ECOVENT USA EV-SHT User manual

ECOVENT USA CHIMNEY MODEL EV-SHT

5"-8" DIAMETER INSTALLATION INSTRUCTIONS

A MAJOR CAUSE OF CHIMNEY RELATED FIRES IS FAILURE TO

MAINTAIN REQUIRED CLEARANCES (AIR SPACES) TO COMBUSTIBLE

MATERIALS. IT IS OF THE UTMOST IMPORTANCE THAT THIS CHIMNEY

BE INSTALLED ONLY IN ACCORDANCE WITH THESE INSTRUCTIONS.

Read through all these instructions before beginning your installation. Failure

to install the chimney as described in these instructions will void the

manufacturer’s warranty and may have an effect on your homeowner

insurance and UL listing status. Keep these instructions for future use.

EcoVent USA, LLC

600 Broadway Street

Joplin, MO 64801

Tel: 214.929.1152

info@ecoventusa.com

www.ecoventusa.com

CONTENTS

CLEARANCES. ................................................................................................1

PERMITS..........................................................................................................1

MODEL EV-SHT APPLICATIONS ...................................................................1

CHIMNEY DIAMETER......................................................................................1

CHIMNEY HEIGHT...........................................................................................1

CHIMNEY PLACEMENT. .................................................................................2

CHIMNEY ENCLOSURE REQUIREMENTS ....................................................2

COLD CLIMATE…........................................................................................... 2

STOVE RECOMMENDATIONS. ......................................................................3

STEP-BY-STEP DIRECTIONS.........................................................................3

CEILING SUPPORTED ....................................................................................3

OFFSET ELBOW INSTALLATION ...................................................................8

ROOF BRACE INSTALLATION .......................................................................9

ROOF SUPPORTED INSTALLATIONS .........................................................12

TEE-SUPPORTED INSTALLATIONS ............................................................14

MASONRY FIREPLACE INSTALLATIONS........................................................ 19

ZERO-CLEARANCE FIREPLACE INSTALLATIONS.....................................20

CHIMNEY MAINTENANCE ............................................................................21

1"

CLEARANCES

Always allow at least a 2-inch clearance between Model EV-SHT chimney

pipe and any combustible materials. Never fill any required clearance space

with insulation or any other materials. Combustible materials include lumber,

plywood, sheetrock, plaster and lath, furniture, curtains, electrical wiring and

building insulation. Keep single wall stovepipe at least 18 inches away from

combustible materials, unless a clearance reduction system that is acceptable

to the authority having jurisdiction is used, or the appliance to be installed is

listed and the instructions specify a different clearance.

PERMITS

Contact your local Building Official or Fire Official regarding permits,

restrictions, and installation inspections in your area.

Model EV-SHT APPLICATIONS

Model EV-SHT chimney is UL 103 Type HT insulated chimney, which can be

used with wood stoves, fireplaces, fireboxes, furnaces, boilers, water heaters,

stoves, ranges, or other residential-type appliances fueled by oil, gas, coal, or

wood, that require a chimney system. Do not use with forced draft, positive-

pressure appliances.

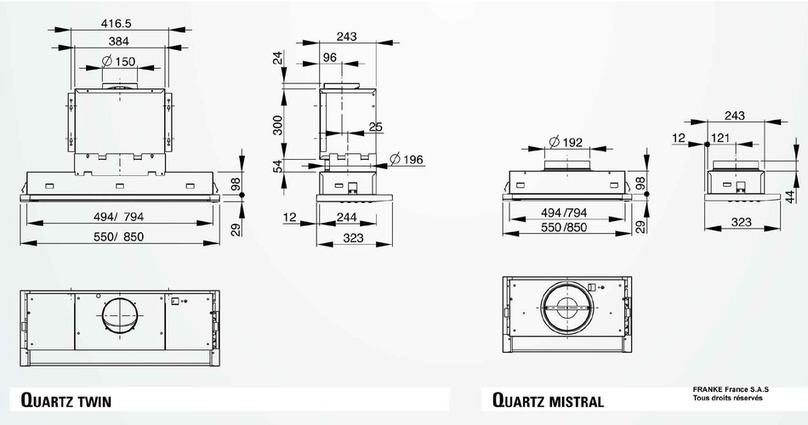

CHIMNEY DIAMETER

Follow the appliance manufacturer’s instructions to determine chimney

diameter and clearances between combustible materials and your heating

appliance. Never choose a chimney with an inside diameter smaller than your

appliance's outlet. To calculate the chimney’s outside diameter, add 2 inches

to the inside diameter.

