5Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

Operator’s Manual

Chipper Shredders

21. Never continue to operate the machine if it starts

making unusual noise or vibration. Shut the engine o

immediately, allow the rotor to stop, disconnect the

spark plug wire and secure the wire away from the spark

plug. Inspect the unit for any signs of damage or foreign

material in the chipping or shredding areas. Remove

any solid material that may be preventing the unit from

operating properly.

22. Never attempt to clear clogs from the chipper cone,

shredder hopper or discharge chute while the unit is

running. Always shut the engine o, allow the rotor to

come to a complete stop, and remove the spark plug wire

from the spark plug before removing excess materials.

23. Never attempt to perform any maintenance, repairs,

or attachment of accessories while the unit is running.

Always shut the unit o, allow the rotor to come to a

complete stop, and remove the spark plug wire from the

spark plug before beginning these activities.

24. Always make sure that the shredding chamber, shredder

hopper, and chipper cone are empty before starting

the unit after it has been idle. Attempting to start the

unit with material in these areas could cause the engine

starting cord to stop suddenly, injuring your hand and

ngers, or toppling the unit over. Vibration is generally a

warning sign of trouble.

25. Before cleaning, repairing, or inspecting, shut o the

engine and make certain that all moving parts have come

to a complete stop. Disconnect the spark plug wire and

secure the wire away from the spark plug to prevent

accidental starting.

26. Do not operate the engine in a conned space where

dangerous carbon monoxide fumes can collect.

27. Never operate the machine without proper guards,

plates, or other safety protective devices in place.

28. Use only attachments and accessories approved of by the

manufacturer of the machine.

TRANSPORTING AND STORAGE

1. Always observe safe refueling and fuel handling practices

when refueling the unit after transportation or storage.

2. Never store the unit (with fuel) in an enclosed poorly

ventilated structure. Fuel vapors can travel to an ignition

source (such as a furnace, water heater, etc.) and cause

an explosion. Fuel vapor is also toxic to humans and

animals.

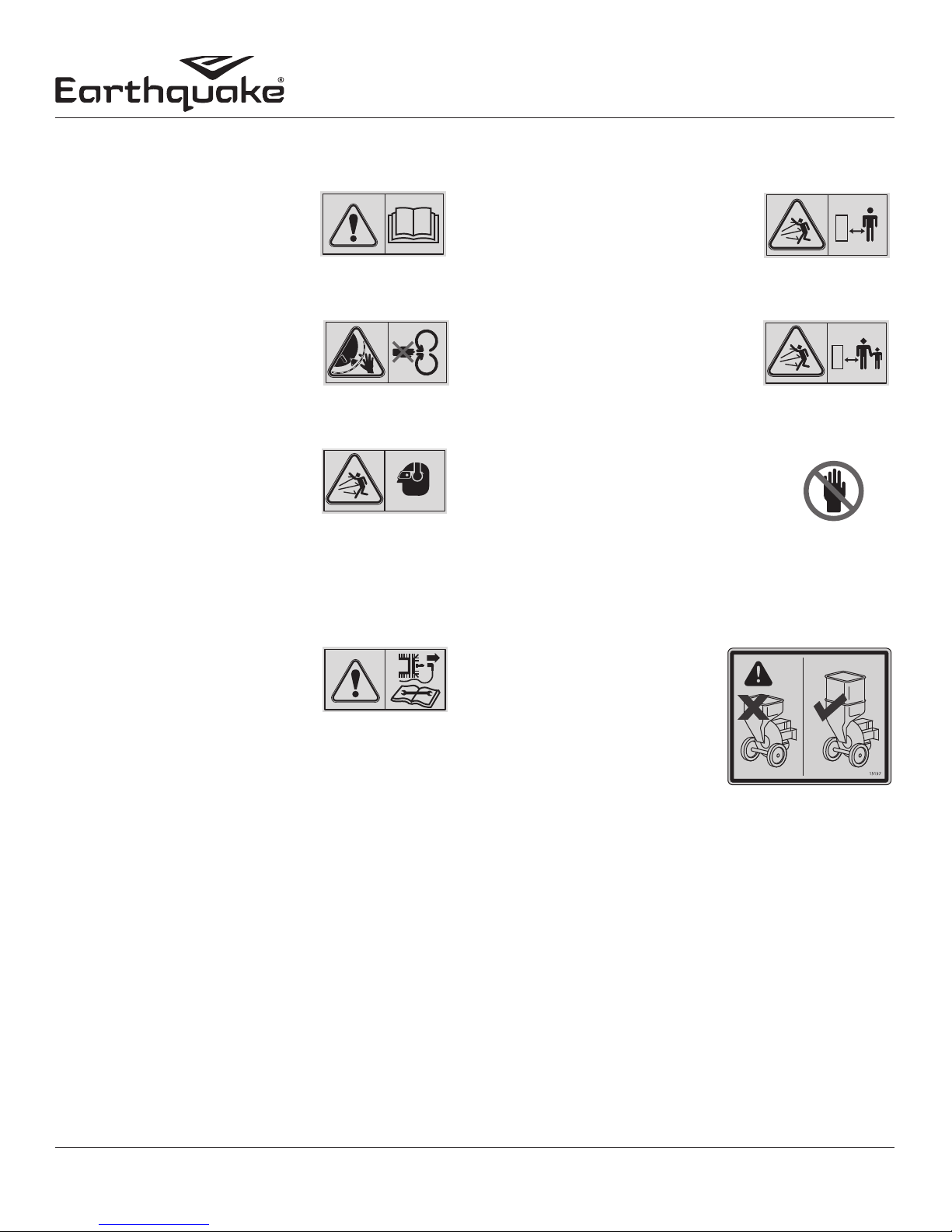

3. Always use the hopper handle and built-in wheels to

move the chipper shredder. Never lift the unit using the

fuel tank for support. If the unit must be lifted , always

use at least two people, and always grip the unit securely

using the front leg and hopper handle.

4. Always follow the engine manual instructions for storage

preparations before storing the unit for both short and

long term periods.

5. Always follow the engine manual instructions for proper

start-up procedures when returning the unit to service.

6. Never store the unit or fuel container inside where there

is an open ame or pilot light, such as in a water heater.

Allow unit to cool before storing.

Children

Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the unit

and the operating activity. Never assume that children will

remain where you last saw them.

1. Keep children out of the work area and under the

watchful care of another responsible adult.

2. Be alert and turn unit o if children enter the area.

3. Never allow children to operate the unit.

Emissions

1. Engine exhaust from this product contains chemicals

known, in certain quantities, to cause cancer, birth

defects, or other reproductive harm.

2. Look for the relevant Emissions Durability Period and Air

Index information on the engine emissions label.

Ignition System

1. This spark ignition system complies with Canadian ICES-

002.

SERVICE AND MAINTENANCE

Safe Handling of Gasoline

1. Extinguish all cigarettes, cigars, pipes, and other sources

of ignition.

2. Use only approved gasoline containers.

3. Never remove the gas cap or add fuel with the engine

running. Allow the engine to cool before refueling.

4. Never fuel the machine indoors.

5. Never store the machine or fuel container where there is

an open ame, spark, or pilot light such as near a water

heater or other appliance.

6. Never ll containers inside a vehicle or on a truck bed

with a plastic bed liner. Always place containers on the

ground away from your vehicle before lling.

7. Remove gas-powered equipment from the truck or

trailer and refuel it on the ground. If this is not possible,

then refuel such equipment on a trailer with a portable

container, rather than from a gasoline dispenser nozzle.