2

SRM-4300

ECHO Grass Trimmers / Brushcutters are lightweight,

high-performance, petrol engined units designed for

weed control, grass trimming and brush cutting in areas

difficult to control by any other means.

Do not use this unit for any purpose other than

aforementioned.

Never let children operate this unit.

This Manual provides the information necessary for

assembly, operation and maintenance.

You must read this Manual to understand the safe and

effective operation of your ECHO product.

For future reference, you should keep this Operator’s

Manual.

If this Operator’s Manual has become illegible through

impairment or is lost, please purchase a new one from

your ECHO dealer.

When renting or lending this machine to a person who

will operate it, always include this Operator’s Manual,

which provides explanation and instructions.

When transferring a product, please deliver it attaching

the Operator’s Manual.

Specifications, descriptions and illustrative material in

this literature are as accurate as known at the time of

publication, but are subject to change without notice.

Illustrations may include optional equipment and

accessories, and may not include all standard

equipment.

If there is any clause in this Manual that is hard to be

understood, please contact your ECHO dealer.

Contents

Introduction................................................................... 2

Decals and symbols ..................................................... 3

Rules for safe operation................................................ 4

Training ................................................................... 4

Eye protection......................................................... 4

Hearing and ear protection ..................................... 4

Protective clothing................................................... 4

Additional protection ............................................... 4

Using shoulder harness .......................................... 5

Fuel......................................................................... 6

Physical condition ................................................... 6

Area and equipment inspection .............................. 6

General operation ................................................... 7

Vibration and cold ................................................... 9

Repetitive stress injuries......................................... 9

With metal blade ..................................................... 10

Reaction forces ....................................................... 10

Blade selection ....................................................... 11

Description ................................................................... 12

Assembling................................................................... 13

Drive shaft............................................................... 13

Handle .................................................................... 13

Throttle cable .......................................................... 13

Installation of shield ................................................ 13

Installing blade........................................................ 14

Check positions of attached cutting blade .............. 14

Check positions of attached shield ......................... 14

Fuel............................................................................... 15

Fuel......................................................................... 15

Handling fuel........................................................... 15

Operation...................................................................... 16

Starting cold engine................................................ 16

Starting warm engine.............................................. 16

Stopping engine...................................................... 16

Service maintenance guide.......................................... 17

Troubleshooting ............................................................ 17

Maintenance and care ................................................. 18

Cleaning air filter..................................................... 18

Check fuel system................................................... 18

Replacing fuel filter ................................................. 18

Check spark plug .................................................... 18

Cooling system maintenance.................................. 18

Carburettor adjustment ........................................... 19

Cleaning silencer .................................................... 20

Angle transmission.................................................. 20

Lubricating shaft tube (SRM-4300R)..................... 20

Storage......................................................................... 21

Long term storage (over 30 days)........................... 21

Disposal procedure....................................................... 21

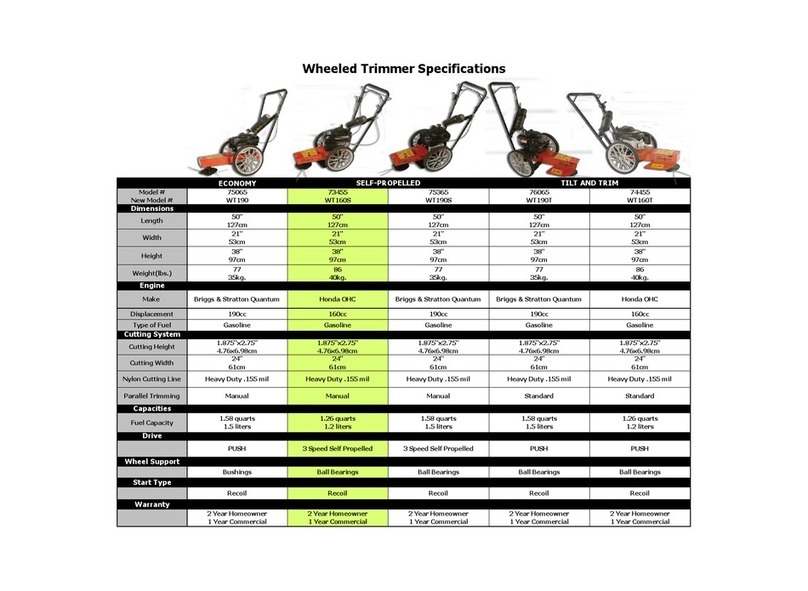

Specifications ............................................................... 22

Introduction