ECH2O Tec. 900-BHL- 2 User manual

BEACH HOUSE SERIES

(WALL MOUNT UNIT)

900-BHL- 2 / 1200-BHL- 3 / 1500-BHL- 4

OWNERS MANUAL

PAGE

2 INTRODUCTION

3 SPECIFICATIONS

4

5

STANDARD SYSTEM FEATURES

INSTALLATION LAYOUT

6-7 INSTALLATION INSTRUCTIONS

8-9 OPERATION INSTRUCTIONS

10 MEMBRANE CLEANING PROCEDURE

11 MAINTENANCE TIMETABLE

12 TROUBLESHOOTING GUIDE

13-14 HIGH PRESSURE PUMP REPAIR INSTRUCTIONS

16-17 LIMITED ARRANTY

TM

E

EE

E

C

CC

C

H

HH

H

2

22

2

O Tec.

O Tec.O Tec.

O Tec.

Watermakers

INTRODUCTION

Thank you for choosing an ECHO Tec. reverse osmosis desalination system. We trust that you will

be completely satisfied with our product.

The Beach House eries has been specially designed for small hotels, marinas and beach houses.

The high power efficiency and low maintenance cost makes high quality RO water in many cases

more economical than land supplied water, if available.

The BHL series is engineered for 24 hours per day, 7 days per week operation.

The purpose of this manual is to allow you to become familiar with each component of your new

ECHO Tec. desalination system.

By understanding the function, importance and normal operation of each part in the system, the

operator can readily diagnose problems when they first develop. uch problems are easily corrected

and require minor adjustments. If left unattended, a small problem in one component will affect the

rest of the system and can lead to an expensive repair.

If you have any doubts or questions, please contact us. We are happy to help “customize” the

seawater reverse osmosis desalinator for your special needs.

ECHO MARINE LTD.

1st Avenue South,

Chaguaramas

Trini a W.I.

TELEPHONE: 1-868-634-2027

FAX: 1-868-634-2026

E-MAIL: echotec@echo-marine.com

www.watermakers.net

SPECIFICATIONS

RATED PERFORMANCE:

ECHO Tec: 500 – BHL – 1 min. 20 gallons – 75ltr. / hour

900 – BHL – 2 min. 38 gallons – 140ltr. / hour

1200 – BHL – 3 min. 50 gallons – 210ltr. / hour

1500 – BHL – 4 min. 60 gallons – 260ltr. / hour

Reverse Osmosis performan e varies with the feed water temperature and salinity.

The rated performan e is tested at 26°C / 80°F water temperature at a salinity of 35g/l.

A de rease in produ t water quantity of 10 to 15% in the first year is normal and

expe ted.

RO MEMBRANE TYPE:

Spe ifi ally sele ted high reje tion proprietary TFC Polyamid, thin film

omposite, spiral wound, single pass reverse osmosis element.

SALT REJECTION: min. 99.5%

SALINITY RANGE: up to 50,000 ppm TDS ( NaCl )

PH RANGE: 4 – 11

CHLORINE TOLERANCE: 1000 ppm hours

OPERATING PRESS RE: 725 to 800 psi ( ontinuous duty)

FEED WATER PRESS RE: 0 to 60 psi

FEED WATER TEMPERAT RE RANGE:

min. 33°F / 0.5°C, max 113°F / 45°C

ELECTRICAL POWER REQ IREMENTS:

115 V / 60Hz 18 amps 230 V / 60Hz 8.6amps

220 V / 50Hz 11 amps

SAFETY SWITCH OFF F NCTIONS:

1) To high RO pressure: 1000psi

2) To low feed pressure: 0psi

3) Blo ked feed water intake

4) Air in feed water system

5) To high produ t salinity (optional)

STANDARD SYSTEM FEATURES

1) 1 Seawater feed pump with 3/4” hose barb outlet

1 PVC sea strainer with 3/4” PVC pipe connection

2) 1 Priming reservoir

2 3/4” pipe connections

3) 2 Fi ter housings with bracket and 5 and 20 micron pre ilter cartridges

1 Storage/cleaning valve with 3/4” and 1/2” hose barbs

1 Shut o valve with 3/4” hose barb

1 Filter wrench

4) 1 High-pressure pump unit with controls

5)

Pressure vesse (s) with reverse osmosis membrane(s)