CHIMNEY HEIGHT

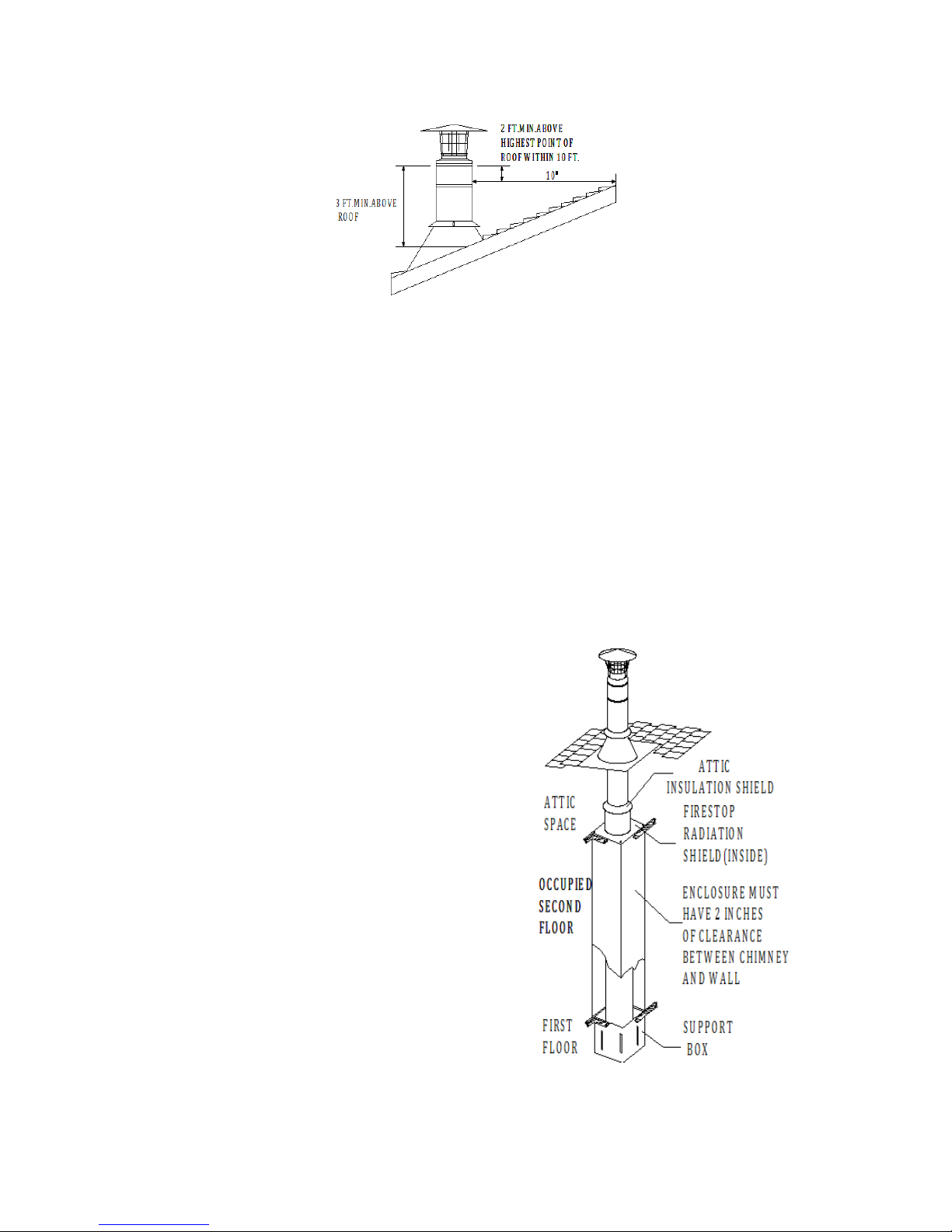

The National Fire Protection Association Standard #211 states: “Chimneys

shall extend at least three feet above the highest point where it passes through

the roof of a building, and at least two feet higher than any portion of a building

within ten feet.” (Fig 1) If the chimney extends more than 5 feet above the roof,

a Roof Brace must be used (see page 9). Due to the overlap of the joints,

subtract 1-1/8 inches from each Chimney Section’s height to calculate installed

height.

The chimney shall at least 10 feet to adjacent walls or buildings.

2"

Fig.1

The Tee Support can hold a maximum of 50 feet of Rainbow Chimney. The

required parts and general configuration are as shown in Figures 21 and 22.

CHIMNEY PLACEMENT

When deciding the location of your chimney, try to avoid modifications to roof

beams and other structural components of the building.

CHIMNEY ENCLOSURE REQUIREMENTS

Through Rooms: Interior chimneys shall be enclosed where they extend

through closets, storage areas, occupied spaces, or any place where the

surface of the chimney could be contacted by persons or combustible

materials. The space between the outer wall of the chimney and the enclosure

shall be at least 2 inches (Fig 2).

Multi-Story: Consult local building codes

for requirements in your area. In the

U.S., the National Fire Protection

Association Standard #211 states:

"Factory-built chimneys that pass through

floors of buildings requiring the protection

of vertical openings shall be enclosed with

approved walls having a fire resistance

rating of not less than one hour when such

chimneys are located in a building less

than 4 stories in height, and not less than 2

hours when such chimneys are located in a

building more than 4 stories in height.” In

Canada, except in single-family and two

family dwellings, chimneys which extend

through another story must have an

enclosure with a fire resistance rating

equal to or greater than that of the floor or

roof assembly through which they pass.

Fig.2

3"

Cold Climates: In cold climates, chimneys mounted on an outside wall should

be enclosed in a chase. Exterior chases reduce condensation and creosote

formation, and enhance draft. Include an access door by the Tee Cap for

chimney cleaning (Refer to Fig 21, page 16).

STOVE RECOMMENDATIONS

Follow the stove manufacturer’s instructions. The requirements stated below

pertain to all stoves or other appliances installed with Model EV-SHT systems.

Choice: Choose an appliance that is listed by a recognized testing laboratory,

is appropriate for your needs, and is not larger than required.

Installation: Once the chimney system is in place, install the stovepipe to

connect the appliance to the chimney as described in the appliance

manufacturer’s instructions. Be sure to maintain all required clearances.

Flues: Connect only one solid fuel appliance per chimney.

Operation: Follow the appliance manufacturer’s instructions for maximum

efficiency and safety. Over firing can damage the appliance, stovepipe and

chimney.

Fuels: Do not burn driftwood, plastic, or chemically treated wood such as

railroad ties. They are corrosive to your appliance, stovepipe and chimney.

Follow the appliance manufacturer’s instructions and safety manual in regards

to fuels. Not all appliances are equipped to burn coal. Coal with a low sulfur

content will reduce the possibility of corrosion.

Mobile Homes: Please read the appliance manufacturer’s instructions and

safety manual carefully. Not all appliances are listed for use in mobile homes.

STEP-BY-STEP DIRECTIONS

There are four general types of EV-SHT installations:

1.

Ceiling-supported

2.

Roof-supported

3.

Tee-supported (through-the-wall)

4.

Masonry Fireplace

5.

Zero-clearance Fireplace

Review the step-by-step directions before beginning your installation.

CEILING SUPPORTED

1. Place Appliance: Position the appliance according to the manufacturer’s

instructions. The flue outlet collar should be placed between the rafters or

joists above, if possible.

2. Frame Support Opening: Drop a plumb bob to the center of the

appliance’s flue outlet and mark this center point on the ceiling. Refer to Table

1 for specific framing and clearance dimensions. Mark appropriate cutting lines

around the center point. Cut a square hole in the ceiling for the Support Box.

Frame a level, square opening centered over the hole which you have cut.

(Figure 3 and 4).

4"

