ECO Sensors PAC-44 Series User manual

28

1

ECO SENSORS, INC.

PAC-44 SERIES PROGRAMMABLE

GAS DETECTION CONTROLLER

1451 Old Pecos Trail

Santa Fe, NM 87505-4737 USA

Ph: 800-472-6626 fx: 505-988-1315 www.ecosensors.com

INSTALLATION / OPERATION MANUAL

REV: D OCT-19-2002

2

27

26

7.9 SYSTEM PROGRAMMING - OTHER CODES

“3132” Toggle Relays: This code allows the user to toggle the system relays to

confirm activation of controlled devices without having to apply test gas on the

sensors to achieve the same. This is a locked function. To achieve this, first input

the software unlock code, then, input code “3132”. The display will indicate that the

relay is “off” and all the relay coil amber LEDs will be go out. Depress push-button

“2” to toggle relay-1. This can be confirmed by the audible “click” from the relay as

well as the amber relay coil LED going on and off as you depress “2”. Next, depress

“3” to scroll to the next relay and repeat the last step. Continue on to the last two

relays by repeating the last two steps or hold down “3” to scroll to the end.

Selection: “On or Off”

“1323” Unlock Code: This code is provided as a safe guard to help ensure that

the user reads this manual before proceeding with the modification of certain

key functions. The code functions that are locked, are so indicated in the

explanation under each code description. Simply enter “1323” then the code

for the function that is to be changed. The display will indicate “Unlocked”.

“3123” Reset System Defaults: This code allows the user to reset all the

programmed functions to the factory default settings. This can help if the user finds

themselves in a position where they may have “messed up” the programming and

cannot figure out how to get everything working properly again. To achieve this, first

input the software unlock code, then input code “3123”. Depress push-button “2 and

the display will indicate “finished” and the system will now be reset to factory

settings. Factory default settings are for a basic system with Carbon Monoxide sen-

sors.

8.0 REPLACEMENT PART NUMBERS

PART NUMBER DESCRIPTON

PAC-44-EN Fiberglass enclosure with Lexan label, audible alarm, silence

PAC-SPS Switching power supply

PAC-MCB Main circuit board

PAC-DDB LCD digital display board c/w ribbon cable

XXXX 90 Db audible alarm (door mounted)

XXXX Silence push-button (door mounted)

XXXX Top mounted, 4” diameter, red strobe light

Note: Consult factory for parts not listed above

RL 1 Menu 3132

Relay Ctrl Off

3

IMPORTANT NOTICE

READ AND UNDERSTAND THIS OPERATION MANUAL PRIOR TO USING

THIS INSTRUMENT.

THIS INSTRUMENT SHOULD BE INSPECTED AND PROGRAMMED BY

QUALIFIED AND TRAINED TECHNICIANS.

THIS INSTRUMENT HAS NOT BEEN DESIGNED TO BE INTRINSICALLY SAFE.

FOR YOUR SAFETY, DO NOT INSTALL IT IN CLASSIFIED HAZARDOUS

AREAS (EXPLOSION-RATED ENVIRONMENTS).

INSTRUMENT SERIAL NUMBER: _____________________________________

PURCHASE DATE: __________________________________________________

PURCHASED FROM: ________________________________________________

WARRANTY POLICY

ECO SENSORS, INC. WARRANTS THIS INSTRUMENT TO BE FREE FROM

DEFECTS IN MATERIALS AND WORKMANSHIP FOR A PERIOD OF TWO

YEARS FROM THE DATE OF PURCHASE. THE WARRANTY STATUS MAY BE

AFFECTED IF THE INSTRUMENT HAS NOT BEEN INSTALLED AND

MAINTAINED AS PER THE INSTRUCTIONS INDICATED IN THIS MANUAL

OR HAS BEEN ABUSED, DAMAGED OR MODIFIED IN ANY WAY. THIS

INSTRUMENT IS ONLY TO BE USED FOR PURPOSES STATED HEREIN. THE

MANUFACTURER IS NOT LIABLE FOR AUXILIARY INTERFACED EQUIP-

MENT OR CONSEQUENTIAL DAMAGE .

DUE TO ONGOING RESEARCH, DEVELOPMENT AND PRODUCT TESTING,

THE MANUFACTURER RESERVES THE RIGHT TO CHANGE SPECIFICATIONS

WITHOUT NOTICE. THE INFORMATION CONTAINED HEREIN IS BASED ON

DATA CONSIDERED ACCURATE. HOWEVER, NO WARRANTY IS EXPRESSED

OR IMPLIED REGARDING THE ACCURACY OF THIS DATA.

ALL GOODS MUST BE SHIPPED TO THE MANUFACTURER BY PREPAID

FREIGHT. ALL RETURNED GOODS MUST BE ACCOMPANIED BY AN RMA

NUMBER.

