Algas-SDI Operations & Maintenance Manual P/N 52632 1-1

Introduction

1

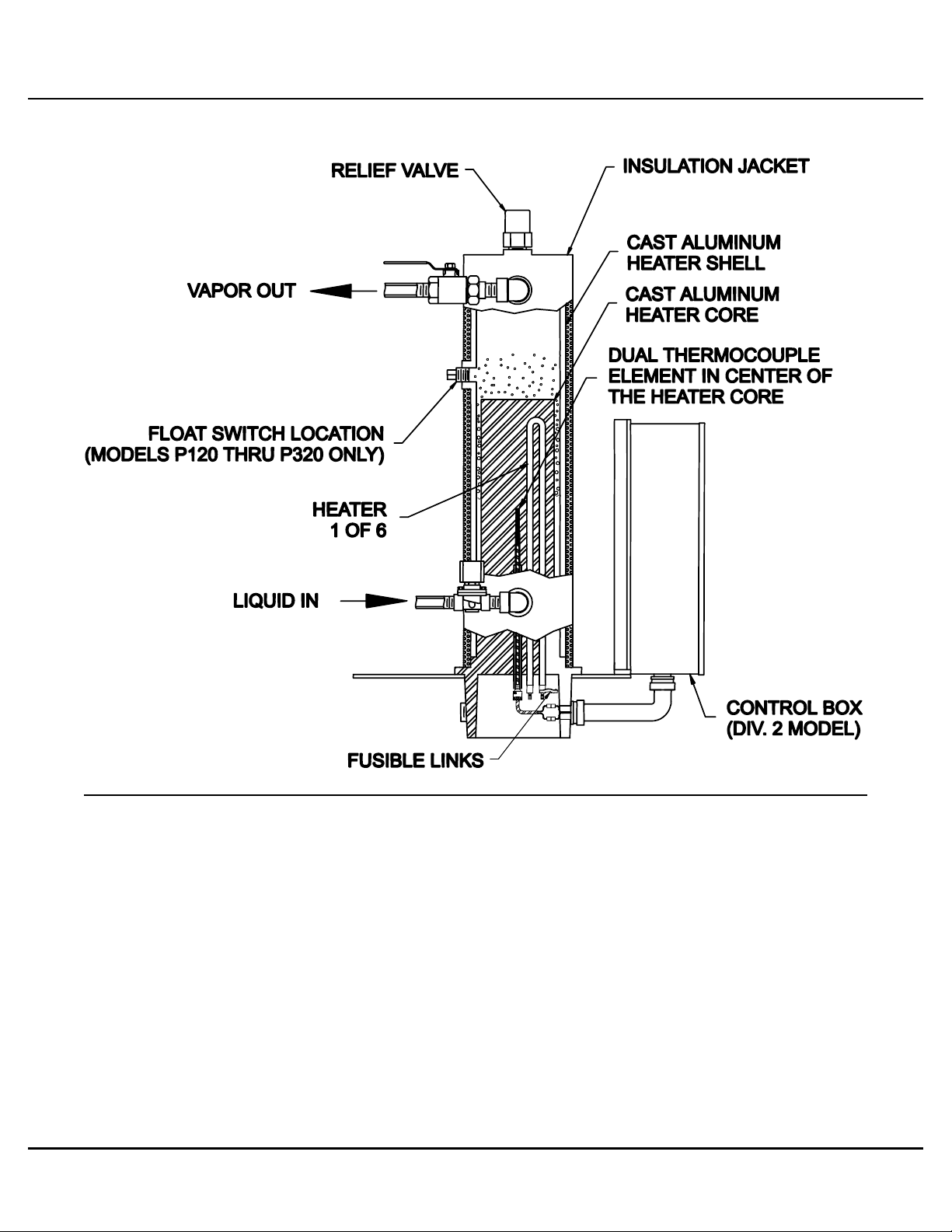

DESCRIPTION

The Algas-SDI POWER Series Vertical Electric Vaporizer heats liquid propane

and transforms it from a liquid to a vapor. The Power Series vaporizers are

“indirect fired”, meaning no open flame is involved in the heating process.

The vaporizers are Factory Mutual and CSA approved and comply with Class I,

Division 1 or Division 2, Group D requirements as specified in NFPA Pamphlet

58. An annotated cut-away drawing of a single unit vaporizer is shown in

Figure 1. Six tubular heater elements are cast into the aluminum heater core.

These elements provide the heat required to vaporizer the LPG. A dual sensor

thermocouple is located in the center of the heater core. One sensor monitors

the heater core temperature and controls the heater ON and OFF cycles.

A second sensor acts as a high temperature safety and shuts the vaporizer off

if an over-temperature situation occurs. A High Liquid Level Safety Float Switch

is integral to each vaporizer. In case of liquid propane build-up in the pressure

vessel due, for example, to demand in excess of the vaporizer’s capacity, the

float will shut the vaporizer off. This will prevent liquid propane carry-over.

Two basic safety devices eliminate the possibility of over-pressurization of the

vaporizer. Over-pressure during normal operation relieves through the Solenoid

Valve and returns to the tank. Abnormal over-pressure relieves

to the atmosphere through a 250 psig (17.58 kg/cm2) pressure Relief Valve.

Three high temperature safety devices protect against over-heating of the

vaporizer. These safety devices are 2 High Temperature Limits on the Control

Board, 1 software shutdown and 1 hardware shutdown and FUSIBLE LINKS on

the heaters.