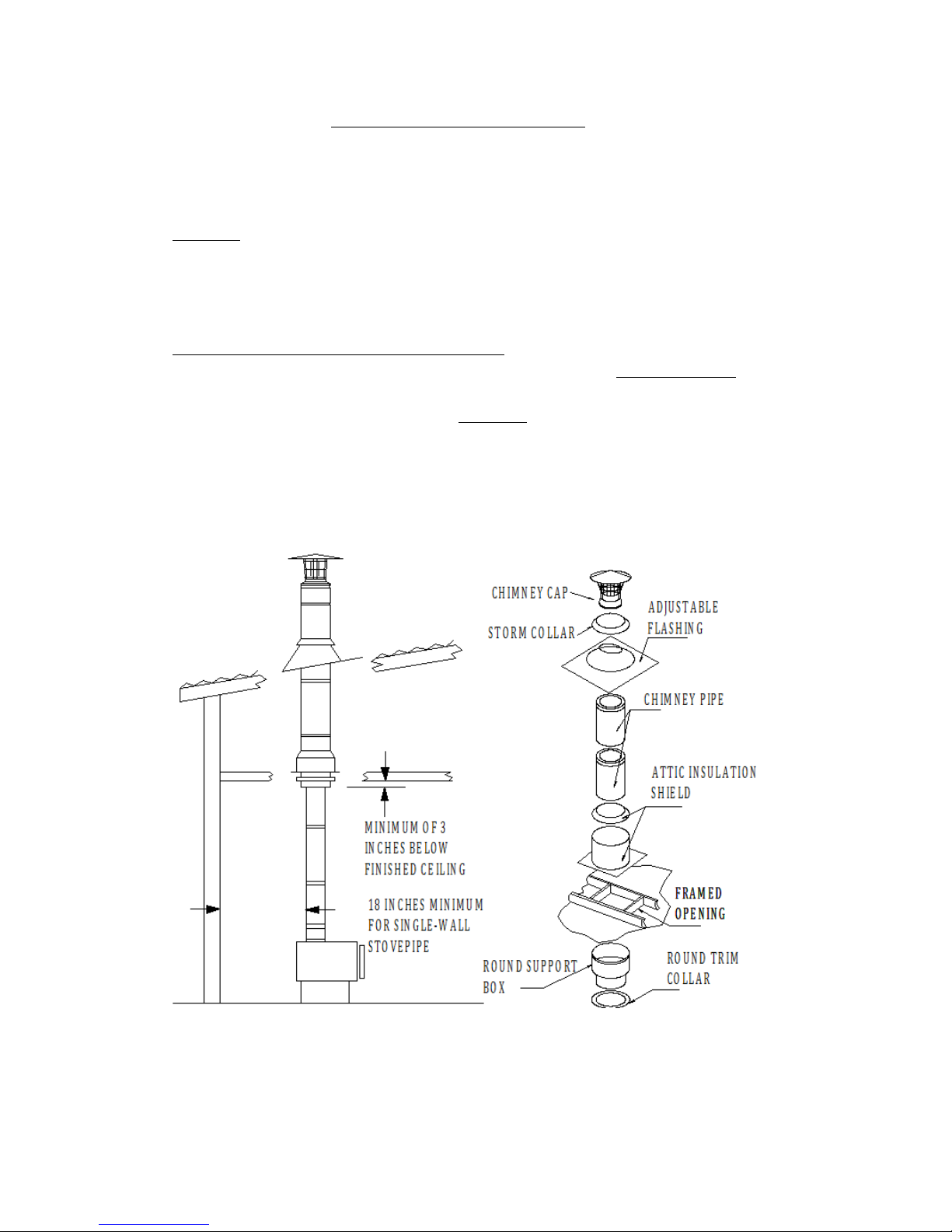

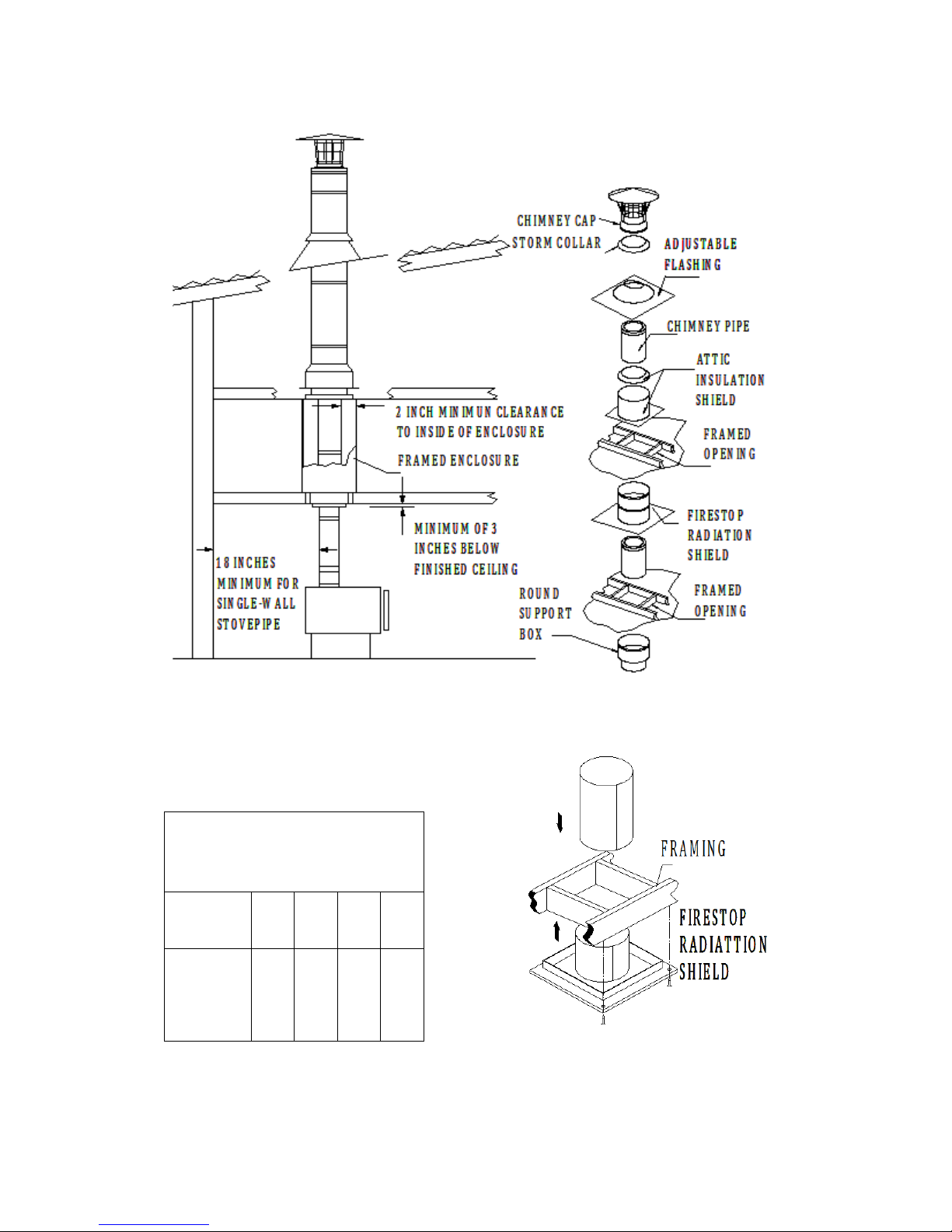

3. Install Support: For installation into a flat ceiling, you may use either the

Round Support Box or the Square Ceiling Support Box. For the Square Ceiling

Support Box, refer to the Square ceiling installation below. The Round Ceiling

Support Box has the option of a square or round Trim Collar available (Fig 5).

The bottom of the Round Support Box must extend at least 3 inches below the

finished ceiling. Level the Support Box and secure it to the framing using at

least three 8-penny nails per side (min. of 12 total ). Alternatively, you may use

1-1/2" #8 wood screws (min. of 12 total), instead of nails. Next, secure the Trim

Collar (round or square) to the framing members using provided hardware (Fig

6).