4

INDEX

SECTION DESCRIPTION PAGE

Notice and Warranty Policy 3

1.0 General 5

2.0 Specifications 5-6

3.0 Installation 6

3.1 Installation “Feet” Drawings 6

4.0 System Enclosure Exterior Dimensional Drawing 7

4.1 System Enclosure Interior Layout Drawing 8

4.2 Wiring 8-9

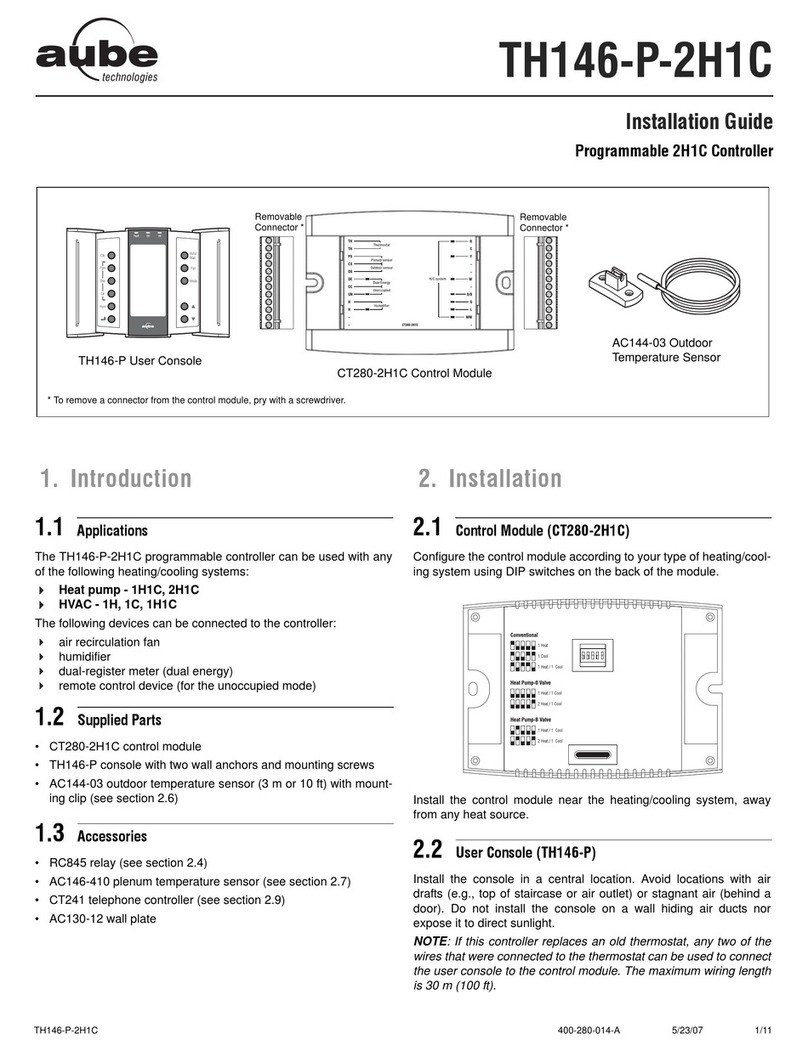

4.3 Wiring Terminals Strip Photos 9

4.4 Wiring Connections Drawing 10

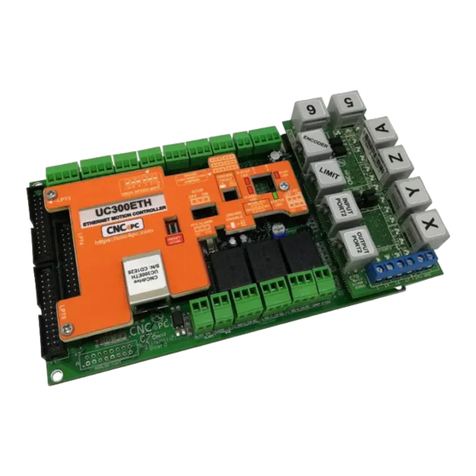

5.0 Main Circuit Board Photo 11

6.0 System Operation 12-13

7.0 System Programming - General 14

7.1 System Programming - Input Codes 14

7.2 System Programming - Output Codes 15

7.3 System Programming - Analog Output Codes 15

7.4 Other Codes 15

7.5 Programming Push-Buttons Photo 16

7.6 System Programming - Input Code Description 16-20

7.7 System Programming - Relay Output Code Description 21-23

7.8 System Programming - Analog Output Code Description 24-25

7.9 System Programming - Other Codes 26

8.0 Replacement Parts 26

25

7.8 SYSTEM PROGRAMMING - ANALOG OUTPUT CODES, CONT’D…..

“1331” Calibrate Analog Output Low Limit: This code provides the user with a

method to calibrate the low limit for each analog output channel. An accurate digital

mulit-meter is required. First attach meter leads to channel-1 output terminal strip.

Set the meter to the DC mA scale. This is a locked function. To proceed, first input

the software unlock code. Next, input code “1331”. The voltage output will be

displayed on your digital multi-meter.

To calibrate this channel, depress push-button “3” to increment to “1” to decrement

the value to achieve “4.00” mA on your meter. Depress push-button “2” to scroll to

the next channel. Move only the positive meter lead to channel-2 and repeat the last

step to once again achieve a reading of 4.00 mA on your meter. Repeat the last two

steps for the last two channels, if they have been enabled for use. Once this function

is finished, continue to depress push-button “2” until you reach the last channel and

the system will automatically start to scroll through all “active” channels.

Selection: N/A

“1332” Calibrate Analog Output High Limit: This code provides the user with a

method to calibrate the high limit for each analog output channel. An accurate

digital mulit-meter is required. First attach meter leads to channel-1 output terminal

strip. Set the meter to the DC mA scale. This is a locked function. To proceed, first

input the software unlock code. Next, input code “1332”. The voltage output will be

displayed on your digital multi-meter.

To calibrate this channel, depress push-button “3” to increment to “1” to decrement

the value to achieve “20.00” mA on your meter. Depress push-button “2” to scroll to

the next channel. Move only the positive meter lead to channel-2 and repeat the last

step to once again achieve a reading of 20.00 mA on your meter. Repeat the last

two steps for the last two channels, if they have been enabled for use. Once this

function is finished, continue to depress push-button “2” until you reach the last

channel and the system will automatically start to scroll through all “active” channels.

Selection: N/A

AC 1 Menu 1331

Null

AC 1 Menu 1332

Span

24

7.8 SYSTEM PROGRAMMING - ANALOG OUTPUT CODES

“3231” Output Channel Enable or Disable: This code allows the user to enable or

disable any of the four system analog output channels. To achieve this, input code

“3231”, then depress push-button “3” for enable or “1” for disable. Depress push-

button “2” to scroll to the next channel. Once this function is finished, continue to

depress push-button “2” until you reach the last channel and the system will

automatically start to scroll through all “active” channels.

Selection: “Yes or No”

“3112” Monitor Input Channel: This code allows the user to select the input

channel each analog output channel will monitor. Each output can monitor only one

input channel. To achieve this, input code “3112”, then depress push-button “3” to

increment or “1” to decrement to the desired channel. Depress push-button “2” to

scroll to the next channel. Once this function is finished, continue to depress push-

button “2” until you reach the last channel and the system will automatically start to

scroll through all “active” channels.

Selection: “1, 2, 3 or 4”

“1321” Setting Analog Output Low Range: This code allows the user to select the

low range measurement for each channel. Default is 4.0 mA = “0”. This is a locked

function. To achieve this, first input the software unlock code, then input code

“1321”, then depress push-button “3” to increment or “1” to decrement the value.

Depress push-button “2” to scroll to the next channel. Once this function is finished,

continue to depress push-button “2” until you reach the last channel and the system

will automatically start to scroll through all “active” channels.

