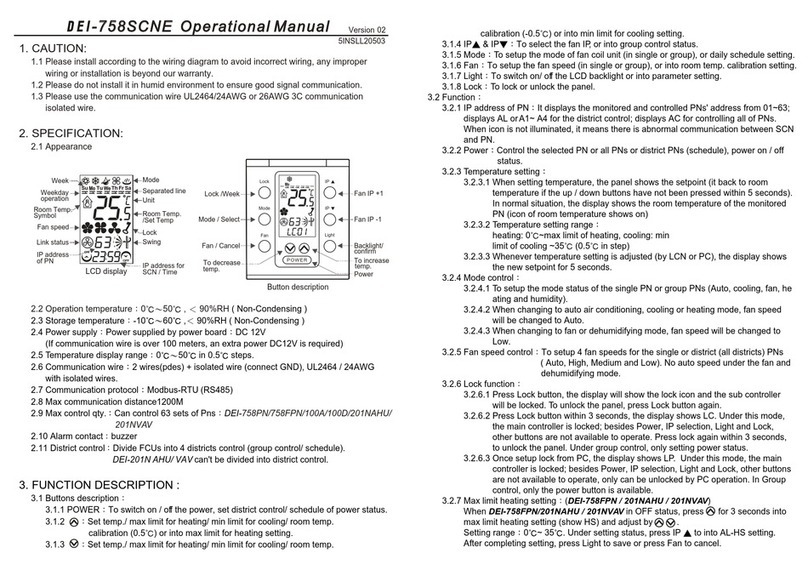

Ecostat ES100 User manual

WALL PLATE

SUBBASE

THERMOSTAT

WIRING OPENING

ES100 ROUND DIGITAL NON-PROGRAMMABLE BATTERY

3. Drill a 1/4"

hole at the locations you marked.

OPERATED THERMOSTAT

4. Insert a molly (provided) into each hole and gently tap in to level with

the wall.

The ES100 Digital Thermostat is designed to work on the

following 24V systems. This Thermostat will not control

multistage heat pumps or 100/120V line voltage electric heating

systems.

Gas-Standing Pilot

• Gas- Electronic Ignition

• Gas- Fired Boilers

• Oil-Fired Boilers

MERCURY NOTICE

If

this control is replacing a control that contains

mercury in a sealed tube, do not place your old

control in the trash. Contact your local waste

management authority for

I

NSTALLATION

When Installing this Product...

1.

Read these instructions carefully. Failure to follow them could

damage the product or cause a hazardous condition.

2.

Check the ratings given in the instructions and on the product to

make sure the product is suitable for your application.

5.

Re-position the wall plate to wall, pull house wires through the wiring

opening and use the two 1"

screws to attach the wall plate to the wall.

6.

Position the switching subbase over the wall plate and pull house

thermostat wires through the wiring opening. Connect the thermostat

house wires to the appropriate wiring terminals before attaching the

subbase to the wall plate.

7. Using the 3/8"

screws, attach the subbase through the round hole

on the left and the vertical slotted hole on the right of the subbase. Before

tightening the screws you can rotate the subbase to level the thermostat.

If attaching switching subbase directly to the wall:

(fig. 1.3 page 5)

1.

Position the switching subbase against the wall with switches at top,

position the square hole over the house wires and pull them through the

hole, •

2.

Use a pencil to mark the wall through the round hole on the left of

subbase and through the center of the slotted hole on the right. Remove

the subbase.

3.

Drill a 1/4"

hole at the locations you marked.

4.

Insert a molly (provided) into each hole and gently tap in to level with

the wall.

•

Oil-Fired Furnace

•

Single Stage Heat Pumps No-

Auxiliary Heat

•Electric Air Conditioning

3.

Installer must be a trained, experienced service technician.

4.

After installation is complete, check out product operation as

provided these instructions.

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment circuitry.

Disconnect power supply before installation.