ECH

2

O Tec. 500-BHL-1

one 40” vessel

900-BHL-2

two 40” vessels

1200-BHL-3

three 40” vessels

1500-BHL-4

our 40” vessels

6) 20 eet / 6 meter 1/2” rein orced vinyl hose (reject, product, lush)

10 eet / 3 meter blue product water tubing (membrane to low panel)

10 eet / 3 meter 3/4” rein orced vinyl hose (pre- ilter to high pressure pump)

3 eet / .9 meter 5/8” service intake hose

2 + 6 eet / .6 + 1.8 meter high pressure hose with ittings (900-BHL-2)

3 + 2 eet / .9 + .6 meter high pressure hose with ittings (1200-BHL-3)

3 + 6 eet / .9 + 1.8 meter high pressure hose with ittings (1500-BHL-4)

7) 6 1/2" Stainless steel hose clamps

1 5/8” Stainless steel hose clamp

3 3/4” Stainless steel hose clamps

8) 1 Handheld TDS Meter

1 Biocide, 1 acid cleaning solution, 1 alkaline cleaning solution

1 Owners Manual

WATER LEVEL AT LOW TIDE

Beach House Series

Installation Layout

Product

Max.2.7m / 9ft.

Max.9m / 30ft.

Reject

Non return valve Sea strainer

INSTALLATION INSTRUCTIONS

HIGH PRESSURE PUMP UNIT

Mount the high pressure pump unit in a cool and dry location, not higher than 30ft above low water level

at a distance not further than 100ft / 30m.

The electrical installation should only be done by a rofessional electrician. Check the correct

voltage before installing the system.

The “M IN” marked cable is to be connected to the power supply. The smaller cable, marked “PUMP”

is to be connected to the raw water feed pump.

MEMBRANE VESSEL RACK

Mount the high-pressure membrane vessels with the provided brackets below the high pressure pump

unit. Vertical mounting is possible if space is limited but you will need to order different high pressure

hose lengths.

The membrane is sealed within its housing by lugs at both ends. Inside is a small amount of

reservative to kee the membrane moist and revent bacterial growth.

It is im ortant that this reservative does not eva orate and allow the membrane to dry out. If

this ha ens, the membrane will be destroyed.

The shelf life of the reservative, under best conditions, is one year. We recommend you install

and use your watermaker as soon as ossible.

When all other components and hoses/pipes are completely assembled, remove the caps on the high

pressure fittings and the blue sealed tube from the product water outlet on the membrane housings, then

finish making all final hose/tube connections. This will insure that the membrane is kept moist until the

last possible moment before operation.

PRE-FILTER ASSEMBLY

Mount the pre-filter in a serviceable location and connect the intake port to the outlet of the raw water

feed pump or multi-media sand filter (optional). For short runs, use 5/8” reinforced PVC hose. For

longer runs, use a 5/8” or 3/4” PVC pipe. Connect the outlet of the pre-filter housing with a 3/4”

reinforced PVC hose to the intake of the high pressure pump.

INSTALL ALL PLUMBING TO ELIMINATE ANY AIR POCKETS IN THE SYSTEM

FRESH WATER FLUSH FILTER

Install the fresh water flush filter housing at a location near the seawater pre-filter assembly. Connect the

flush port of the three-way service valve at the pre-filter assembly with the outlet of the flush filter

housing (out). Supply pressurized fresh water to the shut off valve of the flush filter housing.

SEAWATER FEED PUMP AND PRIMING RESERVOIR

With the aid of the priming reservoir, the feed pump is able to prime the raw water up to a height of 9ft.

Mount the feed pump in a dry location not higher than 9ft above low water level. Mount the priming

reservoir with the outlet (lower connection) at the same level as the intake of the feed pump in a dark

location (inhibits growth of algae). Connect the intake of the feed pump and the outlet of the priming

reservoir with 3/4”PVC pipe or directly if possible.

The suction pipe (PVC 3/4”) connected to the intake of the priming reservoir (upper connection), need to

lead in one single vertical run below the waterline. From this point the pipe can run submerged to the

supplied intake strainer (max 60ft / 20meters) where clean seawater can be taken in. ¾” non-return

valve is to be installed in the suction pipe at any position below the waterline.

HIGH PRESSURE HOSE

Never bend the high ressure hose tighter than a 4”/10cm radius.

