5.OPERATION

5.1 Sequence to pick up the functions of the instrument

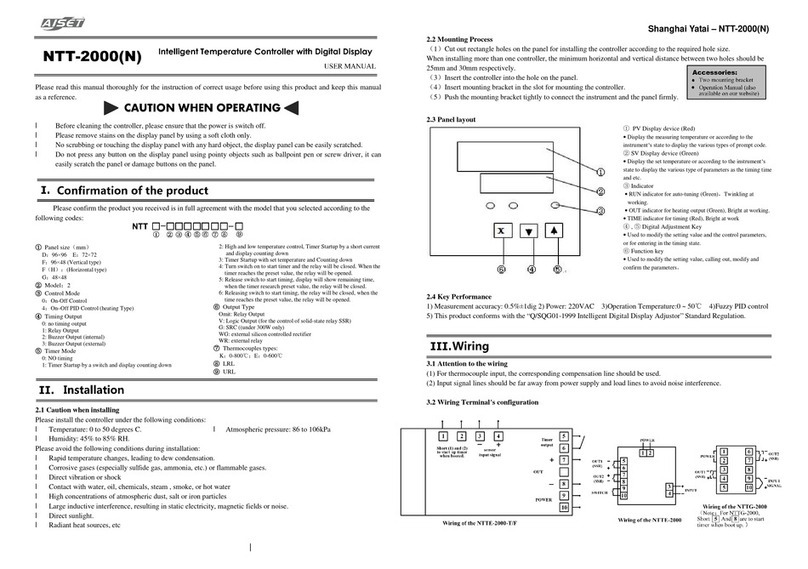

Power on

Upper row displays code

(

Sn

),

lower Row

displays type No. (Display input type)

Upper row: Input high limit, lower row

input low limit(Display input Lange) Automatically turn over after 4 seconds displaying

Upper row displays process value, lower

Automatically return over when not press any key over 1 minute

row displays set value(Standard mode)

Press function key

Upper row displays setting code (SP,St), lower row

displays set value

(

Update the setting mode

)

Press function over 4 seconds

Upper row displays function code (AL

…), Lower row displays

control parameters(

Changing the control parameters

)

5.2 The detail description for every function

If upper row displays ―OVER‖ the sensor is in open circuit or the input signal excesses the range of measurement.

The method for changing set value:

Press

/set key the upper row displays SP. Pressor key,the low row displays the needed

value. Again press

the upper row displays st key. Pressor key, the lower row displays the timing

time needed. Again press

key, the instrument return to the standard display mode.

Timing function

When the value of St is setting to zero, the timing function is canceled. Otherwise when the

value of St is not setting to zero the timing function is available.

When the power is turned on, the timing function starts . In case of achieving the setting timing the heating

output is close. and the buzzer sounds four times to notice the operator.

But the refrigeration output is working continuously. When the system is starting with auto tuning, the timing

function is also canceled. When the auto tuning process is completed, the

timing function would start again. During the operating period of the instrument, it is allowed to update the

value of St online, and the time passed can be memorized and the instrument will operate the updated timing

time. When the updated time is less than the passed accumulative

time, the heating output close immediately, the buzzer sounds 4 times. The refrigeration output is working

continuously.

The method for changing control parameter:

After press

key over 4 seconds, find LK. Then press or key to the lower displayer display 18.Again

press the

key to find the symbol character for the needed parameter. Through press the or key till the

high row displays display the parameter needed is reached. Some parameters may be setting at once. Press the

key over 4 seconds the instrument returned to

the standard mode. If no key is press down the instrument return to its standard mode after 1 minute.

5.3The function of the controllerAuto-tuning

After pressing /TIME key, The instrument displays the time have operated.

After pressing /AT key 20 seconds the AT indicator flashes and the auto-tuning press starts; after the end of

auto-tuning the AT indicator then be turned out. A set of PID parameters can be got automatically for overcoming

temperature overshoot. The controller operates according to this set of PID parameters.

is working continuously.

In the period of auto tuning, if press /AT key beyond 20 seconds the AT indicator turn out and the auto tuning

process is canceled. The instrument operated according to the original PID parameters.

Following table lists the function parameters

0~Full Range

0.0~Full Range

When temperature is beyond SP+AL, the ALM

indicator turn on. The buzzer sounds and the

heating power turn off.

Refrigeration

control setting

0~Full Range

0.0~Full Range

When the temperature less than SP+COL, the

refrigeration point is turn on to drive the

compressor.

1~Full Range

1.0~Full Range

Proportional control action . if P is larger then

the gain of system is lower. it only use on the

heating side.

Integrated time constant. I larger, then the

integrated action is smaller.

Derivative time constant. D larger, then the

derivative action is also larger. D can overcome

overshoot. I=0 and D=0 is called half

proportional control.

Overshoot Control

(re-setting)

At on-off PID control, the value of Ar is a

constant which equals 1.5~2 times of the ratio of

on time to the on-off period in the equilibrium

state. In the half proportional control, the Ar

equals coefficient/P.

For the thyristor output it is about 1 ~3

seconds. For those equipment that the

superfluous power provided is comparatively

larger, select larger T would decrease the stable

error caused by PID control.

Zero point adjust

(intersection)

When the zero error comparatively smaller and

the full point error comparatively larger, to

update this value should be needed. Ordinary for

Pt100,updating this value is rarely needed.

Full point adjust

(intercept)

When the zero error comparatively larger and

the full point error also comparatively larger, to

update this value should be needed. PK=4000×

(setting value –actual value)/actual value. For

Pt100 adjusting this value is need at first time.

Refrigeration

control Time

delayed

When measuring value reaches its alarm value,

the alarm relay output will be delayed this time..

The decimal

Point setting

When D=0 the display resolving power is 1℃

and when DP=1 the display resolving power is

0.1℃

Adjusting rH can make the instrument range

equals 0~rH(℃)

when Lk=18 the parameters listed above then

the above parameters can be updated.