Ecosy+ Snug 7 User manual

Page 1of 11

Snug 7 Stove

(Woodburning With Multi-Fuel Grate Option)

Version number 1: Issue date 14/08/2019

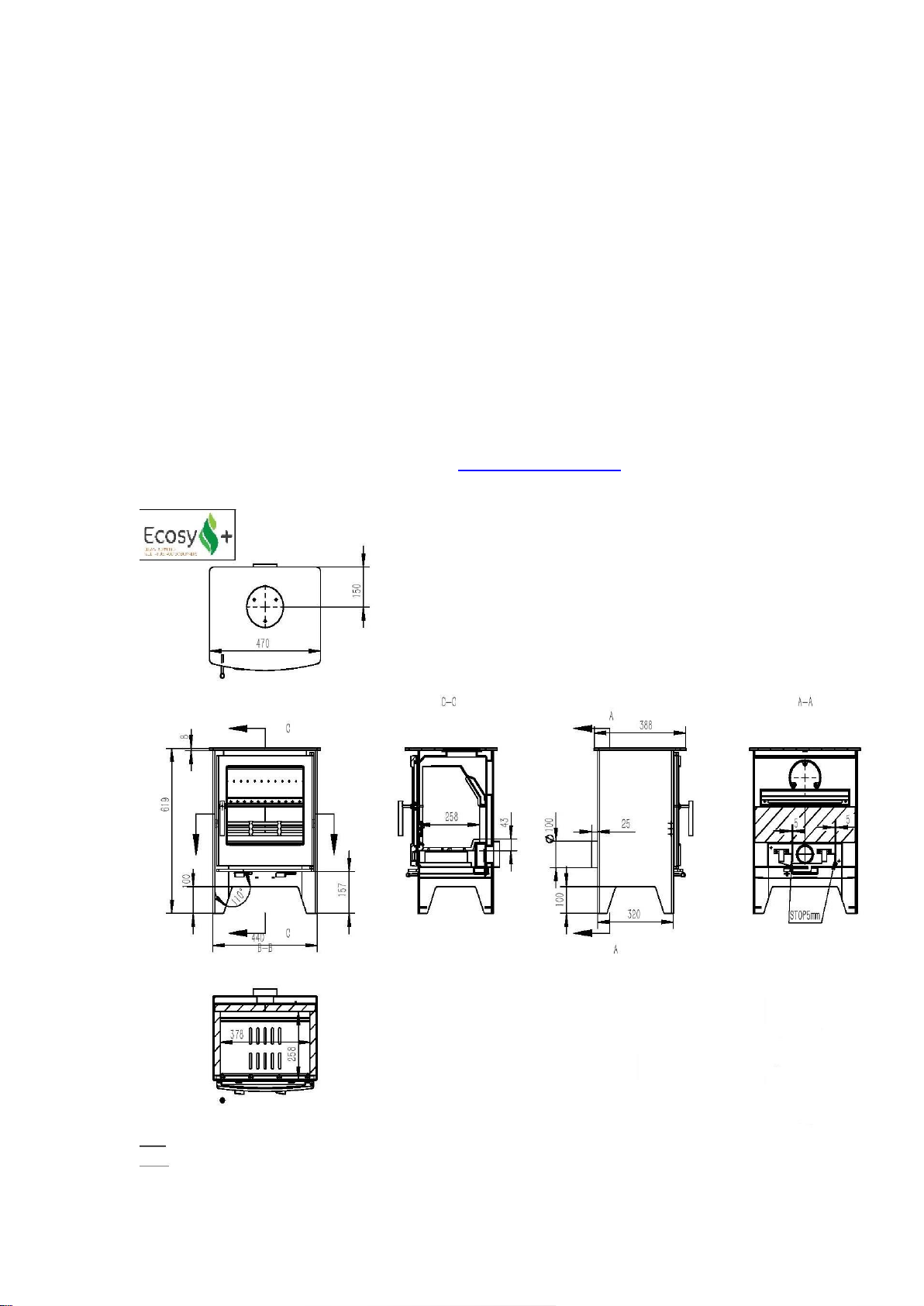

Model: Snug 7 Stove

Size: W470XD388XH619MM

Page 2of 11

INTRODUCTION

Wood-burning with multi-fuel option

Item No.: Snug 7

Size: W470XD388XH619 (mm)

SAFETY

Safety is the most important consideration when using and installing your stove. If not

installed and used correctly, a house fire could result. Installation must comply with

relevant national and local Building Regulations and fire safety standards.

