E.H. Wachs EP 424 User manual

EP 424 End Prep Machine

User’s Manual

Copyright © 2016 E.H. Wachs.All rights reserved.

This manual may not be reproduced in whole or in part

without the written consent of E.H. Wachs.

E.H. Wachs

600 Knightsbridge Parkway

Lincolnshire, IL 60069

www.ehwachs.com

E.H. Wachs Part No. 81-MAN-00

Rev. C, January 2016

Revision History:

Original June 2010

Rev.A April 2013

Rev. B May 2014

EU DECLARATION OF CONFORMITY

WITH

COUNCIL DIRECTIVE 2006/42/EC

Issue Details: DATE:

1/1/2011 Place:

E.H.Wachs, Lincolnshire, IL USA

Directives: Machinery Safety Directive 2006/42/EC

Conforming Machinery: End Prep and Flange Facing Machines:

Model TSE, FSE, and TFS Tube and Fitting Squaring Machines.

Model SDB 103, SDB 206, and SDB 412 Small Diameter

Bevelers; Model FF 206; FF 313, and FF 424 Flange Facers.

Model SB, LB, and MB Plus Boiler Tube Bevelers.

EP 424 End Prep/Flange Facer.

Model Number: 18-000-XX (TSE, FSE); 19-000-XX (TFS); 16-000-XX (SDB-

103/FF-206); 56-000-XX (SDB-206/FF313); 66-000-XX (SDB-

412/FF-424); 70-000-XX (SB); 71-000-XX (MB Plus); 72-000-XX

(LB); 81-000-XX (EP 424)

Serial Number:

Manufacturer: E.H. Wachs

600 Knightsbridge Parkway

Lincolnshire

IL 60069

USA

Responsible Representative: Orbitalum Tools GmbH

Josef-Schüttler-Str. 17, 78224 Singen

Germany

Tel. +49 (0) 7731 - 792 872

Fax +49 (0) 7731 - 792 566

Harmonised Standards &

Other Technical

Standards/Specifications

Applied or Referenced:

EN ISO 12100-1:2003 + A1:2009

EN ISO 12100-2:2003 + A1:2009

EN 60201-1:2006 (for electric machines)

EN ISO 13857:2008

EN 982:1996 + A1:2008 (E) (for hydrailic machines)

EN 983:1996 (for pneumatic machines)

EN 13732-1:2006

EN ISO 14121-1:2007

EN ISO 13850:2008 (for pneumatic machines)

Provisions with which

Conformity is Declared: Essential Health and Safety Requirements of Annex 1 of the

Machinery Directive

WeherebycertifythatthemachinerydescrivedaboveconformstotheprovisionsofCouncilDirective

2006/42/EContheapproximationofthelawsoftheMemberStatesrelatingtothesafetyofmachinery.

Signed:

Signatory: Pete Mullally

Quality Manager

E.H. Wachs

Table of Contents

E.H. Wachs Part No. 81-MAN-00, Rev. C i

Table of Contents

Chapter1: AboutThis Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Purpose ofThis Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

How to Use The Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Symbols andWarnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Manual Updates and Revision Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter2: Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operator Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Protective Equipment Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter3: Introduction tothe Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Overview of the EP424. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Form-Tool Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Single-Point Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

EP424 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Drive Motors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Dimensions andWeights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operating Envelope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Standard Configuration withAir Drive (81-000-01) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Standard Config. with Hydraulic Drive (81-000-02). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Single-Point Configuration withAir Drive (81-000-03) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Single-Point Config. with Hydraulic Drive (81-000-04). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Single-Point with Speed Prep,Air Drive (81-000-05). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Single-Point with Speed Prep, Hyd. Drive (81-000-06) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Standard Mandrel Dimensions/Leg Chart (81-303-00). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Rotating HeadAssembly (81-304-00). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Independent Chuck Dims/Leg Chart (81-305-00). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Single-Point Slide (81-306-00) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter4: Assembly, Disassembly, andStorage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Storage Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Chapter5: Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Mounting the Mandrel on the Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Mounting the Universal (Standard) Mandrel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

EP424 End Prep Machine

ii Part No. 81-MAN-00, Rev. C E.H. Wachs

Mounting the Independent Chuck Mandrel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Using the Drive Motors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Mounting and Operating theAir Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Mounting and Operating the Hydraulic Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

FormTool Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Planning the Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Operating Envelope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

SelectingTooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Adjusting theTool Holder Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Setting Up and Mounting the EP424. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Assembling the Machine Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Removing the Machine from theWorkpiece. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Single Point Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Installing the Single-Point Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Planning the Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Operating Envelope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

SelectingTool Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Beveling O.D. Set-Back . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Setting Up and Mounting the EP424. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Assembling the Machine Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Using the Speed PrepAutofeed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Compound Bevel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Removing the Machine from theWorkpiece. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Removing the Single-Point Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Chapter6: Routine Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Main DriveAssembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

