EBECO Foil 48 V User manual

Table of contents

Popular Solar Panel manuals by other brands

CORAB

CORAB PB-066 installation manual

Qcells

Qcells Q.PEAK DUO L-G5.3/BF Installation and operation manual

CanadianSolar

CanadianSolar CS3U-MB-FG installation manual

CanadianSolar

CanadianSolar CS3W-PB-AG Series installation manual

CORAB

CORAB B-027 installation manual

GOAL ZERO

GOAL ZERO NOMAD 100 user guide

Num'axes

Num'axes NGPIEACC038 user guide

Silvercrest

Silvercrest SLS 13 A1 User manual and service information

SolarPath

SolarPath HIGHLIGHT-NPSL user manual

Regulus

Regulus KPC1-BP Installation and operation manual

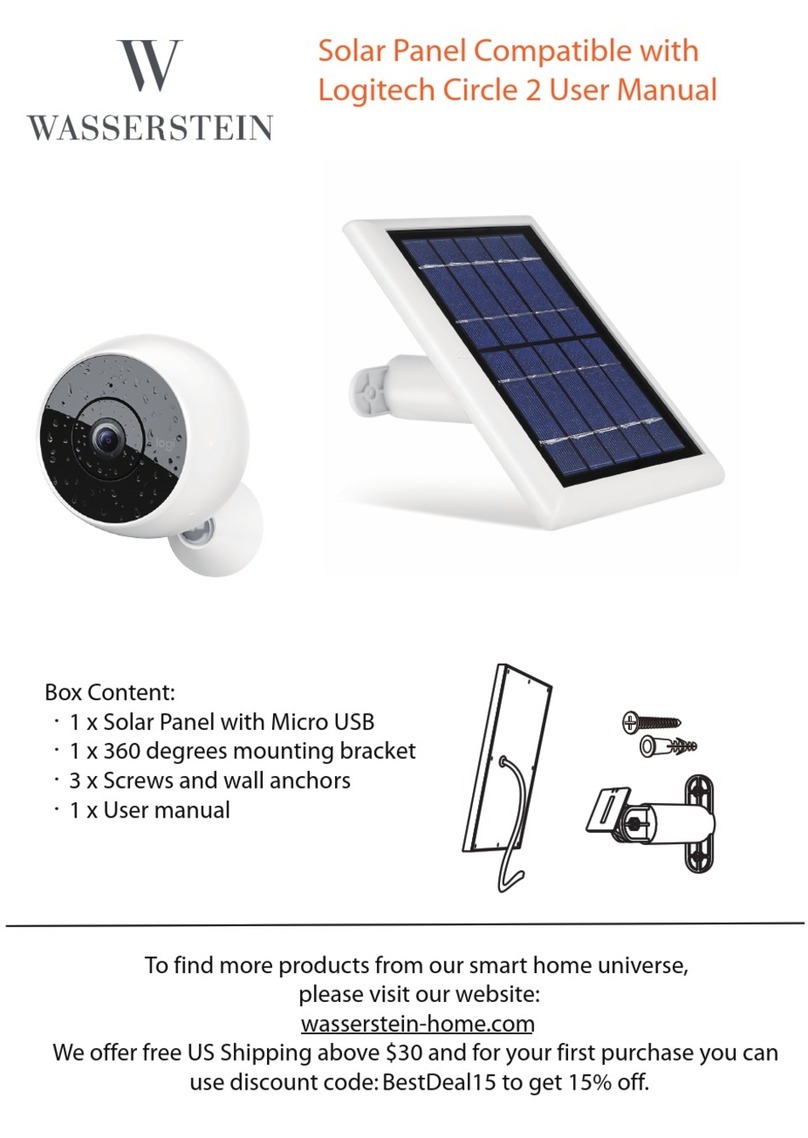

Wasserstein

Wasserstein Solar Panel Compatible with Logitech Circle... user manual

Viessmann

Viessmann VITOSOL 100-F SV1 Technical data manual

LG

LG N1T-G4 Series installation instructions

Solar Technology International

Solar Technology International PV Logic MHD Flexi user manual

Kings Adventure

Kings Adventure 160W Monocrystalline user manual

Viessmann

Viessmann Vitosol 222-T installation instructions

inaa

inaa SR10 installation manual

LG

LG LG N1C-G4 Series installation manual