IN THE EVENT OF A CHIMNEY FIRE, EVACUATE THE PROPERTY AND CALL THE

EMERGENCY

SERVICES.

Your stove will be heavy, and care needs to be taken when lifting - 2 people will normally be

required to lift.

UNPACKING

Your stove will have several of its components stored inside the stove itself for

transportation.

The main component is the flue collar; this will simply need attaching with the provided

bolts on the top or rear of the fire. Ensure you remove the free oven glove and any small

accessories that may be tucked away under the grate.

INSTALLATION

Installation of your stove must comply with relevant local and national Building Regulations

and fire safety standards. We would always suggest using a qualified installer to carry out

the installation of this product. The British recognised standard for solid fuel installations is

HETAS. You can find a HETAS qualified installer in your area by going to the HETAS website

–www.hetas.co.uk. If you are self-installing, the stove must be signed off by the local

authority.

Page 3of 11

TECHNICAL

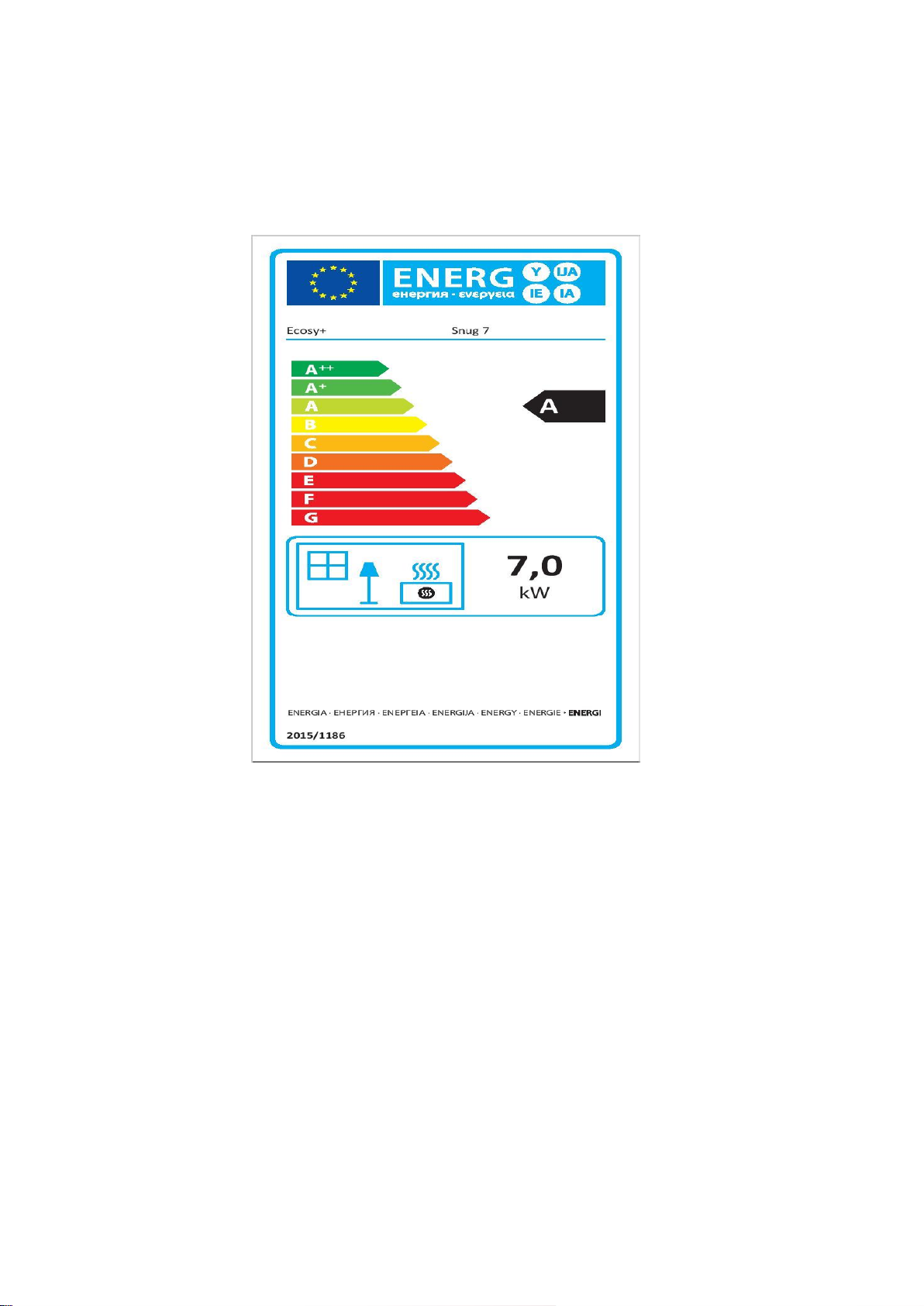

Snug 7 - Performance Test Results.

