C O N T E N T S

1.0 SPECIFICATIONS ................................................................................................................... 5

Finish.......................................................................................................................................... 5

Dimensions ................................................................................................................................. 5

Maximum Capacity (Full Load) (AS 2040) ................................................................................. 5

Water Consumption Per Fill (With Full Clothes Load) ................................................................5

Wash Motor ................................................................................................................................ 5

Pump Motor................................................................................................................................ 6

Water Valves............................................................................................................................... 6

Thermistor .................................................................................................................................. 6

Recirculating Valve..................................................................................................................... 6

Inner Bowl Speed........................................................................................................................ 6

Fabric Softener Dispenser ........................................................................................................... 6

Electric Supply............................................................................................................................ 6

Max Current................................................................................................................................ 6

2.0 INTRODUCTION.................................................................................................................... 7

PERFORMANCE CHANGES .................................................................................................... 7

Recirculating Smart Drive System........................................................................................... 7

ELECTRONICS ......................................................................................................................... 8

STAND BY MODE .................................................................................................................... 9

WATER TEMPERATURE SENSING........................................................................................ 9

WATER VALVES...................................................................................................................... 9

RECIRCULATING VALVE....................................................................................................... 9

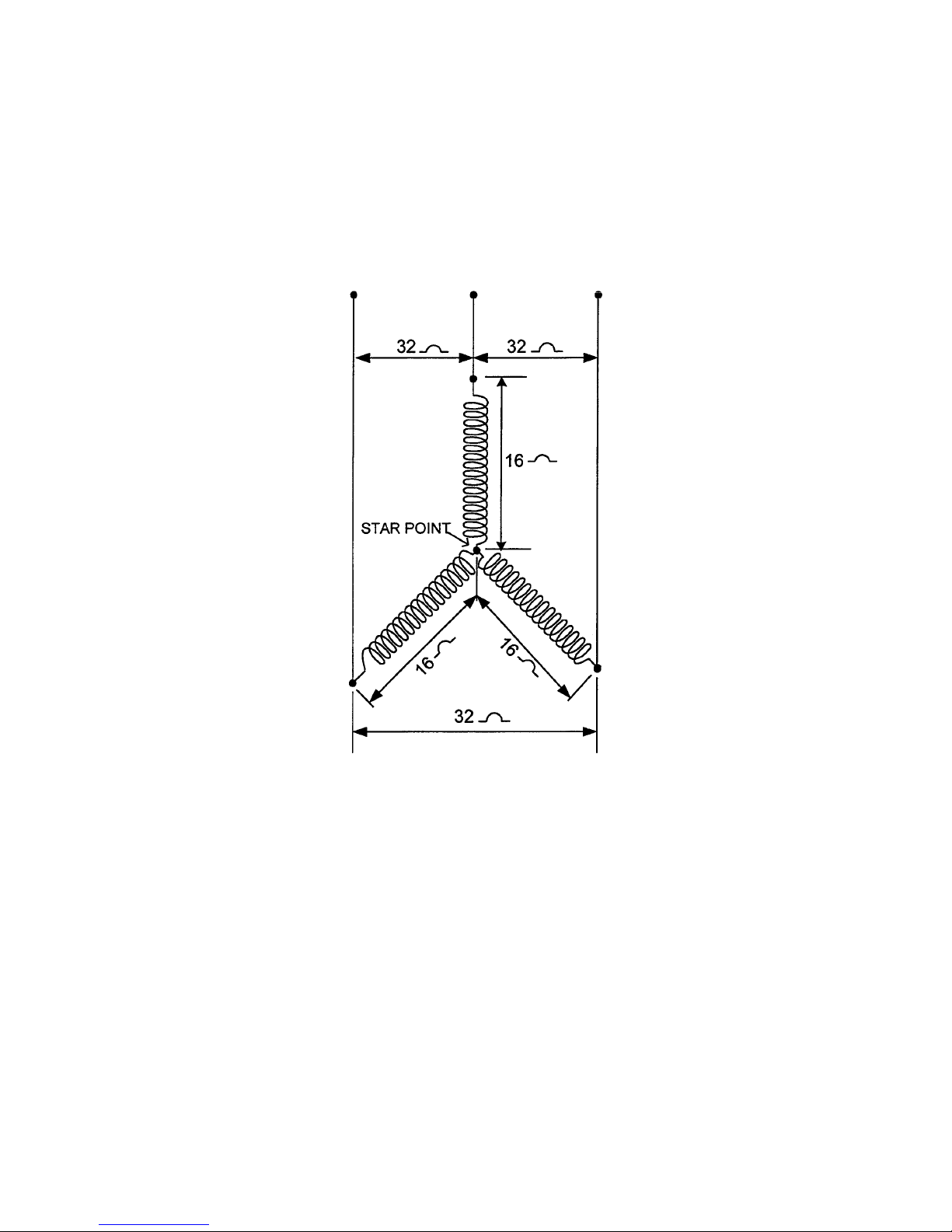

STATOR................................................................................................................................... 10

PUMP ....................................................................................................................................... 10

SIZE SETTING MODE (Same as Series 8)............................................................................... 11

3.0 DIAGNOSTIC MODE........................................................................................................... 12

3.1 EXAMPLES OF BINARY CODE...................................................................................... 13

3.2 LID SWITCH & OUT OF BALANCE SWITCH TEST..................................................... 14

3.3 DRAIN PUMP TEST ......................................................................................................... 14

3.4 WATER VALVE TEST..................................................................................................... 14

3.5 RE-START FEATURE ...................................................................................................... 15

3.6 RE-CYCLE FEATURE...................................................................................................... 15

3.7 HOT TUB FLAG ...............................................................................................................15

3.8 FAULT DISPLAY ............................................................................................................. 16

4.0 WIRING DIAGRAM .............................................................................................................16

5.0 DETAILED FAULT CODES................................................................................................. 17

FAULT DESCRIPTIONS ......................................................................................................... 18