E-one GCM-X User manual

Generator Condition Monitor (GCM-X)

Installation and Operation Manual

GA0353P02 Rev. B

UTILITY SYSTEMS

1GA0383P02 Rev. C

Contents

Specifications....................................................................................................................................... 5

Application .......................................................................................................................................... 6

Principle of Operation .................................................................................................................... 6

System Description ............................................................................................................................. 7

System Electronics .......................................................................................................................... 7

Display Panel ................................................................................................................................. 7

Input/Output Board ......................................................................................................................... 7

Installation........................................................................................................................................... 8

Mounting......................................................................................................................................... 8

System Design Considerations ........................................................................................................... 9

Transit Time Calculations ................................................................................................................ 10

Sampling System Components ........................................................................................................ 11

Electrical Connections ...................................................................................................................... 12

Contacts ........................................................................................................................................ 12

Signals .......................................................................................................................................... 12

System Operation ............................................................................................................................. 13

GCM-A Initial Startup .................................................................................................................. 13

Typical Responses to GCM-A Warning & Alarm Indications ..................................................... 14

GCM-A Initialization ....................................................................................................................... 16

GCM-A Menu Displays .................................................................................................................... 17

Navigating the LCD Display ........................................................................................................ 17

LCD Display Menu — Two Modes of Operation ......................................................................... 17

Menu Profile ................................................................................................................................. 17

Menu Navigation Tutorial ................................................................................................................ 18

Activating the Menu ...................................................................................................................... 18

Navigating the Menu in Scrolling Mode (GCM-A default) .......................................................... 18

Disabling Scrolling Mode ............................................................................................................. 18

Navigating the Menu in Non-Scrolling Mode ............................................................................... 18

Function (FN) Menu ..................................................................................................................... 19

Setup Menu ................................................................................................................................... 19

Test Menu ...................................................................................................................................... 20

View Menu .................................................................................................................................... 21

2

GA0383P02 Rev. C

Log Menu ...................................................................................................................................... 22

Procedures ......................................................................................................................................... 23

Draining the Humidifier ............................................................................................................... 23

Adjusting the Ambient Airflow...................................................................................................... 23

Adjusting the Generator Airflow .................................................................................................. 24

Adjusting the Cloud Chamber Airflow ......................................................................................... 25

Setting the Ambient Gain .............................................................................................................. 25

Setting the Ambient Warning Level...............................................................................................25

Setting the Ambient Alarm Level .................................................................................................. 25

Setting the Generator Gain .......................................................................................................... 26

Setting the Generator Warning Level ........................................................................................... 26

Setting the Generator Alarm Level ...............................................................................................26

Setting the Differential Warning Level ......................................................................................... 26

Setting the Differential Alarm Level ............................................................................................. 27

About the Faults Log .................................................................................................................... 27

About the Power Log .................................................................................................................... 28

Modes of Operation .......................................................................................................................... 29

Startup .......................................................................................................................................... 29

Startup Problems .......................................................................................................................... 29

Alternating Operation .................................................................................................................. 30

Ambient Only Operation ............................................................................................................... 30

Generator Only Operation ........................................................................................................... 31

Troubleshooting ................................................................................................................................ 32

Remote Access ................................................................................................................................... 34

Requirements ................................................................................................................................ 34

GCM-A Modem Installation ......................................................................................................... 34

Using a Custom Modem String.....................................................................................................34

Changing the Modem String ......................................................................................................... 35

Establishing a Direct Connection................................................................................................. 35

Establishing a Dialup Connection................................................................................................36

Viewing Output History ................................................................................................................ 36

Configuring the GCM-A for Historical Data Collection ............................................................. 36

Maintenance ...................................................................................................................................... 38

Periodic Maintenance................................................................................................................... 38

Daily ............................................................................................................................................. 38

Weekly ........................................................................................................................................... 38

Monthly ......................................................................................................................................... 38

Quarterly ...................................................................................................................................... 38

Annually ........................................................................................................................................ 38

3GA0383P02 Rev. C

Figures

Figure 1 - System Overview .............................................................................................................................. 39

Figure 2 - GCM-A Outline ................................................................................................................................ 40

Figure 3 - GCM-A Mounting ............................................................................................................................ 41

Figure 4 - Customer Interface Wiring ............................................................................................................... 42

Figure 5 - Closed Circuit “H” Probe ................................................................................................................. 43

Figure 6 - Closed Circuit “U” Probe ................................................................................................................. 44

Figure 7 - Open Circuit “Sample Heads” .......................................................................................................... 45

Figure 8 - Open Circuit “Probes” ...................................................................................................................... 46

