2

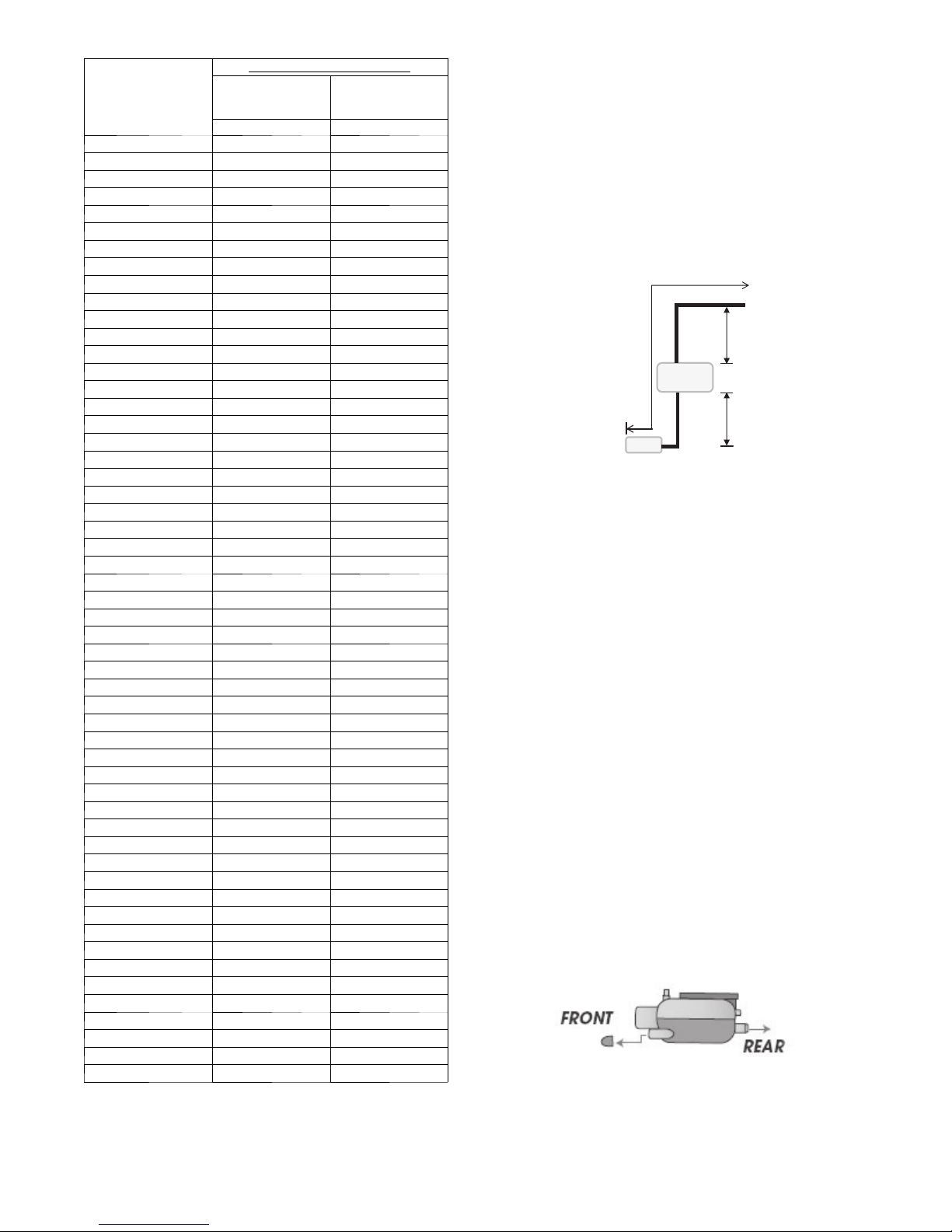

Table 2—Accessory Package Usage

BASE UNIT

ACCESSORY MODEL NUMBER

5 3 D S --- 9 0 0 --- --- --- 1 1

7

(11 5 --- 1 --- 60 )

5 3 D S --- 9 0 0 --- --- --- 1 1

8

(208/230---1---60)

Wiring Fig. No. Wiring Fig. No.