Run one of the high-pressure hoses from the outlet of the HP pump (O ring sealed fitting) to the O ring

sealed fitting at the end of the membrane that is marked “IN”.

Run the second high-pressure hose from the flow control box to the O ring sealed fitting at the end of the

membrane that is market “OUT”.

CAUTION: WHEN CONNECTING THE HIGH-PRESSURE HOSE FITTINGS TO THE

MEMBRANE HOUSING(S), AVOID TURNING THE MEMBRANE VESSEL FITTINGS INTO

THE END CAPS (COUNTER WITH SUITABLE SPANNER). THE END CAPS ARE MADE

FROM INDUSTRIAL PLASTIC AND CAN CRACK IF OVER TIGHTENED.

PRODUCT WATER TUBING

Connect the blue product water tubing or for longer runs than 15ft / 5m a 1/2" PVC hose or pipe from the

center fittings of the membrane housing(s) to the bottom inlet of the flow meter, in the flow control

panel. Connect the tubing or hose from each output port of the 3-way valve to your fresh water storage

tanks and to a taste/test station of your choice. Do not allow the product line to become blocked while

the system is running. It must be avoided that chlorinated water from your storage tanks flows back into

the RO membranes.

The Product water can be led to the storage tanks up to a height of 20m/65ft. In this case a non return

valve must be installed in the product line to protect the membrane from back-pressure.

REJECT WATER TUBING/HOSE

Connect the outlet of the pressure control valve on the back of the flow control panel with a 1/2”

reinforced PVC hose to a reject (brine) 1/2” PVC pipe. The brine should be disposed of as far as

possible (30ft / 10m) and down current from the seawater intake.

SYSTEM OPERATION INSTRUCTIONS

The reverse osmosis membrane contains a preservative solution to prevent microbiological

gro th. If ingested, may cause irritation of the gastro-intestinal tract, colic, diarrhea, or other

similar symptoms.

Therefore, discard all the product ater for at least thirty minutes of initial operation or after

storage before drinking or use in food preparations!

Do not operate the system using contaminated feed ater sources (oil, chlorine or other

chemicals).

Have you filled the high-pressure pump ith the proper amount of oil?

1) Open the pressure control valve on the control panel all the way, counter-clock wise.

2) Set the flush/service valve at the pre-filter assembly to the run position (center) an open

the shut off valve at the pre-filter intake.

3) Set the iverter valve on the flow control panel to the sample (test) position.

4) Switch the selector switch to the “Service” position to run the sea water supply pump

only.

5) Purge the seawater intake system until all entrappe air has escape , then switch the

selector switch “Off” an bring the selector switch in the “Auto” position.

6) Press the start button for about five secon s. If the motor stops when the start-button is

release , purge the seawater intake system again an start the watermaker in the “Auto”

position

7) Close the pressure control valve slowly clockwise an a just the water pressure to

800psi. If the watermaker is use in brackish water, a just the pressure in or er to

achieve the specifie pro uct water output only.

Caution: Never allo any leaks in your hose or pipe connections.

8) Check the quality of the pro uct water with the TDS meter. If the water is pure (un er

500ppm TDS), switch the iverter valve on the control panel to the storage tank position.

SYSTEM SHUT DOWN PROCEDURE

1) Switch the iverter valve to the sample position.

2) Open the pressure control valve all the way counter clockwise.

3) Switch the selector switch off.

4) Fresh water flush the system (see next page).

FRESH WATER FLUSH PROCEDURE

You shoul fresh water flush your watermaker after every use or infuse a bioci e solution for long

term storage. The fresh water flush prepares your watermaker for a shut own perio of seven ays

maximum. You can repeat the flush proce ure every seven ays, to exten the short term storage.

1) Open the pressure control-valve all the way counter-clockwise.

2) Close the seawater intake-valve on the pre-filter assembly an make sure the shut off

valve on the flush filter is open.

3) Open the fresh water flush valve on the pre-filter assembly. Your fresh water pressure

pump shoul now turn on. Allow fresh water to flow until all salt water is flushe out of

the system.

For the next flush proce ure, test how long it takes until the brine at the reject outlet of

the watermaker becomes fresh.

4) Open the seawater shut off valve an back flush the pre-filter system with fresh water

5) Close the fresh water flush valve an the seawater shut off valve.

MEMBRANE STORAGE PROCEDURE

If you inten to store your watermaker for more than ten ays, growth of microorganism will

egra e the RO membranes performance.