For installation into a cathedral ceiling, you must use the Square Ceiling

Support Box and the two-piece Trim. The bottom of the square portion of the

Support Box must be a minimum of 2-inches lower (round portion is an

additional 3 inches lower) than the finished ceiling at the lowest side of the

penetration (Fig 5 & 6). Level the Support Box and secure it to the framing

using at least three (3) 8-penny nails per side (minimum of 12 nails total), or a

minimum of (3) #8, 1-1/ 2" wood screws. Adjust the overlapping "U-shaped"

Trim pieces so they cover the Support Box, and secure them to the framing

members using provided hardware

Fig.3

5"

Fig.4

4. Frame Openings: Frame openings in each ceiling or floor above the

Support Box (Fig 7). These openings are to hold the Radiation Shield and Attic

Shield. Locate each opening by dropping a plumb bob to the four corners of

the opening below. Maintain the minimum clearances and dimensions as

specified in Table 1. If Elbows must be used to avoid an obstruction, refer to

the Offset Elbow Installation section.

Fig.5 Fig.6

5. Cut Roof Opening: Cut an opening in the roof directly above the opening

below, and at least 4 inches larger than the chimney’s outside diameter to

provide at least a 2-inch clearance all around the chimney. The chimney must

be centered within this opening and maintain the 2-inch clearance to

combustibles.

6. Install Radiation Shield: A Radiation Shield is required in multistory

installations at each floor penetration above that where the Support Box is

located when the attic insulation shield is to be enclosed. Example: in a

multistory home where the appliance is on the ground floor (Support Box is in

the 1st floor ceiling), you would need a Radiation Shield at the 2nd floor ceiling,

and at the 3rd floor ceiling, etc., including where the chimney penetrates into

the attic. Figure 7 shows a typical 2-story installation with an attic. Note: a

Radiation Shield is not installed where the chimney penetrates through the roof.

The Radiation Shield is installed on the underside of the ceiling/floor framing,

with the cylindrical "tube" portion of the shield pointing upward (Fig 8). Use a

minimum of either (1) 8 penny nail or (1) #8, 1-1/2” wood screws per corner.

Refer to Table 1 for framing requirements.

6"

Fig.7

Table 1

Fig.8

FRAME" DIMENSIONS" FOR" SQUARE" CEILING" SUPPORT" BOX,"

ROUND" CEILING" SUPPORT" BOX," WALL" THIMBLE," AND"

RADIATION"SHIELD

"

CHIMNEY"SIZE

"

5”"

6”"

7”"

8”"

FRAMED"

OPENING"INSIDE"

DIMENSIONS

"

11"1/2

"

X"

11"1/2

"

12"1/2

"

X"""12

"

1/2

"

13"1/2

"

X"""13

"

1/2

"

14"1/2

"

X"""14

"

1/2

"

7"

7. Assemble Chimney Sections: Lower the female end of the first Chimney

Section in the Support Box (Fig 9). It will twist-lock clockwise onto the male

end of the Support Box. Turn Pipe Sections firmly clockwise to lock them

together. Sheet metal screws are not required, but they may be used to

reinforce the connection, if desired. Use only 1/2" (or shorter) sheet metal

screws. Do not penetrate the inner liner of the chimney.

Fig.9 Fig.10

8. Install Attic Insulation Shield (when the attic insulation shield is to be

enclosed): Install the Attic Insulation Shield where the chimney passes into an

attic. Its purpose is to prevent debris and insulation from getting too close to

the chimney (Fig 10). An installed Attic Insulation Shield is 15 inches high. In

attic areas where this shield cannot fit, you must enclose the attic portion of the

chimney in a framed enclosure. If the chimney is fully enclosed through the

attic, an Attic Insulation Shield is not required. If the chimney passes into the

attic, install the Attic Insulation Shield as follows:

a. If the Radiation Shield extends above the attic floor, no modifications are

necessary. The Radiation Shield will fit inside the Attic Insulation Shield.

b. Assemble Chimney Sections until at least 18 inches of chimney extends

above the Radiation Shield.

c. Extend the Radiation Shield tube extension (keep at least 1" overlap), and

secure in place using sheet metal screws.

d. Slip the Attic Insulation Shield over the Chimney and Radiation Shield until

the base sits squarely on the framed opening (Fig 7 & 10).

e. Secure the Attic Insulation Shield to the top of the framed opening using at

least (3) 8-penny nails or (3) #8, 1-1/2" wood screws per side (Fig 10).

f. Wrap the Collar of the Attic Insulation Shield around the chimney and fasten

it loosely with supplied hardware. Slide the Collar down to meet the Attic

Insulation Shield. Tighten the hardware to secure theCollar.