40GV C 0 0 9 --- --- --- 1 16

40GV C 0 1 2 --- --- --- 1 16

40GV C 0 1 2 --- --- --- 3 18

40GV C 0 1 8 --- --- --- 3 19

40GV C 0 2 4 --- --- --- 3 19

40GV C 0 3 6 --- --- --- 3 19

40GV M 0 0 9 --- --- --- 3 20

40GV M 0 1 2 --- --- --- 3 20

40GV M 0 1 8 --- --- --- 3 20

40GV Q009 --- --- --- 1 17

40GV Q012 --- --- --- 1 17

40GV Q012 --- --- --- 3 18

40GV Q018 --- --- --- 3 19

40GV Q024 --- --- --- 3 19

40GV Q030 --- --- --- 3 19

40GV Q036 --- --- --- 3 19

40GXC (Q) 00 9 --- --- --- 1 11

40GXC (Q) 01 2 --- --- --- 1 11

40GXC (Q) 01 8 --- --- --- 3 14 15

40GXC (Q) 02 4 --- --- --- 3 14 15

40GX M 0 0 9 --- --- --- 3 14 15

40GX M 0 1 2 --- --- --- 3 14 15

40GX M 0 1 8 --- --- --- 3 14 15

40MV C ( Q) 0 09 --- --- --- 1 8

40MV C ( Q) 0 12 --- --- --- 1 8

40MV C ( Q) 0 12 --- --- --- 3 910

40MV C ( Q) 0 18 --- --- --- 3 14 15