FeltWipers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Single-Point Slide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Mandrel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Drive Motor Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Chapter7: Service andRepair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Adjusting the Single-Point Slide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Tighten the Starwheel Stop Collar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Adding/Removing Gib Shims. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Adjust the Push Plate Set Screws. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Calibrating the Speed Prep Scale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Chapter8: Parts Listsand Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Standard Config.,Air Drive (81-000-01). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Standard Config., Hydraulic Drive (81-000-02) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Single-Point with Independent Chuck,Air Drive (81-000-03) . . . . . . . . . . . . . . . . . . . . . . . 100

Table of Contents

E.H. Wachs Part No. 81-MAN-00, Rev. C iii

Single-Point with Independent Chuck, Hydraulic Drive (81-000-04). . . . . . . . . . . . . . . . . . 101

Single-Point with Standard Mandrel,Air Drive (81-000-05) . . . . . . . . . . . . . . . . . . . . . . . . 102

Single-Point with Standard Mandrel,Air Drive (81-000-06) . . . . . . . . . . . . . . . . . . . . . . . . 103

Standard Config. with Electric DriveAdapter (81-000-07). . . . . . . . . . . . . . . . . . . . . . . . . . 104

Main DriveAssembly (81-300-00) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Rear FeedAssembly (81-301-00) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Speed PrepAuto Feed (81-302-00) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

EPD Electric DriveAdapter Kit (81-500-00) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Standard MandrelAssembly (81-303-00) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Rotating HeadAssembly (81-304-00). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Independent ChuckAssembly (81-305-00). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Single-Point SlideAssembly (81-306-00). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

TripAssembly (81-307-00). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Safety StopAssembly (81-316-00) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Hydraulic DriveAssembly (81-310-00) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Optional Remote-Operated Hydraulic DriveAssembly (81-310-01) . . . . . . . . . . . . . . . . . . 114

Air DriveAssembly (81-311-00). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Feed Lock (81-317-00) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Single-Point Holder Kit (81-702-00). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Chapter9: Accessories andSpareParts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Chapter10: Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Ordering Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Repair Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Return GoodsAddress. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

EP424 End Prep Machine

iv Part No. 81-MAN-00, Rev. C E.H. Wachs

Chapter 1, About This Manual

E.H. Wachs Part No. 81-MAN-00, Rev. C 1

Chapter1

About This Manual

PURPOSE OF THIS MANUAL

This manual explains how to operate and maintain the EP424 end prep machine. It includes

instructions for set-up, operation, and maintenance. It also contains parts lists, diagrams, and

service information to help you order replacement parts and perform user-serviceable repairs.

Before operating the EP424, you should read through this manual and become familiar with all

instructions.At a minimum, make sure you read and understand the following chapters:

• Chapter 1,About This Manual

• Chapter 2, Safety

• Chapter 3, Introduction to the Equipment

• Chapter 5, Operating Instructions

• Chapter 9,Accessories

If you will be performing service or repairs, make sure you read and understand these chapters:

• Chapter 1,About This Manual

• Chapter 4,Assembly and Disassembly

• Chapter 6, Routine Maintenance

• Chapter 7, Service and Repair.

You will also want to refer to Chapter 8, Parts Lists and Drawings.

EP 424 End Prep Machine

2 Part No. 81-MAN-00, Rev. C E.H. Wachs

HOW TO USE THE MANUAL

This manual is organized to help you quicklyfind the information you need. Each chapter de-

scribes a specific topic on using or maintaining your equipment.

Use these instructions to operate and maintain the equipment.

SYMBOLS AND WARNINGS

The following symbols are used throughout this manual to indicate special notes and warnings.

They appear in the outside column of the page, next to the section they refer to. Make sure you

understand what each symbol means, and follow all instructions for cautions and warnings.

Throughout this manual, refer to warnings, cautions, and notices with supplementary information.

WARNING

AWARNING alert with the safety alert symbol indicates a potentially hazardous situation that could

result in serious injury or death.

CAUTION

ACAUTION alert with the safety alert symbol indicates a potentially hazardous situation that could result

in minor or moderate injury.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

This is the equipment damage alert symbol. It is used to alert you to potential

equipment damage situations. Obey all messages that follow this symbol to

avoid damaging the equipment or workpiece on which it is operating.

CAUTION

ACAUTION alert with the damage alert symbol indicates a situation that will result in damage to the

equipment.

Chapter 1, About This Manual:

E.H. Wachs Part No. 81-MAN-00, Rev. C 3

IMPORTANT

An IMPORTANT alert with the damage alert symbol indicates a situation that may result in damage

to the equipment.

NOTE

This symbol indicates a user note. Notes provide additional information to supple-

ment the instructions, or tips for easier operation.

MANUAL UPDATES AND REVISION TRACKING

Occasionally, we will update manuals with improved operation or maintenance procedures, or

with corrections if necessary.When a manual is revised, we will update the revision history on the

title page.