Selection: “0 to 1000”

“1322” Setting Analog Output High Range: This code allows the user to select

the high range measurement for each channel. Default is 20.0 mA = “full sensor

measurement scale”. This is a locked function. To achieve this, first input the

software unlock code, then input code “1322”, then depress push-button “3” to

increment or “1” to decrement the value. Depress push-button “2” to scroll to the

next channel. Once this function is finished, continue to depress push-button “2” until

you reach the last channel and the system will automatically start to scroll through all

“active” channels.

Selection: “ 0 to 10,000”

Note: Carbon Dioxide (CO2) is the only gas sensor type that provides a measure-

ment range selection from “0 to 50,000”.

AC 1 Menu 3231

Enabled ? Yes

AC 1 Menu 3112

Mon Channel 1

AC 1 Menu 1321

Range Low 0

AC 1 Menu 1322

Range High 200

5

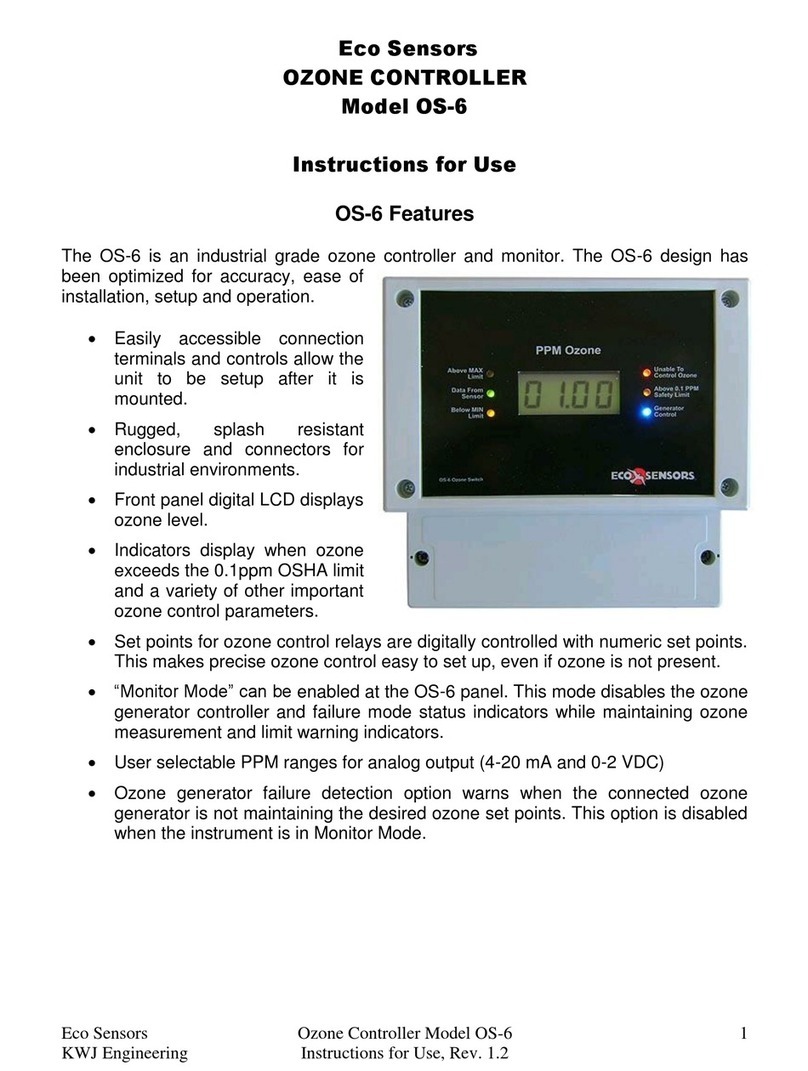

1.0 GENERAL

The PAC-44 series systems are rugged, microprocessor based, programmable

controllers for use in non-hazardous (non-explosion rated) environments for

commercial and industrial applications. They can be configured for use with one to

four remote analog transmitters. They can also be configured with one integral

electrochemical sensor.

A standard system provides an LCD digital display, a common set of LED indicating

lights for fail, low, mid and high alarms, audible alarm with silence button, four

analog inputs, four analog outputs and four dry contact relays.

A large selection of “AST” series analog transmitters, utilizing electrochemical,

catalytic, infrared and MOS (Metal Oxide Semiconductor) sensor elements, are

available for use with this controller.

2.0 SPECIFICATIONS

Physical: a) Dimensions: 8.78” (223 mm) Wide X 10.5” (267 mm) High X

6.25” (159 mm) Deep

b) Weight: 6.33 pounds (2.87 kg)

Construction: Water/dust tight, corrosion resistant fiberglass with hinged,

secured door and Lexan door label

Power: 90 to 240 VAC, 47 to 63 Hz.

Current Load: Maximum allowable system current load is 1.36 Amps @ 24 VDC

Relays: Standard: Four only S.P.D.T. dry contact relays rated 5 amps @

240 VAC each

Output Signal: Linear, analog 4 - 20 mA or 0 - 10 VDC, jumper selectable

Visual: a) Common set of LED indicating lights for: Fault Alarm (red),

Low (Warning) Gas Alarm (amber), Mid Gas Alarm (red), High

Gas Alarm (red)

b) 16-character, two-line, back-lit LCD digital display

c) Amber colored, LED light, relay coil status indicators (internal)

d) Red colored, LED light “open loop” indicators for analog inputs

and analog outputs (internal)

6

1) PLASTIC MOUNTING

FOOT

2) SECURING BOLT

2.0 SPECIFICATIONS, CONT’D…..

Environment: a) Temperature: 0 deg. C. to + 40 deg. C (32 deg. F to 104 deg.

F.)

b) Humidity: 0 to 95% Rh

Fuses: System primary: Automatic resetting thermal fuse rated 1.5 amps

Switching power supply secondary: replaceable 2.0 amp

Certifications: CSA field inspected for low voltage safety

Options: a) Top mounted red strobe light (user programmable)

b) Water tight audible alarm & silence push-button

c) Top mounted audible alarm (103 dB horn)

d) Battery back-up system

e) Internal, programmable data logger

f) Internal sensor (one electrochemical toxic or Oxygen sensor)

3.0 INSTALLATION

Four removable mounting feet are supplied in a plastic bag inside the enclosure c/w

mounting bolts. These should be secured to the rear, outside corners of the

enclosure base. The mounting feet can be loosened off and rotated to two different

mounting positions, straight up vertically from the enclosure base or at a 45 degree

angle from the corner of the enclosure base.