40MV C ( Q) 0 24 --- --- --- 3 14 15

40QN C( Q) 0 3 0 --- --- --- 3 13

40QN C( Q) 0 3 6 --- --- --- 3 13

40QNC018024--- --- ---3 12

40QN Q0 1 8 --- --- --- 3 12

40QN Q0 2 4 --- --- --- 3 12

PW3C(H)AM009 8

PW3C(H)AM012 8

PW3C(H)NM018 14 15

PW3C(H)NM024 14 15

RA S --- 09 EKC V --- UL 14 15

RA S --- 09 EK V --- U L 14 15

RA S --- 09 LK V --- U L 14 15

RA S --- 12 EKC V --- UL 14 15

RA S --- 12 EK V --- U L 14 15

RA S --- 12 LK V --- U L 14 15

RA S --- 15 EKC V --- UL 14 15

RA S --- 15 EK V --- U L 14 15

RA S --- 15 LK V --- U L 14 15

RA S --- 17 EKC V --- UL 14 15

RA S --- 17 EK V --- U L 14 15

RA S --- 17 LK V --- U L 14 15

RA S --- 22 EKC V --- UL 14 15

RA S --- 22 EK V --- U L 14 15

RA S --- 22 LK V --- U L 14 15

RAV---SP180KRT---UL 14 15

RAV---SP240KRT---UL 14 15

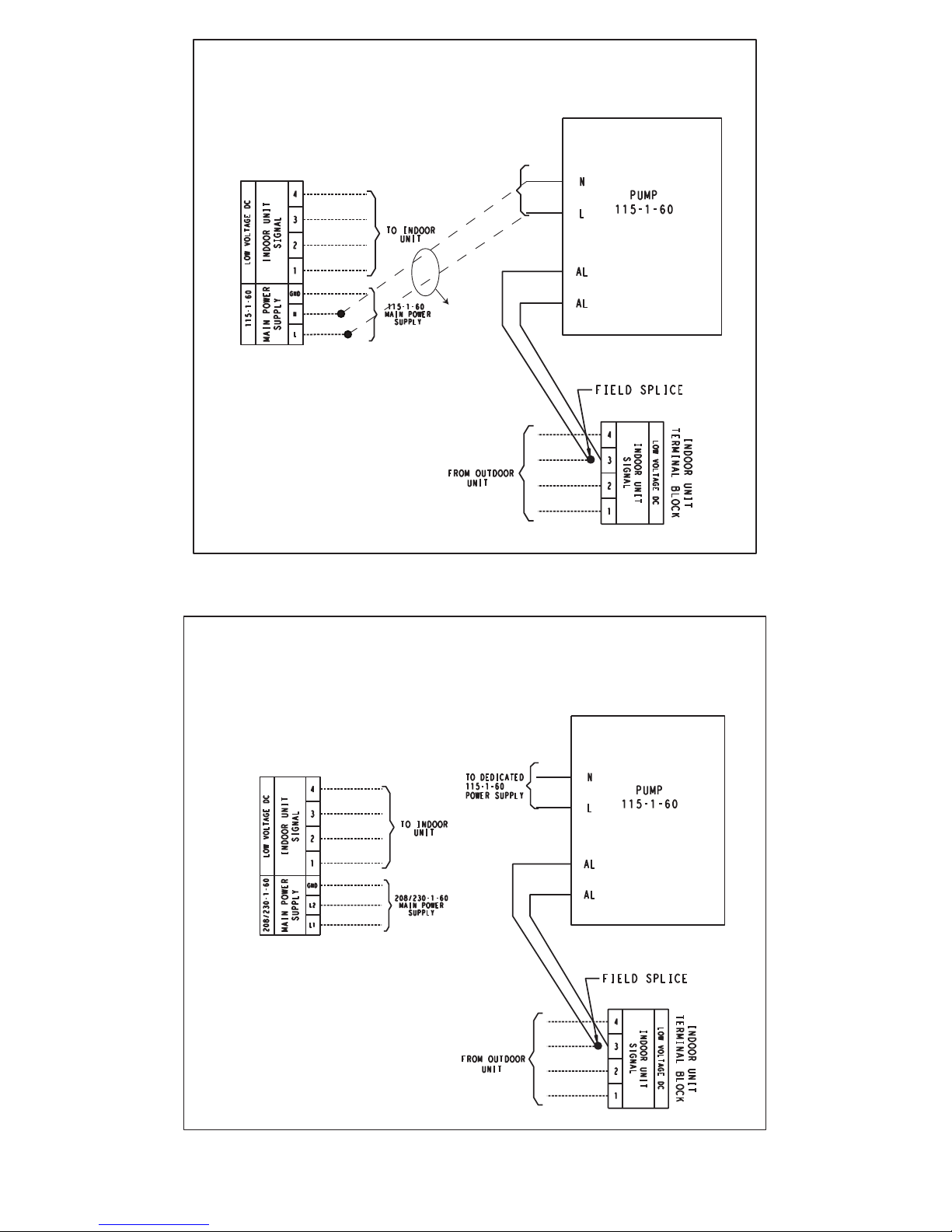