Current versions of E.H. Wachs Company manuals are also available in PDF format. You can

You may have factory service or upgrades performed on the equipment. If this service changes any

technical data or operation and maintenance procedures, we will include a revised manual when

we return the equipment to you.

EP 424 End Prep Machine

4 Part No. 81-MAN-00, Rev. C E.H. Wachs

Chapter 2, Safety

E.H. Wachs Part No. 81-MAN-00, Rev. C 5

Chapter2

Safety

E.H. Wachs takes great pride in designing and manufacturing safe, high-quality products.We

make user safety a top priority in the design of all our products.

Read this chapter carefully before operating the EP424 end prep machine. It contains important

safety instructions and recommendations.

OPERATOR SAFETY

Follow these guidelines for safe operation of the equipment.

Look for this symbol throughout the manual. It indicates a personal injury haz-

ard.

•READTHE OPERATINGMANUAL. Make sure you understand all setup and operating instructions

before you begin.

•INSPECTMACHINEANDACCESSORIES.Before starting the machine, look for loose bolts or nuts,

leaking lubricant, rusted components, and any other physical conditions that may affect

operation. Properly maintaining the machine can greatly decrease the chances for injury.

•ALWAYSREADPLACARDSANDLABELS. Make sure all placards, labels, and stickers are clearly

legible and in good condition.You can purchase replacement labels from E.H. Wachs Compa-

ny.

•KEEPCLEAROFMOVINGPARTS.Keep hands, arms, and fingers clear of all rotating or moving

parts.Always turn machine off before doing any adjustments or service.

•SECURELOOSECLOTHINGANDJEWELRY.Secure or remove loose-fitting clothing and jewelry,

and securely bind long hair, to prevent them from getting caught in moving parts of the ma-

chine.

•KEEPWORKAREACLEAR. Keep all clutter and nonessential materials out of the work area. Only

people directly involved with the work being performed should have access to the area.

EP 424 End Prep Machine

6 Part No. 81-MAN-00, Rev. C E.H. Wachs

Safety Symbols

This icon is displayed with any safety alert that indicates a personal injury hazard.

WARNING

This safety alert indicates a potentially hazardous situation that, if not avoided, could result in

death or serious injury.

CAUTION

This safety alert, with the personal injury hazard symbol, indicates a potentially hazardous situation that,

if not avoided, could result in minor or moderate injury.

Protective Equipment Requirements

WARNING

Always wear impact resistant eye protection

while operating or working near this equipment.

For additional information on eye and face protection, refer to Federal OSHAregulations, 29 Code

of Federal Regulations, Section 1910.133., Eye and Face Protection andAmerican National

Standards Institute,ANSI Z87.1, Occupational and Educational Eye and Face Protection. Z87.1 is

available from theAmerican National Standards Institute, Inc., 1430 Broadway, NewYork, NY

10018.

CAUTION

Personal hearing protection is recommended

when operating or working near this tool.

Hearing protectors are required in high noise areas, 85 dBAor greater. The operation of other tools

and equipment in the area, reflective surfaces, process noises, and resonant structures can increase

the noise level in the area. For additional information on hearing protection, refer to Federal OSHA

regulations, 29 Code of Federal Regulations, Section 1910.95, Occupational Noise Exposure and

ANSI S12.6 Hearing Protectors.

Chapter 2, Safety: Safety Labels

E.H. Wachs Part No. 81-MAN-00, Rev. C 7

SAFETY LABELS

The following safety labels are on the EP424 machine. If a label is lost or unreadable, order and

attach a replacement. See ordering instructions in Chapter 10.

