Installation & Operation Manual

Proven Quality since 1892

ECON bucket filter Fig. 1096 www.eriks.com

Rev. 1

8. Maintenance

Before starting any service jobs, make sure that the medium supply to the pipeline is cut off,

pressure was decreased to ambient pressure, the pipeline is completely ventilated and the plant is

cooled down. Always keep safety instructions in mind and take all personal safety precautions.

During maintenance, the following rules should be observed:

- always keep personal safety precautions in mind and always use appropriate protection

e.g. clothing, masks, gloves etc.

- be alert that the temperature still can be very high or low and can cause burns.

- check the strainer on all possible leaking possibilities.

- check if all bolts and nuts, are still fastened.

- the thickness of the body must be checked to ensure safety operation at an interval of at

least three months.

During cleaning the following steps have to be taken:

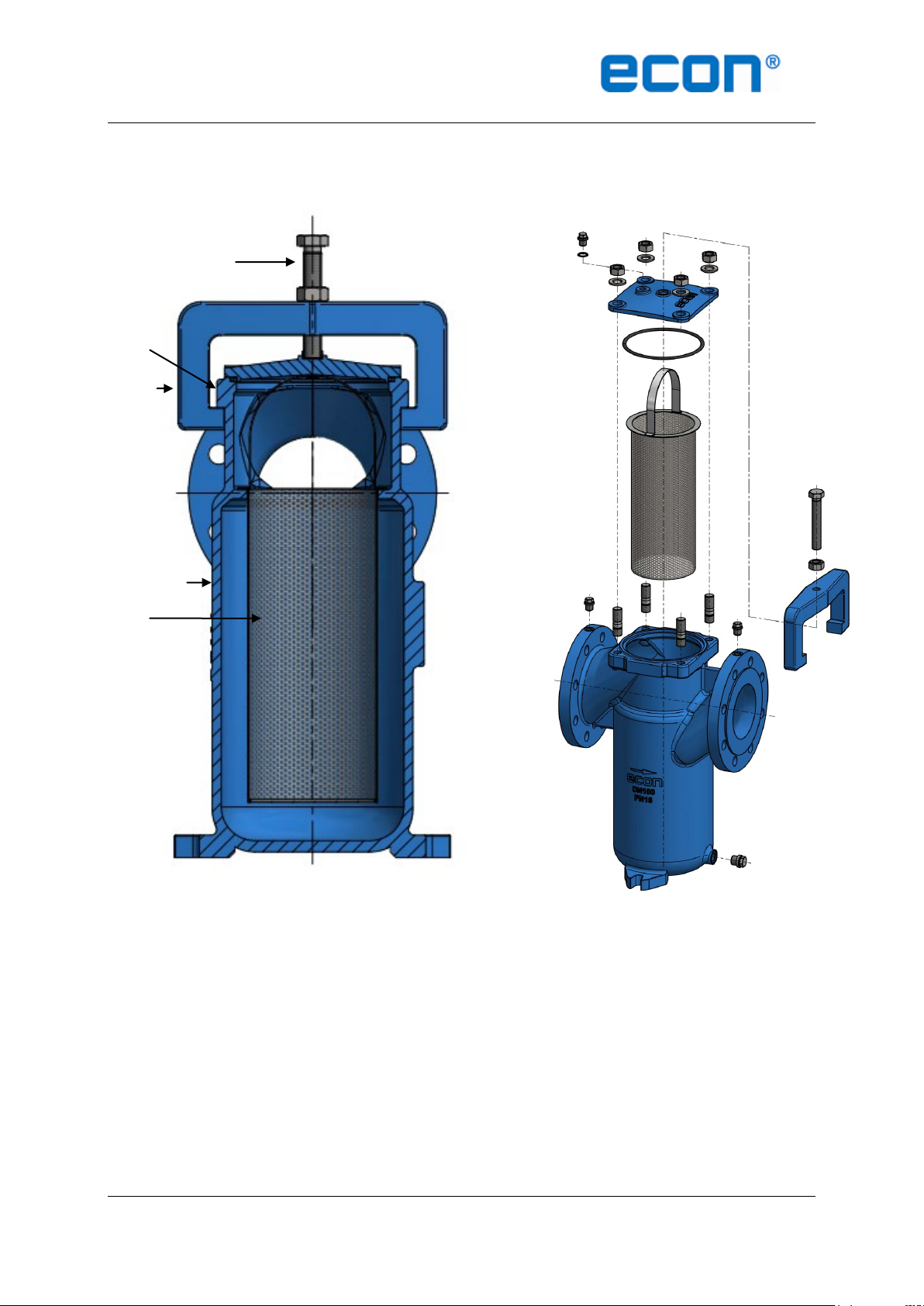

- relieve the pressure on the bucket filter by means of the venting device and drain unit.

- loosen the cover bolts and lift off the cover

- drain the filter through the drain unit to a level that is at least below the filterer insert

support.

- pull the filter insert upwards and out of the filter housing. The filter insert can now be

cleaned by careful blowing it out or blasting it with compressed air, steam, or water. If

necessary the filter insert must be soaked and cleaned in a suitable cleaning space. In

some circumstances optimum cleaning is achieved by means of ultrasound. For all

cleaning types ensure that the filter mesh is not damaged.