The RO membranes shoul be flushe with a bioci e solution to preserve the membrane for long-

term storage of up to ten months.

1) Fresh water flush the system.

2) In a clean plastic container, mix 5 gallons / 20 litres of un-chlorinate fresh water with

200 grams (2/3 container) of Echo Tec. Preservative # 3.

3) Switch the three-way valve to the service position. Switch the iverter valve to the

sample position. Switch the shut off valve to the off position.

4) Open the pressure control valve all the way anti-clockwise an start the high pressure

pump only by hol ing own the start-button in the selector switch “Off” position.

5) Infuse the solution via the service hose connecte to the three-way valve while running

the high-pressure pump without pressure. When the solution has been infuse , switch the

watermaker off an remove the pre-filter cartri ges for ry storage.

Un er best con itions your watermaker is now prepare for a shut own perio of ten months.

Discar the pro uct water for at least thirty minutes of initial operation, after storage, before

rinking or before use in foo preparations.

MEMBRANE CLEANING PROCEDURE

The membranes of the ECHO Tec. Watermaker must be chemically cleaned when the

product water output drops by 20% of the specified amount. The fre uency of this

occurring will vary greatly depending upon feed water. Fouling of the membranes will

naturally occur during normal

usage of the ECHO Tec. Watermaker. Increased amounts of fouling without proper

cleaning of the membrane will reduce the performance of your water maker. Cleaning of

the membranes will not enhance the uality (TDS reading) of the product water.

CAUTION: The use of chemicals or cleaning me hods o her han hose ou lined in

he cleaning ins ruc ions will void he ECHO Tec. warran y. Nonionic surfac an s

for membrane cleaning or o her chemicals no approved in wri ing by Echo Marine

L d. will void he elemen warran y.

CAUTION: Cleaning chemical #1 is an alkaline de ergen . See warning label on

side of he con ainer and observe all safe y precau ions on label.

CAUTION: Cleaning chemical #2 is an acid, a mineral scale remover. See warning

label on side of con ainer and observe all safe y precau ions on label.

CAUTION: Do no mix differen cleaning chemicals oge her. Do no use differen

cleaning chemicals oge her a he same ime. Mix he cleaning chemicals separa ely

and use hem separa ely.

No e: All cleaning and preserving procedures can be done with either seawater or non-

chlorinated freshwater. However, the cleaning process is more effective using non-

chlorinated freshwater.

To clean the ECHO Tec. reverse osmosis membranes mix one container (330gram) of

cleaning chemical #1 with 5gal / 20ltr of water at 104° F / 40° C.

Re-circulate (disconnect the reject water hose and lead it in the cleaning container) the

solution in intervals for up to one hour wi hou pressure (observe the maximum

operating temperature of 112° F / 45° C). Open the pressure control valve all the way

anti-clockwise and start the high pressure pump only, by holding down the start-button in

the selector switch “Off” position. Do not allow the cleaning container to run dry or air to

enter the system.

It is important that the fresh water, remaining from the last flush is dumped before the

reject hose is led in the cleaning container to ensure the re-circulation of the undiluted

cleaning solution only.

Use cleaning chemical #1 first. If the performance does not improve, use the acid cleaner

#2 at the same ratio and instruction.

MAINTENANCE TIMETABLE

The following maintenance timetable is an estimate of the time intervals at which maintenance may

be required only. This schedule must be adjusted to the regularity of usage, the condition of the

intake water, the length of time the system is exposed to seawater and the total running time

following each system cleaning.

COMPONENT MAINTENANCE

REQUIRED

TIME INTERVAL

INTERMITTENT DUTY

Seawater intake

strainer

Inspect and clean intake. 000 hrs, or when clogged.

Pre filters Replace or clean elements and

clean housings.

When system intake pressure

drops below 5psi.

Charcoal flush filter Replace element. Every 6 months.

High pressure pump Change crankcase oil.

Change packings, seals

and “O” rings.

Initial change after 50 hrs.

Every 200 operating hours or

6 months.

Every 2000 hrs or when

leaking.

R.O. membrane When production or salt rejection

decreases by 20%.

Replace

Clean with acid and/or

alkaline cleaning compound.

When cleaning does not

increase production.

Flow meter Clean inside the clear tube.

