ECKELMANN KGLZCANREP User manual

Firmware V2.0L - Doku-Version V2.0 - Current to March 2021

Operating instruction

CAN bus Repeater

Firmware V2.0L

Firmware V2.0L - Doku-Version V1.9 - Current to March 2021 1

Eckelmann AG

Business Unit Refrigeration and Building Automation

Berliner Straße 161

65205 Wiesbaden, Germany

Tel.: +49 611 7103-0

Fax: +49 611 7103-133

elds-[email protected]

www.eckelmann.de

Board of Directors:

Dipl.-Ing. Peter Frankenbach (Management Spokesman),

Dipl.-Wirtsch.-Ing. Philipp Eckelmann, Dr.-Ing. Marco Münchhof

Chairman of the Supervisory Board: Hubertus G. Krossa

Deputy Chairman of the Supervisory Board: Dr.-Ing. Gerd Eckelmann

Registration court / registration number, district court Wiesbaden, Germany, HRB 12636

The current operating manual and information such as data sheets, more detailed documentation and FAQs

are available for you on-line in E°EDP (Eckelmann ° Electronic Documentation Platform) at

www.eckelmann.de/elds

You reach all relevant documents for this component directly using the QR code:

Information on safety and connection instructions are described in detail in the manual "Basics and General

Safety and Connection Instructions".

All rights to any use whatever, utilisation, further development, forwarding and creation of copies remain with

the Eckelmann AG company.

In particular, neither the contract partners of Eckelmann AG nor other users have the right to distribute or

market the IT programs/program parts or modified or edited versions without express written permission.

To some extent, names of products/goods or designations are protected for the respective manufacturer

(registered trademarks etc.); in any case, no guarantee is assumed for their free availability/permission to

use them. The information provided in the description is given independently of any existing patent protection

or other third-party rights.

Before commissioning and use, please check that this is the latest version of the

document.With the publication of a new version of the documentation, all previous

versions lose their validity. Errors and technical modifications are expressly

reserved.

Firmware V2.0L - Doku-Version V1.9 - Current to March 2021 2

1Technical safety information...................................................................................3

2Function of the CAN bus Repeater.........................................................................4

2.1 Sample applications........................................................................................................................... 5

3Installation and Commissioning of the CAN Bus Repeater.....................................6

3.1 Installation and connection to the CAN bus.......................................................................................6

3.2 Wire assignment for male connectors in the CAN bus ...................................................................... 7

3.3 Commissioning................................................................................................................................... 8

3.4 Indication of the Operating Status...................................................................................................... 8

4Specifications CAN bus Repeater ..........................................................................9

4.1 Electrical data.....................................................................................................................................9

4.2 Mechanical data................................................................................................................................. 9

Firmware V2.0L - Doku-Version V1.9 - Current to March 2021 3

1 Technical safety information

1. Commissioning and operation of the device may only be performed by qualified

personnel. "Qualified personnel" as defined by this technical safety information

means persons who have the authorisation to start up, earth and designate devices,

systems and electric circuits in accordance with security technology standards.

2. Mounting, positioning and wiring may only be conducted when the electricity

supply to the assembly has been cut off.

3. The faultless and safe operation of the product presupposes proper transport,

appropriate storage, positioning and assembly, as well as careful operation and

maintenance.

4. Voltage must only be supplied by VDE-tested and CE-certified power packs.

5. Ensure that the voltage supply and the data cable are correctly connected.

6. If the product is brought into the working area from a cold environment,

condensation may form. The product must be completely dry before being

commissioned. Do not assemble or install the product near water or in damp

surroundings.

7. Do not take the product apart or remove the enclosure. The guarantee rights will

become invalid if the housing is opened.

Firmware V2.0L - Doku-Version V1.9 - Current to March 2021 4

2 Function of the CAN bus Repeater

The CAN bus repeater extends the CAN bus within the E*LDS system by a further 500 m, see the operating

instruction introductory chapter in the E*LDS documentation), see operating instruction „E*LDS for

systematic cooling - Basics and general safety and connection instructions“ of the der E*LDS documentation.

In this process, CAN bus data from the first (primary) CAN bus segment is transformed in a second

(secondary) CAN bus segment. In order to implement the CAN bus protocol from the primary side on the

secondary side, and the reverse, the CAN bus repeater is equipped with its own microcontroller.

Note: The determination „First CAN bus segment“ resp. „Second CAN bus segment “ is scalable.

CAN bus Repeater (order No. KGLZCANREP)

Interfaces

2 x CAN bus in accordance with ISO/DIS 11 898

Voltage supply

The CAN bus repeater is powered by an external 24 V DC power pack, order No. KGLNT24V1P.