GENERAL

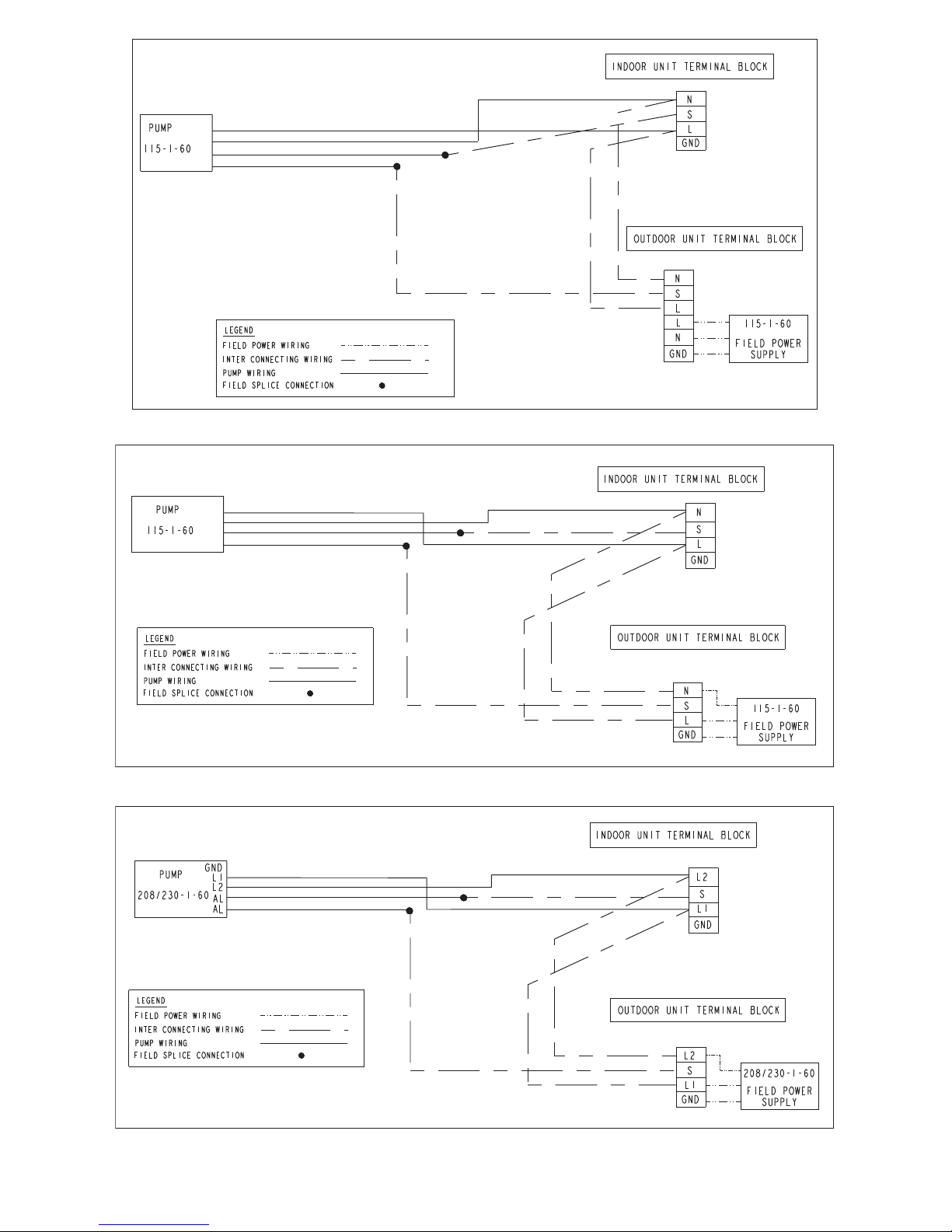

Use the two--part accessory kit (condensate pump and detection

unit) with high wall fan coils. The pump operates whenever the

condensate level in the detection unit is high enough to cause the

magnetic float switch to send a signal to start the pump.

The float switch in the detection unit also prevents overflow and

can act as a safety device by shutting down the system. The

detection unit comes with normally closed (NC) alarm contacts

(user optional, but recommended). The normally closed alarm

contact is a dry contact rated for 8 amps at 250 volts. In the event

of a problem such as a clogged drain or pump discharge line, the

alarm contact can be wired to shut down the entire system. The

condensate pump provides 10 ft (3.0 m) maximum suction lift

(A)--Fig. 2.