Disconnect product tubing and

infuse rust remover. Rinse

thoroughly!

Whenever dirty.

HIGH PRESSURE PUMP SYSTEM

TROUBLESHOOTING GUIDE

MALFUNCTION CAUSE REMEDY

The pressure Worn packing seals Replace seals

drops broken valve spring Replace spring

Fouled inlet strainer Clean strainer

Fouled pre-filter(s) Replace filter cartridge(s)

Cavitation Check suction lines for

restrictions

Water in crankcase High humidity Reduce oil change interval

Worn seals Replace seals

oisy operating Worn bearings Replace bearings, refill crankcase

with recommended lubricant

Cavitation Check inlet lines for restrictions

Check strainer and filter(s)

Inability to Discharge valve chamber Allow more time to prime

build up pressure has air trapped within it and ensure that there are no

air suction leaks.

Open valve chambers and allow

air to escape

Rough/Pulsating Worn seals Replace seals

operation with Check system for stoppage or

air suction leaks

pressure drop Cavitation Check inlet lines for restrictions

Excessive Worn plunger(s) Replace plunger(s)

leakage between Worn seals Replace seals

the high pressure

pump manifold Cracked plunger(s) Replace plunger(s)

and rear crankcase

section

High crankcase Wrong grade of oil Use specified type of oil.