Figure 9 - Sampling System, 3/8” Typical (PVC) ............................................................................................. 47

Figure 10 - Sampling system, 1/2” Typical (PVC) ............................................................................................ 48

Figure 11 - Sampling System, 1/2” Flange Configuration ................................................................................ 49

Figure 12 - Zone Manifold ................................................................................................................................ 50

Figure 13 - Sample Head ................................................................................................................................... 51

Figure 14 - Sample Probe .................................................................................................................................. 52

Figure 15 - Zone Manifold Flow, DP mm Water ............................................................................................... 53

Figure 16 - Particle Concentration .................................................................................................................... 54

Figure 17 - Control Panel Detail ....................................................................................................................... 55

Figure 18 - Manifold DP Gage .......................................................................................................................... 56

4

GA0383P02 Rev. C

GENERATOR CONDITION MONITOR (GCM-A)

IMPORTANT INFORMATION

THIS EQUIPMENT OPERATES AT VOLTAGE LEVELS THAT CAN BE HAZARDOUS TO

PERSONNEL. THE SECTION ABOUT SAFETY CONSIDERATIONS SHOULD BE READ

BEFORE INSTALLING OR SERVICING.

THESE INSTRUCTIONS DO NOT PURPORT TO COVER ALL DETAILS OR VARIATIONS

IN EQUIPMENT NOR TO PROVIDE FOR EVERY POSSIBLE CONTINGENCY TO BE

MET IN CONNECTION WITH INSTALLATION, OPERATION OR MAINTENANCE.

SHOULD FURTHER INFORMATION BE DESIRED, OR SHOULD PARTICULAR

PROBLEMS ARISE THAT ARE NOT COVERED SUFFICIENTLY FOR THE

PURCHASER’S PURPOSES, THE MATTER SHOULD BE REFERRED TO

ENVIRONMENT ONE CORPORATION AT +1 518 346 6161 OR WWW.EONE.COM/

DETECTION.

SITE MANAGEMENT IS RESPONSIBLE FOR ASSURING THAT ALL PERSONNEL

WORKING WITH THIS SYSTEM ARE ADEQUATELY TRAINED IN SAFETY

CONSIDERATIONS AND THAT THEY HAVE RECEIVED THE NECESSARY TRAINING TO

PROPERLY OPERATE THE EQUIPMENT.

GENERATOR CONDITION MONITOR (GCM-A)

SAFETY CONSIDERATION

THE SYSTEM ELECTRONICS ENCLOSURE CONTAINS 115 AND/OR 230 VOLTS AC.

THIS VOLTAGE APPEARS AT THE AC POWER STRIP AND VARIOUS OTHER POINTS.

ALL ELECTRICAL CONNECTIONS TO THE SYSTEM ELECTRONICS SHOULD BE

TESTED AND VERIFIED TO BE CORRECT.

ALL WIRING MUST BE IN ACCORDANCE WITH LOCAL CODES AND PROFESSIONAL

PRACTICE.

USE OF THIS EQUIPMENT IN A MANNER NOT SPECIFIED BY ENVIRONMENT ONE

CORPORATION IS STRICTLY PROHIBITED.

5GA0383P02 Rev. C

Specifications

Measurement Characteristics

Detection principle Submicron particle detector

Air Flow Rate Adjusted by Zone Manifold, nominal 14 LPM

Readout (bar graph) Ambient Air 0% to 100% of scale

Generator Air 0% to 100% of scale

Electrical Characteristics

Power Input, grounded power cable 115/230 VAC, 50/60 Hz

Output Relays, general purpose

Ambient Alarm, Generator Alarm,

Differential Alarm, Common Warning,

System Trouble, Flow Trouble 120 VAC/28VDC / 3.0 A

Output Signal (4-20 mA)

Ambient Air 0% to 100% of scale

Generator Air 0% to 100% of scale

Mechanical Characteristics

Dimensions, overall 24” H x 22” W x 9 1/8” D*

(610 mm x 559 mm x 232** mm)

Weight, approximate 88 lbs. (40 kg)

Connectors, gas inlet 3/8” NPT, female

Temperature, maximum 32-122 F (0-50 C)

Area Classification CE, Non Hazardous

Relative Humidity 0-95%

Controls 5-key membrane switch keypad with liquid

crystal display

* 8”/203 mm for GD0080G02

** 10”/254 mm for GD0080G01

6

GA0383P02 Rev. C

Application

The Generator Condition Monitor for air-cooled machines (GCM-A) is a sensitive real-time

instrument designed to provide early warning indication of overheating (or arcing) in air-

cooled generators before extensive damage can occur. Tests conducted on operating air-

cooled generators have shown that the GCM-A can detect thermal decomposition of small

amounts of insulating materials.