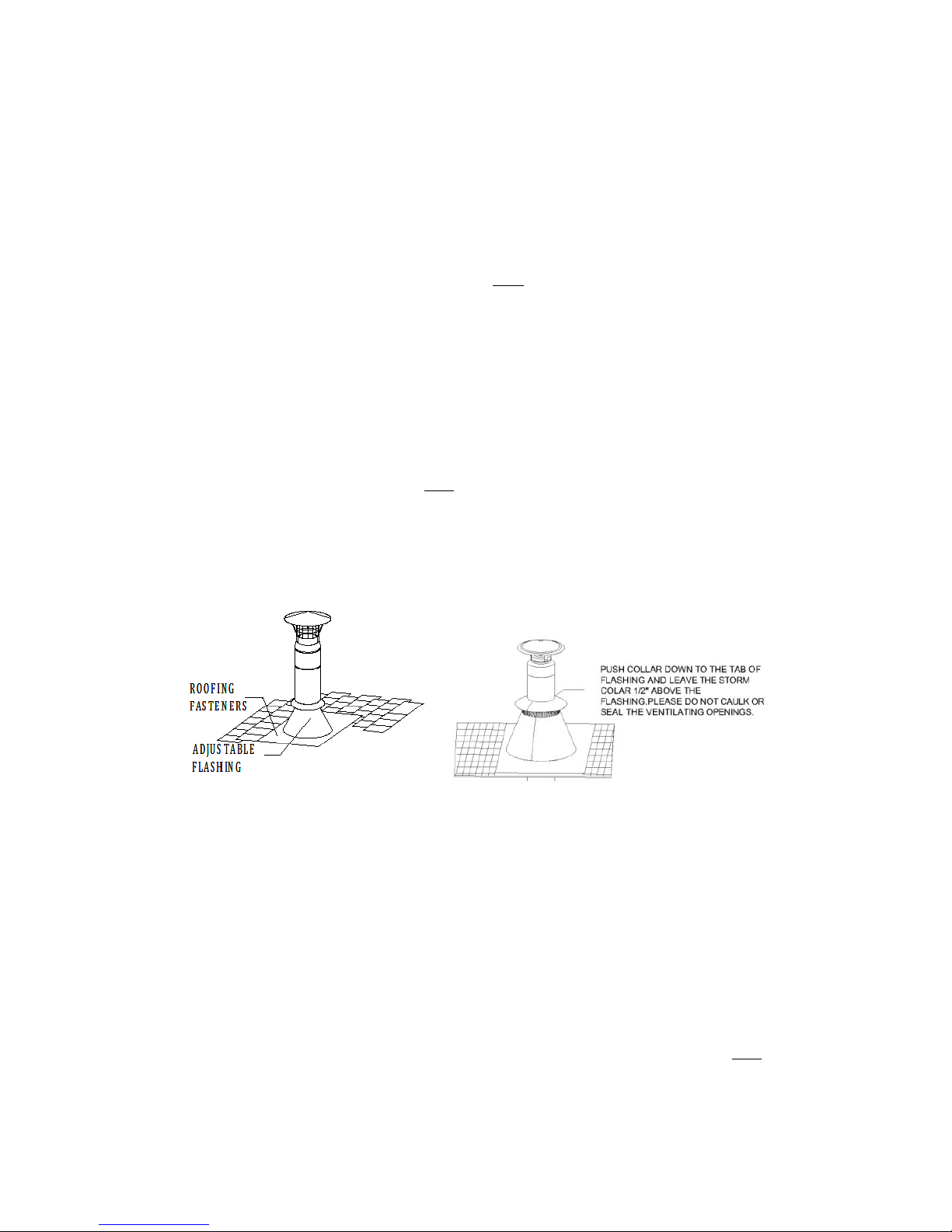

9. Attach Flashing: In new construction, assemble the Chimney Sections to a

point above the roof, then slip the Flashing over the chimney. On an existing

roof, center and install the Flashing before extending the chimney above the

roof. Allow space to permit sliding the next Chimney Section up through the

8"

Flashing. Always insure the chimney remains vertical (use level), and that at

least a 2-inch clearance to combustible materials is maintained all around.

Install the upper edge of the Flashing under the roofing. Nail to the roof along

the upper edge and down each side with 1-inch roofing nails. Do not nail the

lower edge of the Flashing (Fig 11). Be sure to follow local building practices,

as needed. Seal all nail heads with a non-hardening waterproof sealant. On

flat or tarred and graveled roofs, nail and seal the Flat Roof Flashing to the roof

on all sides with roofing compound. Do not put screws through the Flashing

into the Chimney Pipe.

10. Finish Top: Apply a high-temperature (5000F), non-hardening waterproof

sealant around the chimney at the point where the Storm Collar will meet the

chimney just above the Flashing 1/2 INCH. (Figures 11 and 12). Slide the

Storm Collar down over the chimney to the tab of the Flashing. Tighten and

seal the Storm Collar against the sealant. After installing sufficient Chimney

Sections to meet the height requirement (Fig 1), attach the Chimney Cap onto

the top of the chimney by holding the collar of the cap and twist locking it

clockwise onto the chimney. Do not hold upper portion of the cap and twist, as

this may damage the cap. The Chimney Cap can be removed for chimney

cleaning as described in the Chimney Maintenance section of the instructions.

Use a Roof Brace if the chimney extends more than 5 feet above the roof

(Figures 14 & 15 in the Roof Brace).

Fig"11"Fig"12"

11. Enclosures: Enclose chimneys where they pass through occupied spaces,

including closets. Always maintain at least a 2-inch clearance between the

chimney and any combustible materials. Interior enclosures may be

constructed with standard framing and sheathed with sheetrock or plywood.

Use Wall Brackets as needed to maintain a minimum of 2 inches of air space

between the chimney and combustible materials.

OFFSET ELBOW INSTALLATION

Elbows are manufactured in 15° and 30° angles measured from the vertical. A

30° Elbow is the largest that can be used in an offset. A 30° Elbow may not be

combined with a 15° Elbow to make a 45° offset. Avoid Elbows if possible,

since a totally vertical chimney is more efficient. When Elbows are necessary

9"

to avoid obstructions such as rafters, ridgepoles, or joists, use no more than

two 30° offsets in any one chimney system.

1. Attach Elbows: Attach Elbow to Chimney Section or other Elbow. Please

be noticed that the female end of the elbows are not lanced, in order to ensure

proper alignment of the chimney system can be maintained. Locking bands

must be used at all chimney joints. Attach one Elbow to the Chimney Section

below, and align it for the offset. Refer to Table 2 to determine the required

offset length and attach an appropriate length (or lengths) of Chimney

Section(s) above the Elbow. The maximum length of chimney pipe between

elbows is not to exceed 72" (maximum of two chimney sections only). Attach

the second Elbow above the Chimney Section to complete the offset (Fig 13).

2. Secure Offset: Place the Elbow Strap’s band around the angled portion of

the top Elbow, then tighten the nut and bolt until the clamp is firm. Wrap the

Elbow Strap end over an adjacent joist or rafter and secure it with at least (2)

8-penny nails or (2) #8, 1-1/2 screws. Do not add more Chimney Sections until

the Elbows are supported. Be sure that the chimney remains vertical. If there is

more than one Chimney Section between the Elbows, install a second Elbow

Strap around the joint of the two Chimney Sections (Fig13).

