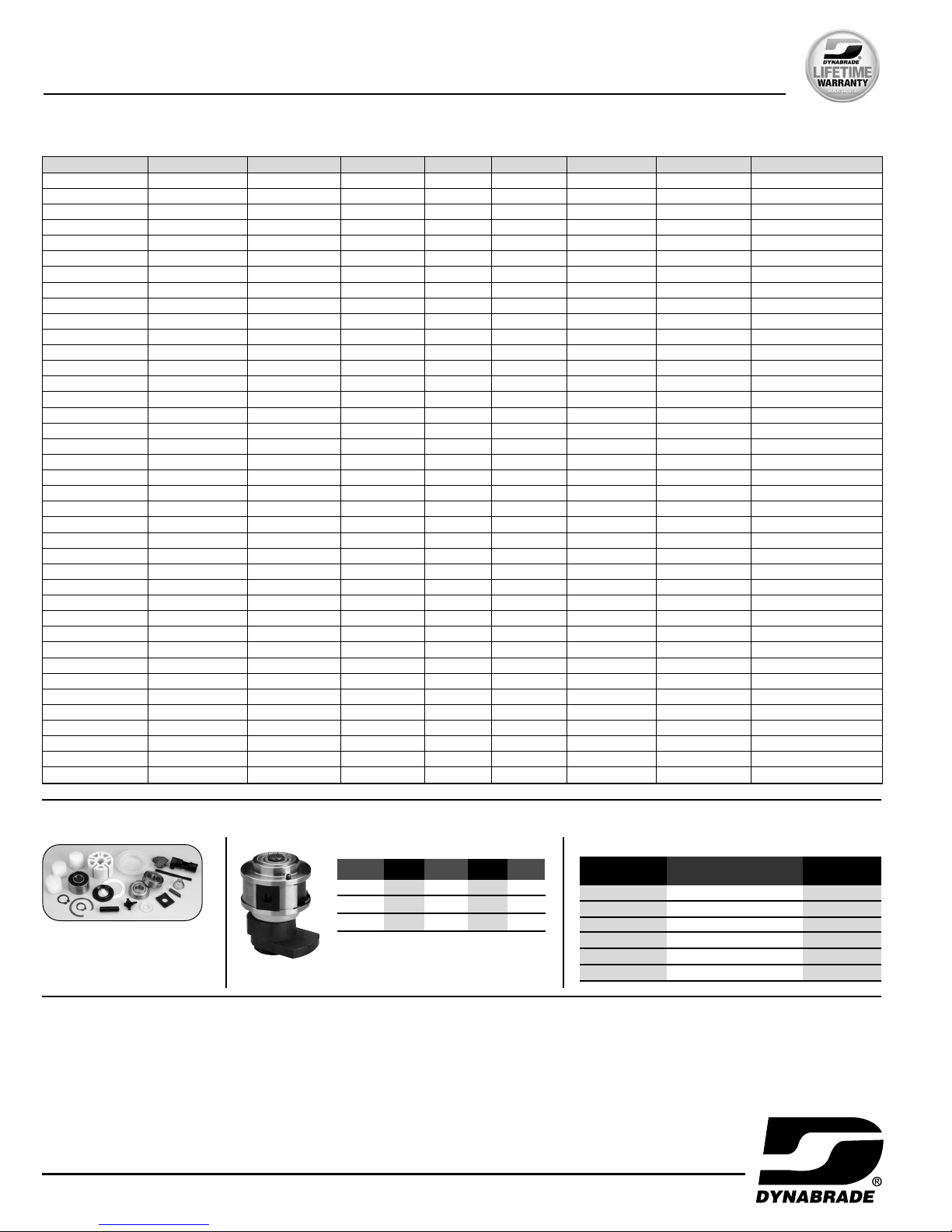

REPAIR

• Use only genuine Dynabrade replacement parts to ensure quality. To order

replacement parts, specify Model#, Serial# and RPM of your air tool.

• Mineral spirits are recommended when cleaning the tool and parts. Do

not clean tool or parts with any solvents or oils containing acids, esters,

ketones, chlorinated hydrocarbons or nitro carbons.

• A Motor Tune-Up Kit is available which includes high wear and medium

wear motor parts.

• Air tool markings must be kept legible at all times, if not, reorder housing

and replace. User is responsible for maintaining specification information.

After maintenance is performed on tool, add a few drops of 95842

Dynabrade Air Lube to the tool inlet and start the tool a few times to

lubricate air motor. Verify RPM (per 20 hr maintenance schedule),

vibration and operation.

HANDLING & STORAGE

• Use of tool rests, hangers and/or balancers is recommended.

• Protect tool inlet from debris (see Notice below).

•Do Not carry tool by air hose or near the tool throttle lever.

• Store accessories in protective racks or compartments to prevent damage.

• Follow the handling instructions outlined in the operating instructions when

carrying the tool and when changing accessories.

• Protect accessories from exposure to water, solvents, high humidity,

freezing temperature and extreme temperature changes.

END OF USE/ DISPOSAL

When tool has reached its end of useful service, disassemble tool into its

primary components (i.e. steel, aluminum and plastic) and recycle or discard

per local, state and/or federal regulations as to not harm the environment.

NOTICE

All Dynabrade air motors use the highest quality parts available and are

manufactured to exacting tolerances. Air motor failures are often traced to lack

of lubrication or unclean air supply. Compressed air can force dirt and other

contaminants into motor bearings causing early failure. Contaminants can score

cylinder wall and vanes resulting in reduced efficiency and power. Our warranty

obligation is contingent upon proper use of our tools. Air motors which have been

subjected to misuse, contaminated air or lack of lubrication will void warranty.

Filter

Regulator

Lubricator

Lubricator Setting

90 PSIG

(6.2 Bar)

Air Flow to Tool Station

Ball

Valve

Ball

Valve

Air Flow

Drain

Valve

Drain

Valve

Air Tool

Air Compressor and Receiver

Drain Valve

Air Hose

90 PSIG Max.

(6.2 Bar)

Air Flow

Refrigerated

Air Dryer

• Dynabrade Air Power Tools

are designed to operate at 90

PSIG (6.2 Bar) maximum air

pressure at the tool inlet,

when the tool is running. Use

recommended regulator to

control air pressure.

• Ideally the air supply should

be free from moisture. To

facilitate removing moisture

from air supply, the installation

of a refrigerated air dryer after

the compressor and the use of

drain valves at each tool

station is recommended.

‰‰

‰

‰

‰

‰

CLOSED LOOP AIR SYSTEM

Sloped in Direction of Air Flow

O

W

G

O

2

‰

~

1 Drop/Minute per 20 SCFM

G