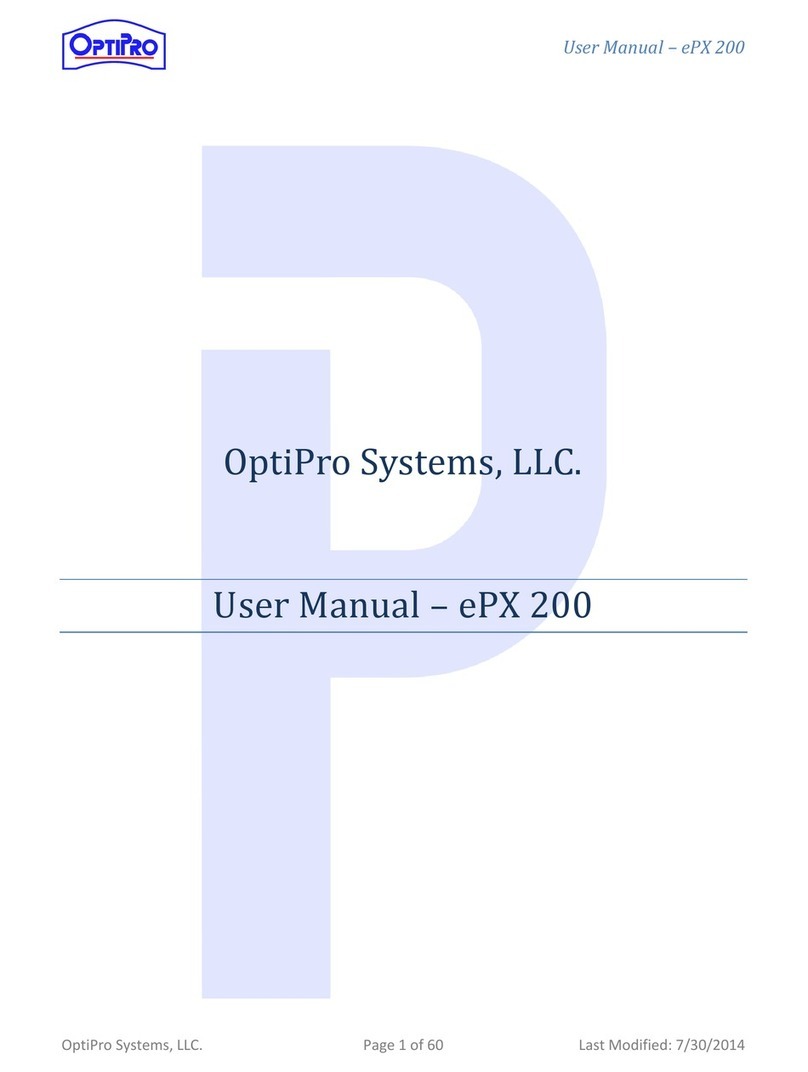

Figure 2-1. Crush hazard safety label (part no. 81-165-00).

Figure 2-2. Crush and cut hazard safety label (part no. 90-401-04).

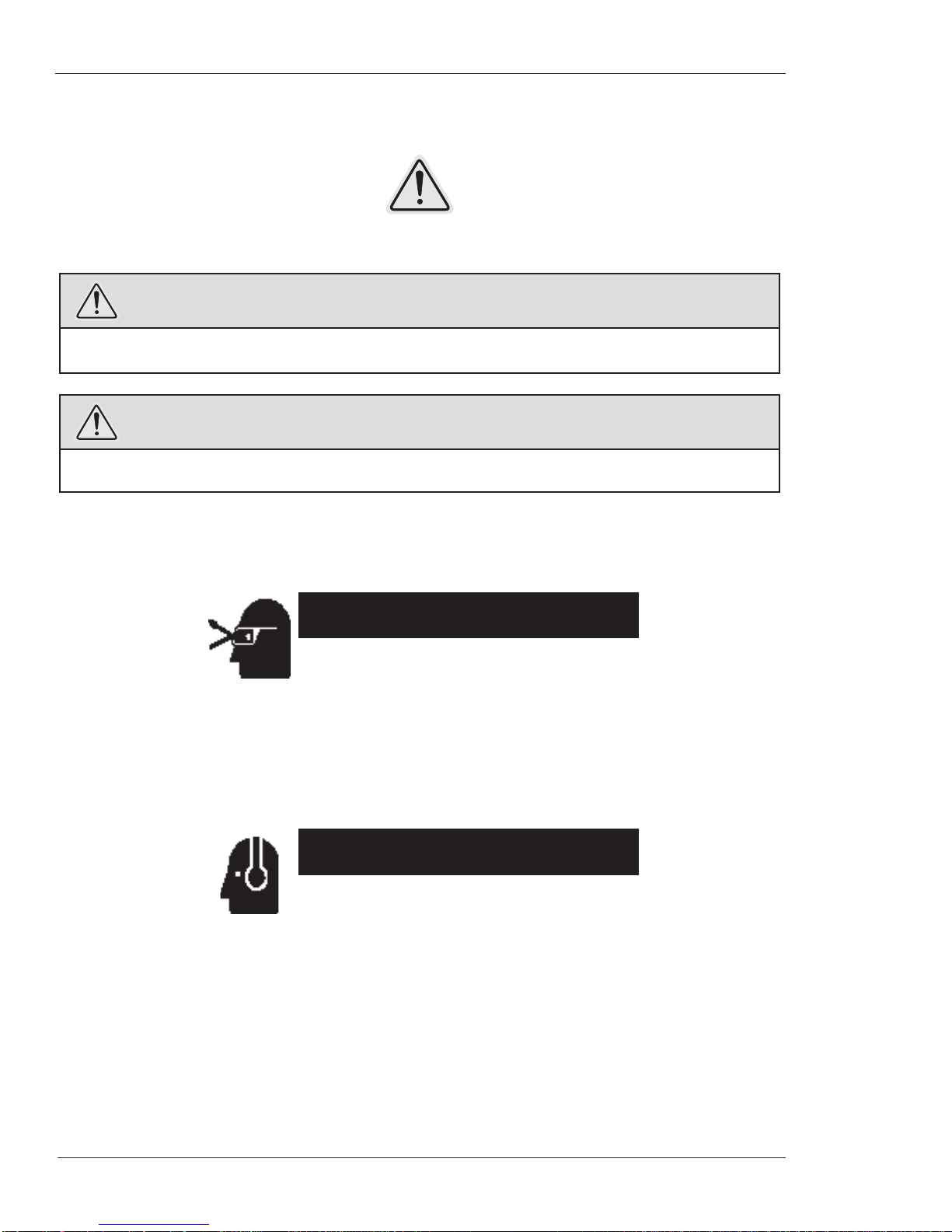

Figure 2-3. Loud noise hazard safety label, provided with air drive configurations (part no.

