8.3 Remote control via a terminal .............................................................................................................74

8.3.1 Menus and operating screens................................................................................................................75

8.3.2 Calling the controller menu via remote control.......................................................................................78

8.3.2.1 System Centre........................................................................................................................................78

8.3.2.2 Store computer CI 3x00 / operator terminal AL 300 ...............................................................................79

8.3.3 Deactivating the input lock-down............................................................................................................80

8.3.3.1 System centres.......................................................................................................................................80

8.3.3.2 Store computer CI 3x00 / operator terminal AL 300 ...............................................................................80

8.3.4 Activating service mode .........................................................................................................................81

8.3.4.1 System centre - service mode................................................................................................................81

8.3.4.2 Store computer CI 3x00 .........................................................................................................................81

9 Menu Structure of UA 410 L ................................................................................................................82

9.1 Controller type UA 410 L – Menu tree (Rx.1 to Rx.0).........................................................................83

9.2 Main menu.............................................................................................................................................84

9.3 Menu 1 Actual Value.............................................................................................................................85

9.4 Menu 2 Setpoints..................................................................................................................................85

9.5 Menu 3 Clock ........................................................................................................................................86

9.6 Menu 4 Messages.................................................................................................................................87

9.7 Menu 5 Archive .....................................................................................................................................88

9.8 Menu 6 Configuration ..........................................................................................................................89

10 Decommissioning and disposal .........................................................................................................91

10.1 Decommissioning / Dismantling.........................................................................................................91

10.2 Disposal ................................................................................................................................................91

11 Alarms and Messages of UA 410 L.....................................................................................................92

11.1 Alarm signaling and monitoring .........................................................................................................93

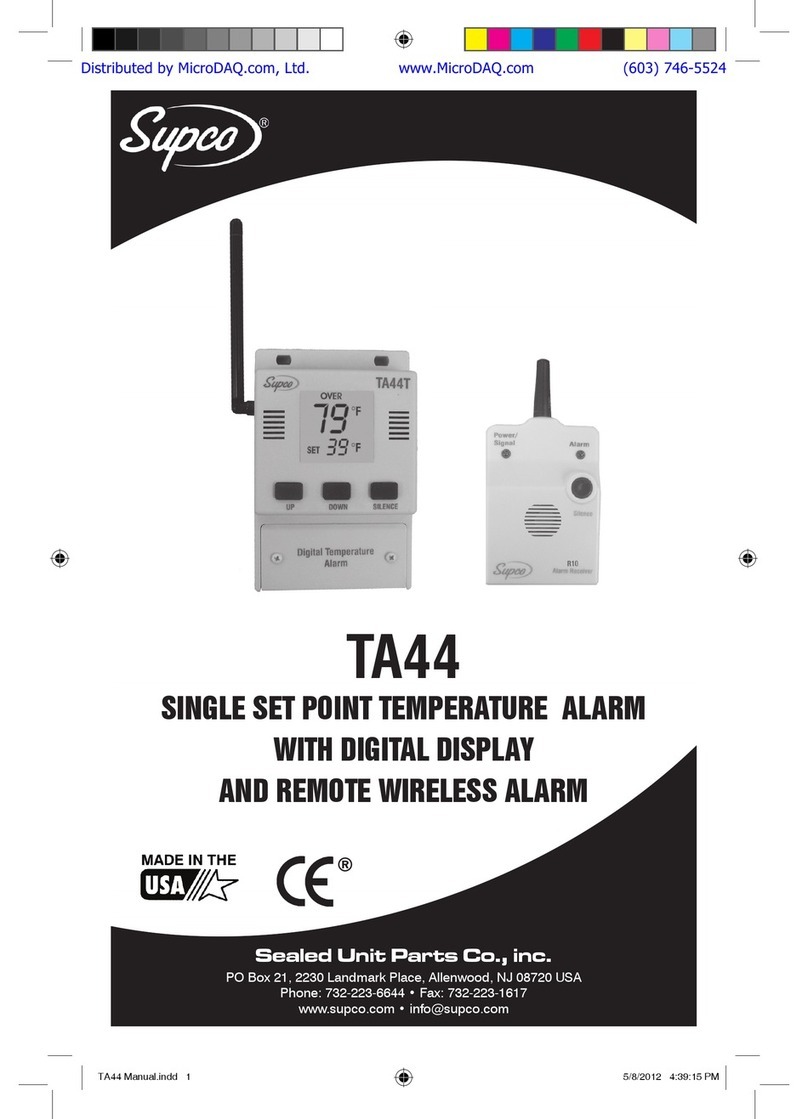

11.1.1 High or low temperature alarm...............................................................................................................93

11.1.2 Disabling high or low temperature alarm................................................................................................93

11.1.3 No defrost alarm.....................................................................................................................................93

11.1.4 Sensor break alarm ................................................................................................................................94

11.1.5 Hardware fault alarm ..............................................................................................................................94

11.1.6 Alarm routes ...........................................................................................................................................94

11.2 Messages ..............................................................................................................................................95

11.2.1 Transient alarms and messages ............................................................................................................95

11.2.2 Message log ...........................................................................................................................................95

12 Specifications of UA 410 L ..................................................................................................................96

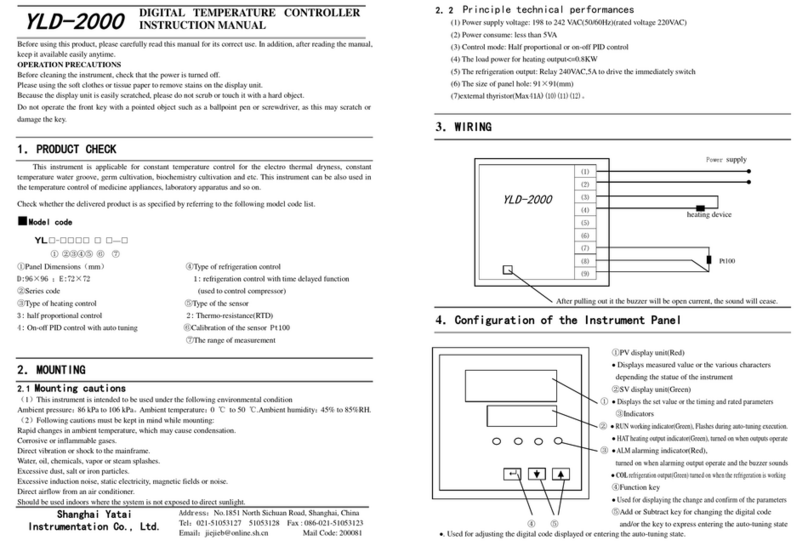

12.1 Electrical data .......................................................................................................................................96

12.2 Mechanical data....................................................................................................................................98

12.3 Mechanical data of the temperature sensor L243 / 5K3A1...............................................................99