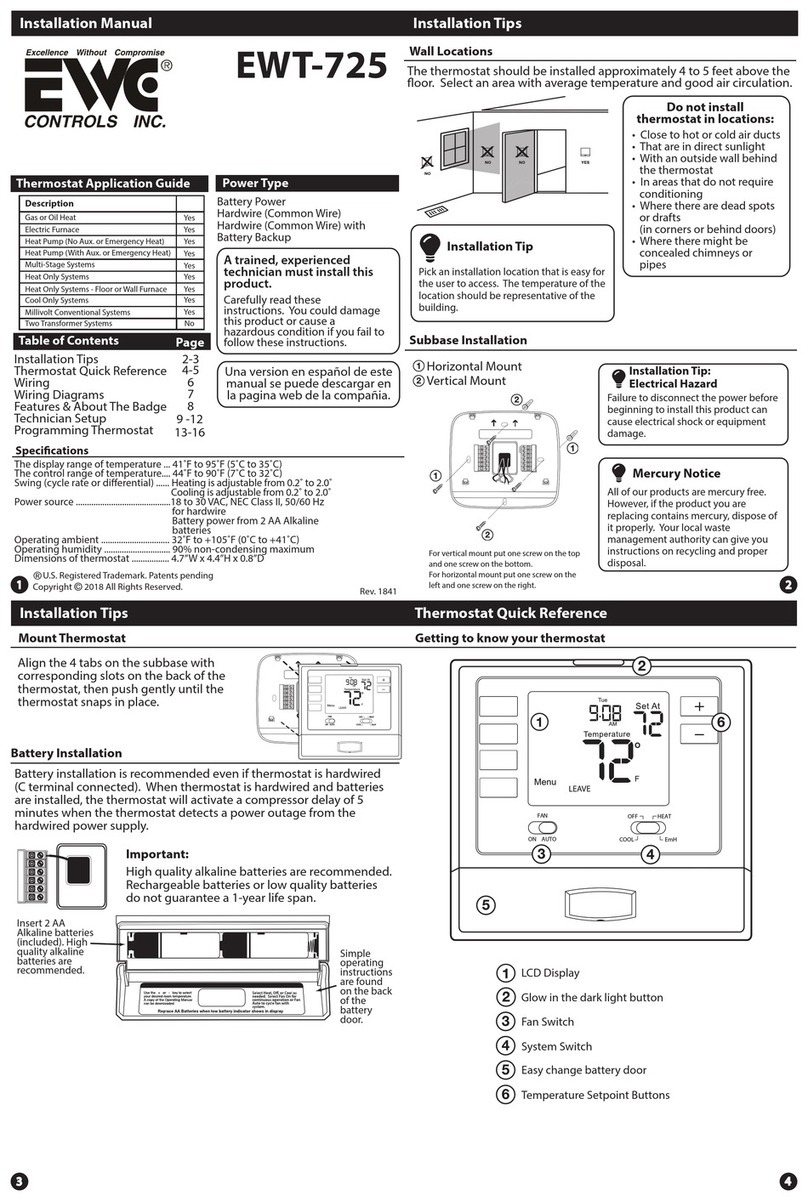

Location

Install the thermostat about 1.5m(5ft) above the floor in an area with

good air circulation at average temperature. Do not install the

thermostat where it can be affected by:

Drafts or dead spots behind doors and in corners.

Hot or cold air from ducts.

Radiant heat from the sun or appliances.

Concealed pipes and chimneys.

Unheated (uncooled) areas such as an outside wall behind the

thermostat.

The ES100 Models Include

•

2-AM Alkaline Batteries

• 1-Switching Subbase

1-Wall Cover Plate

(For Optional use to cover svall marl, it needed)

•6-Mounting Screws

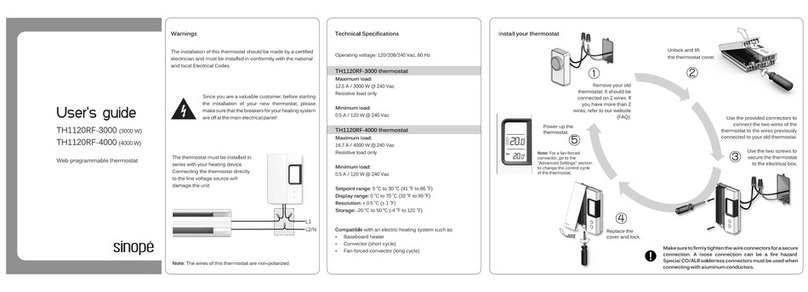

INSTALLING THE WALL PLATE AND SUBBASE

NOTE: BEFORE REMOVING OLD THERMOSTAT FOLLOW LABELING

INSTRUCTIONS ON PAGE 3.

If using the wall plate Fig. 1:

1.

Position the wall plate against the wall so that the arrow is pointing

upward, position the square hole over the house thermostat wires

and pull them through the hole.

2.

Holding wall plate flat against the wall, use a pencil to mark the

wall through the center of the slotted screw holes on the right and

left of the wall plate. Remove the wall plate.