Weight 80kg

Test Fuel

Wood Logs

Maxibrite

(Optional Grate)

Total Efficiency (%)

80.8

77.7

Nominal heat output (kW)

7.1

7.3

Mean CO emission (@13% O2)

0.08

0.08

Flue gas mass flow (g/s)

4.3

5.4

Mean CnHm(at 13 % O2) Nmg/m3

89

31

Mean NOx (at 13 % O2) Nmg/m3

96

105

DIN Plus dust (at 13 % O2) Nmg/m3

28

29

Suitable for a direct air feed / Sealed air –100mm spigot on the stoves rear.

Distances to combustible materials:

Back Wall –650mm

Side Wall –700mm

Hearth Temperatures

Maximum hearth temperature –79c

This stove is suitable for a 12mm hearth. For example, a 12mm glass hearth can sit directly

onto a wooden floor and this unit can be sat on top of that.

Your stove will require a constant air supply and should not be used at the same time or in

the same room/space as extractor fans or any device which may draw air supply away from

the stove. The stove should be installed on a level floor with adequate load bearing capacity.

The stove does include adjustable feet for levelling.

Normally for most houses in the UK, no extra ventilation is required when installing a stove

rated at 5kW or less.

Note: The requirements regarding ventilation have been updated in the most recent

version of the Building Regulations and are now based on the air permeability of the house.

The stove is NOT suitable for installation in a shared flue system.

The flue pipe must be fitted INSIDE the flue spigot and sealed with a generous amount of

Fire Cement. A 5”flexible flue liner or twin walled chimney system can be used with this unit,

as it has passed the DEFRA testing.

Page 4of 11

Access should be provided for cleaning the flue to ensure that the passageways for exhaust

gases remain free from obstruction.

OPTIONAL EXTRAS

•Multi-Fuel Grate –Your stove will come as standard with a Wood-burning only style of

flat grate. You are only permitted to burn dry seasoned wood and no other fuels on this

style of grate that comes with the stove. We also offer a Multi-fuel grate if you are wanting

the option of burning smokeless coal. The two grates simply lift in and out and are not fixed

into the unit, giving great flexibly and the best efficiency for each fuel.

•Vertical Flue Box –This flue box can be bolted to the stoves rear and enables you to

position the stove further into the room; away from the wall. This box can make

installations easier and does not push the stove out as far as 90-degree T pieces. The flue

box cannot be used at the same time as the heat shield (above)

OPERATING INSTRUCTIONS

Regulations

All National and local regulations, including those referring to National and European

standards, need to be complied with when installing the stove.

The Clean Air Act 1993 and Smoke Control Areas

Under the Clean Air Act local authorities may declare the whole or part of the district of the

authority to be a smoke control area. It is an offence to emit smoke from a chimney of a

building, from a furnace or from any fixed boiler if located in a designated smoke control

area. It is also an offence to acquire an “unauthorised fuel” for use within a smoke control

area unless it is used in an “exempt” appliance (“exempt” from the controls which generally

apply in the smoke control area).

In England appliances are exempted by publication on a list by the Secretary of State in

accordance with changes made to sections 20 and 21 of the Clean Air Act 1993 by section

15 of the Deregulation Act 2015. Similarly, in Scotland appliances are exempted by

publication on a list by Scottish Ministers under section 50 of the Regulatory Reform

(Scotland) Act 2014. In Northern Ireland appliances are exempted by publication on a list

by the Department of Agriculture, Environment and Rural Affairs under Section 16 of the

Environmental Better regulation Act (Northern Ireland) 2016. In Wales appliances are

exempted by regulations made by Welsh Ministers.

Further information on the requirements of the Clean Air Act can be found here:

https://www.gov.uk/smoke-control-area-rules

Page 5of 11

The Ecosy+ Snug 7 has been recommended as suitable for use in smoke control areas

when burning seasoned wood logs. The appliance has a factory-fitted modification to the

secondary air control to prevent closure beyond 5mm open position at the vent opening.

Your local authority is responsible for implementing the Clean Air Act 1993 including

designation and supervision of smoke control areas and you can contact them for details of

Clean Air Act requirements.