Thermal decomposition of organic materials such as epoxy paint, core lamination enamel or

other insulating materials used in the generator results in the production of a large number

of small particles. The onset of particle production, as the material is heated, occurs at a

temperature characteristic of the material (thermal particulation point) and its surrounding

atmosphere. Below this temperature, no particles are created, yet once the critical

temperature is reached (thermal particulation point – TPP), millions of submicron particles

are generated each second for every square centimeter of surface area.

The GCM-A features:

·Microprocessor-based electronics

·Self-diagnostics

·Output indication

·Trouble indication

·Allowance for remote control/display and communication

Principle of Operation

A basic understanding of the GCM-A is necessary to properly utilize the information that the

instrument provides.

Particle detection is by means of a detector utilizing the condensation nuclei principle (cloud

chamber).

In operation, an air sample is delivered to the detector by means of a centrifugal blower

connected to two sets of sampling lines; one line is dedicated to the ambient air and the

second is dedicated to the generator’s cooling circuit. A portion of these air samples is first

diverted into a humidifier and humidified to approximately 100% relative humidity, then

directed to the cloud chamber where it is subjected to a rapid vacuum expansion. The effect

of the vacuum is to cool the air sample and cause water droplets to condense onto particles

that may be present in the air sample.

It is known that particles smaller than the wavelength of visible light occur spontaneously as

material is heated, and in numbers far above those present in a normal ambient

environment. As a result, thermally generated particles cause many droplets to form a cloud

which is then detected by the optical system of the cloud chamber.

7GA0383P02 Rev. C

System Description

The GCM-A is primarily designed for use on air-cooled generators, although application to

other air-cooled machines is possible. Its main purpose is to provide early warning and

detection of overheating (or arcing) in these machines.

The major components of the GCM-A are the System Electronics and the sampling system.

System Electronics

The System Electronics consist of one display board, one controller board, one input/output

board, two airflow metering boards, one power supply, one vacuum pump, one cloud

chamber, one blower fan and one sampling manifold.

The System Electronics provide calibration, mode selection, alarm contacts, data logging,

system inputs/outputs and diagnostics.

Fail-safe operation of the GCM-A is assured by:

• On power-up the GCM-A must execute and pass qualifying self tests. Failure in any test

results in the suspension of operation and the annunciation of the condition causing the

failure.

• Following power-up and/or system reset, the GCM-A is continuously supervised by an

independent watchdog monitor that serves to reset it should its operation become

erratic.

• The GCM-A is completely self-supervised and continuously checks itself for legal

processor functioning, proper vacuum levels, internal voltages, communication accuracy,

integrity of cabling and relay operation. Any faults are immediately annunciated.

Display Panel

The Control/Display Panel provides control of all functions of the GCM-A as well as

complete annunciation of GCM-A’s status (Figure 17). Functions are accessed by means of

a four-button membrane-switch keypad and 20-character Liquid Crystal Display (LCD).

Generally, pressing the Fn (Function) key causes the LCD to continuously scroll the names

of the available functions. A function may then be accessed by pressing the Enter key when

the function name appears. See “GCM-A Menu Displays” for more information.

The Display Panel provides Light Emitting Diodes (LED’s) to annunciate GCM-A status; they

indicate Warning, Alarm and Trouble conditions. A green LED indicates AC Power.

Since all configuration constants are stored in non-volatile memory, these values will not be

lost should the system be initialized, or should it lose, then regain, AC power.

Input/Output Board

The Input/Output board assembly has terminal strips where all customer connections to the

relay and signal outputs are made. Wire access is provided by the three knockouts at the

top and/or bottom of the Enclosure.

8

GA0383P02 Rev. C

Installation

These instructions provide details to facilitate the equipment installation.

Mounting

The GCM-A (GD0080G01) should be installed indoors. If outdoor installation is necessary, a

protective enclosure should be considered and discussed with Environment One. Locate the

GCM-A out of direct sunlight to prevent the interior ambient temperature from exceeding

50 C (122 F). If a protective enclosure is used, it should also be ventilated.

A GCM-A may be supplied with a protective enclosure. Installation of this variation

(GD0080G02) system begins with installation of the exterior enclosure. This enclosure

should be mounted in accordance with Figure 3.

Please note that both the exterior enclosure and the GCM-A cabinet should be securely

attached to the mounting surface. Securing the GCM-A cabinet only to the exterior

enclosure is not recommended.

9GA0383P02 Rev. C

System Design Considerations

The GCM-A system consists of the detector unit (the GCM-A itself) and an associated air

sampling system. When designing a system for a particular application, one needs to

consider:

a) The configuration of the generator’s cooling system. In particular, it is important to

know whether the application is a single pass (open) or enclosed (closed) cooling circuit.