A maximum of 2 CAN bus repeaters can be employed in an E*LDS system, for

further details see the introductory chapter in the E*LDS documentation.

Firmware V2.0L - Doku-Version V1.9 - Current to March 2021 5

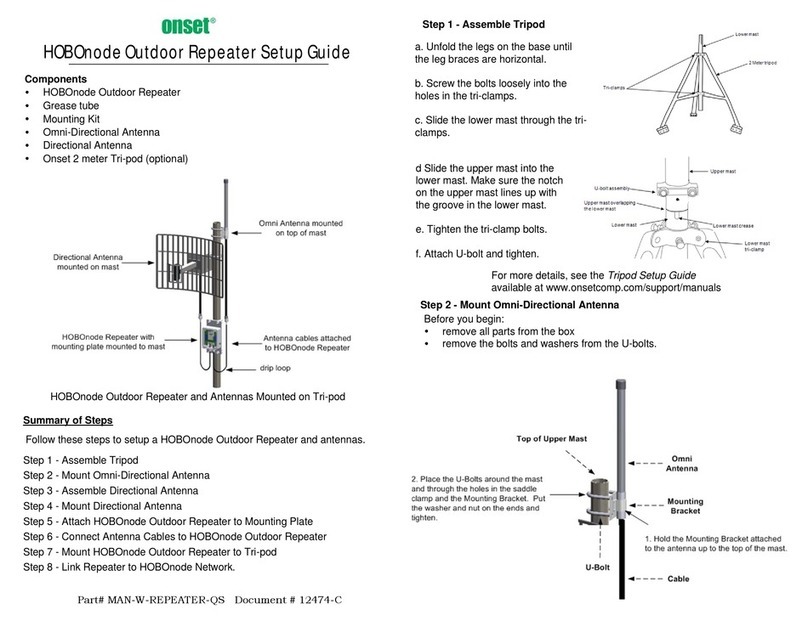

2.1 Sample applications

NK=NT TK=LT

Firmware V2.0L - Doku-Version V1.9 - Current to March 2021 6

3 Installation and Commissioning of the CAN Bus Repeater

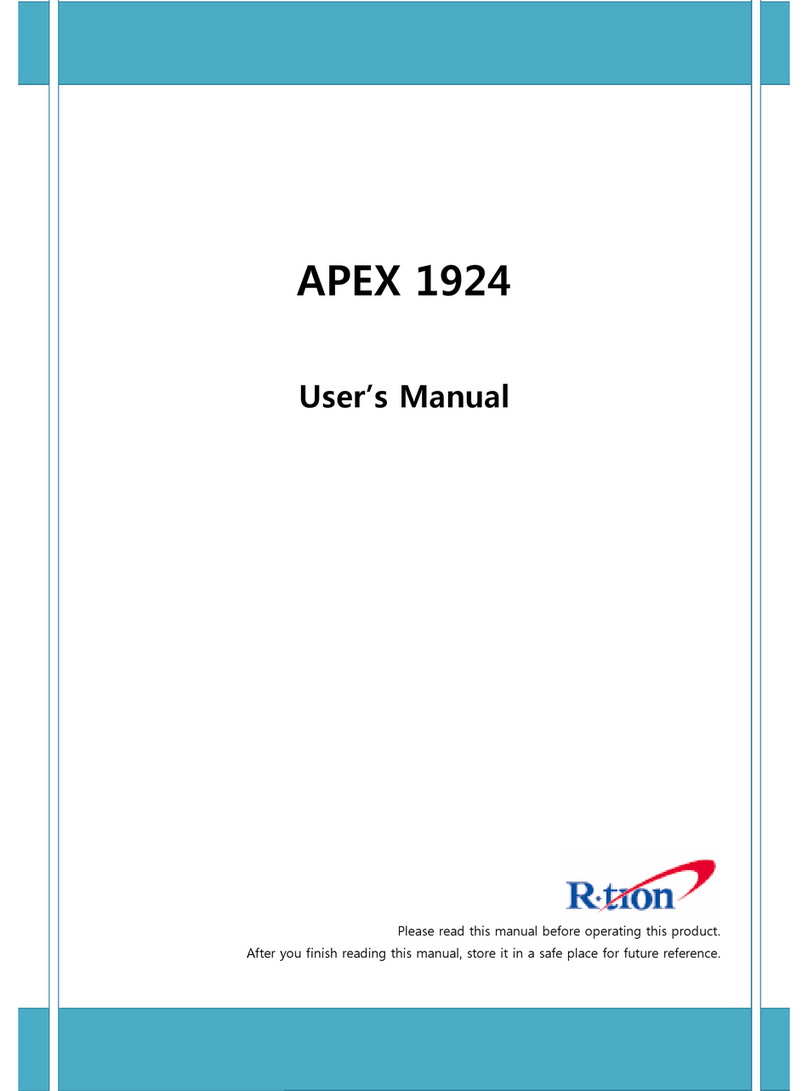

3.1 Installation and connection to the CAN bus

Before commissioning, the CAN bus repeater must first be connected to the first CAN bus segment via the

front COMBICON plug. The second CAN Bus segment is then connected to the top connections of the CAN

bus repeater. Finally, the device is supplied with 24 V DC power (power pack, order number KGLNT24V1P):