Please note the following advice on minimising smoke emissions:

Refuelling on to a low fire bed

If there is insufficient burning material in the fire bed to light a new fuel charge, excessive

smoke emission can occur. Refuelling must be carried out onto a sufficient quantity of

glowing embers and ash that the new fuel charge will ignite in a reasonable period. If there

are too few embers in the fire bed, add suitable kindling to prevent excessive smoke.

In order to establish and maintain flames on a new refuel charge, it is necessary to operate

with the door ajar for a period of 1- 3 minutes.

Fuel overloading

The maximum amount of fuel specified in this manual should not be exceeded, overloading

can cause excess smoke.

Dampers Left Open - Operation with the air controls or appliance dampers open can

cause excess smoke. The appliance must not be operated with air control, appliance

dampers or door left open except as directed in the instructions.

FUEL

Wood- All types of wood are suitable provided they are well seasoned, UNTREATED, and

have a moisture level between 12% and 20%. For soft woods, typically they will need to

have been left in suitable storage for 9+ months for the moisture to evaporate. For

hardwoods, this will usually be 18 months+. It is recommended that logs should be no

more than 5” (125mm) in diameter and 8” (200mm) in length. If you are unsure of the

moisture content of your fuel, then you can buy a moisture meter which will indicate the

moisture levels in your fuel. Liquid fuels must NEVER be used.

WARNING: Wet timber should not be used as this will create excess tar deposits in the

chimney and stove and could increase the risk of chimney fire. Timber which is not of a

suitable moisture content will also create more smoke and harmful emissions, and will

damage the stove and flue system.

Page 6of 11

Solid Fuel –(Please ensure Multi-Fuel grate is installed before burning smokeless coal)

Solid mineral fuel should be placed in the stove so that there is no more than a 30° incline

of the fuel bed from front to back. It should not be stacked above the level of the rear

firebrick as this may result in damage to the stove.

Always de-ash before refuelling and do not let the ash build up to the underside of the grate

bars. Solid mineral fuel produces ash, which if allowed to build up will stifle the airflow

through the Primary air sliders and grate. This will eventually cause the fire to go out.

With some solid mineral fuels, a residue of burnt fuel or clinker will accumulate on the grate

- allow the fire to go out periodically to remove this.

Important! - We cannot stress firmly enough how important it is to empty the ashpan

regularly. Air passing through the fire bed cools the grate bars. Distortion or burning out the

grate bars is nearly always caused by ash being allowed to build up to the underside of the

grate. Anthracite is an approved natural smokeless fuel (not processed) and therefore can

vary greatly in quality and performance. It generally requires excellent air supply and above

average fire-bed temperatures to maintain maximum performance and with experience we

would suggest that it is used in conjunction with other approved manufactured smokeless

fuels as per the HETAS approved list http://www.hetas.co.uk/find-fuels/ . Smokeless fuels

AIR INLET CONTROLS

The base control lever on the right controls the rate of primary air flowing under the fire.

Having this lever to the left reduces the amount of air and to the right increases the

amount of air drawn into the stove. If you have the woodburning grate installed, we only

suggest having this vent open when first lighting the fire. When the fire is established, we

would suggest closing this off fully as wood burns best with air flowing over the top of it

as opposed to underneath. If you have the Multi-Fuel grate in place this lever will be used

a lot more as mineral fuels like a lot of air flowing under them and very little flowing over

the top of them.

The base control on the left controls the airwash system and secondary burn system.

When pushed to the right, this feeds more air through the stoves rear. The air is fed over

the fire reburning the initial smoke produced from the stove. The air is also warmed and

fed over the glass helping to keep it clean. When pushed to the left this is restricted. When

you have the Woodburning grate installed you will use this lever to control the burn rate

of the fire. If you have the Multi-fuel grate installed, you will have the vent almost closed

and control the burn rate with the primary lever.

It is often a case of trial and error to get the maximum performance from the stove as

every installation and chimney is different.

TOOLS

Page 7of 11

The glove is provided for adjusting the air inlets and for opening the door when the stove is

hot, as these knobs will heat up when in use. The tool handle provided is for removing the

ash-pan.

NOTE –all parts of the stove will become hot during use and care needs to be taken to

avoid injury through burning.

LIGHTING THE FIRE AND RE-FUELING

Prior to lighting the fire for the first time, ensure that-

Installation and building work is complete.

The chimney is suitable and sound and has been swept and free from obstruction.

Adequate ventilation and provision for combustion air has been made.