5. Re-position the subbase to wall, pull house wires through the wiring

opening and connect the thermostat house wires to the appropriate

wiring terminals before attaching the subbase to the wall using the two 1"

Fig, 1 (Option A)

NO.

3(8"

INCH

SHEET METAL SCREWS

(2)

If installing on an outlet box Fig. 2

I.

Place the wall plate against the outlet box with arrow pointing up.

2.

Pull the wires through the wiring opening.

3.

Use the 1 / 2" screws to attach the wall plate to the box through the two

horizontal slotted holes.

4.

Place the switching subbase over the wall plate, pull the wires through

the wiring hole in the subbase and connect the wires to the subbase

terminals.

5.

Use the 3/8" screws to attach the subbase to the wall plate as

described under Fig. 1 item 7.

•

1-Thermostat

--1

SYSTEM SWITCH

SELECTS

COOL/OFF/HE

AT

FAN SWITCH

SELECTS

AUTO/ON

OUTLET

BOX

WALLPLATE

1/2 IN, BINDING

HEAD SCREW

BOW Y

p000l

\ RC

RH

SUB-EASE

OLE

GAS

Selector Switches

Gas - 011 / HYD

or

Dec I I-1T Pump

C

i

m

u

n

t

s

fe

fo

r

f

t

,n

w

e

o

r

systems

Al

Fig 5. ESloo

Subbase (front)

ES100 Specifications

•

Terminal Designations - RC,RH,G,W,Y,B4O

Current Draw -0.1 To 1.5 AMPS

•

Operating Differential - +/- 1 degree F

THERMOSTAT

WIRING OPENING

3/8" SHEET METAL

SCREWS (2)

Fig. 2 (Option B)

Wiring Hole

SYSTEM SWITCH

FAN SWITCH

SELECTS

COOL/OFF/HEATz-Go°:

.

AUTO/ON

Low Battery

Indicator

Temperature

Read Out

/

°

C

\\\

Set temperature

DIAL

ADJUSTS

TEMPERATURE

SETTINGS/TURNS

BACKLIGHT ON.

BACKLIGHT BUTTON

Room Temperature

Fig

3 ES100 Thermostat (feature and operation).

SELECTS

AAA battery

AAA battery 13

Cycle Time Selector

Switch

"Refer to Factory

Settings, item 4"

Celsius and

Fahrenheit

Switch

Fig 4 ES100 Thermostat (Back)

Fig

6 ES100 Subbase (Back)

Factory Settings

1.

Temperature selection switch (on back of thermostat) set for

degree F. (fig 4)

The ES100 is factory set for degree F readout. To change to

degree C readout simply move the selector switch located on

the back of the thermostat body to the "C" position. (fig. 4)

2.

Application switch on front of subbase set to "G" for Gas, Oil

or Hydronic systems. Move to "E" for Electric Air Conditioning

and Single Stage Heat Pump systems.

3.

Fan switch - auto (fig. 3)

4.

Cycle control switch on back of thermostat set to CY5M, Max.

1 cycle per 5 minutes. Move selector down to CY2M to

increase cycle rate. (fig. 4)

5.

Red Jumper - in place on back of subbase for standard 4 -

wire system (fig. 6)

D

t

is

c

l

he

"

display provides a large readout of the actual room temperature

and a smaller readout for the set point. (fig. 3)

2.

A flame t'h appears when the heat is turned on and a snowflake

appears when the cooling is on. (fig. 3)

3.

A fan "tii appears when the system is running or when the fan

switch is in the on position. (fig. 3)

FAN

RELAY

POV't ER SUPPLY, PROVIDE DISCONNECT MEANS AND OVERLOAD

f ROrECTION AS REQUIRED

A FACTORY INSTALLED JUMPER ON BACK OF SUBBASE.

Fin B. Typical hookup of Earns in heat-only system wee fan.

HEATING

RELAY OR

VALVE COIL

Caution:

Temperature setting 41 degrees F to 90 degrees F (5C to 30C)

The thermostat can be adjusted between 41 degrees F and 90 degrees F

by simply rotating the soft dial clockwise to raise the set point or

counterclockwise to lower the set point, The selected set point appears

on the right side of the display. The room temperature is the larger

readout that appears in the middle of the display. (fig. 3)

High/Low Limits

The ES100 will automatically cutoff in the heat mode if the temperature

rises above 90 degrees F, and automatically cutoff in cool mode if the

temperature drops below 41 degrees.

Low Temperature Hazard.

Operating at too low of an outdoor temperature may

cause compressor damage.

Do not operate cooling if outdoor temperature is

below 50F(10F). Refer to manufacture's

recommendations.