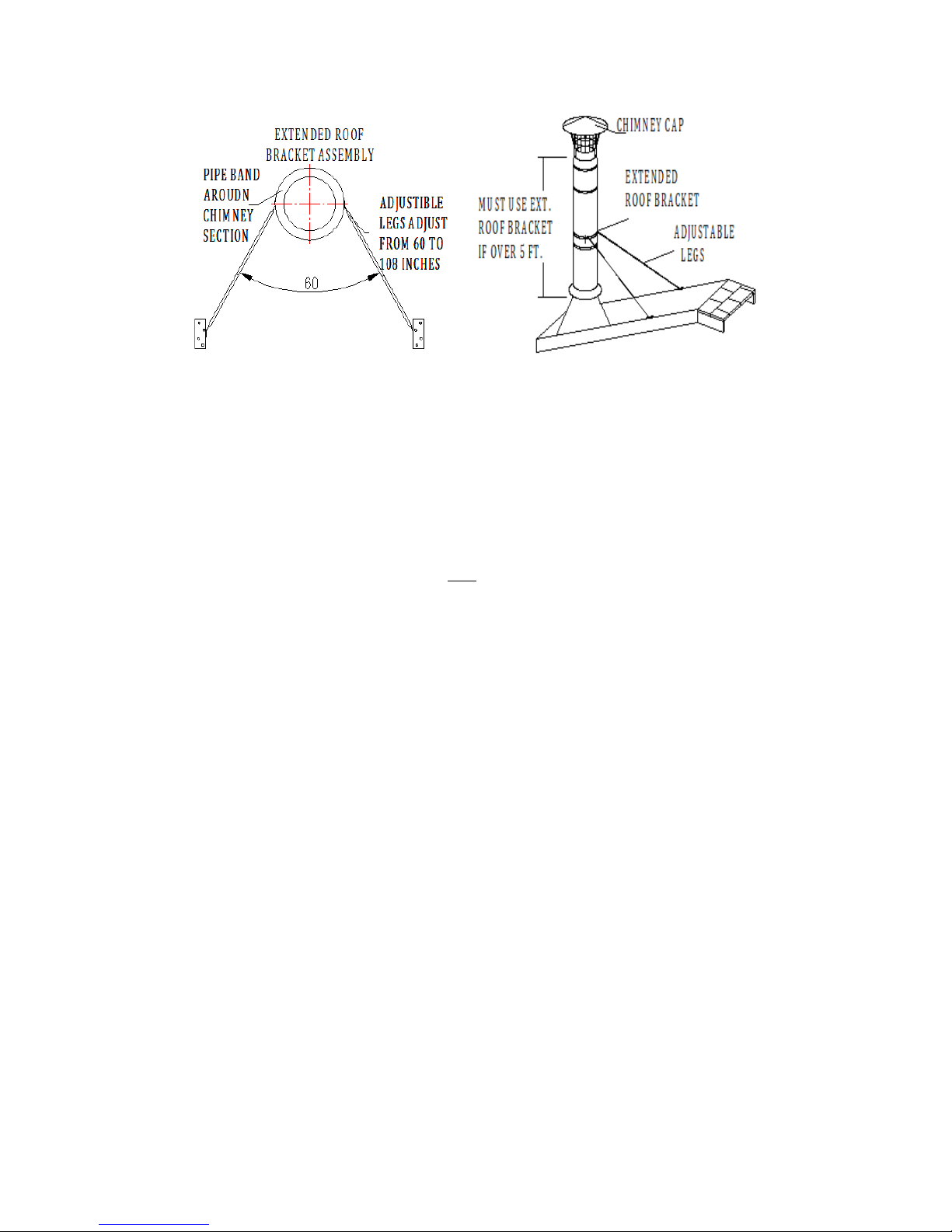

ROOF BRACE INSTALLATION

If the chimney extends more than 5 feet above the roofline, a Roof Brace must

be installed at every 5-foot increment of chimney height above the roofline,

leaving no more than 5 feet of chimney extending above the last Roof Brace.

The Roof Brace consists of the Pipe Band, the Adjustable Legs, and the Roof

Brackets.

Fig"13"

10"

1. Mount Pipe Band: Slip the Pipe Band around the chimney and secure by

tightening the nut and bolt.

2. Attach the Legs: The Adjustable Legs of the assembly will adjust from 60"

to 108". Secure one end of the Legs to the Pipe Band using the nuts and bolts

included (1 per Leg). Position the Adjustable legs so they form approximately a

60° angle with the chimney, and with each other (Figures 14 and 15). Be sure

that there is at least 3" of overlap between the top and bottom halves of the

Adjustable Leg. In order to secure Legs in proper position, there is a hole

provided in the outer leg where the outer and inner halves overlap. Use a 1/4"

drill bit to drill through the inner leg at that location. Use the nut & bolt provided

to pin the Adjustable Legs in position.

3. Install Roof Bracket: Mount the two Roof Brackets where each of the

adjustable Legs meets the roof, using (6) 1" roofing nails per bracket. Seal the

nail heads carefully with a non-hardening, waterproof sealant. Attach the

bottom end of the Adjustable Legs to the Roof Brackets using the nuts & bolts

provided.

CHIMNEY

LENGTH

BETWEEN

ELBOWS

5

6

7

8

OFFSET

RISE

OFFSET

RISE

OFFSET

RISE

OFFSET

RISE

ELBOW DEGREE =

15

0

1 29/64

12

6/64

1 29/64

12 16/64

1 32/64

12 33/64

1 34/64

12 48/64

6

2 62/64

17 51/64

3

17.94277

3

2/64

18 14/64

3

4/64

18 29/64

12

4 32/64

23 32/64

4 33/64

23.64705

4 36/64

23 59/64

4 38/64

24 10/64

18

6

2/64

29 13/64

6

3/64

29.35134

6

6/64

29 40/64

6

8/64

29 55/64

24

7 36/64

34 58/64

7 37/64

35.05563

7 39/64

35 21/64

7 41/64

35 36/64

30

9

6/64

40 39/64

9

7/64

40.75991

9

9/64

41

2/64

9 11/64

41 17/64

36

10 40/64

46 20/64

10 41/64

46.4642

10 43/64

46 47/64

10 45/64

46 63/64

42

12

9/64

52

1/64

12 11/64

52.16849

12 13/64

52 28/64

12 15/64

52 44/64

48

13 43/64

57 46/64

13 44/64

57.87277

13 47/64

58

9/64

13 49/64

58 25/64

ELBOW DEGREE =

30

0

3

7/64

12 46/64

3 15/64

13 10/64

3 25/64

13 50/64

3 27/64

13 60/64

6

6

4/64

17 53/64

6 11/64

18.25035

6 23/64

18 58/64

6 25/64

19

4/64

12

9

1/64

22 61/64

9

8/64

23.36467

9 20/64

24

1/64

9 22/64

24 11/64

18

11 62/64

28

4/64

12

5/64

28.47899

12 17/64

29

9/64

12 19/64

29 18/64

24

14 59/64

33 11/64

15

2/64

33.59332

15 14/64

34 16/64

15 16/64

34 26/64

30

17 56/64

38 18/64

17 63/64

38.70764

18 10/64

39 23/64

18 13/64

39 33/64

36

20 53/64

43 26/64

20 60/64

43.82196

21

7/64

44 31/64

21 10/64

44 40/64

42

23 50/64

48 33/64

23 57/64

48.93629

24

4/64

49 38/64

24

7/64

49 48/64

48

26 47/64

53 40/64

26 54/64

54.05061

27

1/64

54 45/64

27

4/64

54 55/64

TABLE 2 ELBOW OFFSET CHART

11"