For security, the PAC-44 controller should be installed inside a locked electrical,

mechanical or instrumentation room.

3.1 INSTALLATION “FEET” DRAWINGS

23

7.7 SYSTEM PROGRAMMING - RELAY OUTPUT CODES, CONT’D…..

“2321” Setting Relay Coil State: This code allows the user to select the normal

state of the relay in non-alarm condition (normally energized or normally

de-energized). To achieve this, input code “2321”, then depress push-button “3” to

increment or “1” to decrement through the choices. Depress push-button “2” to scroll

to the next channel. Once this function is finished, continue to depress push-button

“2” until you reach the last channel and the system will automatically start to scroll

through all “active” channels.

Selection: “Fail Safe-Yes or No”

Note: The definition of “Fail-Safe”, for the purposes of this manual, means to keep

the relay coil in a normally energized state in non-alarm condition.

“2313” Setting Relay Latching State: This code allows the user to select if one or

more of the system relays should “latch” when activated by a gas alarm or fault

alarm condition. Latching means that when the relay state changes because it was

activated by an alarm condition, it is held in this changed state. To achieve this,

input code “2313”, then depress push-button “3” to increment or “1” to decrement

through the choices. Depress push-button “2” to scroll to the next channel. Once this

function is finished, continue to depress push-button “2” until you reach the last

channel and the system will automatically start to scroll through all “active” channels.

Note: The user must depress and hold the acknowledge push-button for

approximately 10 seconds to release the latched relays.

Selection: “No or Yes”

“2333” Strobe Light Activation: The system circuit provides 24 VDC voltage

output to power a strobe light (see photo on page-9). This code allows the user to

select which alarm level activates the strobe light. The alarm level selected is

common to all channels. To achieve this, input code “2333”, then depress push-

button “3” to advance through the choices. Once this function is finished, depress

push-button “2” and the system will automatically start to scroll through all “active”

channels.

Note: Strobe always activates with all fault alarms.

Selection: “Low, Mid or High”

RL 1 Menu 2321

Fail Safe ? Yes

RL 1 Menu 2313

Latching ? No

ST 1 Menu 2333

Act Level Low

22

7.7 SYSTEM PROGRAMMING - RELAY OUTPUT CODES, CONT’D…..

“2332” Setting Relay Fault Activation: This code allows the user to assign one or

more relays to respond to fault alarm conditions. To achieve this, input code “2332”,

then depress push-button “3” to increment or “1” to decrement through the choices.

Depress push-button “2” to scroll to the next channel. Once this function is finished,

continue to depress push-button “2” until you reach the last channel and the system

will automatically start to scroll through all “active” channels.

Selection: “Zone, All, None, Sens”

“2112” Monitor Zone Number: This code allows the user to assign the zone

number the relay will monitor with regards to gas or fault alarms, if the input chan-

nels have been set up for “zone”. To achieve this, input code “2112”, then depress

push-button “3” to increment or “1” to decrement through the choices. Depress push-

button “2” to scroll to the next channel. Once this function is finished, continue to

depress push-button “2” until you reach the last channel and the system will

automatically start to scroll through all “active” channels.

Selection: “1, 2, 3 or 4”

“2113” Monitor Channel Number: This code allows the user to assign the channel

number the relay will monitor with regards to gas or fault alarms, if the input

channels have been set up for “zone”. To achieve this, input code “2113”, then

depress push-button “3” to increment or “1” to decrement through the choices.

Depress push-button “2” to scroll to the next channel. Once this function is finished,

continue to depress push-button “2” until you reach the last channel and the system

will automatically start to scroll through all “active” channels.

Selection: “1, 2, 3 or 4”

“2323” Setting Relay Alarm Level: This code allows the user to select the alarm

state to activate each relay. To achieve this, input code “2323”, then depress push-

button “3” to increment or “1” to decrement through the choices. Depress push-

button “2” to scroll to the next channel. Once this function is finished, continue to

depress push-button “2” until you reach the last channel and the system will

automatically start to scroll through all “active” channels.

Selection: “Low, Mid or High”

RL 1 Menu 2332

Fault Act All

RL 1 Menu 2112

Mon Zone 1

RL 1 Menu 2113

Mon Zone 1

RL 1 Menu 2323

Act Level Low

7

4.0 SYSTEM ENCLOSURE EXTERIOR DIMENSIONAL DRAWING

8

4.1 SYSTEM ENCLOSURE INTERIOR LAYOUT DRAWING

4.2 WIRING

Line voltage power to system: Take caution when drilling holes for installing

conduit connections to avoid damaging internal system components. An input

wiring terminal strip for line voltage (line and neutral) can be located at the top left

corner of the circuit board. A ground stud is located on the metal mounting plate

directly beside this terminal strip. Reference minimum and maximum system

voltage specifications on page-5 of this manual.

21

7.7 SYSTEM PROGRAMMING - RELAY OUTPUT CODES

“3221” Relay Enable or Disable: This code allows the user to enable or disable

any of the four system relays. To achieve this, input code “3221”, then depress

push-button “3” for enable or “1” for disable. Depress push-button “2” to scroll to the

next channel. Once this function is finished, continue to depress push-button “2” until

you reach the last channel and the system will automatically start to scroll through

all “active” channels.

Selection: “Yes or No”

“2311” Time Delay on “Make”: This code allows the user to set a time delay period

before one or more relays are activated in the event of a gas alarm. There is no time

delay available for a fault condition. To achieve this, input code “2311”, then depress

push-button “3” to increment or “1” to decrement the time. Once this function is

finished, continue to depress push-button “2” until you reach the last channel and

the system will automatically start to scroll through all “active” channels.

Note: A relay assigned to activate in the event of a gas alarm will activate

immediately unless an off delay is programmed. If an off time delay has been

programmed, the relay will deactivate after the off delay has expired.

Selection: “0.0 to 10.0” minutes

“2312” Time Delay on “Break”: This code allows the user to set a time delay

period before each relay is deactivated. To achieve this, input code “2312”, then

depress push-button “3” to increment or “1” to decrement the time. Once this

function is finished, continue to depress push-button “2” until you reach the last

channel and the system will automatically start to scroll through all “active” channels.