90-401-03).

Figure 2-4. Eye injury hazard label, provided with hydraulic drive configurations (part no.

90-401-01).

EP 424 End Prep Machine

8 Part No. 81-MAN-00, Rev. C E.H. Wachs

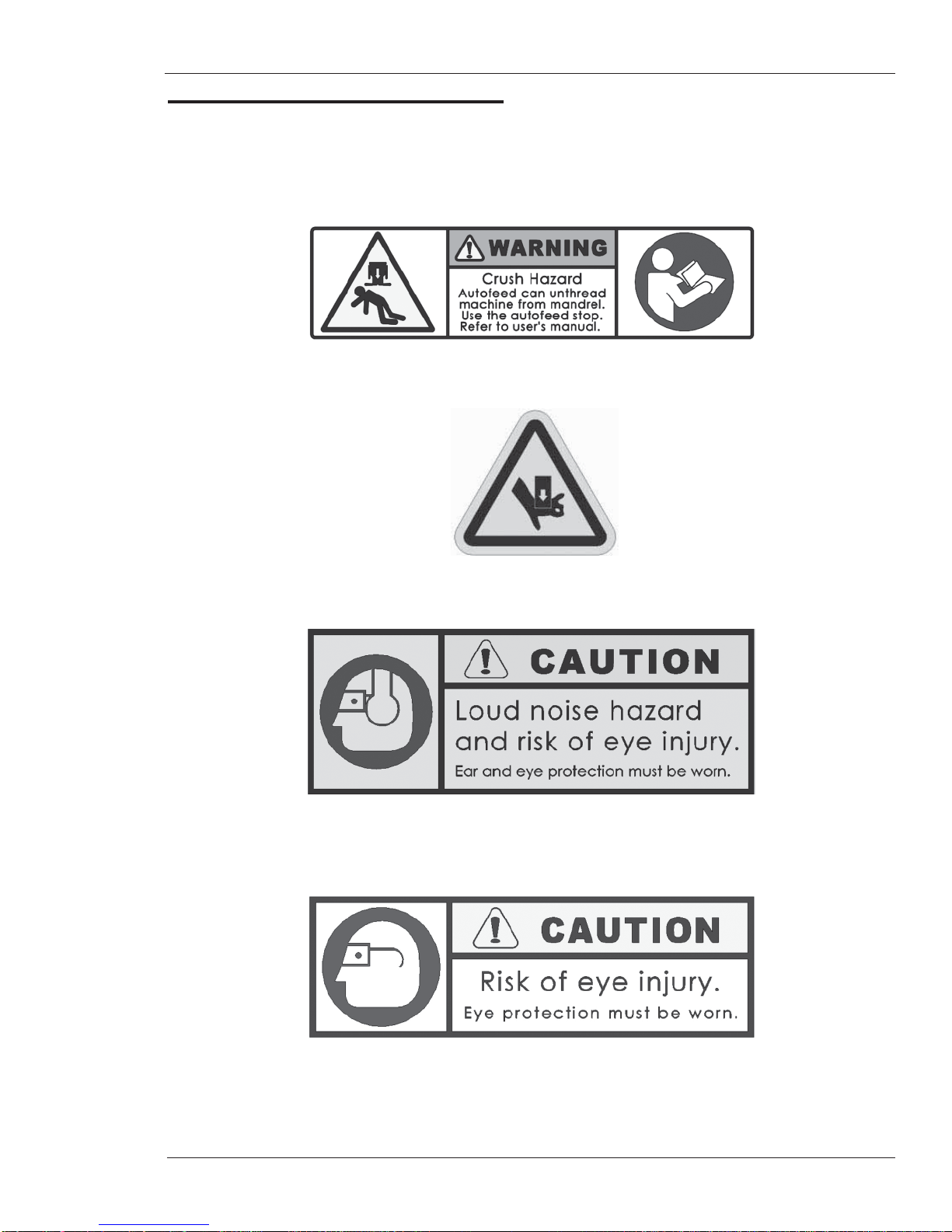

Figure 2-5. Compressed air pressure safety label (part no. 90-401-02).

Figure 2-6. Hydraulic pressure safety label (part no. 90-402-01).

Chapter 3, Introduction to the Equipment

E.H. Wachs Part No. 81-MAN-00, Rev. C 9

Chapter3

Introduction to the Equipment

OVERVIEW OF THE EP 424

The EP424 is an I.D. (inside diameter) mounted end prep machine for facing, beveling, counter-

boring, and J-prepping pipes and flanges. It can be used for pipes from 4-24 inches O.D., with wall

thicknesses up to 1.6” (41 mm) using form tools, or 6.5” (165 mm) with single-point operation.