This will play a major role in the sampling system design layout. A cooling system

schematic and sectional views of the generator are valuable to this process and should

be provided to Environment One.

b) The mounting location of the GCM-A cabinet. The particular location of the GCM-A

cabinet will play a role in the sampling system design layout and electrical connections

and will also assist in identifying key mechanical installation considerations. For

example, if the GCM-A is to be mounted near or on the generator’s exterior case, the

generator OEM may need to be contacted for information, approval and/or instruction.

Consideration of these and other mechanical factors will facilitate installation.

c) The distance between the GCM-A cabinet and the farthest point the sampling

system will reach. This information is key to the transit time analysis of the sampling

system. Identification of physical obstacles and/or considerations that will impact the

specific piping layout will also be considered. Often, the cooling system schematic

referred to above will provide much of the information sought.

d) The preferred piping material to be used in the sampling system. The GCM-A’s

sampling system can employ a variety of pipe sizes and types. Environment One does

not supply the sampling system’s pipe, but will be interested in learning whether the

power plant has a preference for a particular material – for example, a plant may have a

supply of 1/2-inch conduit left over from electrical service installations throughout the

plant; this material could be viewed as the preferred sampling system pipe. Environment

One will ask the plant whether there is a preference in this regard. Typically, 3/8-inch

NPT is used in a GCM-A sampling system.

10

GA0383P02 Rev. C

Transit Time Calculations

Environment One will utilize information from the customer to develop a sampling system

transit time calculation. The main purpose for this analysis is to verify that the sampling

system will meet minimum system requirements for air flow through the sampling system

and to establish an expectation for the amount of time an overheat signal generated from

within the generator will take to reach the detector unit.

During a typical GCM-A system start-up and commissioning, a 100-watt resistor will be

overheated within the cooling circuit. When this is done, the transit time analysis will be

validated, as there should be a rough correlation between the transit time design

expectation and the actual interval between the resistor being overheated and a response

by the GCM-A.

Should the approximated transit time not be validated during the commissioning of the

system, air flow through the Zone Manifolds would be validated using an external DP gage

to verify proper flow rates and adjustments to flow would be made to meet system

requirements and customer expectations.

11 GA0383P02 Rev. C

Sampling System Components

As noted, the GCM-A’s sampling system is composed of a pipe network that delivers an air

sample to the GCM-A. The individual components of a GCM-A sampling system may differ

from installation to installation (see isometric views Figures 5 though 8 of an open and

closed circuit application). In most instances, the following components are used (see

Figures 9 through 14 for component details):

• Zone Manifold – Two Zone Manifolds are used in the GCM-A system; one for the

Ambient signal, the other for the Generator signal. These components are typically

installed close to the GCM-A and are used to adjust airflow from each segment of the

sampling system network. Each Zone Manifold will be supplied with pipe unions to ease

removal of these components from the sampling system should the need arise.

Communication between Environment One and the power plant customer will confirm

the particular configuration of the pipe unions. A Zone Manifold also contains a

replaceable filter that helps guard against dirt and insects from entering the inlet manifold

of the GCM-A system (possibly obstructing flow).

• Sampling pipe — This material is supplied by the site. Communication between

Environment One and the power plant customer will determine necessary lengths. It is

the responsibility of site management to assure that sampling system piping is installed

in accordance with sampling system design parameters, local codes and professional

practice.

• Sample Heads — Sample Heads may be used as part of the sampling system, and

particularly for the Ambient signal. Sample Heads have a fixed orifice and contain a

replaceable filter that helps guard against dirt and insects from entering the sampling

system (possibly obstructing flow); see Figure 13.

• Sample Probes — Sample Probes are sections of sampling system pipe that have

holes drilled in them at particular spacing and with particular diameters. They are used as

an alternative to Sample Heads and are often preferred for the Generator signal portion of

the sampling system because of their inherent flexibility. Communication between

Environment One and the power plant customer will determine whether Sample Probes

will be used in a GCM-A sampling system; see Figure 14.

• DP Gage — The DP Gage is an external metering component used to confirm the air

flow across a Zone Manifold. The default GCM-A system design parameter for air flow is

14 LPM for each sample line. The DP Gage will be utilized during system commissioning

and at maintenance intervals to validate sampling system operation; see Figure 18.

12

GA0383P02 Rev. C

Electrical Connections

Electrical connections are made through three knockouts provided at the top and bottom of

the GCM-A cabinet (Figure 4). The system power requirement is 115/230 VAC (+/- 10%),

50/60 Hz. The source of AC power should be reliable and not subject to severe transients.