Example:

Picture 3.1: Connection of the CAN bus-repeater

Note: The determination „First CAN bus segment“ bzw. „Second CAN bus segment “ is scalable.

* The start and end of a CAN Bus segment must each be connected to a terminating

resistor R=100 Ohm (0.25 W)!

Tip: Use connector set with terminating resistor to terminate the CAN bus,

order No. KGLCANTERM.

Firmware V2.0L - Doku-Version V1.9 - Current to March 2021 7

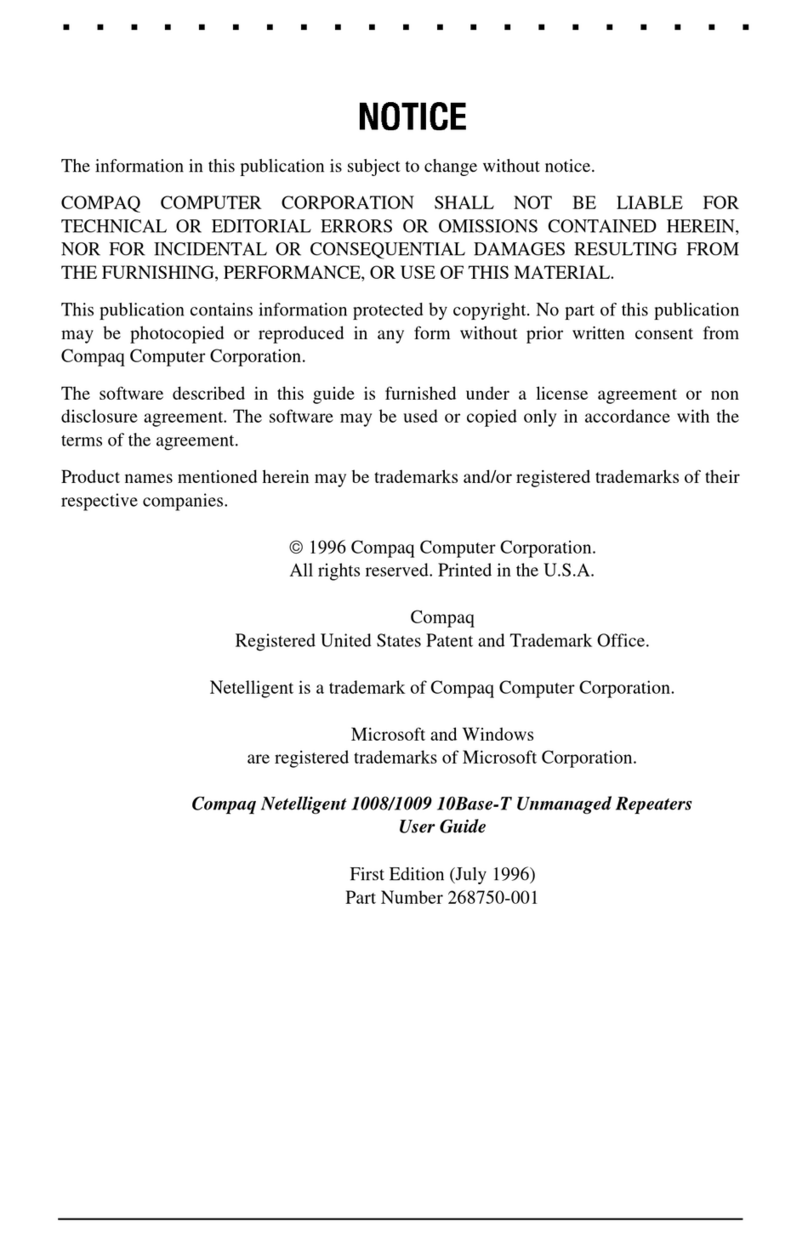

3.2 Wire assignment for male connectors in the CAN bus

CAN bus Wire/

colour

COMBICON- plug

e.g. System centre,

UA 400, VS 3010,

WR 300

CAN bus Repeater Comments

SHLD SHLD 1 --- Connect shield (SHLD) to

earthing clamps,

see chapter 3.1.