A12134

Fig. 2 --- Maximum Lengths

INSTALLATION

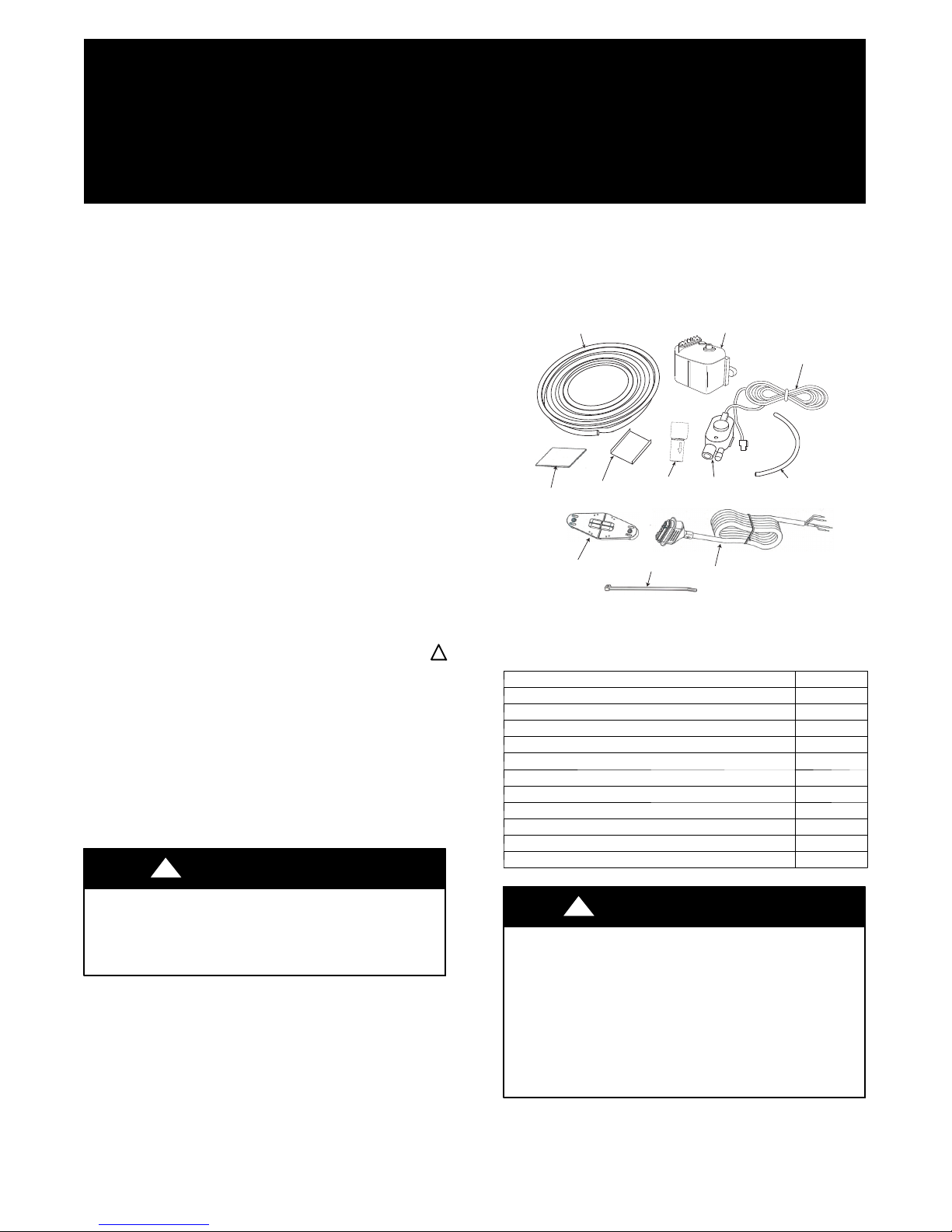

Refer to Fig. 1 and Table 1 for kit content.

NOTE: To make the installation easier, install the detection unit

assembly before installing the fan coil unit.

1. Unpack the contents of the condensate pump accessory

package. Attach the rubber adapter and transparent vent

tubing to the detection unit (see Fig. 6). Rubber adapter

may be cut to size if 5/8” connection is required. If 7/8”

connection to unit drain pipe is required, use rubber

adapter as shipped. Do not use a vent tube longer than

2.95” (75 mm). Slide the mounting bracket onto the bot-

tom of the detection unit. Uncoil the low voltage power

cord.

