Important Operating, Maintenance and Safety Instructions

Carefully read all instructions before operating or servicing any Dynabrade®Abrasive Power Tool.

Warning: Hand, wrist and arm injury may result from repetitive work motion and overexposure to vibration.

Important: All Dynabrade Rotary Vane air tools must be used with a Filter-Regulator-Lubricator to maintain all warranties.

Operating Instructions:

Warning: Eye, face, respiratory, sound and body protection must be worn while operating power tools. Failure to do so may result in serious injury or death.

Follow safety procedures posted in workplace.

1. With power source disconnected from tool, securely fasten abrasive/accessory on tool.

2. Install air fitting into inlet bushing of tool. Important: Secure inlet bushing of tool with a wrench before attempting to install the air fitting to avoid

damaging valve body housing.

3. Connect power source to tool. Be careful not to depress throttle lever in the process.

Maintenance Instructions:

1. Check tool speed regularly with a tachometer. If tool is operating at a higher speed than the RPM marked on the tool, the tool should be serviced to

correct the cause before use.

2. Some silencers on air tools may clog with use. Clean and replace as required.

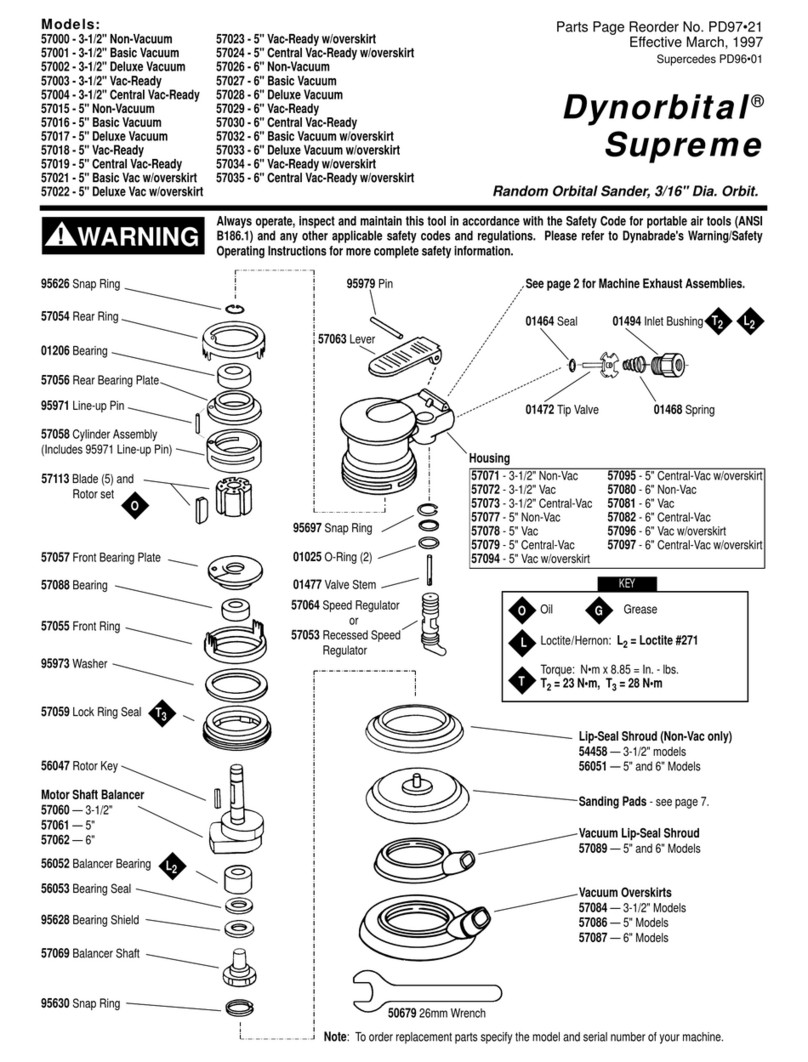

3. All Dynabrade Rotary Vane air motors should be lubricated. Dynabrade recommends one drop of air lube per minute for each 10 SCFM (example: if

the tool specifications state 40 SCFM, set the drip rate of your filter-lubricator at 4 drops per minute).

Dynabrade Air Lube (P/N 95842: 1 pt. 473 ml.) is recommended.

4. It is strongly recommended that all Dynabrade rotary vane air tools be used with a Filter-Regulator-Lubricator to minimize the possibility of misuse due

to unclean air, wet air of insufficient lubrication. Dynabrade recommends the following: 11405 Air Line Filter-Regulator-Lubricator — Provides accurate

air pressure regulation, two-stage filtration of water contaminants and micro-mist lubrication of pneumatic components. Operates 40 SCFM @ 100

PSIG has 3/8" NPT female ports.

5. Use only genuine Dynabrade replacement parts. To reorder replacement parts, specify the Model #, Serial #, and RPM of your machine.

