OPERATING TIPS AND TROUBLESHOOTING

Keep machine clean to ensure optimum performance. After each

use, lift off vacuum head and knock dust from filter. After one hour

of continuous use, lift out the Motorhead/Vacuum Head Assembly

and check the amount of dust accumulated in the unit. Remove the

dust bag if necessary and replace with a new one. We recommend

a soft brush to clean the filter. DO NOT USE A BLOW GUN.

Decrease in Vacuum Performance

1. Clean the filter thoroughly and as often as necessary. The

filter used inside is water resistant and washable. To prevent

damage, do not use high pressure or solvent to wash the filter.

2. If the filter (P/N 80459) should become damaged or badly

clogged and cannot be cleaned, replace with a new one.

3. Check all the vacuum lines for blockage or leakage.

Vacuum Stops During Use

1. This vacuum is equipped with a Electronic Thermal Protection

Device. If the vacuum stops and the red indicator light appears

ON, the unit has shut down as a result of increased

temperature. Once the unit has regained a temperature that is

allowable for operation the vacuum will resume operation.

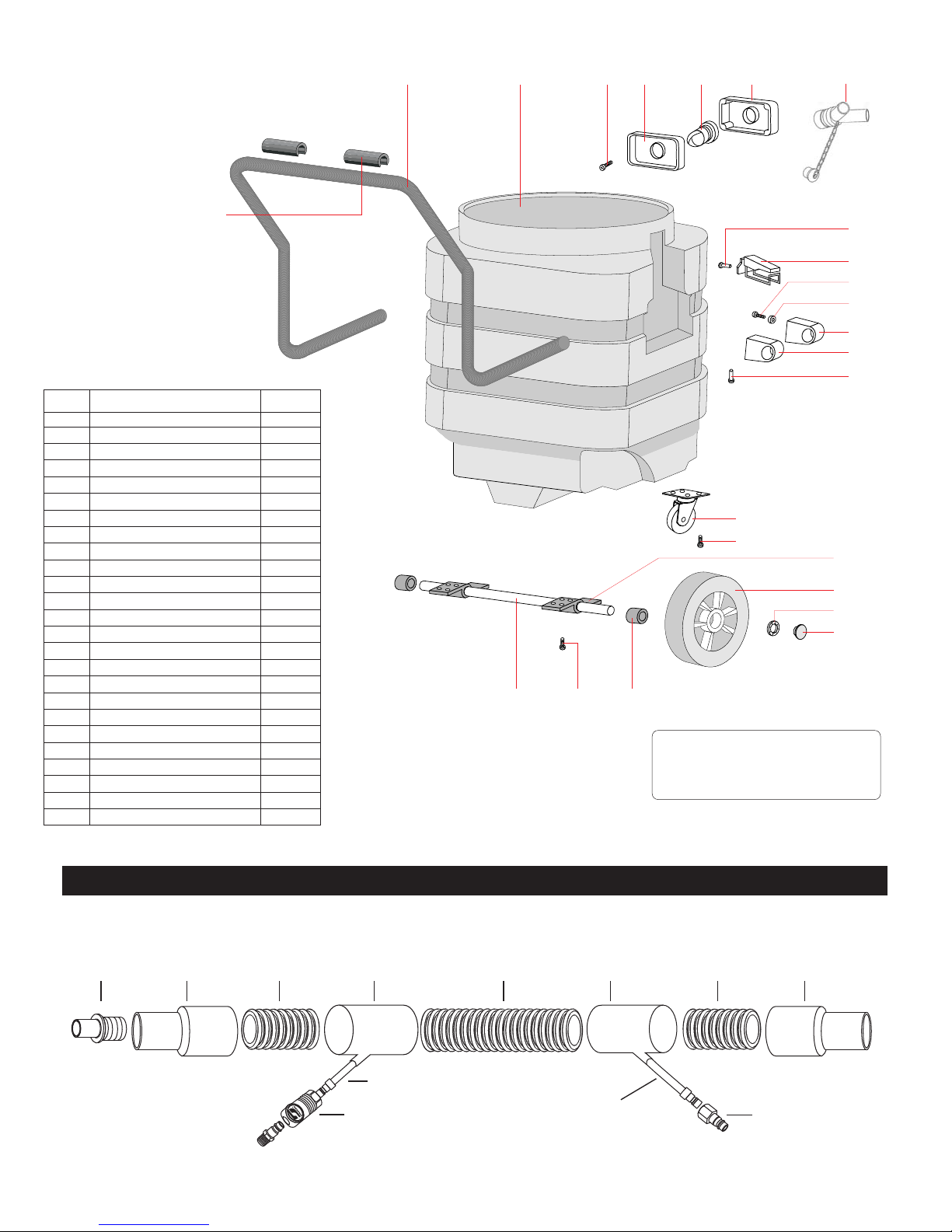

REMOVAL/INSTALLATION OF MOTORHEAD FROM MAIN ASSEMBLY

If the filter element becomes clogged or to clean the inner portions

of the drum (canister) the Motorhead Assembly must then be

removed to perform cleaning. When removal becomes necessary

for cleaning or other service, follow the procedures described

below.

Removal

1. Unplug the unit before attempting service or maintenance work.

2. Remove Top Lid by unlatching (2) hinges.

3. Use a conventional vacuum cleaner to clean entire inside of

Motorhead/Vacuum Head Assembly and drum (canister).

Upon completion of the service work, install top lid according to

the following procedure:

Installation

1. Place cleaned unit onto the drum (canister) and latch (2)

hinges to properly attach the lid. Unit is now ready for

operation.

TILT-N-CLEAN OPERATION INSTRUCTION

Unit has a Tilt-n-Clean feature to aid in overall functionality of the

work equipment and work environment:

1. Unplug the unit before attempting service or maintenance

work.

2. Unclamp and remove Motorhead/Vacuum Head Assembly.

Drum (canister) is now able to be tilted backwards and emptied.

Dispose of debris properly.

3. Or, Pull side release hinges away from the drum (canister)

and remove the entire drum (canister) from the trolley. With

drum (canister) removed dispose of debris properly.