Wiring and wire routing should be in accordance with Figure 4 so that noise generated from

the AC power and contacts does not interfere with the signals. If a circuit breaker is used, it

should be 10 amps. The ground wire should be 12 AWG with 25-amp capacity.

ALL WIRING MUST BE IN ACCORDANCE WITH LOCAL CODES AND PROFESSIONAL

PRACTICE.

Contacts

As shown in Figure 4, the GCM-A provides these relay contacts:

· Ambient Alarm Relay. Both a normally open and a normally closed contact (single pole,

double throw configuration) is provided and an alarm is signaled by an energized relay.

· Generator Alarm Relay. Both a normally open and a normally closed contact (single

pole, double throw configuration) is provided and an alarm is signaled by an energized

relay.

· Differential Alarm Relay. Both a normally open and a normally closed contact (single

pole, double throw configuration) is provided and an alarm is signaled by an energized

relay.

· Warning Relay. Both a normally open and a normally closed contact (single pole,

double throw configuration) is provided and a warning is signaled by an energized relay.

· Flow Trouble Relay. Both a normally open and a normally closed contact (single pole,

double throw configuration) is provided a flow rate problem is signaled by an energized

relay.

· System Trouble Relay. Both a normally open and a normally closed contact (single

pole, double throw configuration) is provided, and Trouble is signaled by a de-energized

relay.

Signals

· Ambient Output Level Signal. 4 to 20 mA signal (transmitter)

· Generator Output Level Signal. 4 to 20 mA signal (transmitter)

13 GA0383P02 Rev. C

System Operation

GCM-A Initial Startup

The GCM-A leaves the factory without any water in the water bottle or in the humidifier to

prevent damage during shipping. Before starting the GCM-A, fill the water bottle with

distilled water. (WARNING: The use of anything other than distilled water will damage

the GCM-A and will void the warranty.)

To fill the GCM-A water bottle:

• Open the outer door.

• Remove the six screws from the GCM-A subdoor.

• Remove the water bottle from the water bottle shelf.

• Remove the cap from the water bottle and fill it with distilled water.

• Secure the cap on the water bottle and return the bottle to the water bottle shelf.

• Secure the GCM-A subdoor and outer door.

The humidifier is filled during the boot process (see the section GCM-A Initialization for

details of the boot process). At the point in the boot process where the GCM-A normally

indicates “WATER OK,” it will instead indicate “WATER=0”. After one second, “WATER=0”

will be followed by “WATER=1,” and so on until “WATER=15” is reached. At this point the

GCM-A will flash the prompt “CONTINUE FILLING?”. Press the enter key to continue filling.

The humidifier will be filled to capacity at or about “WATER=17”.

The GCM-A may detect that the Zone Manifolds need to be adjusted during the initial boot.

If it detects that the flow rates are out of specification, it will stop the boot process and flash

the out of specification reading on the display. It will flash “AMB FLO = N.N LPM” if the

ambient air flow rate is out of specification and/or “GEN FLO = N.N LPM” if the generator

airflow rate is out of specification. Adjust the appropriate Zone Manifold to a nominal 14 LPM

correct the problem and validate the air flow through the Zone Manifold using the DP Gage.

The two zone manifolds are adjusted with an allen head set screw located on their lower

right hand side (see Figure 12). Turn the set screw in a clockwise direction to decrease the

airflow or in a counterclockwise direction to increase the airflow. The GCM-A requires

that the airflow be between 7 and 21 LPM (nominal 14 liters per minute) for initial startup.

After the GCM-A has started successfully, adjust the airflow and clear the event logs.

You may want to run the tutorial called “Menu Navigation Tutorial” to familiarize yourself with

menu navigation before proceeding with these steps.

See the procedures titled “Adjusting the Ambient Airflow” and “Adjusting the Generator

Airflow” to adjust the airflow. See the sections “CLEAR FAULTS LOG” and “CLEAR POWER

LOG” under the heading “Log Menu” to clear the event logs.

14

GA0383P02 Rev. C

Typical Responses to GCM-A Warning & Alarm Indications

This section addresses what a power plant may consider as reasonable actions in response

to particular GCM-A indications. It does not purport to cover all instances.

The GCM-A provides information for plant personnel to use in making operational decisions.

The information provided is often validated by other I&CS. Plant management is encouraged

to consider the relationship of the GCM-A to other systems installed on site. By considering

these relationships, plant management will be in the best position to maximize the utility of

the GCM-A to the plant’s efficient operation.