Note: All time delays are +/- 6 seconds timing tolerance

Selection: “0.0 to 10.0” minutes

“2331” Setting Relay Gas Alarm Activation: This code allows the user to select

the normal activation for each relay in the event of a gas alarm. To achieve this,

input code “2331”, then depress push-button “3” to increment or “1” to decrement

through the choices. Depress push-button “2” to scroll to the next channel. Once this

function is finished, continue to depress push-button “2” until you reach the last

channel and the system will automatically start to scroll through all “active”

channels.

Selection: “Zone, All, None, Sens”

RL 1 Menu 3221

Enabled ?

RL 1 Menu 2311

On Delay 0.0

RL 1 Menu 2312

Off Delay 0.0

RL 1 Menu 2331

Normal Act Zone

20

7.6 SYSTEM PROGRAMMING - INTPUT CODES, CONT’D…..

“2233” Set High Range Input: This code allows the user to set the high input

measurement range for each channel. This is a locked function. To achieve this, first

input the software unlock code, then input code “2233”, then depress push-button

“3” to increment or “1” to decrement the value. Depress push-button “2” to scroll to

the next channel. Once this function is finished, continue to depress push-button “2”

until you reach the last channel and the system will automatically start to scroll

through all “active” channels.

Selection: “0 to 10,000”

Note: Carbon Dioxide (CO2) is the only gas sensor type that provides a

measurement range selection from “0 to 50,000”.

“2131” Calibrate Low Input Range: This code allows the user to actually calibrate

the low analog input for each channel. An accurate, known source of 4.00 mA is

required to perform this function. This is a locked function. To achieve this, first input

the software unlock code, then input code “2131”, then depress push-button “2” and

the display will indicate the analog voltage supplied to the channel in question.

Depress push-button “3” to scroll to the next channel. Once this function is finished,

continue to depress push-button “2” until you reach the last channel and the system

will automatically start to scroll through all “active” channels.

Selection: N/A

“2231” Calibrate High Input Range: This code allows the user to actually calibrate

the high analog input for each channel. An accurate, known source of 20.0 mA is

required to perform this function. This is a locked function. To achieve this, first input

the software unlock code, then input code “2231”, then depress push-button “2” and

the display will indicate the analog voltage supplied to the channel in question.

Depress push-button “3” to scroll to the next channel. Once this function is finished,

continue to depress push-button “2” until you reach the last channel and the system

will automatically start to scroll through all “active” channels.

Selection: N/A

CH 1 Menu 2131

Null 4.0

CH 1 Menu 2231

Span 20.0

CH 1 Menu 2233

Range High 200

9

4.2 WIRING, CONT’D…..

Relay wiring: All system are supplied with dry contact relays for control of remote

devices such as contactors for exhaust fans, contactors for make up air fans, horns,

etc. The relay wiring terminal strip is located along the top right edge of the circuit

board. Reference the relay specifications on page-5 of this manual before con-

necting load devices.

Note-1: With regards to fans, the system relays should be used to control the fan

starters or contactors and NOT the fan motor directly.

Note-2: The PAC-44 circuit design is such that the relay coils can be selected as

normally energized (fail-safe) or not normally energized. Unless advised, the factory

default is normally energized in non alarm state. Thus, control wiring should be con-

nected to “COM” and “N/C” terminals. Fail-safe selection means that in the event of

a failure / fault condition, the relay coil changes state and the devices being

controlled, operate continuously until the fault condition is corrected.

Note-3: The PAC-44 controller utilizes a fused, switching power for total system

power. The power supply is located directly on top of the main circuit board and has

a clear, Lexan plastic plate secured on top of it. This helps to protect the power

supply from damage from tools, etc. that may be dropped onto it during installation

or servicing.

Note-4: DO NOT USE SOLID-CORE WIRE AT ANY OF THE CIRCUIT BOARD

TERMINAL STRIPS. Heavy gauge, solid-core wire has memory because of the

thickness of the wire and, over time, can literally pull a soldered terminal strip right

off the circuit board.

4.3 WIRING TERMINAL STRIP PHOTOS

ANALOG INPUT WIRING TERMINALS ANALOG OUTPUTS

RELAY OUTPUT TERMINALS

BATTERY

B/U

TERMI-

NALS

STROBE

TERMINAL

INCOMING

POWER

10

4.4 WIRING CONNECTIONS DRAWING

19

7.6 SYSTEM PROGRAMMING - INTPUT CODES, CONT’D…..

“1211” Low Alarm Set Point: This code allows the user to select or change a

low alarm set point for each channel. To achieve this, input code “1211”, then

depress push-button “3” to increment or “1” to decrement the value. Depress push-

button “2” to scroll to the next channel. Once this function is finished, continue to

depress push-button “2” until you reach the last channel and the system will

automatically start to scroll through all “active” channels

Selection: “0 to 10,000”

“1212” Mid Alarm Set Point: This code allows the user to select or change a

mid alarm set point for each channel. To achieve this, input code “1212”, then

depress push-button “3” to increment or “1” to decrement the value. Depress push-

button “2” to scroll to the next channel. Once this function is finished, continue to

depress push-button “2” until you reach the last channel and the system will

automatically start to scroll through all “active” channels

Selection: “0 to 10,000”

“1213” High Alarm Set Point: This code allows the user to select or change a

high alarm set point for each channel. To achieve this, input code “1213”, then

depress push-button “3” to increment or “1” to decrement the value. Depress push-

button “2” to scroll to the next channel. Once this function is finished, continue to

depress push-button “2” until you reach the last channel and the system will

automatically start to scroll through all “active” channels

Selection: “0 to 10,000”

Note: Carbon Dioxide (CO2) is the only gas sensor type that provides alarm set

point selection from “0 to 50,000”.

“2133” Set Low Range Input: This code allows the user to set the low input

measurement range for each channel (default value is “0”). This is a locked function.

To achieve this, first input the software unlock code, then input code “2133”, then

depress push-button “3” to increment or “1” to decrement the value. Depress push-

button “2” to scroll to the next channel. Once this function is finished, continue to

depress push-button “2” until you reach the last channel and the system will

automatically start to scroll through all “active” channels.