Compressor Protection

If a call for cooling is made before the compressor has been off for five

minutes, or if a power interruption occurs while the compressor is

running, the thermostat will go into a five (5) minute delay before the

compressor can be restarted. This feature will prevent damage to the

compressor caused by rapid cycling.

Set system running cycles

Use the switch marked with "CY5M" & "CY2M" (fig.2 )

in the middle of Setting pin switches to set system running cycles.

At CY2M side: maximum 'I cycle per 2 minutes.

At CY5M side: maximum 1 cycle per 5 minutes.

Backlight and battery warning

The backlight activates when the backlight button is depressed or when the dial is

rotated.

The two fresh AM Alkaline batteries should provide well over one year of service.

However, when the batteries become drained, the low battery indicator will appear on

the lower right display. When this message occurs, install new batteries. Once the

batteries have become too low to ensure proper operation, the system will be turned

off, and the display will be cleared except for the low battery indicator on the display.

Caution:

When only the low battery icon is displayed, the thermostat will shut down,

and the system will no longer operate. In this condition, there is no

temperature control of the dwelling

Note: If the homeowner plans to be away from the premises over 30 days, we

recommend that the batteries be replaced prior to leaving.

To replace batteries: The batteries are located in the back of the thermostat body. (fig. 4)

Follow the instructions below under "Mounting the Thermostat" to remove the

thermostat body from the subbase. Remove the old batteries and replace with two (2)

new AM Alkaline batteries. Gently replace the thermostat body to the subbase by

positioning the bottom clips on the thermostat into the subbase. Then align and push

together the black pin receptacle on the back of the thermostat body with the white

pin receptacle on the subbase. Then press and latch the top of the thermostat into the

top of the subbase.

Remove old thermostat

Caution: Do not remove any wiring from the existing thermostat before reading the

instructions. Wiring must be labeled prior to removal.

Important: Turn off the power to the furnace at the main power panel or at the

furnace.

Wiring labeling

Each wire coming from the wall to the existing thermostat is connected to a terminal

point on the thermostat. Each terminal point is usually marked with an alpha letter.

The number of wires in the system can be as few as two (2) (for heat only systems.

There is often no terminal marking on the existing thermostat of two (2) wire, heat

only systems. Just conned either stills wires to the Rh terminal, then connect the

other wire to the W terminal to complete the circuit).

Important: Before disconnecting any wires, apply the self-adhesive labels provided,

to the wires, since the wire colors cio not always comply with the standard alpha letter

terminal designations.

Separating and attaching switching subbase with thermostat body

Hold the thermostat body and depress the top center of the thermostat with your thumb or use

a screwdriver to depress the indent. Gently pull down and outward to separate the thermostat

from the subbase. Determine the desired meathod of installation from Fig.1 or Fig.2

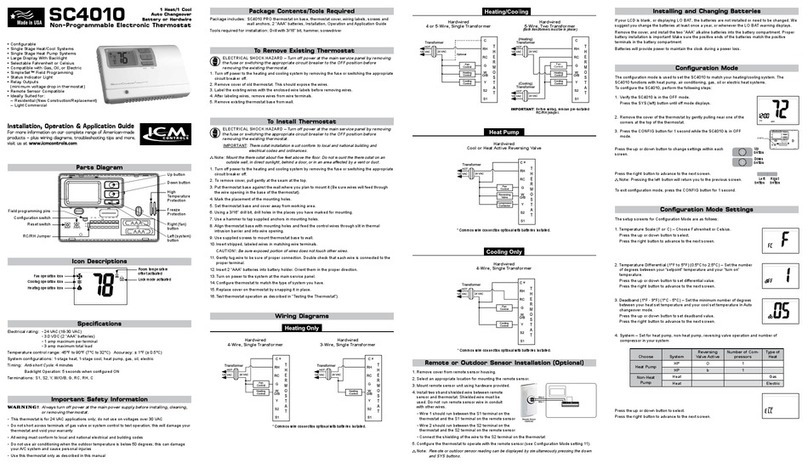

Typical system wiring diagrams

Important:

Use only 18-gauge thermostat wire. All wiring must comply with local electrical

codes and ordinances. Disconnect the power supply to prevent electrical shock or

damage to the thermostat or equipment.

Fig. 7 - Heat only system

Fig. 8 - Heat only system with fan

Fig. 0- Cool only system

Fig. 10- Heat-cool single transformer hookup

Fig. 11 - Heal-cool with Iwo transformers

Fig. 13 - Single-stage heat pump

HEATING

RELAY OR

VALVE COIL

Z

\ POWER SUPPLY, PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

Fig 7. Typical hookup of ES100 in a heat-only system.