In the event of:

GCM-A System Trouble — Select SHOW FAULTS LOG from the <LOG MENU>. If no

faults are indicated, then the operator may have disabled monitoring. If faults are indicated,

see the section “About the Faults Log” for interpretation.

Ambient Warning and Alarm — The Warning point is typically selected based on an initial

examination of the normal, or typical, background particle level at the site. Standard practice

is to allow a GCM-A run for several days to determine the highest nominal background

particle level at the site and then select a Warning point that is marginally above that. The

Alarm set point is similarly arrived at; the Alarm point must always higher than the Warning.

When Ambient particle levels rise above the Warning and possibly to the Alarm threshold, it

is reasonable to ask whether this is a short-term condition or whether the nominal

background particle level has changed due to the introduction of another environmental

factor.

In the event of an Ambient Warning or Alarm, examine the operating environment for the

presence of particle generation sources that are not common to the normal operating

environment (excessive exhaust or a fire is a good example of an extraneous source). If

there is such a temporary extraneous event, site personnel should consider whether it

can/should be eliminated/anticipated in the future and make adjustments to Warning and

“Alarm” set points as necessary.

If additional equipment has been installed at the plant site since the GCM-A’s installation

date, an Ambient Warning or Alarm may result from that equipment’s impact on nominal

background particle levels. In such an instance, site personnel may need to consider

increasing the Warning point to a level that is above the highest anticipated nominal particle

level. Essentially, the GCM-A is an environmental monitor; therefore, if the nominal

background particle level has changed because of the introduction of a sustained particle

generating source, reassessment of Warning and Alarm points is required.

Generator Warning and Alarm — The Generator Warning and Alarm points are selected

similarly to the Ambient points (see above). Therefore, a change in the nominal Ambient

particle level could be expected to cause a similar particle level increase in the Generator

signal, insofar as the Ambient air represents the same air as the air contained within the

generator’s cooling circuit.

If a Generator Warning or Alarm occurs and it is not accompanied by an Ambient Warning

or Alarm, site personnel are advised to consider that overheating may be occurring within

15 GA0383P02 Rev. C

the generator cooling circuit. In this instance, other site instrumentation should be reviewed

for corroborating indications of generator overheating.

Differential Warning and Alarm — A Differential Warning or Alarm occurs as a result of a

difference existing between Ambient and Generator particle levels. It is an expression of

“Generator less Ambient” and its value cannot equal less than zero.

The Differential Warning and Alarm set points are adjustable, with the factor default being a

30 percent difference for Warning and a 50 percent difference for Alarm. These settings are

adjustable.

In the event of a Differential Warning or Alarm, other site instrumentation should be

reviewed for corroborating indications of generator overheating. The GCM-A’s indication of a

Differential Warning, and particularly a Differential Alarm, is the most serious indication of a

thermal particulation event occurring within the generator’s cooling circuit. Site personnel

are advised to immediately initiate internal procedures for dealing with an acute problem that

could lead to generator failure.

Environment One is sometimes asked whether a GCM-A Differential Alarm should be used

to “trip” a generator off-line. This is not a question that Environment One is in a position to

respond to, as decisions relating to taking a generator off-line involve significant economic

considerations/repercussions and are solely the responsibility of site management.

Environment One can only advise GCM-A end-users that our experience has been that

operators typically reduce load upon a verified alarm in one of our overheat monitoring

instruments. They typically evaluate whether a reduced load changes the alarm condition

and then act in accordance with their established internal procedures. In the event that plant

operators choose to use a GCM-A to trip a generator, the “Differential Alarm” is the only

indication that should be used.

(Typical Responses, cont’d)

16

GA0383P02 Rev. C

GCM-A Initialization

Apply system power to the GCM-A. The GCM-A DISPLAY PANEL will respond with (a) all

discrete LED’s lit; (b) all segments of the AMBIENT and GENERATOR bar graphs lit; and (c)

all pixels of the LCD display on.

After a delay of two seconds, (a) all discrete LED’s, except the AC POWER, SYSTEM

TROUBLE and FLOW LED’s, will turn off; (b) all segments of the AMBIENT and

GENERATOR displays will turn off; and (c) the display will echo the results of cold start

initialization:

·“GCM-A Ver 1.7B-8”

·“CHECKSUM OK”

·“POWER OK”

·“RELAY TEST …”

·“… PASSED”

·“STARTING …” will flash for two seconds;

·“ROTARY VALVE …”

·“… PASSED”

·“VACUUM OK”

·“SAMPLE LINE ...”

·“… PASSED”

·“GEN SOLENOID ...”

·“… PASSED”

·“AMB SOLENOID ...”

