Personal Safety

1. Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use tool while tired or under the influence of drugs,

alcohol, or medication. A moment of inattention while operating power tools may result in serious personal injury.

2. Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your hair, clothing, and gloves away from moving parts. Loose clothes,

jewelry, or long hair can be caught in moving parts.

3. Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools with your finger on the switch or plugging in tools that have the switch

on invites accidents.

4. Remove adjusting keys or switches before turning the tool on. A wrench or a key that is left attached to a rotating part of the tool may result in personal injury.

5. Do not overreach. Keep proper footing and balance at all times. Proper footing and balance enables better control of the tool in unexpected situations.

6. Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes, hard hat, or hearing protection must be used for appropriate conditions.

Tool Use and Care

1. Use clamps or other practical way to secure and support the workpiece to a stable platform. Holding the work by hand or against your body is unstable and may

lead to loss of control.

2. Do not force tool. Use the correct tool for your application. The correct tool will do the job better and safer at the rate for which it is designed.

3. Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled with the switch is dangerous and must be repaired.

4. Disconnect the plug from the power source before making any adjustments, changing accessories, or storing the tool. Such preventative safety measures

reduce the risk of starting the tool accidentally.

5. Store idle tools in a high, dry place, locked up out of reach of children and other untrained persons. Tools are dangerous in the hands of untrained users.

6. Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools, with sharp cutting edges are less likely to bind and are easier to control.

7. Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect the tools operation. If damaged, have the

tool serviced before using. Many accidents are caused by poorly maintained tools.

8. Use only accessories that are recommended by the manufacturer for your model. Accessories that may be suitable for one tool, may become hazardous

when used on another tool.

9. Use the right tool. Do not force small tools or attachments to do the job of a heavy duty tool.

Service

1. Tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified personnel could result in a risk of injury.

2. When servicing a tool, use only identical replacement parts. Follow instructions in the Maintenance section of this manual. Use of unauthorized parts or failure

to follow Maintenance Instructions may create a risk of electric shock or injury.

SPECIFIC SAFETY RULES

1. Accessories must be rated for at least the speed recommended on the tool warning label. Wheels and other accessories running over rated speed can fly

apart and cause injury.

2. Hold tool by insulated gripping surfaces when performing an operation where the tool may contact hidden wiring or its own cord. Contact with a “live”

wire will make exposed metal parts of the tool "live" and shock the operator.

(See Definitions for label symbols on pg. 3)

TOOL DESCRIPTION

Random Orbital Polisher – Is a random orbital electric hand tool which includes: a variable speed on/off switch, side handle, an RPM Dial, and is equipped with

a 6 ft. cord set.

ASSEMBLY and OPERATION INSTRUCTIONS

1. With power source disconnected from tool, securely fasten abrasive/accessory on tool by depressing spindle locking button located on the right angle head. The rated

RPM of the accessory must be equal to or greater than the rated RPM of the tool.

2. Hold tool by the motor housing and the side handle. Do Not hold tool by head/housing assembly. Keep hands away from all sanding

edges and moving parts.

3. Squeeze trigger on rear handle to run tool. To lock tool in “on” position continue to squeeze trigger and depress side button. To disengage tool when locked in “on”

position push trigger inward.

MAINTENANCE and ACCESSORY CARE INSTRUCTIONS

Important: A preventative maintenance program is recommended whenever portable power tools are used.

