Part 3. Basic knowledge about this freeze dryer

1. Thereare5workingstagesinthefreezedryingprocess.

Ittakesafreezedryer24‐30hourstofinishthecompleteprocessincluding:

Pre‐freeze,ColdTrapCooling,VacuumPumping,DryingandTemperaturekeeping.

Totalfreezedryingtime(24‐30hours)dependsonsugarcontents,oilcontents,water

contents,sizeofthematerials,androomtemperature.

If‐45Cdeepfreezerisavailable,pleaseuseittopre‐freezethematerialsforabout9

hourssothefreezedryercanskipthepre‐freezestage(setpre‐freezetime:1minute)

toreducefreezedryer'stotalworkingtimetoabout18hours(Coldtrapcooling

needstobestartedbeforethepre‐frozenmaterialsareloadedintothechamberto

coolthechambertolowtemperaturerequestedforthenextstage‐vacuumpumping)

2. Theworkingstageindicatorkeepsflashingineachstageallthetime.Thisflashingisnormalanddoesnotmeanany

alarm.

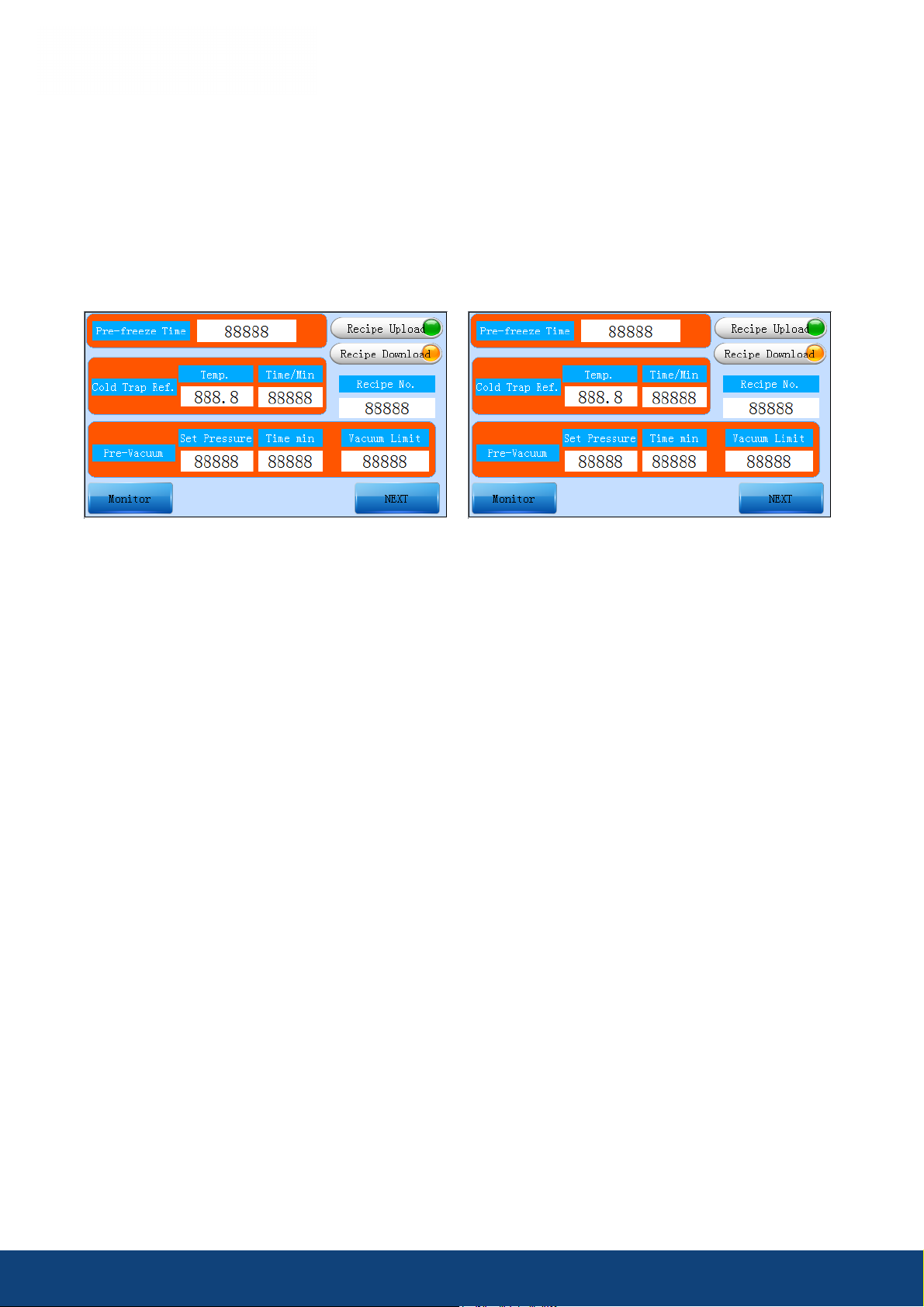

3. Thereare2controlmodesforthisfreezedryer:VacuumControlandProgramControl.

Bothmodessharethesamesettingsinthefirst3stages(pre‐freeze,coldtrapcoolingandpre‐vacuum)buthave

differentsettingsatdryingstage.

VacuumControlmode:Parametersatdryingstageispresetandtheuserisnotallowedtomodifyparameters.

ProgramControlmode:Parametersatdryingstageisnotpresetandtheuserisallowedtomodifyparameters

accordingtodifferentmaterials.

ProgramControlModeisrecommendedbecausethismodecanbeusedforallthematerialswhileVacuumControl

Modeisnotsuggestedforsomematerialssuchasmilkandflowers.

4. Aparametersettingchartisofferedbyusaccordingtoourtestsondifferentmaterials.Theusercantrytomodify

it afterthebestparametersettingisfoundaftersometrialrunning.

5. Afterstarted,thefreezedryerandvacuumpumpcanrunautomaticallyaccordingtothesetparameters.

6. ThevacuumpumpdoesNOTstartatthefirst2stages(pre‐freeze,coldtrapcooling).Itwillbestarted

automatically fromvacuumpumpingstageandwillkeeprunninginworkingstatusuntilendoffreezedrying

(exceptitisstopped bytheuser).

7. Afterstarted,thevacuumpumpwillinitially be a little noisy(about60‐70dB),

togetherwithwhitesmokedischargefromoutletofthevacuumpump.Thiswill

lastforafewminutes.Itisnormal.

Afterthat,noisewillbereducedandwhitesmokewilldisappear.

Itisnormalthatthevacuumpumpfeelshotallthetime.

8. Thereare3workingstatusdisplayedonthemainmenu:

NormalStatus VacuumAlarm PleaseRemoveMaterials

Referto8‐2:

Refertopoint9forsolution:

“HowtoEliminateVacuumAlarm”

Indicatingthefreezedryerisworking

ingoodcondition.