·“… PASSED”

·“AMB FLO=14.0 LPM”

·“GEN FLO=14.0 LPM”

·“WATER OK”

·“END DIAGNOSTICS”

“NORMAL OPERATION” will flash for two seconds; the GCM-A will begin normal operation

and the display will read “GCM-A by E/One.”

17 GA0383P02 Rev. C

GCM-A Menu Displays

The following sections provide definitions and user information regarding the various menus

that are accessible via the GCM-A’s LCD display. It is strongly recommended that users

familiarize themselves with this section. Additional questions can be forwarded to

Environment One at +1 518 346-6161 or www.eone.com/detection.

Navigating the LCD Display

Four keys are used to control menu operation. The keys are FN, ENTER, UP ARROW and

DOWN ARROW.

·The FN key activates the menu and exits the menu.

·The ENTER key selects an item from the menu.

The UP ARROW and DOWN ARROW keys change the selection displayed.

LCD Display Menu — Two Modes of Operation

The menu has two modes of operation. The modes are scrolling and non-scrolling.

·In scrolling mode the selection shown on the LCD changes automatically every two

seconds.

·In non-scrolling mode the UP ARROW and DOWN ARROW keys must be used to

change the selection.

Scrolling is the default mode. Users can change modes by reviewing the SETUP MENU

section in the following pages.

Menu Profile

Five menus are available: the Function menu, the Log menu, the Setup menu, the View

menu and the Test menu. The Function menu is the top-level menu; all of the other menus

are accessed through this menu.

Function

·Log

·Setup

·View

·Test

18

GA0383P02 Rev. C

Menu Navigation Tutorial

Activating the Menu

Press FN to start the menu. The LCD should display the prompt <FUNCTION MENU>.

Press FN again to turn it off.

Navigating the Menu in Scrolling Mode (GCM-A default)

1. Press FN to start the menu. The LCD should display the prompt <FUNCTION MENU>.

After two seconds the prompt should change to GO REMOTE.

2. Wait until the prompt GO TO VIEW MENU and press the ENTER key. The LCD should

display the prompt <VIEW MENU>.

3. Wait until the prompt VIEW LEVEL and press the ENTER key. The display should show

GENERATOR=N.N% (or AMBIENT=N.N%) where N.N is the present value of the cloud

chamber response. Press the FN key; the prompt will be restored to VIEW LEVEL.

4. Press FN again. The prompt will be restored to GO TO VIEW MENU.

5. Press FN a third time. The LCD will display “GCM-A by E/One” as the menu is

deactivated.

Disabling Scrolling Mode

1. Press FN to start the menu.

2. Wait until the prompt GO TO SETUP MENU and press ENTER.

3. Wait until the prompt SET SCROLL OFF and press ENTER.

4. The prompt will flash SET SCROLL OFF.

5. Press FN to return to the beginning of the menu.

Navigating the Menu in Non-Scrolling Mode

1. The LCD should display the prompt <FUNCTION MENU>. Press the DOWN ARROW

key until the prompt GO TO VIEW MENU and press the ENTER key.

2. The LCD should display the prompt <VIEW MENU>. Press the DOWN ARROW key until

the prompt VIEW LEVEL and press the ENTER key. The display should read

GENERATOR=N.N% (or AMBIENT=N.N%) where N.N is the present value of the cloud

chamber response.

3. Press the FN key. The prompt will be restored to VIEW LEVEL.

4. Press FN again. The prompt will be restored to GO TO VIEW MENU.

5. Press FN a third time. The LCD will display “GCM-A by E/One.”

19 GA0383P02 Rev. C

Function (FN) Menu

· GO REMOTE Select this item to transfer control to an active remote control software

session. The GO REMOTE prompt will flash for two seconds after it is selected. If the

FN key is pressed while GO REMOTE is still flashing, transfer will be canceled. If the

GCM-A cannot detect an active remote control software session, the transfer will be

canceled and the GCM-A will remain in local mode.

· GO LOCAL Select this item to transfer control to the display panel located on the front

of the GCM-A cabinet (only shown if control was previously transferred to an active

GCM-A Remote Control Software session). The GO LOCAL prompt will flash for two

seconds after it is selected. If the FN key is pressed while GO LOCAL is still flashing,

transfer will be canceled.

· GO TO LOG MENU Select this item to enter the LOG MENU. The log menu contains

selections to view and clear the fault and power logs. The log menu also includes a

selection to view the software version number.

· GO TO SETUP MENU Select this item to enter the SETUP MENU. The setup menu

includes selections for setup and configuration.

· GO TO TEST MENU Select this item to enter the TEST MENU. The test menu contains

selections to test the power supplies, the keypad, the relays, the vacuum pump, the

cloud chamber, the bar graphs and the four- to 20-milliamp (4-20 mA) outputs.