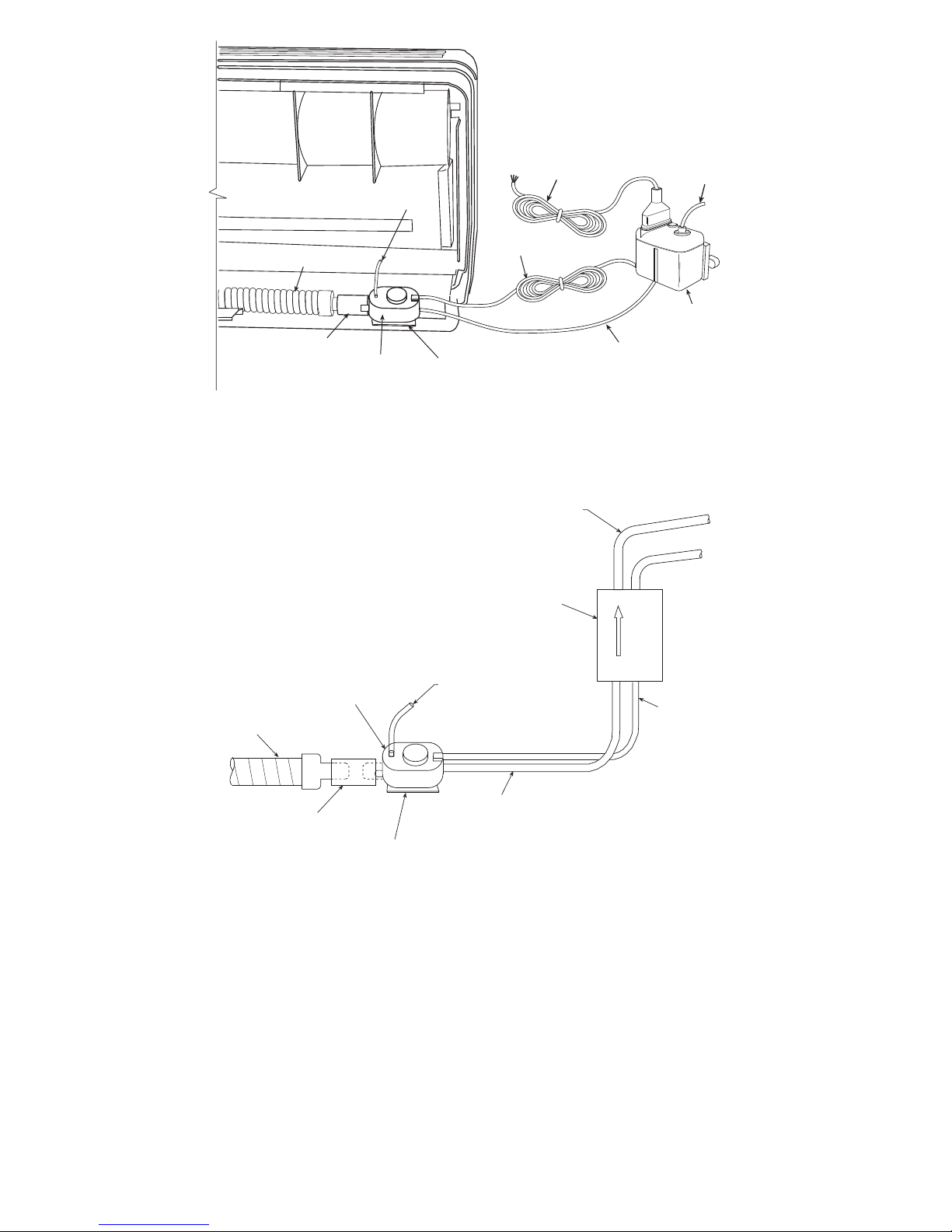

2. Remove the fan coil mounting bracket from the back of

the unit. Connect the detection unit with the rubber

adapter, to the condensate drain line (see Fig. 6).

3. Peel the adhesive cover on the back of the detection unit

mounting bracket and attach it to the inside of the unit ad-

jacent to the fan coil drain as shown in Fig. 6. Make sure

the detection is installed horizontally for proper opera-

tion of the float switch.

