9 of 16

earth safe

Fuel Systems for Critical Power

Pipin

The cause of many pumping problems can be traced to suction piping. It should always be as

large and short as practical. Before starting layout and installation of your piping system,

consider the following points:

1. N v r us piping small r than th pump port conn ctions.

2. B sur th insid of th pip is cl an b for hooking it up.

3. Foot valv — Wh n pumping a light liquid with a suction lift, a foot valv at th nd of th

suction piping or a ch ck valv in th first horizontal run will hold th liquid in th lin and

mak it asi r for th pump to prim . B sur th foot or ch ck valv is big nough so that it

do sn’t caus xc ssiv lin loss.

4. Wh n approaching an obstacl in th suction or discharg lin , go around th obstacl

inst ad of ov r it. This minimiz s air pock ts air pock ts which mak it hard for th pump to

prim .

5. For a suction lin with a long horizontal run k p th horizontal portion b low th liquid

l v l if possibl . This k ps th pip full so th pump do s not hav to r mov so much air

wh n starting.

6. B sur allowanc is mad for xpansion and contraction of th piping. Loops, xpansion

joints, or uns cur d (this do s not m an unsupport d) runs should b us d so th pump

casing is not str ss d by th piping.

7. Strain r — Th pump inl t strain r will k p for ign obj cts from going into th pump. Th

strain r is particularly important at start up to h lp cl an th syst m of w ld b ads, pip

scal , and oth r for ign obj cts.

8. Th pump should not b us d to support th piping. Th w ight of th pip should b

carri d by hang rs, supports, stands, tc.

9. Wh n fast ning th piping to th pump it should not b n c ssary to impos any strain on

th pump casing. “Springing” or “drawing” th piping up to th pump will caus distortion,

possibl misalignm nt, and probabl rapid w ar of th pump. Do not us th pump to

corr ct rrors in piping layout or ass mbly.

10. All joints of th piping syst m should b tight; pip s al r will h lp assur l ak-fr thr ad d

joints. L aks in th suction lin r duction in capacity.

11. Provid a pr ssur r li f d vic in any part of a pump and piping syst m that can b valv d

off and, thus, compl t ly isolat d. Th ris in t mp ratur caus s th liquid to xpand; if

th r is no provision for pr ssur r li f in th clos d off s ction, th r is a chanc that th

pump or piping will ruptur .

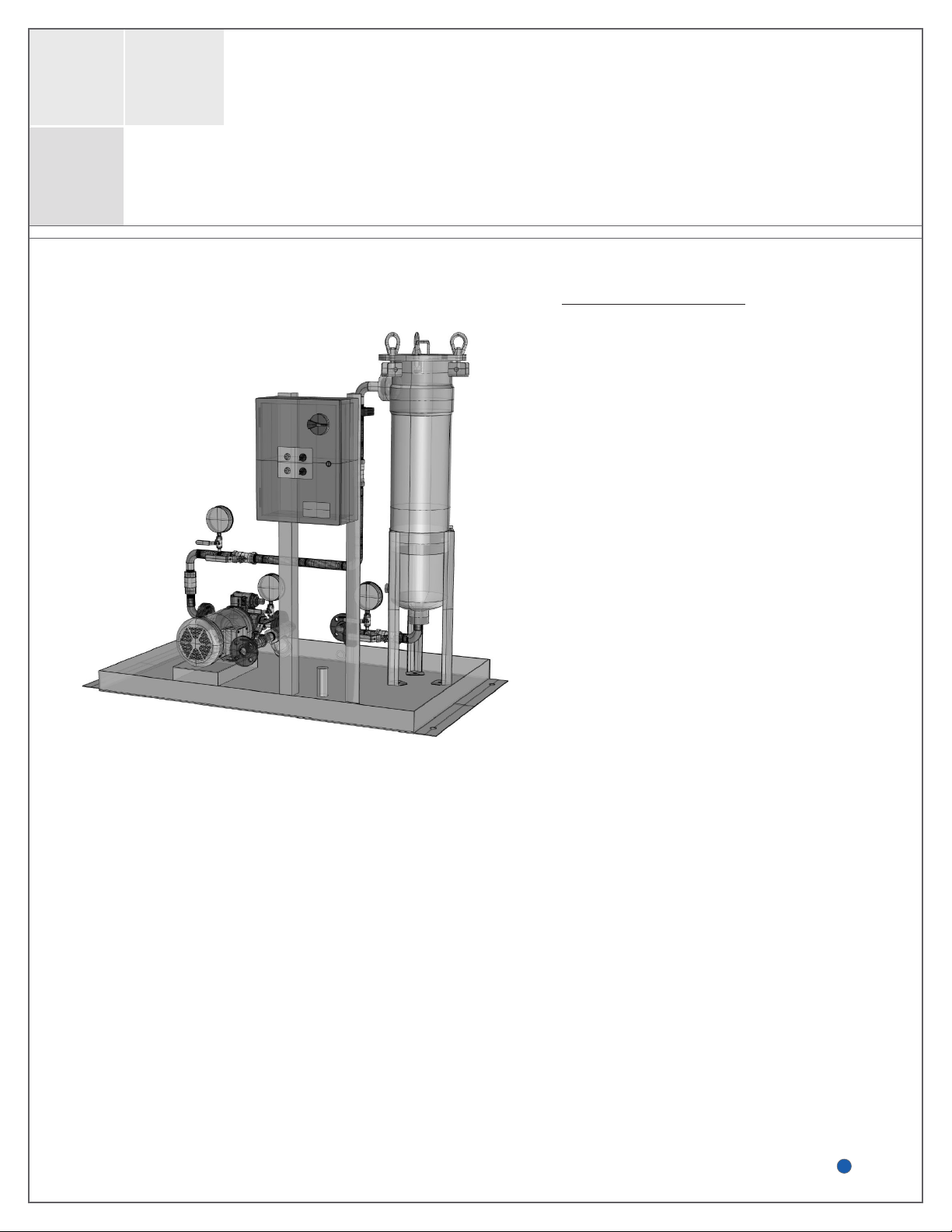

EMERGENCY POWER FUEL SYSTEMS

Model M300

Filtration Polisher

INSTALLATION, OPERATION, AND MAINTENANCE