--3--

COMPRESSOR

CONTACTOR

FAN

RELAY

FAN

RELAY

HEATING

RELAY OR

VALVE COIL

a

COMPRESSOR

CONTACTOR

HEATING

RELAY OR

VALVE COIL

COMPRESSOR

CONTACTOR

FAN

RELAY

FUEL

SWITCH

COOL

CHANGE OVER

VALVE

HEAT

CHANGE OVER

VALVE

COMPRESSOR

CONTACTOR

FAN

RELAY

POWER SUPPLY, PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED,

Fig 9. Typical hookup of ES100 In cool-only system with single transformer.

POWER SUPPLY, PROVIDE DISCONNECT tvlEANS AND OVERLOAD

A PROTECTION AS REQUIRED.

Z

.

3

..

\ FACTORY INSTALLED JUMPER -RC, RH ON THE BACK OF SUBBASE

Fig 10. Typical hookup of ES100 in heat-cool system

with single transformer.

A

POWER SUPPLY, PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED. (Heal Transformer)

CUT OR REMOVE FACTORY INSTALLED JUMPER BETWEEN RH AND RC.ON

THE BACK OF SUBBASE

A

POWER SUPPLY, PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED. (Cooling Transformer)

Fig 11. Typical hookup of ES100 In heat-cool system with two transformers.

Fig 12. FUEL SWITCH SUB-BASE

L\ POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED

A

FACTORY INSTALLED JUMPER -RC.RH ON THE BACK OF SUBBASE

USE A JUMPER WIRE (NOT SUPPLIED) TO CONNECT W TO Y.

USE EITHER 0 ORB FOR HEAT PUMP CHANGEOVER

Fig 13. Typical hookup of ES100 In single-stage heat pump system.

CHECKOUT

NOTE: Temperature setpoint range is 5C to 30C or 41F to POE in

heating and cooling.

Heating

1. Slide the SYSTEM switch to HEAT and the FAN switch to AUTO.

2.

Raise the temperature setpoint several degrees above the room

temperature.

3.

A flame 1:ti indicator will appear in the display and the heat should

turn on.

4.

Lower the temperature setpoint below the room temperature.

5.

The flame indicator will disappear from the display and the heat

should turn off.

Cooling

CAUTION

Low Temperature Hazard.

Operating at too low of an outdoor temperature may

cause compressor damage.

Do not operate cooling if outdoor temperature is below

50F(10F). Refer to manufacture's recommendations.

NOTE: If a call for cooling is made before the compressor has been

off for five minutes, or if a power interrution occurs while the

compressor is running, the thermostat will go into a five-minute

delay to protect the compressor.

P

‹)

WIRING HOLE

1 INCH SCREW

INCH SCREW

SUB-BASE

WALL ANCHORS (2)

0

Top of thermostat

The Hole on top of thermostat

fluLn

n

{

L_LA

11

O

N

111.1

IIE

Top of sob-base.

Fig 14 The top view of thermostat and sub-base

WIRING HOLE

TROUBLESHOOTING GUIDE

Heating or cooling does not come on.

1

Make sure that the SYSTEM switch on the thermostat is set to Heat

or Cool.

2 In heating, make sure the temperature setting is above the room

temperature and the flame

iN

indicator is present in the display.

3.

In cooling, make sure the temperature setting is below the room

temperature and the snowflake iII indicator is present in the display

4 In cooling, If a call for cooling is made before the compressor has

been off for five minutes, or if a power interrution occurs while the

compressor is running, the thermostat will go into a five-minute delay

to protect the compressor.

5 Check the system fuse or circuit breaker and replace or reset if

necessary.

6. Check for air movement at the register.

The thermostat does not have any display.

1.

Check if the SYSTEM switch is OFF, turn it to HEAT or COOL.

2.

For a single transformer system check if the jumper on back of the

subbase is in place.

3.

Check that batteries are installed properly in battery holder. Replace

batteries if needed.

Fan

1.

Slide the SYSTEM switch to OFF and the FAN switch to ON. The

fan should run continuously.

2.

Slide the FAN switch to AUTO. The fan should turn off.

A WHEN USING WALL ANCHORS, DRILL 3116 IN. HOLES FOR DRY- WALL,

7/32 IN, HOLES FOR PLASTER.

Fig 1.3 (option C) Mounting sub-base to wall.

Table of contents