CAN-

GND green 2 G (COMBICON, front)

GND (top terminal) ---

CAN-

LOW brown 3 L (COMBICON, font)

C-L (top terminal) The start and end of a CAN bus

segment must each be connected

to a terminating resistor

R=100 Ohm (0.25 W) !

CAN-

HIGH white 4 H (COMBICON, front)

C-H (top terminal)

Connetion to e.g. Connection to

System centre / UA 400 / VS 3010 / WR 300 CAN-Bus-Repeater

Assignment of the COMBICON plug (depicted without looping and terminating resistor 100 Ohm)

CAN bus cable type: LiYCY 2x2x0,75 mm“ – twisted pair,

see the introductory chapter in the E*LDS documentation.

Details for the connection to the CAN bus are contained in the introductory chapter

of the E*LDS documentation (e.g. specification of the cable type, permissible cable

length, required terminating resistor, the correct routing and the max. number of

CAN bus repeaters).

Incorrect shielding can lead to electromagnetic noise fields.

During wiring it must be ensured that the cables with shielding are correctly

connected.

Firmware V2.0L - Doku-Version V1.9 - Current to March 2021 8

3.3 Commissioning

The commissioning of the CAN bus repeater consists of the following steps:

1. Connect the CAN bus repeater to the first and second CAN bus circuits, see chapter 3.

2. Attach the CAN bus repeater to the power supply 24 V DC.

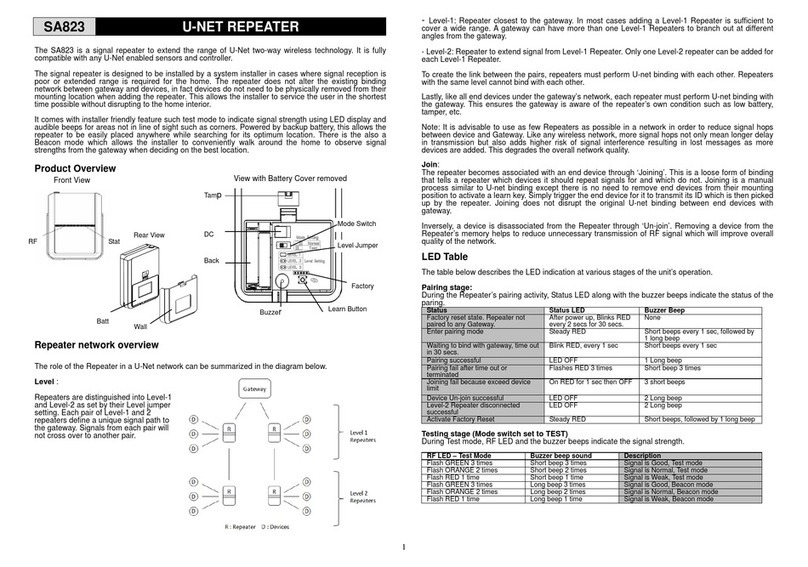

3.4 Indication of the Operating Status

The CAN bus repeater is equipped with a display element consisting of a yellow and a green LED with the

following functions:

•Yellow LED (BA) = CAN bus status

Flickering yellow LED:

The CAN bus repeater is transmitting data via the first (primary) CAN bus segment.

•Green LED (ON) = operating voltage

Flickering green LED:

The CAN bus repeater is transmitting data via the second (secondary) CAN bus segment.

•Both LEDs are flashing at 0.5 second intervals:

The processor is running, no data is being transmitted via the CAN bus.

•Both LEDS are extinguished:

- No 24 V DC voltage supply or

- CAN bus OFF: The device is receiving data but is not able to re-transmit it.

Front of the CAN bus repeater with status LEDs and 3-pole COMBICON plug

Firmware V2.0L - Doku-Version V1.9 - Current to March 2021 9

4 Specifications CAN bus Repeater

4.1 Electrical data

Technical data CAN bus repeater

Order No. KGLZCANREP

Physical interface CAN Bus in accordance with ISO/DIS 11 898

Transmission rate 50 kBit/s

Voltage supply 24 V DC, max. 100 mA, separate power supply required,

order No. KGLNT24V1P

Status display 2 x LEDs (yellow / green)

Electrical isolation 1 kV DC via optocoupler and DC/DC converter

Temperature range - in operation 0..+55 °C

max. 95 % humidity without condensation

Temperature range - storage 0..+70 °C

Enclosure Plastic, for DIN rail mounting, IP20

CE conformity Manufacturer’s CE declaration of conformity

4.2 Mechanical data

Technical modifications and errors reserved!

Table of contents