That the stove installation has been carried out in accordance with Building Regulations

and any applicable local regulations as well as these installation instructions.

That chimney draw has been checked and within specification. (The stove has been

tested at nominal output with a flue draught of 12 Pa) INITIAL CURING AND TEMPERING

FIRES

ESSENTIAL INSTRUCTIONS BEFORE USE –It is essential to follow these ‘tempering in’

instructions in order to avoid serious damage to your stove. The castings of your stove

require very gentle ‘normalising’ to release stresses in the metal formed during the casting

process. The paint finish also requires an initial curing process to be followed: -

For the first 2 burns on day one just use small controlled kindling wood fires with each fire

lasting around 40 minutes –the second fire can be started when the stove is almost cooled

down after the first. A third slightly hotter medium type fire should then be lit using smallish

logs and lasting around 1 hour. Then for the next week or around 15-20 hours total burn

time, fires must be gently increased in temperature and log size and load and NO

SMOKELESS COAL must be used during this period. A stove thermometer will be a valuable

tool in helping you to achieve this safely and also to ensure an efficient burn rate in future.

Starting a large fire too soon is likely to damage the stove in which case it will not be

covered by the warranty. Note: the paint on any new stove is relatively soft. As such do not

clean, wash or

wipe the surface until the paint has fully cured. Never wipe the stove whilst warm. If the

above advice is ignored then there is a high risk of the paint being “shocked” by excessive

heat and could peel. Furthermore, if the stove is over fired it will invalidate your guarantee.

ENSURE THAT YOU HAVE READ AND UNDERSTOOD THESE INSTRUCTIONS BEFORE

LIGHTING THE FIRE AND THAT YOU ARE CONFIDENT THE STOVE HAS BEEN INSTALLED

CORRECTLY.

ALWAYS WEAR A PROTECTIVE GLOVE WHEN REFUELLING YOUR STOVE.

Ignition (FOLLOW INITITAL TEMPERING INSTRUCTIONS ABOVE FIRST TO AVOID

DAMAGE)

Ensure the ash-pan is in place. Ensure all air inlets are fully open (tertiary air should be

closed for first 3 burns)

Construct a pile of kindling in the middle of the grate using approx 500g of kindling wood

Page 8of 11

Light with a single chemical firelighter

Partially shut the door but leaving it cracked open slightly

After about 5 minutes or when the fire is well established, shut the door

After a further 3-5 minutes as the fire starts to die, add a further three larger pieces of

wood weighing approx. 0.75kg in total.

Once theses logs are alight, and after about 7 minutes or so, a normal load of 3 logs

weighing up to 1.4kgs in total can be added (ONLY AFTER THE INITIAL TEMPERING

PERIOD HAS BEEN FOLLOWED –SEE ABOVE)

First use troubleshooting.

When the stove is new the paint is very tacky where the stove is curing. The door locks very

tight and when opened can pull away the fire rope from its chamber. If the instructions are

followed above this should not happen. if it does, the rope will need to be stuck back in

place with “heat resistant fire rope glue” After a few burns the paint will be cured and this

should no longer happen.

Refuelling

When re-fuelling the stove, it is necessary to fully open both the primary and secondary air

controls for a period of 3 minutes to establish the fire before closing down to the minimum

output setting.

At high power output, your stove will require refuelling approximately every hour.

It is important to follow these instructions in order to achieve clean burning and to

maximise the efficiency of the stove

Do not leave the fire unattended until flames are well established on the newly charged

logs

Always refuel onto hot embers.

If the fire has died out at the point of refuelling, use kindling to re-establish the fire and

follow the “Ignition” procedure above.

It is important that the stove is not overloaded with fuel.

Reduced burn rates can be achieved by reducing the openings of the Secondary and

Tertiary air vents.

Refuelling on to a low fire bed –If there is insufficient burning material in the firebed to

light a new fuel

charge, excessive smoke emission can occur. Refuelling must be carried out onto a

sufficient quantity of

glowing embers and ash that the new fuel charge will ignite in a reasonable period. If there

are too few embers in the fire bed, add suitable kindling to prevent excessive smoke.

Fuel overloading - The maximum amount of fuel specified in this manual should not be

exceeded, overloading can cause excess smoke.

Operation with door left open –Operation with the door open can cause excess smoke. The

appliance must not be operated with the door left open except as directed in the

instructions.

Page 9of 11

The Ecosy+ Snug 7 stove is suitable for use in smoke control areas when used in

accordance with these instructions.