•

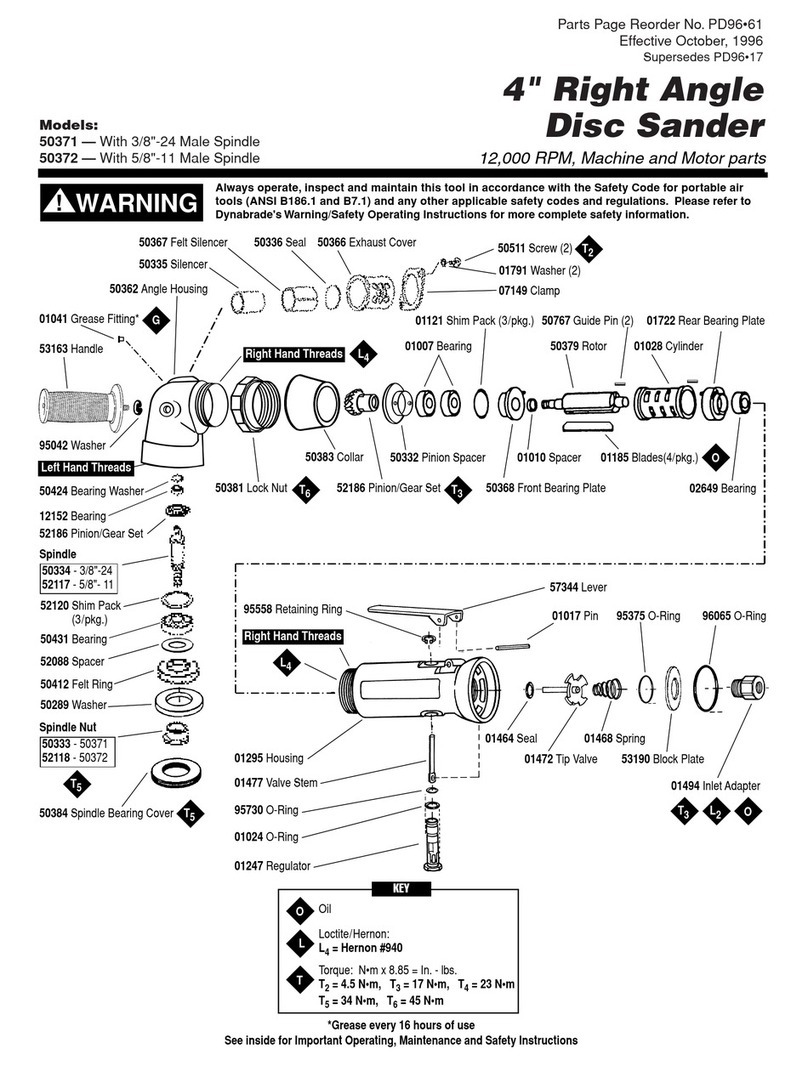

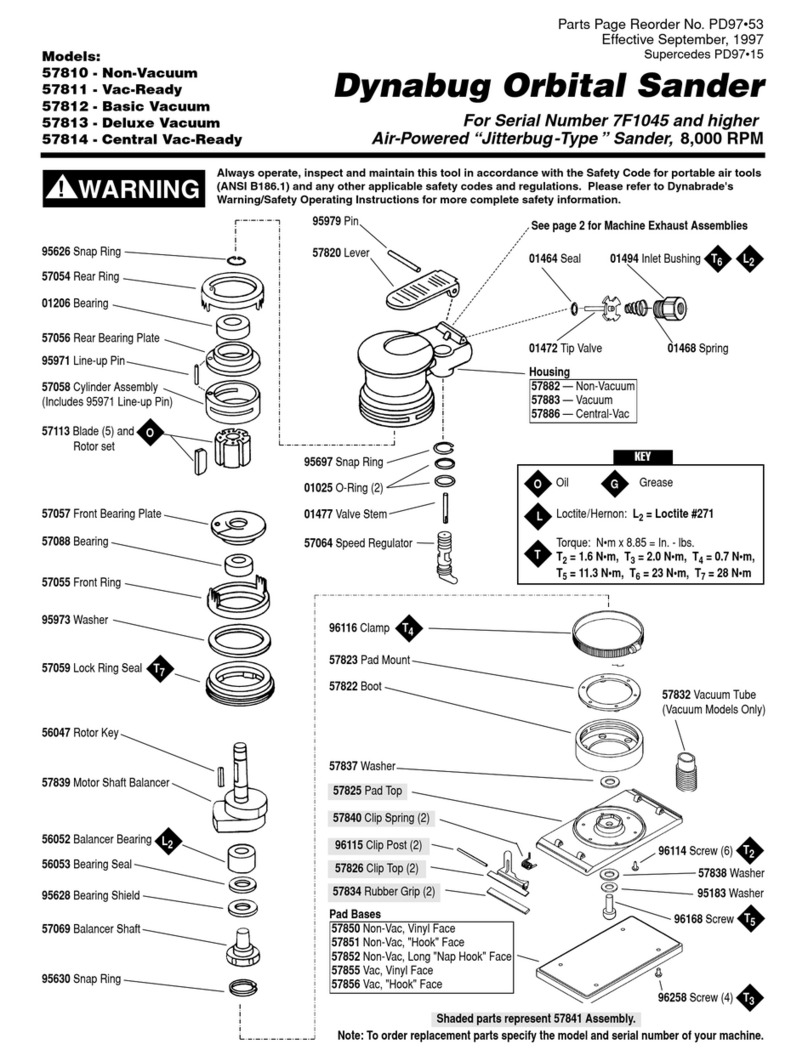

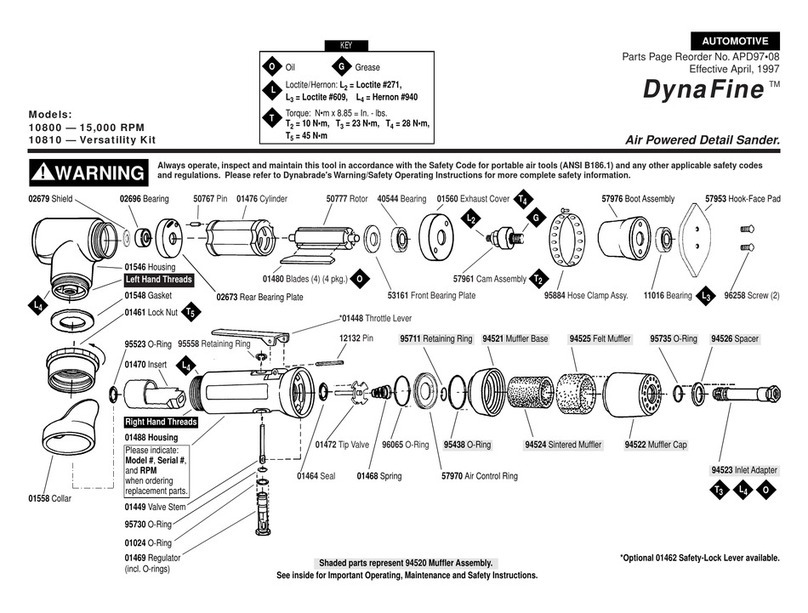

Use only genuine Dynabrade replacement parts to insure quality. To order replacement parts, specify Model #, Serial # and RPM of your tool.

Routine Preventative Maintenance:

•

Mineral spirits are recommended when cleaning the sanding heads. Do not use on electrical components or clean tool or parts with any solvents or oils containing acids,

esters, ketones, chlorinated hydrocarbons or nitro carbons. Blow the dirt from electrical components with air.

•

DO NOT clean or maintain tools with chemicals that have a low flash point (example: WD-40®).

•

Tool labels must be kept legible at all times, if not, reorder label(s) and replace. User is responsible for maintaining specification information i.e.:

Model #, S/N, and RPM. (See Assembly Breakdown)

•

Visually inspect plugs and cords for frays, visible damage and signs of deterioration. Replace damaged or worn components.

•

Refer to Dynabrade's Warning/Safety Operating Instructions Tag (Reorder No. 95903) for safety information.

•

Brush Changing – Unplug tool and remove brush caps and replace brushes. Replace brush caps. Brush changing – Change brushes every 225 hrs. to

ensure proper tool function.

After maintenance is performed on tool check for excessive tool vibration. Check for excessive current leakage at 550 volts with a current leakage checker on all screws and

the gear case, if the electrical components have been disturbed during repair.

Handling and Storage of Tool and Accessories:

•

Use of tool rests, hangers and/or balancers is recommended.

•

DO NOT carry tool by cord.

•

Protect abrasive accessories from exposure to water, solvents, high humidity, freezing temperature and extreme temperature changes.

•

Store accessories in protective racks or compartments to prevent damage.

2