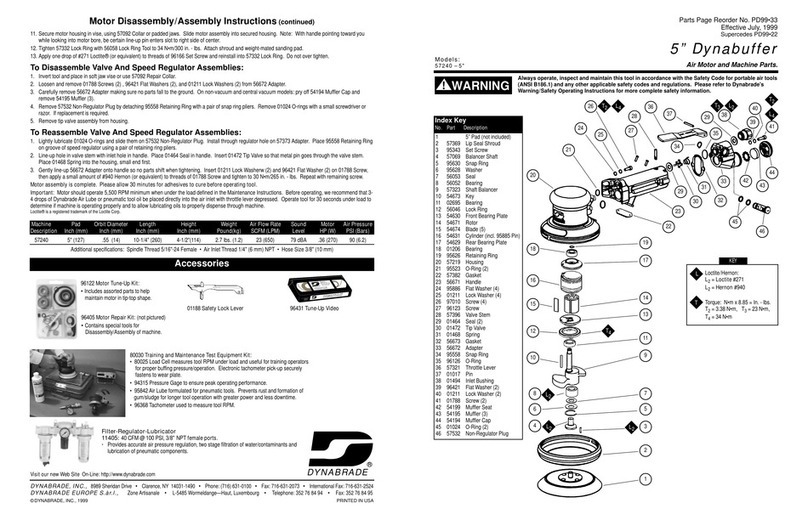

6. A Motor Tune-Up Kit (P/N 96122) is available which includes assorted parts to help maintain motor in peek operating condition. Please refer to

Dynabrade's Preventative Maintenance Schedule for a guide to expectant life of component parts.

7. Mineral spirits are recommended when cleaning the tool and parts. Do not clean tool or parts with any solvents or oils containing acids, esters, keytones,

chlorinated hydrocarbons or nitro carbons.

2

(PD00•80R)

Full OneYear Warranty

Following the reasonable assumption that any inherent defect which might prevail in a product will become apparent to the user within one year from the date

of purchase, all equipment of our manufacture is warranted against defects in workmanship and materials under normal use and service. We shall repair or

replace at our factory, any equipment or part thereof which shall, within one year after delivery to the original purchaser, indicate upon our examination to

have been defective. Our obligation is contingent upon proper use of Dynabrade tools in accordance with factory recommendations, instructions and safety

practices. It shall not apply to equipment which has been subject to misuse, negligence, accident or tampering in any way so as to affect its normal

performance. Normally wearable parts such as bearings, contact wheels, rotor blades, etc., are not covered under this warranty.

•Important: User of tool is responsible for following accepted safety codes such as those published by the American National Standards Institute (ANSI).

•Always disconnect power supply before changing abrasive/accessory or making machine adjustments.

•Inspect abrasives/accessories for damage or defects prior to installation on tools.

•Please refer to Dynabrade’s Warning/Safety Operating Instructions Tag (Reorder No. 95903) for more complete safety information.

Notice

All Dynabrade motors use the highest quality parts and metals available and are machined to exacting tolerances. The failure of quality pneumatic motors can

most often be traced to an unclean air supply or the lack of lubrication. Air pressure easily forces dirt or water contained in the air supply into motor bearings

causing early failure. It often scores the cylinder walls and the rotor blades resulting in limited efficiency and power. Our warranty obligation is contingent upon

proper use of our tools and cannot apply to equipment which has been subjected to misuse such as unclean air, wet air or a lack of lubrication during the

use of this tool.

Safety Instructions:

Products offered by Dynabrade should not be converted or otherwise altered

from original design without expressed written consent from Dynabrade, Inc.