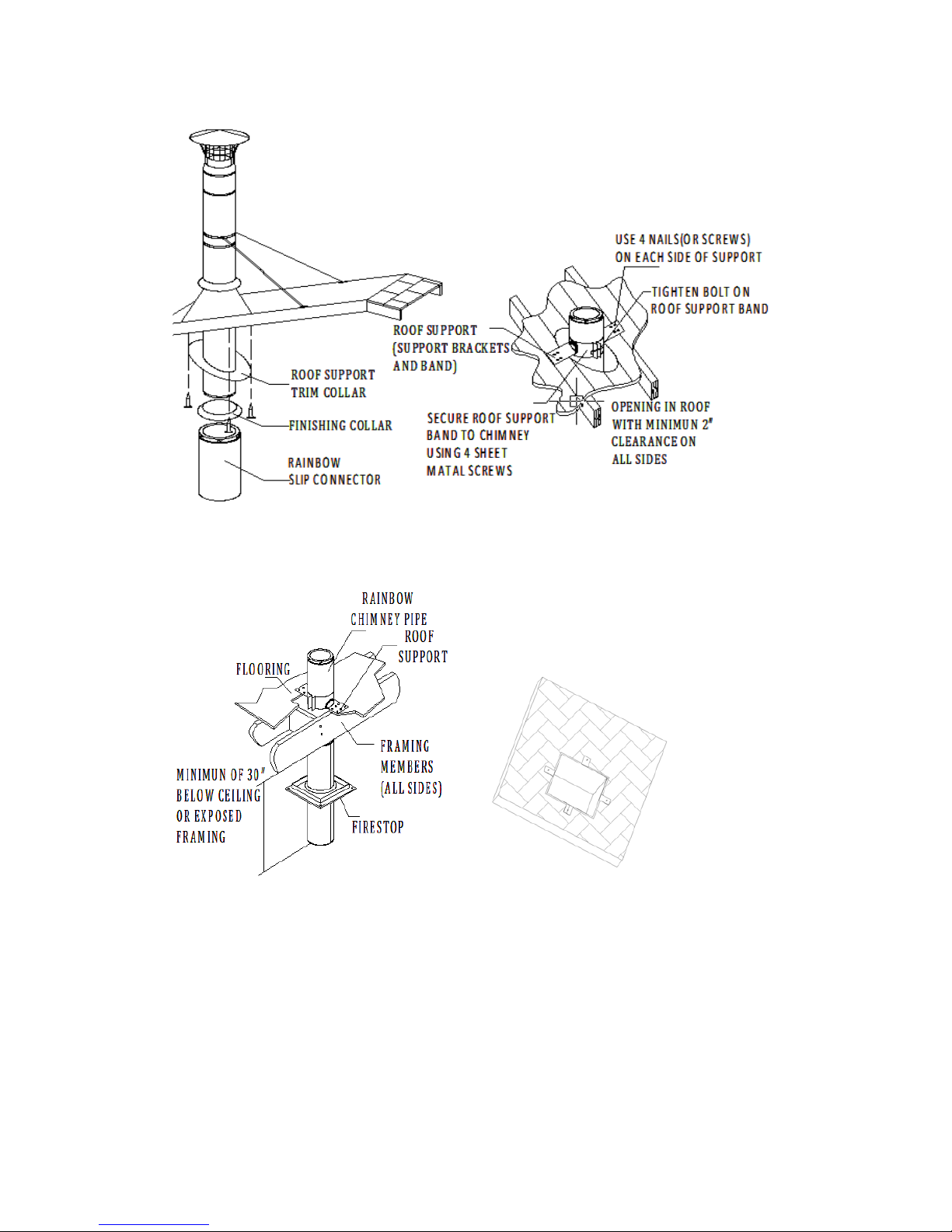

ROOF SUPPORTED INSTALLATIONS

There are two types of Roof Supported Installations: (1) Using a roof jack, and

(2) Using a Roof Support.

(1)

For a roof jack installation, make sure that the square box portion of the

Support Box can extend at least 2" below the low side of the finished ceiling

(Fig 16). The roof jacket must remain level, and the top edge of the box must

cover the edge of the roof’s decking material. Mobile home chimney

installations are roof supported. Do not seal openings in flashing.

1. Place Appliance: Place the appliance in its proper location, referring to the

manufacturer’s instructions as to allowable distances from combustibles, etc.

2. Cut Openings: Cut a roof opening in your desired location, just as in a

Ceiling Supported Installation (Steps 1 through 5, page 4 – 6). If a separate

ceiling and roof exists, as shown in Figure 17 (Low Attic), first cut and frame a

ceiling opening as described in Ceiling-Supported Installations (Step 2). Refer

to Table 1 for clearance and framing specifications. If it is desired to install

through a cathedral ceiling (Fig 16), then the hole is cut in the roof.

3. Install Roof jack: Slip the roof jack into the framed opening so the square

portion projects at least 2 inches below the finished ceiling and rafters (bottom

of round portion is 5" below), and extends above the ceiling to framing or

decking materials that it can be nailed to. Level the roof jacket, and slit the

corners to the roofline where they extend beyond it. Using 8-penny nails, or 1-

1/2", #8 screws, per side (Fig 20). Screw the trim sections into the ceiling (Fig

6). Roof jack must extend from the roof line 6inches.

4. Complete Installation: Refer to Steps 7, 9 & 10 in the Ceiling Supported

Installation section to complete the Roof Supported installation.

(2)

A Roof Support is used in installations where there is a cathedral ceiling,

and a Square Ceiling Support is not desired. The Roof Support allows the EV-

HST to come down into the room below the level of the ceiling (Fig 18). The

Roof Support can support a maximum of 45 feet of EVHST total, and

maximum of 20 feet below the support.

1. Cut and frame opening to provide a minimum 2" clearance on all sides of the

Fig"14"

Fig"15"

12"

chimney pipe.

2. Bolt on the Roof Support Brackets to the Roof Support Band using the

supplied hardware. Attach the Roof Support Brackets to roof using (4) 8 penny

nails or (4) #8, 1-1/2” screws per side (Fig 18).

Fig"16"

"

"

3. Determine how much EV-HST chimney will be extending into the room

(minimum of 3" below the ceiling). Be sure to maintain the proper clearance to

combustibles (walls and ceilings) for the connector pipe. Once you have

identified the proper height for your installation, attach the Roof Support Band

to the Chimney Section by tightening the Bolt, and secure it with supplied

hardware.

4. Attach desired length of Chimney Sections above and below the roof level

(max. of 45' total, 20' below the support) (Fig 18).

5. Refer to Steps 10 & 11 in the Ceiling Supported Installation section (page 8,

9) to complete the Roof Supported installation.

Alternative Installation Location for Roof Support: The Roof Support may be

used at the bottom of a Chimney installation (Fig 19). This may be useful for

some basement installations. Maintain a minimum of 2” clearance to

combustibles at all times. The EV-HST chimney needs to extend a minimum of

3” below the finished ceiling or exposed framing members. Please note that

you cannot extend the chimney all the way to the appliance – you must have

some connector pipe.

13"

1. Cut and frame opening to provide a minimum of 2" clearance on all sides of

the chimney. Be sure to maintain the proper clearance to combustibles for the

connector pipe

2. Bolt on the Roof Support Brackets to the Roof Support Band. Attach the

Roof Support Brackets to floor (Fig 19).

3. Determine how much EV-HST chimney will be extending into the room

(minimum of 3" below the framing), and attach the Roof Support Band to the

Chimney Section by tightening the Bolt, and secure it with supplied hardware

(Fig 18 & 19).

4. Install the specialized Firestop below the finished ceiling or framing

members. The Firestop can only be used when installed with the Roof Support

in this type of installation. Use a standard Radiation Shield at all other locations.