Selection: “0 to 1000”

CH 1 Menu 1211

Low Set Pt: 5

CH 1 Menu 1212

Mid Set Pt: 50

CH 1 Menu 1213

High Set 100

CH 1 Menu 2133

Range Low 0

18

7.6 SYSTEM PROGRAMMING - INTPUT CODES, CONT’D…..

“2211” Low Alarm Ascending or Descending: This code allows the user to select

a descending (Desc) or ascending (Asc) low alarm set point for one or more

channels. To achieve this, input code “2211”, then depress push-button “3” for

ascending or “1” for descending. Depress push-button “2” to scroll to the next

channel. Once this function is finished, continue to depress push-button “2” until you

reach the last channel and the system will automatically start to scroll through all

“active” channels.

Selection: “Asc or Desc”

“2212” Mid Alarm Ascending or Descending: This code allows the user to select

a descending (Desc) or ascending (Asc) mid alarm set point for one or more

channels. To achieve this, input code “2212”, then depress push-button “3” for

ascending or “1” for descending. Depress push-button “2” to scroll to the next

channel. Once this function is finished, continue to depress push-button “2” until you

reach the last channel and the system will automatically start to scroll through all

“active” channels.

Selection: “Asc or “Desc”

“2213” High Alarm Ascending or Descending: This code allows the user to select

a descending (Desc) or ascending (Asc) high alarm set point for one or more

channels. To achieve this, input code “2213”, then depress push-button “3” for

ascending or “1” for descending. Depress push-button “2” to scroll to the next

channel. Once this function is finished, continue to depress push-button “2” until you

reach the last channel and the system will automatically start to scroll through all

“active” channels.

Selection: “Asc or Desc”

Note-1: A descending alarm is typically set for Oxygen sensors. Although,

application dependent, Oxygen can have both descending low alarm and ascending

high alarm.

Note-2: CO2 can only have ascending gas alarms.

CH 1 Menu 2211

Low Alarm Asc

CH 1 Menu 2212

Mid Alarm Asc

CH 1 Menu 2213

High Alarm Asc

11

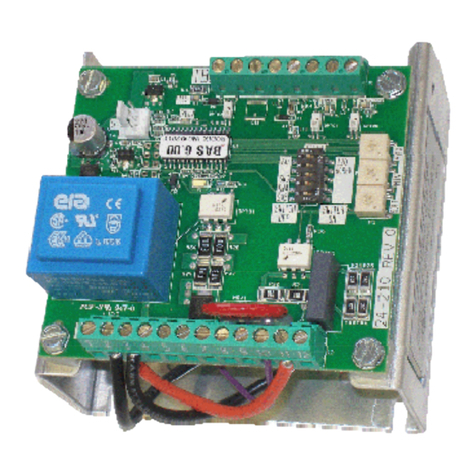

5.0 MAIN CIRCUIT BOARD PHOTO

NOTE: PHOTO SHOWN IS WITH SWITCHING POWER SUPPLY REMOVED TO EXPOSE

ENTIRE CIRCUIT BOARD

NOT

USED

12

6.0 SYSTEM OPERATION

Powering Up: Double check wiring connections prior to powering up the system.

Upon application of line voltage power to the system, the LCD display will

momentarily indicate the software version number then immediately display the

system status and start to scroll through all programmed channels. The display

indicates pertinent information for each programmed channel for approximately 3

seconds before scrolling to the next channel. The information displayed is: Channel

number, Alarm status (top line), Gas type, Actual gas concentration (bottom line).

Any relays programmed as fail-safe will energize (an audible “click” can be heard).

The display can indicate “ppm” (parts per million) for toxic sensors, % LEL (Lower

Explosive Level) for combustible gases and vapors or % Vol. (percent volume) for

Oxygen or other gases. Note: If the fault LED (red) illuminates shortly after system

power up, allow approximately 20 to 30 seconds for the sensor to stabilize and

output the appropriate signal. If the fault condition does not go away after

approximately 30 seconds, it may indicate a wiring problem between the controller

and one or more of the remote analog sensor/transmitters.

All PAC-44 controllers are shipped, tested and programmed to customer job

requirements, assuming project details have been provided to CETCI prior to ship-

ment of the system. If project details have not been provided, all systems are tested

and shipped out with a generic program, addressing the number and type of sensors

ordered and one general zone for all sensors and relays. A label on the inside of the

PAC-44 enclosure door indicates factory default programming. A programming

sheet, unique to the controller supplied can also be found inside the enclosure.

The “AST” series remote analog transmitters are available for use with the PAC-44

controllers. The “TSM” series miniature sensor/transmitters are available for use as

one optional, internal sensor for toxic gases or Oxygen. All sensor/transmitters

supplied are pre-calibrated and ready for installation.

Signals: Eight only 4-20 mA “open loop” LED (red) indicators are provided for the

PAC-44 inputs and outputs. They are located along the lower section of the circuit

board, just above the lower wiring terminal strips. The four open loop indicators

located just above the channel 1 to 4 analog input wiring terminal strips, provide

indication of a good or bad analog signal to each channel. The four open loop

indicators located just above the 4-20 mA output wiring terminal strips, provide

indication of a good or bad analog signal connection to remote devices.

One or more of these red LEDs will illuminate if one or more of the 4-20 mA signal

loops are not connected properly or the connection is broken. This could also

indicate a burned out sensor element from a remote analog transmitter with a solid-

state or catalytic sensor element. It could also indicate an expired Oxygen sensor

element from an integral Oxygen sensor or remote Oxygen sensor/transmitter.

Alarms: Upon detection of a gas concentration above a preset level for any of the

alarm set points, the low, mid or high alarm LED will illuminate and the appropriate

relay will be activated, assuming relays have been enabled, properly programmed,

and any programmed time delays have timed out. In the event of a fault alarm

condition, the fault LED (red) will illuminate, the audible alarm will sound and any

relays programmed to respond to a fault condition will be activated.

17

7.6 SYSTEM PROGRAMMING - INTPUT CODES, CONT’D…..

“1112” Zoning: This code allows the user to selectively group one or more

channels (sensors) with one or more relays for selective output control. To achieve

this, input code “1112”, then depress push-button “3” to increment or push-button “1”

to decrement the number. Depress push-button “2” to scroll to the next channel.

Once this function is finished, continue to depress push-button “2” until you reach

the last channel and the system will automatically start to scroll through all “active”

channels.

