Ecomax Eco f Series User manual

Eco f series (eco-f201, eco-f301, eco-f502)

X-ray Generator

INSTALATION / SERVICE MANUAL

Eco f Series MANUAL (service / installation)

DOCUMENT NO. : Eco f Series Page : 1

I N D E X

Chapter 1. generator specification

page

.

Generator specification ----------------------------- 4

. Radiation arning for diagnostic x-ray systems -------------------------- 7

. Mechanical / electrical arning for diagnostic x-ray systems ---------- 8

Chapter 2. Generator parts

. Control box internal sides ---------------------------- 10

. Console PANEL ---------------------------- 14

. HV tank ---------------------------- 15

. Cables ---------------------------- 16

Chapter 3. Connections

. HV tank connections ---------------------------- 18

. X-ray Tube connections ---------------------------- 20

. console connections ---------------------------- 21

. Collimator light and 24Vdc locks connection ---------------------------- 22

. input po er connections ---------------------------- 22

Eco f Series MANUAL (service / installation)

DOCUMENT NO. : Eco f Series Page : 2

Chapter 4. Calibration and Adj stment

Name on Operating Panel --------------------------- 24

Calipration

. kV calipration --------------------------- 29

. mA calipration --------------------------- 32

Chapter 5. Errors and Tro ble shooting

Inspection points identification and limits calibration points---------- 35

over mA safety limits calibration -------------------------- 41

Error indication list ------------------------- 42

Tro ble Shooting G ide ------------------------ 43

Chapter 6. Wire Connection

. P I/O Board Connections ------------------------- 47

. CP Board Connections ------------------------- 50

. Rabun signal cable ------------------------- 51

. Po er supply terminals ------------------------- 51

Eco f Series MANUAL (service / installation)

DOCUMENT NO. : Eco f Series Page : 3

Chapter 1.

Generator specification

Eco f Series MANUAL (service / installation)

DOCUMENT NO. : Eco f Series Page : 4

Generator specifications

CH.1

Spec,

Explanation

Active

CONTACTING

back to back SCR‘s ith zero start and stop. The

SCR ‘S is protected by mechanical main contactor

Feedback sense ith closes before and opens

After the SCR’S ensuring full safety.

STARTER

Electro mechanical ith filament boost and time delay.

TUBE SAFETY

Built in circuit

have ability to be calibrated

to protect tube

from Techniques beyond its rating. Protects kv and mA time

.

RECTIFIER’s

Solid state, compensated, rated to 125 kvp Working.

X

-

RAY TUBE

FILAMENT

Constant voltage stabilizer orking into a Temperature

Compensated calibrating net ork.

KVP

hen the mA is correctly adjusted and Compensated,

Kvp Is correct to plus or Minus 5% of full scale, any

Station.

MA

The mA, hen correctly adjusted for space Charge is

Accurate to plus or minus 10% any station.

ACCURA

TE

TIMER

Timer is accurate to plus or minus zero pulses.

MAS

The product of

multiply of milli amperes selected and time

Chosen.

Tube rotor

Rotor brake protection system

Eco f Series MANUAL (service / installation)

DOCUMENT NO. : Eco f Series Page : 5

.Digital normal frequency generator

model

eco

-

f201

eco

-

f301

eco

-

f502

voltage inp t req irements

1phase 220VAC +15%

1phase

220VAC +15%

1phase 220VAC +15%

power o tp t

20 KVA

25 KVA

32 KVA

Max. c rrent inp t const.

70A

95A

120A

KV range

40

-

100 kv (step 1kv)

40

-

110 kv (step 1kv)

40

-

120 kv (step 1kv)

t be mA range

25,50,100,150,200

25,50,100,150,200,300

50,100,150,200,300,500

mAS range

0.4

-

300 mAs

0.4

-

400 mAs

0.4

-

500 mAs

Time range

0.02

-

5 sec

0.02

-

5 sec

0.02

-

5 sec

C rrent at common se @ 85kv

~ 52A

~ 75A

~ 110A

t be

canon (toshiba 7239) 140 KHU / 2800 RPM

Weight of control box

80 Kg

90 Kg

Weight of HV tank

120 Kg

160

Kg

.Control box dimensions

570 mm L x 466 mm W x 650 mm H

CH.1

Eco f Series MANUAL (service / installation)

DOCUMENT NO. : Eco f Series Page : 6

. HV tank dimensions

540 mm L x 380 mm W x 490 mm H

Console stand dimensions

250 mm L x 150 mm W x 800 mm H

CH.1

Eco f Series MANUAL (service / installation)

DOCUMENT NO. : Eco f Series Page : 7

RADIATION

WARNING

FOR

DIAGNOSTIC

X-RAY

SYSTEMS

X-rays are dangerous to both operator and others in the vicinity unless established safe

exposure procedures are strictly observed.