The EP424 is provided in 4 configurations:

• Form tool machine with air drive, part no. 81-000-01

• Form tool machine with hydraulic drive, part no. 81-000-02

• Single-point machine with air drive, part no. 81-000-03

• Single-point machine with hydraulic drive, part no. 81-000-04.

Form tool operation is quick to set up and easy to perform on pipe walls up to schedule 160

(1.6” on 16” pipe). For heavier wall pipe up to 6.5” wall thickness, the single-point kit allows you

to perform any bevel profile.

EP 424 End Prep Machine

10 Part No. 81-MAN-00, Rev. C E.H. Wachs

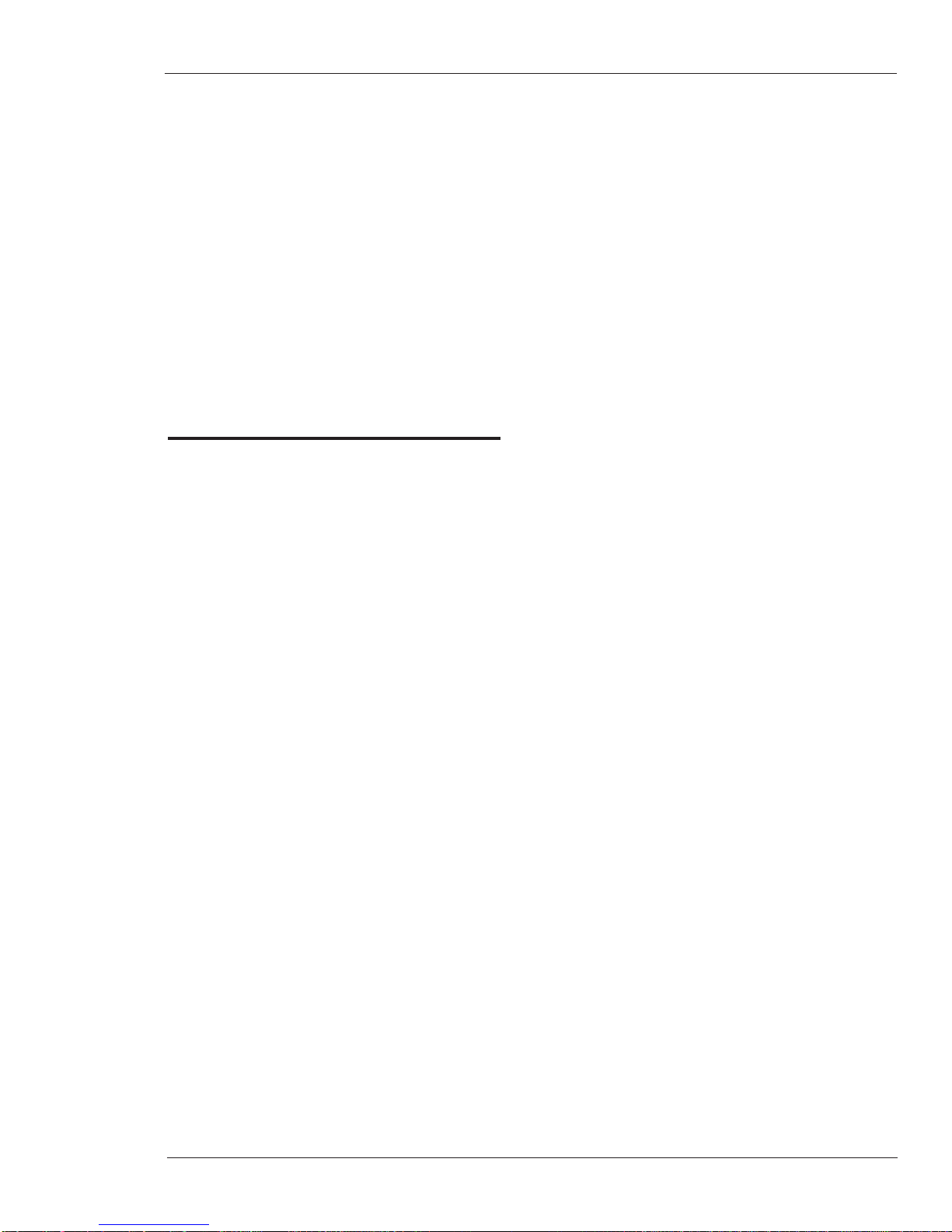

Form-Tool Configuration

The form tool configurations have a rotating tool head with 3 tool holders, for performing up to 3

simultaneous operations. Tooling is available for facing, single-angle beveling, compound bevel-

ing, and counterboring.

The form tool configuration will perform end prepping (facing, beveling, J-prepping, and counter-

boring), with the operator manually feeding the tool head.

Figure 3-1. The photo shows the form tool configuration of the machine with the standard

self-centering mandrel.