Selection: “1, 2, 3 or 4”

“1232” Units of Measure: This code allows the user to select the units of measure

to be displayed for each sensor connected to each channel. To achieve this, input

code “1232”, and the LCD display will indicate the units last selected for that

channel. Next, depress push-button “3” to scroll up through the choices or push-

button “1” to scroll down through the choices. Depress push-button “2” to scroll to

the next channel. Once this function is finished, continue to depress push-button “2”

until you reach the last channel and the system will automatically start to scroll

through all “active” channels.

Selection: “ppm, % LEL, % Vol., % rH, 0C, 0F, PSI”

“1231” Sensor Type: This code allows the user to select a specific sensor gas type

to be displayed for each channel. This information tells the user exactly which gas is

being monitored for and which type of sensor technology has been selected to

detect it. Example “CO” (Carbon Monoxide), “el” (electrochemical). To achieve this,

input code “1231”, then depress push-button “3” or “1” to scroll through the selection.

Depress push-button “2” to scroll to the next channel. Once this function is finished,

continue to depress push-button “2” until you reach the last channel and the system

will automatically start to scroll through all “active” channels.

Selection: “CO % LEL, CO el, CO ss, CO2 ir, C3H8 ss,

C3H8 ct, NH3 ss, NH3 el, NO el, NO2 el, O2 el, O3 el, R11

ss, R12 ss, R22 ss, R123 ss, R134A ss, R507 ss, R407A ss,

R408A ss, R404A ss, HP62 ss, HP80 ss, CH4 ss, CH4 ct,

Cl2 el, Temp, Humid, Press, H2 ct, H2 ss, H2 el, Alco ct, Tol

ct, ETO el, H2S el, SO2 el, HCN el, O2 ga,

Interpretation: el = electrochemical Tol = Toluene

ss = solid-state Alco = Alcohol

ct = catalytic (pellistor for combustibles) ir = infrared

ga = galvanic (Oxygen high range) Press = pressure

Temp = Temperature

Humid = Humidity (rH relative humidity)

CH 1 Menu 1112

Input Zone 1

CH 1 Menu 1232

Units ppm

CH 1 Menu 1231

CO el

16

7.6 SYSTEM PROGRAMMING - INPUT CODE DESCRIPTION

“3211” Channel Enable / Disable: This code allows the user to select the number

of channels to be activated. This is determined by the number of remote analog

devices to be connected to the controller. To achieve this, input code “3211”, then

depress push-button “3” to enable a channel or push-button “1” to disable a

channel. Depress push-button “2” to scroll to the next channel. Once this function is

finished, continue to depress push-button “2” until you reach the last channel and

the system will automatically start to scroll through all “active” channels. The system

will ignore the “inactive” channels during normally scrolling. Active channels are

channels that have been switched on and inactive channels are channels that have

been switched off.

Note: This code also allows the user to take a channel “off line” to remove and

service a sensor, if required, while the other channels are being monitored and

displayed normally. Power is still live at the inactive channel terminal strip even

though the channel is offline.

Selection” “Yes or No”

“1122” Decimal: This code allows the user to add up to three decimal points to the

displayed value. To achieve this, input code “1122”, then depress push-button “3” to

select 1, 2 or 3 decimals. To add or remove decimal points, depress push-button “3”

to increment or push-button “1” to decrement the number. Depress push-button “2”

to scroll to the next channel. Once this function is finished, continue to depress

push-button “2” until you reach the last channel and the system will automatically

start to scroll through all “active” channels.

Selection: “0, 1, 2 or 3”

CH 1 Menu 1122

Decimal Pts 0

7.5 PROGRAMMING PUSH-BUTTONS PHOTO

USE THESE THREE PUSH-BUTTONS TO ENTER ALL FOUR DIGIT PROGRAMMING CODES

CH 1 Menu 3211

Enabled ? Yes

13

6.0 SYSTEM OPERATION, CONT’D…..

The audible alarm will also sound in the event of a high level alarm. This can be

silenced by depressing the acknowledge/silence push-button located on the front

enclosure door just below the audible alarm.

Note-1: The operation of any of the relays is subject to any user programmed time

delays and/or latching functions. More information is provided further on in this

manual with regards to these two features.

Note-2: If more than one alarm condition occurs, the display will automatically scroll

only through channels that are in alarm condition. The scroll rate for channels in

alarm condition is slightly faster than the normal scroll rate. The scroll pattern is from

the most serious alarm condition to the lesser alarm condition. Fault is considered to

be the most serious alarm condition folowed by high gas alarm, mid gas alarm and

finally low gas alarm.

Fault Alarms: Upon detection of a fault condition, the red fault LED is illuminated, the

audible alarm sounds and any relays programmed to respond to fault condition are

activated.

Programming: The PAC-44 circuit is completely programmable on site without the

need for a computer. Any changes in the system operation can be made quickly and

easily by means of the push-button programming feature. Three small, momentary

push-buttons can be located on the lower left center area of the circuit board (just

above the analog input terminal strips). These push-buttons can be used to enter a

large selection of four digit codes to access a wide range of system functions and

features. For more detailed information on system programming, consult the

programming section of this manual.

Battery back-up: The PAC-44 system has been designed to accept an optional

battery back up system to provide uninterrupted power to the gas detectors in the

event of a power failure. The wiring input terminal strip for wires coming from the

battery back up system are located at the top of the wiring terminal strip which is

located on the lower left side of the circuit board, just to the left of the programming

push-buttons.

In the event of a system failure fault alarm, first check to ensure that the system

primary fuse has not “blown”, prior to performing other trouble shooting tasks. The

system primary fuse is an automatic resetting thermal fuse and is located just to the

right of the incoming power terminal strip. If the fuse is hot to the touch, this

indicates that it has “blown”. This fuse will not reset itself until the power or wiring

problem has been rectified.

System alarm: The software installed in the PAC-44 controller has a “watchdog

timer” built into it. The watchdog timer watches the microprocessor and if it

encounters an interruption that causes it to veer off track and cause a fault condition,

the watchdog timer automatically resets the microprocessor so the user does not

have to deal with the problem. The system alarm is activated on the LCD display

after the fourth watchdog timer reset. The display will indicate “SYSM ALRM”. The

system will continue to work properly, however, this display will continue to indicate

the alarm message. The user should contact their supplier about this problem. To

clear this alarm, depress and hold the acknowledge push-button for 10 seconds.