The useful and scattered beams can produce serious, genetic or potentially fatal bodily

injuries to any persons in the surrounding area if used by an unskilled operator adequate

precautions must al ays be taken to avoid exposure to the useful beam, as ell as to

leakage radiation from ithin the source housing or to scattered radiation resulting from

the passage of radiation through matter

Those authorized to operate ,test ,participate in or supervise the Operation must be

thoroughly familiar and comply completely ith the currently established safe exposure

factors and procedures described in publications such as sub chapter J of Titel21 of the

code of federal regulation of the equipment s ‘’Diagnostic X-ray systems and their major

components “and the national council on radiation protection (NCRP) No.33 medical S-Ray

and Gamma-ray protection for energies up to 10 MeV-equipment design and us ,revised

or replaced in the future

Failure to observe these arning may cause serious, genetic or potentially fatal bodily

injuries to the operator or those in the area

CH.1

Eco f Series MANUAL (service / installation)

DOCUMENT NO. : Eco f Series Page : 8

MECHANICAL

/

ELECTRICAL WARNING FOR DIAGNOSTIC X

-

RAY SYSTEMS

All of the moveable assemblies and parts of X-Ray equipment should be operated ith care.

Only properly trained and qualified personnel should be permitted access to any internal

parts. Live electrical terminals are deadly be sure line disconnect s itches are opened and

other appropriate precautions are taken before opening access doors removing enclosure

panels or attaching accessories.

Do not remove the flexible high voltage cables; they must be grounded immediately in

order to dissipate any electrical charge that may remain on the cables or the tube.

Failure to comply ith the foregoing may result in serious or potentially fatal bodily injuries

of the operator or those in the area.

CH.1

Eco f Series MANUAL (service / installation)

DOCUMENT NO. : Eco f Series Page : 9

Chapter 2.

Generator parts

Eco f Series MANUAL (service / installation)

DOCUMENT NO. : Eco f Series Page : 10

.Control box internal sides

Control box side 1

CH.2

1 nput connector (TB1)

2 Main Power switches

3 nternal power protection switch

4 Power supply

5 SCR Exp electronic switch

6 Safety contactor

7

Power indication

8 Variable transformer motor connector

9 Variable transformer connector

10 Rotor brake timing unit

7

4

9

6

1

8

10

2

5

3

Eco f Series MANUAL (service / installation)

DOCUMENT NO. : Eco f Series Page : 11

Control box side 2

1

P /O Board

2 CP Board

3

24Vdc /O Board

4 Variable power transformer

5 Tube rotor capacitor

CH.2

5

1

4

2

3

Eco f Series MANUAL (service / installation)

DOCUMENT NO. : Eco f Series Page : 12

Control box side 3

CH.2

1

Stand by pre heating adjustable resistor

2

Common main filament adjustable resistor (common mA)

3

Large focus filament adjustable resistor

4

Small focus filament adjustable resistor

5

Rotor current control adjustable resistor

6

24Vdc collimator fuse

7

Output power

connectors (TB2)

1

2

3

4

7

5

6

Eco f Series MANUAL (service / installation)

DOCUMENT NO. : Eco f Series Page : 13

Control box side top

1

Variable transformer DC motor

2 Belt

3 Constant stabilizer filament transformer

4 Motion limit switches

CH.2

1

4

2

3

Eco f Series MANUAL (service / installation)

DOCUMENT NO. : Eco f Series Page : 14

Console PANEL

Power switch Control cable connector

Hand switch cable connector

PREP/EXP hand switch

CH.2

Eco f Series MANUAL (service / installation)

DOCUMENT NO. : Eco f Series Page : 15

HV tank

Oil inlet

Cathode

Anode

Terminals Earth

CH.2

Eco f Series MANUAL (service / installation)

DOCUMENT NO. : Eco f Series Page : 16

Cables

.

HV cables 75Kv 8m 10m 15m

. Console cable D25 M/F 8m 10m 15m

CH.2

Eco f Series MANUAL (service / installation)

DOCUMENT NO. : Eco f Series Page : 17

Chapter 3.

Connections

Eco f Series MANUAL (service / installation)

DOCUMENT NO. : Eco f Series Page : 18

HV tank connections

Oil inlet

Cathode HV

Anode HV

Terminals GND

Terminals

NO.

Symbol

Description

Remark

1

F1

Small

Filament terminal

2

F0

Common filament terminal

3

F2

Large filament terminal

4

P1

Primary HVT terminal 1

5

P2

Primary HVT terminal 2

6

M

mA

measuring terminal

7

G

GND

CH.3

This manual suits for next models

3

Table of contents

Popular Portable Generator manuals by other brands

Scheppach

Scheppach SG2500 Translation from the original instruction manual

Honeywell

Honeywell G0060651 Operator's manual

Briggs & Stratton

Briggs & Stratton 14000 Series installation instructions

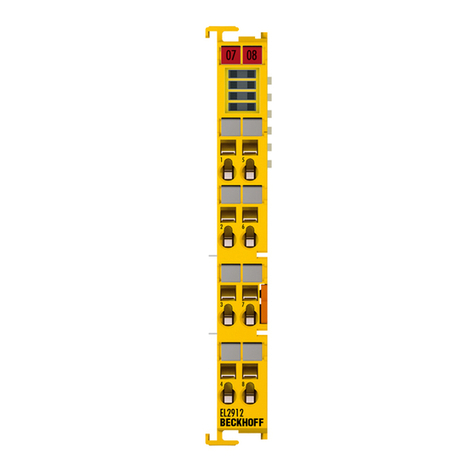

Beckhoff

Beckhoff TwinSAFE EL2912 operating instructions

Matsusada Precision

Matsusada Precision PKTS Series instruction manual

Firman

Firman P03634 Operator's manual