Single-Point Configuration

The single-point machine is provided with a tool slide that feeds the tool radially across the face of

the pipe or flange. The slide is driven by a starwheel that engages trips on a ring mounted to the

machine housing. Bevels are performed using the Speed Prep auto-feed system, which automati-

cally feeds the machine axially as it cuts.

The single-point machine will perform facing or beveling of thick-walled pipes and flanges.

Chapter 3, Introduction to the Equipment: Overview of the EP424

E.H. Wachs Part No. 81-MAN-00, Rev. C 11

Figure 3-2. The photo shows the single-point configuration of the EP 424.

EP 424 Components

The following components are provided with the form tool configuration of the EP424:

• main drive assembly with lifting attachments

• feed assembly

• rotating tool head

• standard self-centering mandrel

• drive motor (air or hydraulic)

• hand tool set

EP 424 End Prep Machine

12 Part No. 81-MAN-00, Rev. C E.H. Wachs

The single-point configuration includes the following additional components:

• single-point slide

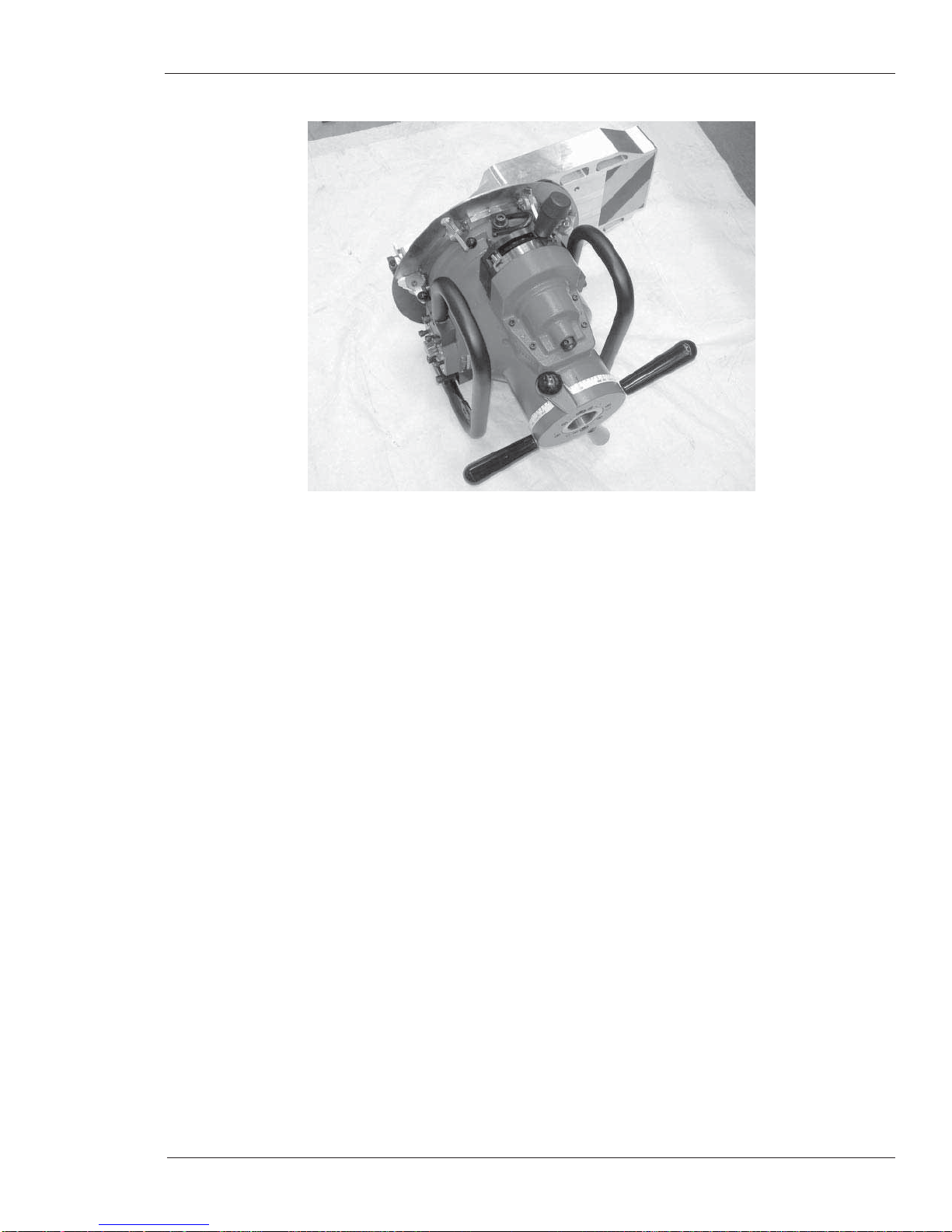

StarwheelFeed screws

Male tool slide

Tool holder

Feed gauge

Figure 3-3. The single-point slide feeds the tool radially across the pipe face. It is driven

along a feed screw by a starwheel.