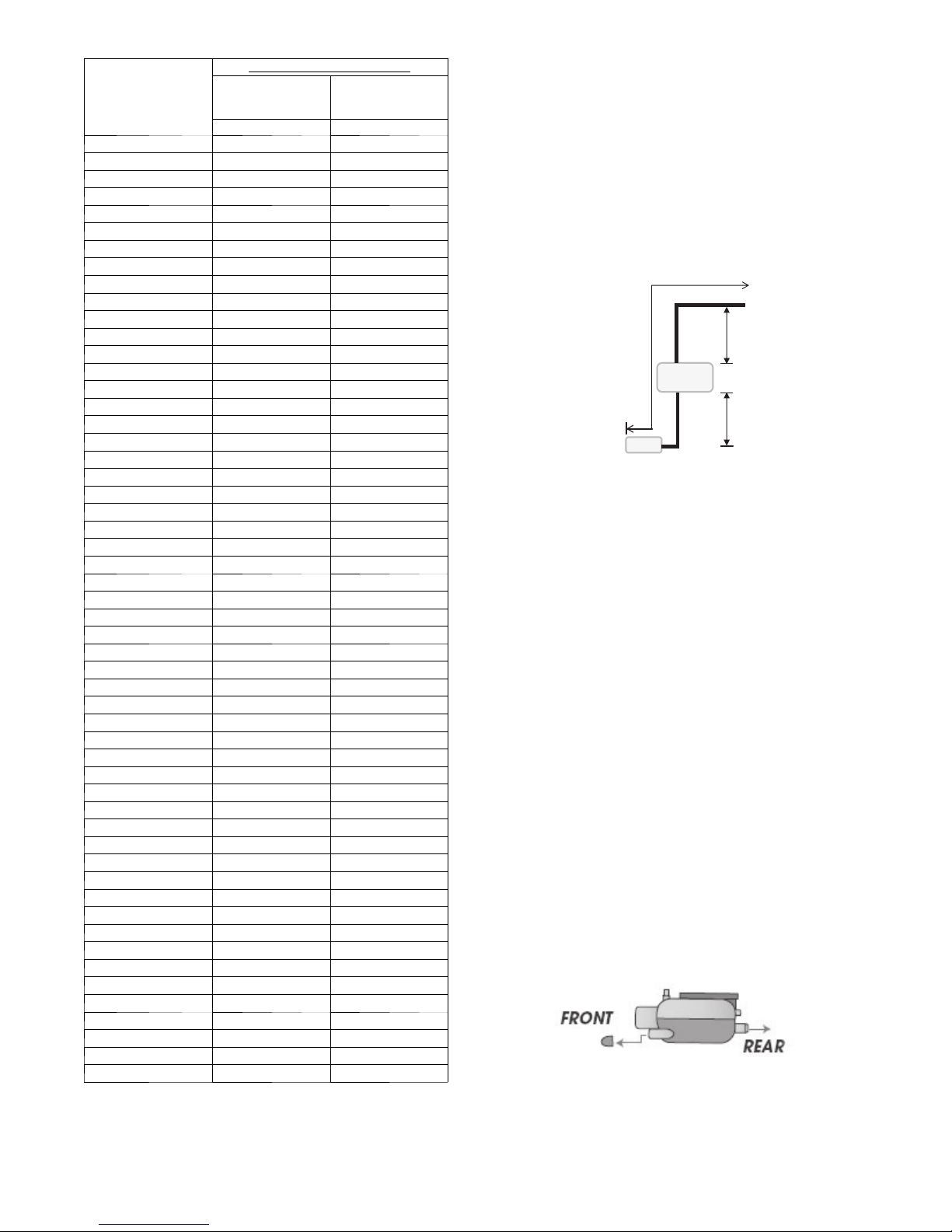

4. Attach one end of the transparent tubing to the detection

unit. The tube can be connected to either the front or the

rear as shown in Fig. 3. block the unused outlet with the

plug supplied.

A09398

Fig. 3 --- Detection Unit