· GO TO VIEW MENU Select this item to enter the VIEW MENU. The view menu contains

selections to view the water usage, the LED current, the cloud chamber output, the

vacuum, the air flow and the cloud chamber period.

Setup Menu

· AMBIENT GAIN Select this item to change the ambient gain. See Setting the Ambient

Gain for more information.

· GENERATOR GAIN Select this item to change the generator gain. See Setting the

Generator Gain for more information.

· AMBIENT FLOW ADJ Select this item to change the ambient flow limits. See Adjusting

the Ambient Airflow for more information.

· GENERATOR FLOW ADJ Select this item to change the generator flow limits. See

Adjusting the Generator Airflow for more information.

· AMBIENT WARN Select this item to change the ambient warning level. See Setting the

Ambient Warning Level for more information.

· GENERATOR WARN Select this item to change the generator warning level. See

Setting the Generator Warning Level for more information.

· DIFFERENCE WARN Select this item to change the difference warning level. See

Setting the Difference Warning Level for more information.

Table of contents

Popular Microphone manuals by other brands

Shure

Shure SM35 Brochure & specs

Earthworks

Earthworks QTC Series user manual

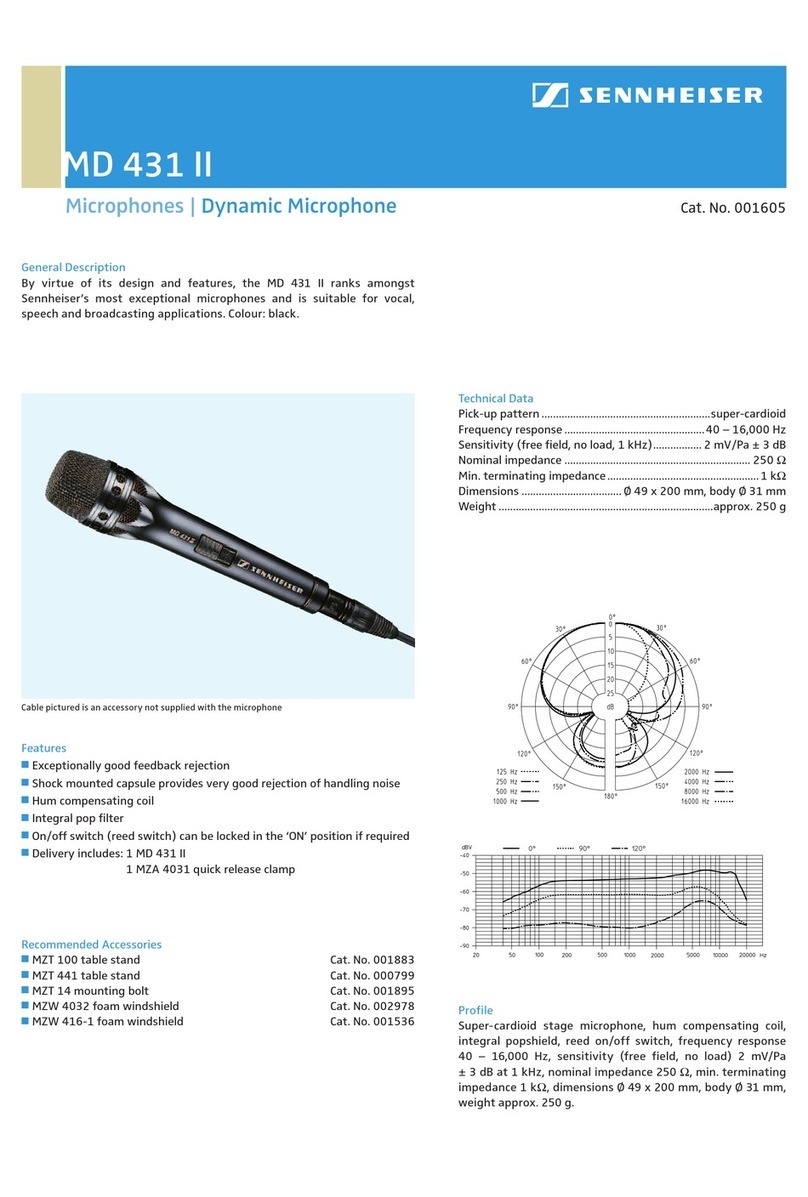

Sennheiser

Sennheiser MD 431 Technical data

Neumann.Berlin

Neumann.Berlin Series 180 operating instructions

Audio Technica

Audio Technica ES935ML6 Installation and operation

Accessory Power

Accessory Power ENHANCE ENPCCM1100BKEW user guide