• radial feed trip assembly

Figure 3-4. The photo shows the trip assembly mounted on the main drive housing.

Chapter 3, Introduction to the Equipment: Overview of the EP424

E.H. Wachs Part No. 81-MAN-00, Rev. C 13

• Speed Prep autofeed module

Speed Prep

module

Figure 3-5. The speed prep module is installed on the main drive to operate the feed mecha-

nism for single-point beveling.

WARNING

The Speed Prep autofeed can feed the machine until it comes off the mandrel. Crushing or other serious

injuries could occur. Use the autofeed stop plate (81-316-00) to keep the machine from feeding too far.

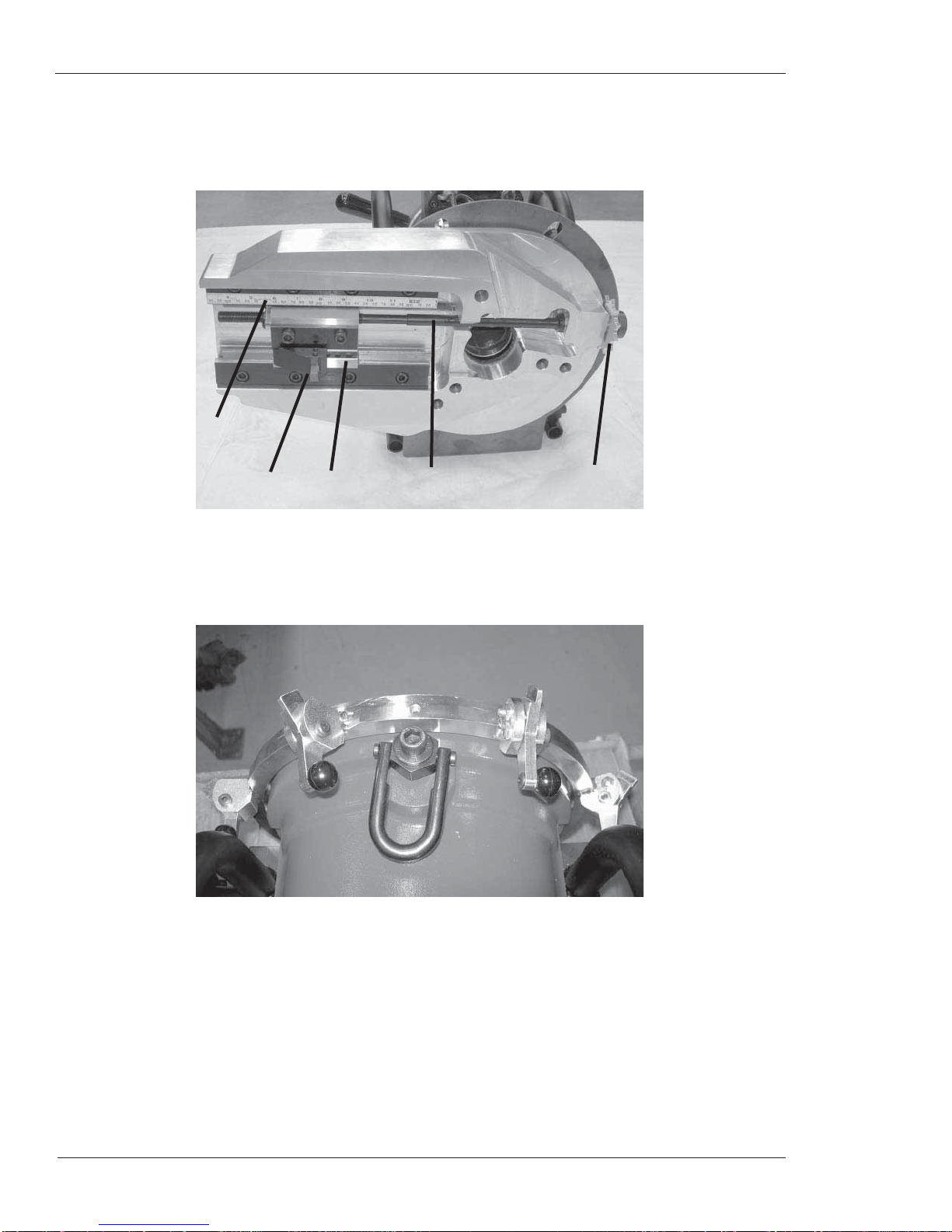

• independent chuck mandrel

Figure 3-6. The independent chuck mandrel allows you to center the machine on the O.D. of

the pipe.

EP 424 End Prep Machine

14 Part No. 81-MAN-00, Rev. C E.H. Wachs

• extension leg kit for standard mandrel

Figure 3-7. Two sets of extension legs allow the standard mandrel to be mounted in pipes up

to 23.64” I.D.

• dial indicator assembly

Figure 3-8. The dial indicator is provided for centering the independent chuck in the pipe.

Table of contents