temperature Improper amount of oil in crankcase Adjust oil level to proper

amount

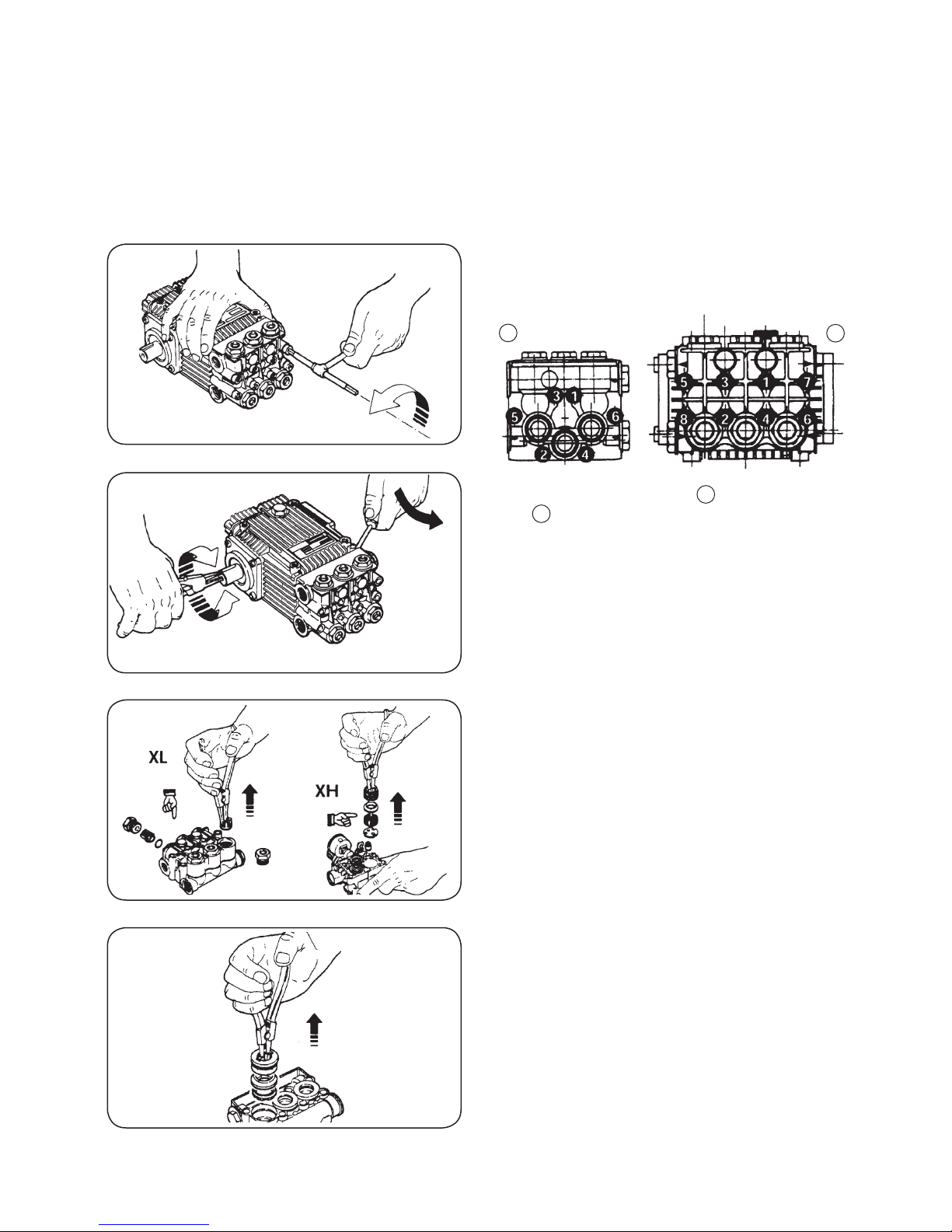

∂Assembly - DisAssembly OfThe PumP heAD

1.1 - Unscrew head bolts.

Tightening sequence of head bolts, for XT Series and HPE

Series, for XR Series and XL Series.

1.2 - Remove the head by rotating the shaft and levering

between head and body.

1.3 - For re-assembly: Invert above instructions, and keep

to torque rates shown on page 8.

insPecTiOn inleT/OuTleT vAlves

2.1 - Remove valve caps, slide out inlet/outlet valves

check the sondition of the various components of the

valve and well as the O-Ring, replace if necessary.

2.2 - For re-assembly: Invert previous operation.

RePlAcing PAcking AnD RecOveRy seAls

3.1 - Remove the head (See ∂), then slide out piston

guides, being careful not the deform them, using the

special extractor pliers.