WARNING- The high temperature paint covering the stove will give off some fumes during

the initial few uses of the stove. The fumes are non-toxic, but some people may find them

unpleasant –Ensure the area is well ventilated during this period. The higher power output

rating of this stove is based on around 1.4kg of seasoned logs which would require

refuelling every hour.

Under certain abnormal weather conditions, e.g. down draughts, it may be difficult to get

enough draw through the appliance to achieve good combustion. When this happens, the

stove should not be used.

IMPORTANT: -

As of October 2010, it is a legal requirement to use a Carbon Monoxide Detector in the

same room as the stove. This needs to incorporate a battery which lasts the life of the

detector.

CLEANING/MAINTENANCE

When cold, the inside of the stove should be given a regular sweep out.

The flue and flue pipe will require cleaning with a suitable chimney brush, to minimise

build-up of soot and tar. Your chimney will also require periodic sweeping.

If the glass becomes stained from the inside, the air-wash vent may need opening more

during use. If the vent is fully open and the glass is still going black it will most likely be

down to poor quality wet wood. The high temperature paint which your stove is finished in

should last many years with normal use, but when it does eventually require re-finishing,

black heat resistant paint in spray cans can be purchased from most hardware stores but

we would suggest using “Calfire flat black paint”. – Do not use regular paint which is not

high temperature resistant. After prolonged periods of not using the fire, the stove and flue

system should be checked for blockages prior to relighting. We recommend regular

servicing and safety checks are carried out by a qualified engineer. There must be no

unauthorised modification of the appliance. Use only replacement parts recommended by

the

manufacturer.

CLEANING THE GLASS - Just use a clean cloth with warm water or specialist stove glass

cleaner. You must ensure the stove is cold before cleaning the glass. It is very important

that the glass is 100% dry before the stove is lit again. If you do not follow these

instructions, your glass couls “craze”. Crazing can also occur if incorrect fuels are burnt on

the stove or if fuels with impurities or high moisture in them are used. Broken or crazed

glass is not covered under any guarantee for any period of time.

FIRE BRICKS

Page 10 of 11

If fire bricks have just split, they do not need replacing. The bricks only need replacing

when they have fully crumbled away exposing the stoves rear or sides. Fire bricks are fully

heat resistant but can easily split if struck with a log or other similarly hard object.

GUARANTEE

The main body of your stove is guaranteed for 5 years. This does not include broken glass,

Crazed glass, fire bricks, door seals, grates, ash pans, paint and over-firing.

Incorrect use or installation not carried out by a registered HETAS installer will void the

guarantee. The only exceptions will be if the install has been signed off by your local

authority. Please keep hold of the invoice as this will be requested if a claim is started. If

this is not provided upon request, we will not be able to escalate your claim. The guarantee

will begin from the sale date on the invoice and we do not cover any cost incurred when

removing faulty appliances or installing new ones, even if it has been proven that the stove

is faulty. For full guarantee details please visit www.ecosystoves.co.uk

Page 11 of 11

DRAWINGS

-

Ecosy+, Unit 22-26 –Folly farm, Ramsdell, Tadley, RG26 5GJ

Table of contents

Other Ecosy+ Stove manuals

Popular Stove manuals by other brands

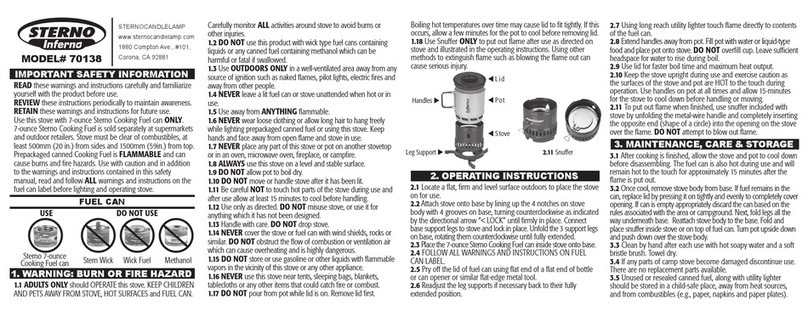

Sterno Inferno

Sterno Inferno 70138 instruction manual

Arada

Arada Stratford Ecoboiler user guide

Piazzetta

Piazzetta MT 361 Installation, use and maintenance instructions

Hunter Stoves

Hunter Stoves AVALON 4 Instructions for Installation/Operating/Maintenance/Servicing

Morsø

Morsø 1410 Installation and operating instructions

Alfa Plam

Alfa Plam CFA XILA Instructions for installation, use and maintenance manual