14

7.0 SYSTEM PROGRAMMING / GENERAL

The PAC-44 controller has an extensive menu system that allows the user maximum

flexibility, through programming, to achieve a wide range of system functions.

Please carefully read through the programming section before attempting to make

programming changes.

The system menu structure is broken into three major sections, “Input Control”,

“Relay Output Control” and “Analog Output Control”. Input control allows the user to

program all the desired parameters for the sensor input channels. Output control

allows the user to program all the desired parameters for the relays and analog

outputs for controlling external devices and sending signals to remote devices.

The following table indicates available programmable functions and the input codes

for each. Detailed descriptions for each can be found on the following pages.

Note: Holding down a button for more than 2 seconds will allow the user to scroll

very quickly.

7.1 SYSTEM PROGRAMMING - INPUT CODES

CODE DESCRIPTION PAGE

Input Set Up

3211 Channel Enable or Disable 16

1122 Decimal Points 16

1112 Zoning 17

1231 Gas Sensor Type 17

1232 Units of Measure 17

2211 Low Alarm Ascending / Descending 18

2212 Mid Alarm Ascending / Descending 18

2213 High Alarm Ascending / Descending 18

1211 Low Alarm Set Point 19

1212 Mid Alarm Set Point 19

1213 High Alarm Set Point 19

Input Channel Calibration

2133 Set Low Input Range (Null Value) 19

2233 Set High Input Measurement Range (Span Value) 20

2131 Calibrate Low Input Range (4 mA source required) 20

2231 Calibrate High Input Range (20 mA source required) 20

15

7.2 SYSTEM PROGRAMMING - OUTPUT CODES

CODE DESCRIPTION PAGE

Relay Output Set Up

3221 Relay Enable or Disable 21

2311 Time Delay “On Make” 21

2312 Time Delay “On Break” (Minimum Run Time) 21

2331 Setting Relay Gas alarm Activation 21

2332 Setting Relay Fault Condition Activation 22

2112 Monitor Zone Number 22

2113 Monitor Channel Number 22

2323 Setting Relay Alarm Level State 22

2321 Setting Relay Coil State 23

2313 Setting Relay Latching State 23

2333 Strobe Light Activation 23

7.3 SYSTEM PROGRAMMING - ANALOG OUTPUT CODES

CODE DESCRIPTION PAGE

Analog Output Setup

3231 Channel Enable or Disable 24

3112 Monitor Input Channel 24

1321 Setting Analog Output Low Range 24

1322 Setting Analog Output High Range 24

Output Channel Calibration

1331 Calibration of Analog Output Lower Limit 25

1332 Calibration of Analog Output Upper Limit 25

7.4 OTHER CODES

CODE DESCRIPTION PAGE

3132 Relay Toggle 26

1323 Unlock 26

3123 Reset System Defaults 26

This manual suits for next models

4

Table of contents

Other ECO Sensors Controllers manuals

Popular Controllers manuals by other brands

Lenz

Lenz DIGITAL plus LZ100 Information

Helios

Helios TSD 0,8 Installation and operating instructions

JLCooper Electronics

JLCooper Electronics SloMoPro user manual

Moons'

Moons' LIN ENGINEERING Silverpak 17C user manual

Emerson

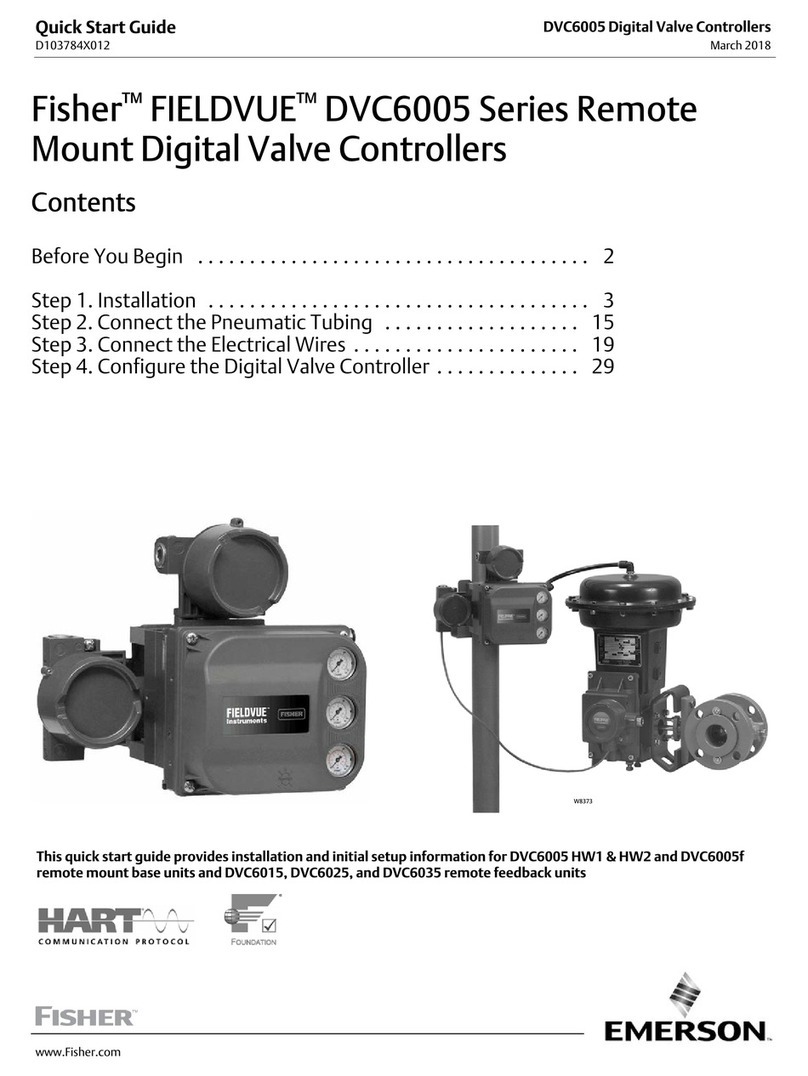

Emerson Fisher FIELDVUE DVC6005 Series quick start guide

LEAMING INDUSTRIES

LEAMING INDUSTRIES AGC-100 Instruction book