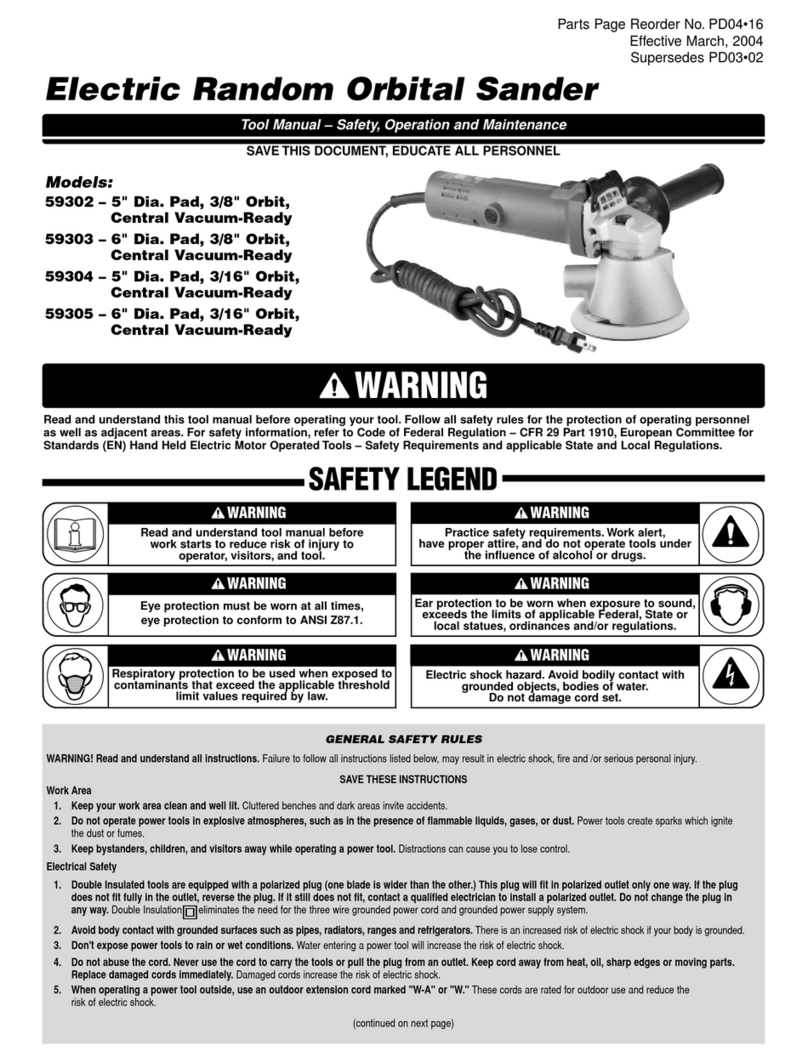

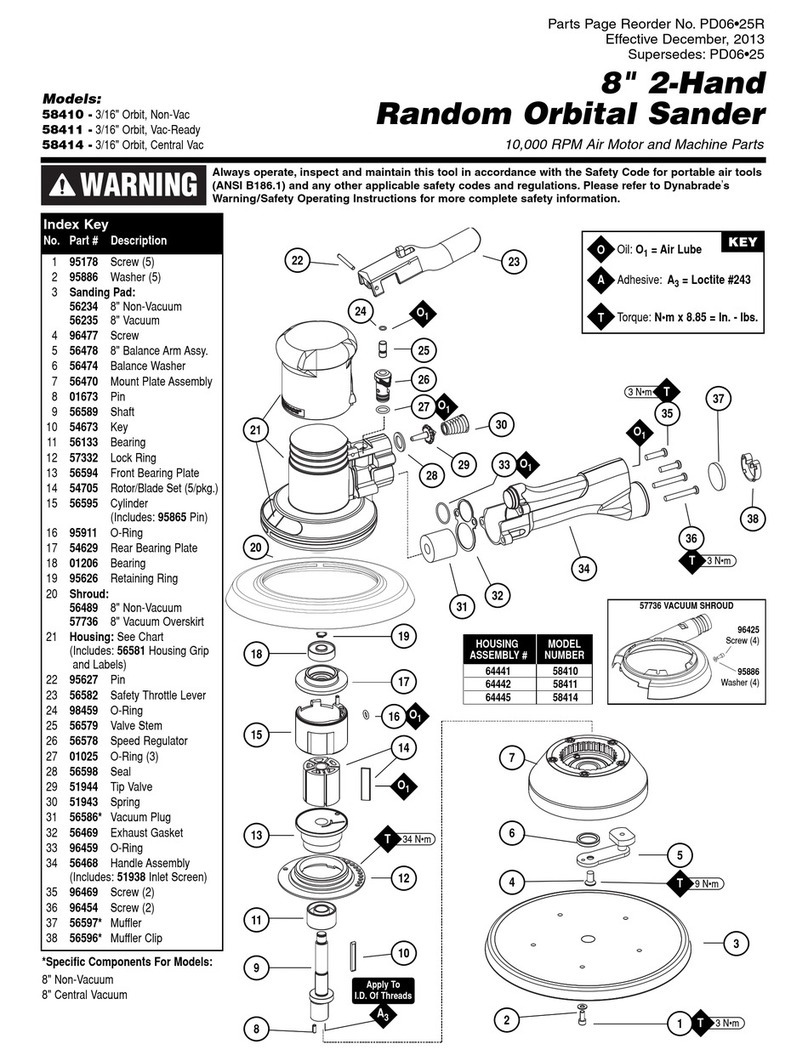

Model Motor Motor Sound Air Flow Rate Air Pressure Pad Dia. Weight Length Height

Number HP (W) RPM Level CFM/SCFM (LPM) PSIG (Bars) Inch (mm) Pound (kg) Inch (mm) Inch (mm)

57600 .31 (231) 10,000 82 dB(A) 3/19 (538) 90 (6.2) 8 (203) 3.4 (1.5) 12 (305) 4-1/2 (114)

57601-03 .31 (231) 10,000 82 dB(A) 3/19 (538) 90 (6.2) 8 (203) 3.4 (1.5) 12 (305) 4-1/2 (114)

57604 .31 (231) 10,000 82 dB(A) 3/19 (538) 90 (6.2) 8 (203) 3.4 (1.5) 12 (305) 4-1/2 (114)

Additional Specifications: Air Inlet Thread 1/4" NPT • Hose I.D. Size 3/8" (10mm)