- when assembling the filter insert in the reverse sequence, check the sealing elements for

wear and replace them if necessary.

9. Service and repair

All service and repair jobs should be carried out by authorized staff, using suitable tools and user

shall use original gasket, bolt and nut of the same size and material as the original one.

- welding (repair) and drilling of the bucket filter is forbidden.

- it is forbidden to replace the bolt, nut or packing when the strainer is under pressure.

- tighten the hexagon nuts evenly crosswise in the there for standard order.

- after replacement of the gasket, bolts or nuts, it is necessary to check the strainer

operation and tightness of all connections. A tightness test should be carried out.

- after installation, the filter should be checked and maintained periodically at least every

3 months, depending on the medium.

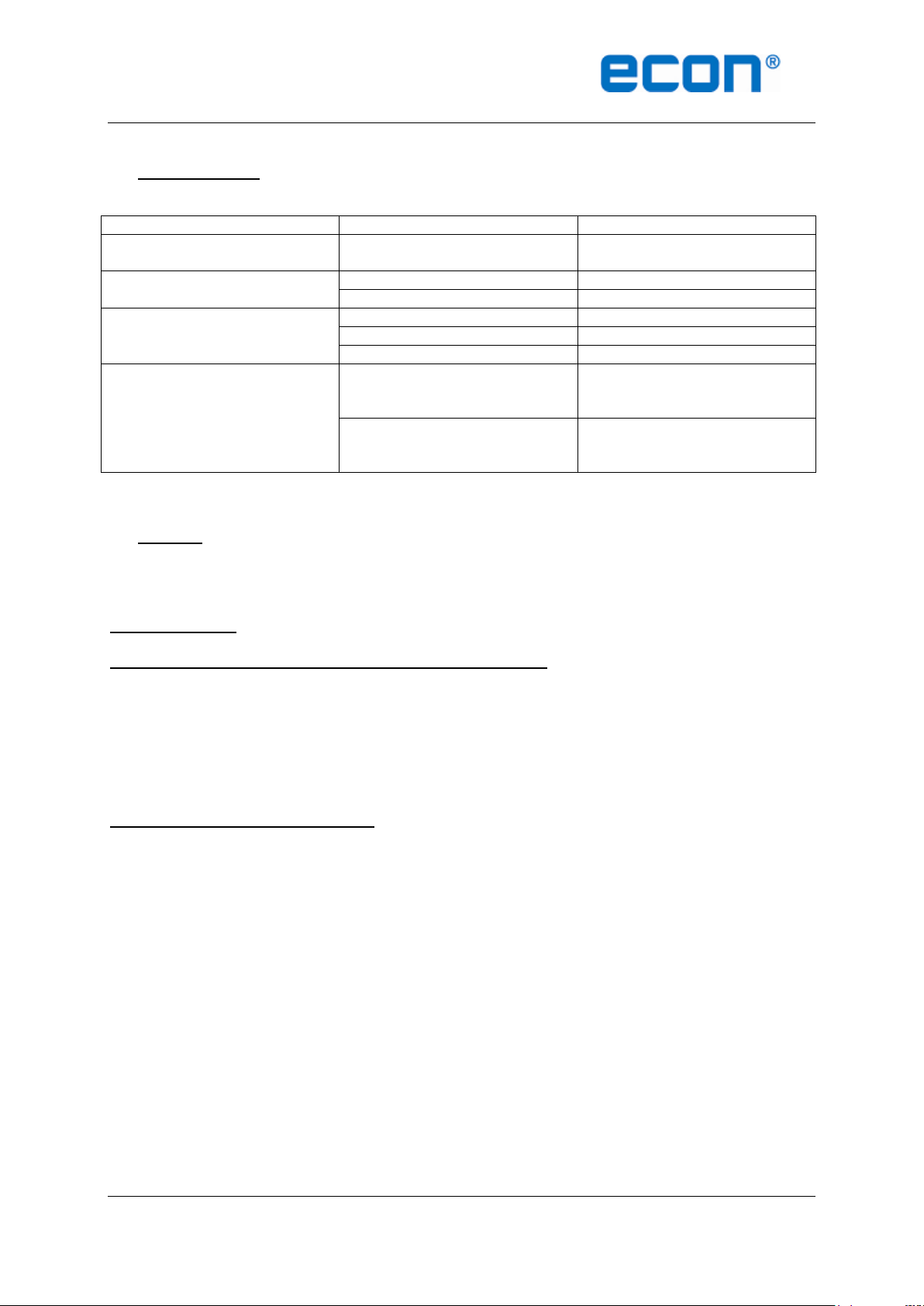

10. Changing from mounted cover to clamped cover

- for DN15 –DN200 there is a combination cover available with clamp catch, for quick

release and easy installation of the cover after maintenance.

With the clamp on the cover and mounted behind the cams of the filter body, the cover

can be fixed by turning the bolt in the middle of the clamp clockwise till the cover is

secured. Please check if the cover is correct mounted on top of the body and bodyseal.

After checking, the lock nut of the bolt can be fasten.

When changing the bucket filter from bolted cover version to clamped cover version the

stud bolts and nuts can be forgotten.

Please note that the clamped version has a lower maximum working pressure,

depending on Nom. diameter and housing size.