HIGH PRESSURE PUMP REPAIR INSTRUCTION

ECHO TEC PUMP SERIES

XL-60/2.3, XL-60/3.0 AND XL-60/3.6

∂

AB

B

A

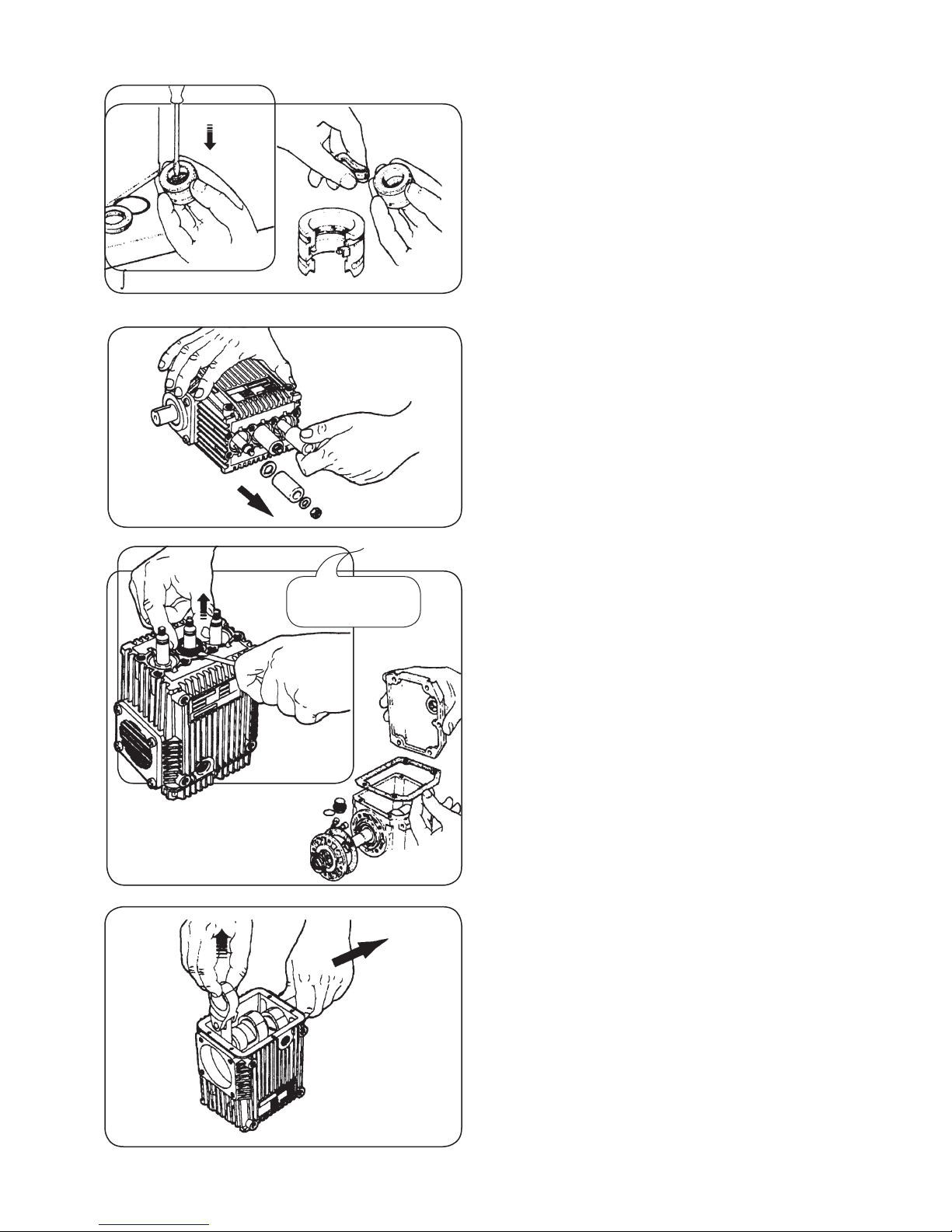

3.2 - Disassemble the components of the piston guide,

checking the condition, replace if necessary.

3.3 - For re-assembly: Invert operation.

RePlAcing The PisTOns

4.1 - Remove the head (See ∂), then unscrew the piston

retainers.

4.2 - Slide off the ceramic pstions, check their condition,

and replace if necessary.

4.3 - For re-asembly: Invert above operations. Keep to

torque rating and shown on page 8.

RePlAcing Oil seAls

6.1 - Remove the head (See ∂),

remove the ceramic pistons

discharge oil

6.2 - Remove the oil seals and the O-Rings, checking the

seats and the piston guides.

6.3 - Remove the rear cover gasket.

6.4 - For re-assembly: Invert above operations. Keep to

torque ratings as shown on page 8.

cRAnk mechAism mAinTenAnce

7.1 - Remove the head (See ∂),

remove the ceramic pistons

discharge oil

7.2 - Remove the rear cover.

7.3 - Remove the con-rod sliding the one piece-rod

whilst removing the shaft.

7.4 - For re-assembly: Invert above operations. Replace

the oil seals!

•

•

•

•

Be careful not to

scratch piston

guide!

ECHO TEC. WATERMAKER LIMITED WARRANTY

Echo Marine Ltd. warrants to the original purchaser for a period of twelve (12) months from the date of

shipment that the ECHO ec. watermaker will perform according to specifications. Echo Marine’s

liability under this warranty shall be limited to repair or replacement of the ECHO ec. watermaker at

Echo Marine’s option. Under no circumstances shall Echo Marine Ltd. be liable for consequential

damages arising out of or in any way connected with the failure of the system to perform as set forth

herein. his limited warranty is in lieu of all other expressed or implied warranties, including those of

merchantability and fitness for a particular purpose.

In the event of a defect, malfunction, or failure during the warranty period, Echo Marine Ltd. will repair

or replace, at its option, the product or component therein which, upon examination by Echo Marine,

shall appear to be defective, or not up to factory specifications.

o obtain warranty service, the defective product or part must be returned to Echo Marine’s Service

Center. he purchaser must pay any transportation or labor expenses incurred in removing and returning

the product to the service center.

he limited warranty does not extend to any system component which has been subjected to misuse,

neglect, accident, improper customer installation, or used in violation of instructions furnished by Echo

Marine Ltd. he warranty does not extend to components on which the serial number has been removed,

defaced or changed.

Echo Marine Ltd. reserves the right to make changes or improvements in its product during subsequent

production without incurring the obligation to install such changes or improvements on previously

manufactured equipment.

he implied warranties, which the law imposes on the sale of this product, are expressly LIMI ED, in

duration to the time period above. Echo Marine shall not be liable for damages, consequential or

otherwise, resulting from the use and operation of this product or from the breach of this LIMI ED

WARRAN Y.

his limited warranty service does not apply to normal recurring user maintenance as described below.

Pre-filter Cartridges Pump Valve Assemblies

Pump Seals Gauge Instrument Calibration

Pump Packings Pump Crankcase Oil

he ECHO ec. Membrane Element is guaranteed to be cleanable for a minimum of one year from date

of shipment, or commissioning of the system by Echo Marine Ltd, provided that cleaning instructions are

adhered to and foulant is acid soluble metal hydroxides and calcium carbonates or alkaline soluble

organic, inorganic substances and microbiological slimes. he ECHO ec. Membrane Element is not

guaranteed against iron fouling (rust), chemical attack, extreme temperatures (over 113º F/under 33ºF),

drying out, or extreme pressures (over 1000 psig).

CAU ION: Use of parts not supplied directly by Echo Marine (generic parts), including but not limited

to maintenance parts, pre-filter elements, cleaning and storage chemicals, pump oil, spare parts,

replacement parts, system components and or system accessories, shall void all warranties expressed or

implied.

ECHO MARINE LTD.

1st Avenue South,

Chaguara as

Trinidad W.I.

TELEPHONE: 1-868-634-2027

FAX: 1-868-634-2026

E-MAIL: echotec@echo- arine.co

www.water akers.net

This manual suits for next models

2

Table of contents

Other ECH2O Tec. Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Theralux

Theralux THERACLEAR 255 Technical description and installation instructions

WaterSoft

WaterSoft SIDEWINDR SW10 Installation & operation manual

Tetra

Tetra Whisper 10-30 manual

Viqua

Viqua PRO24-186/2 owner's manual

Contech

Contech CatchBasin StormFilter Operation and maintenance

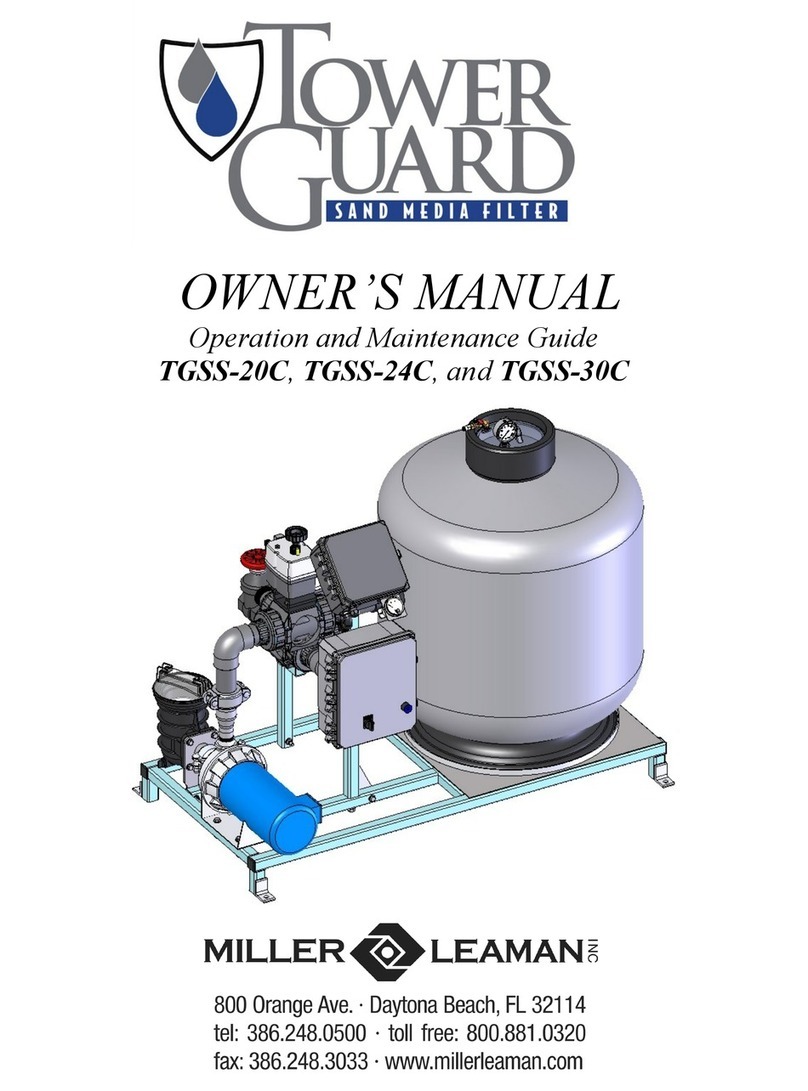

Miller-Leaman

Miller-Leaman TGSS-20C owner's manual