5. Follow steps 4, 5 for the Roof Support Installation (page13).

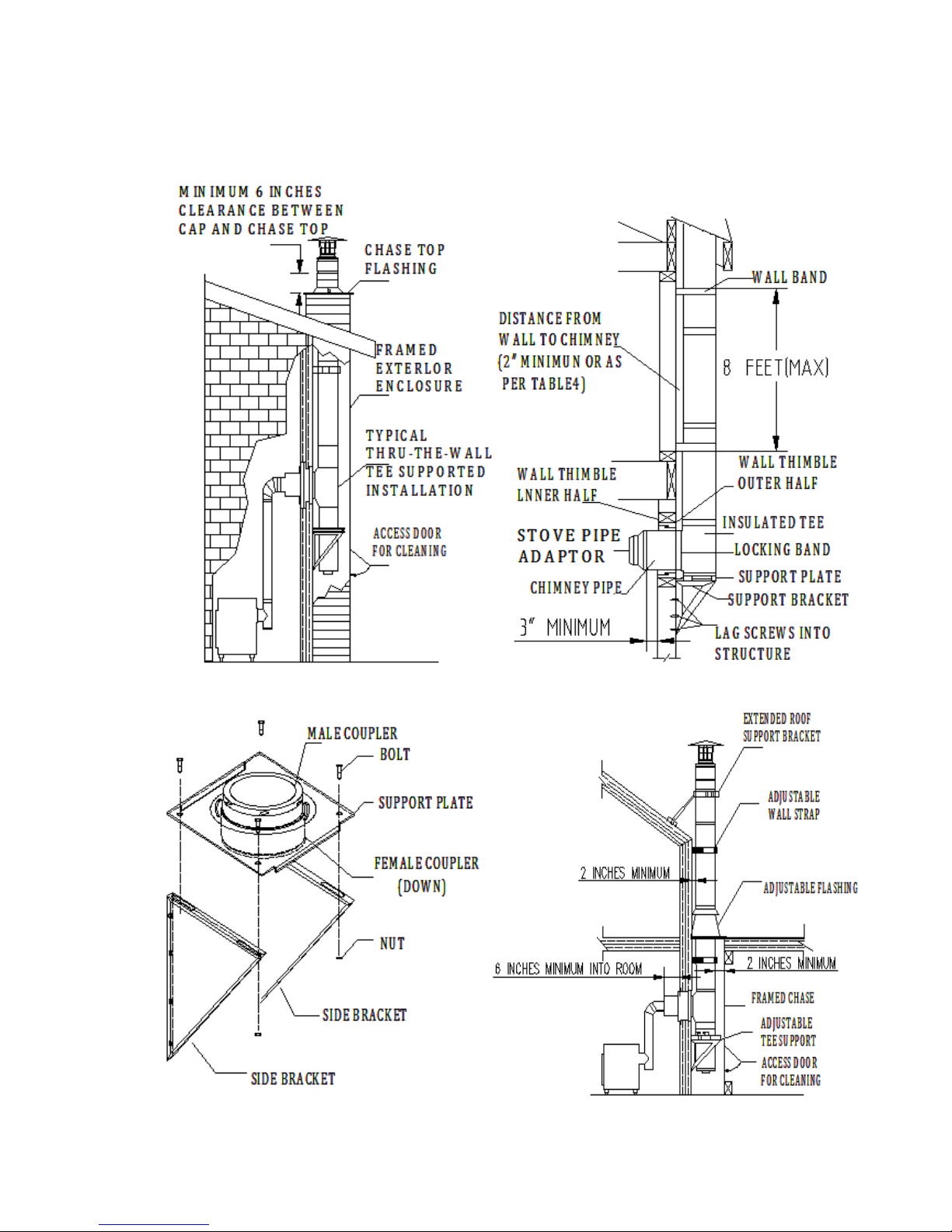

TEE-SUPPORTED INSTALLATIONS

Tee-Supported installations are used when passing through a wall to an

outside chimney. The Tee Support can hold a maximum of 50 feet of ev-HST

chimney. The required parts and general configuration are as shown in Figures

21 and 22.

Fig"17"

14"

1. Place Appliance: Position the appliance according to the manufacturer’s

instructions. It is a good idea to try to position the appliance so it will allow the

chimney to line up centered between studs.

2. Locate, Cut & Frame Opening: Determine the location where the chimney

will pass through the wall. The chimney should pass through the wall, centered

between two studs. The height of the penetration can be determined by

positioning sections of stove pipe until you have the desired configuration

(refer to the appliance manufacturer's installation instructions for restrictions

Fig"18"

Fig"19"

Fig"20"

15"

on stove pipe). Cut and frame an opening in the inner and outer walls at this

location. Refer to Table 1 (page 7) for the appropriate framing dimensions.

Fig"21"Fig"22"

"

Fig"23"

Fig"24"

16"

3. Install Wall Thimble: From the outside wall, put the outer half of the Wall

Thimble in the opening. Center the outer half of the Wall Thimble. Secure the

Wall Thimble to the outside wall with at least (4) 8 penny nails or (4) #8, 1-1/2”

screws. For concrete wall, Wall Thimble is not needed. The hole on the wall

just needs to be slightly larger than the chimney. Install the inner half (with

round plate) of the Wall Thimble in the inside wall surface, ensuring that the

shield slides into the shield of the outer half. Secure the Wall Thimble to the

inside wall with at least (4) 8 penny nails or (4) #8, 1-1/2”screws

4. Install Wall Support, Tee and Tee Cap: Assemble the Wall Support

(Figure 23) by attaching the 2 side brackets to the support plate, with the

hardware supplied (female coupler of the insulated coupling section is down).

Install one 6” Chimney Section (or longer as required) to the horizontal branch

of the insulated tee. Lock securely into the tee by twisting clockwise. A locking

band must then be installed at this connection. Make sure the clamp is facing

down to prevent any water from collecting in the lockingband.

From outside the building, slide the chimney length (previously installed on a

tee) through the wall thimble ensuring the male coupling on a tee is facing

upward.

Install the male coupler of insulated coupling section on the support plate into

the female coupler of the Tee. Lock securely into the tee by twisting clockwise.

Place the assembled wall support against the wall (plate up) directly below the

insulated coupling section of the Wall Support. Tighten the insulated coupling

section and the support plate with supplied lag screws (14#, 2”). Then secure

the whole Wall Support assembly onto wall using 14#, 2” wood screws

through the pre-punched slots in each bracket. Important: Verify that Wall

Support is level, and secure the leg brackets of the Tee Support to the wall

(Figs 24). Finally, install Tee Cap into the female coupler of the insulated

coupling section. Lock securely by twistingclockwise.

5. Complete Chimney: Attach the Chimney Sections as in Step 7 in the

Ceiling Supported Installation section (page 7). Secure the chimney to the wall

with Wall Straps at a minimum of 8-foot intervals and maintain at least 2 inches

of clearance to combustible materials. Slip the Wall Straps around the chimney,

tighten the bolts, adjust the clearance, and fasten the Wall Straps to the wall

Once the chimney is at the minimum height specified in Figure 1, attach the

Chimney Cap onto the top of the chimney by holding it by the collar and twist

locking it clockwise onto the Chimney Pipe. If the chimney penetrates an

overhang, frame for at least 2 inches of clearance, and install Flashing and

Storm Collar as described in Steps 9 & 10 for Ceiling Supported Installations

(page 8). Another option is to cut away the overhang for a 2-inch clearance

(Fig 25). If the chimney extends more than 5 feet above the top Wall Strap or

Flashing, use a Roof Brace.

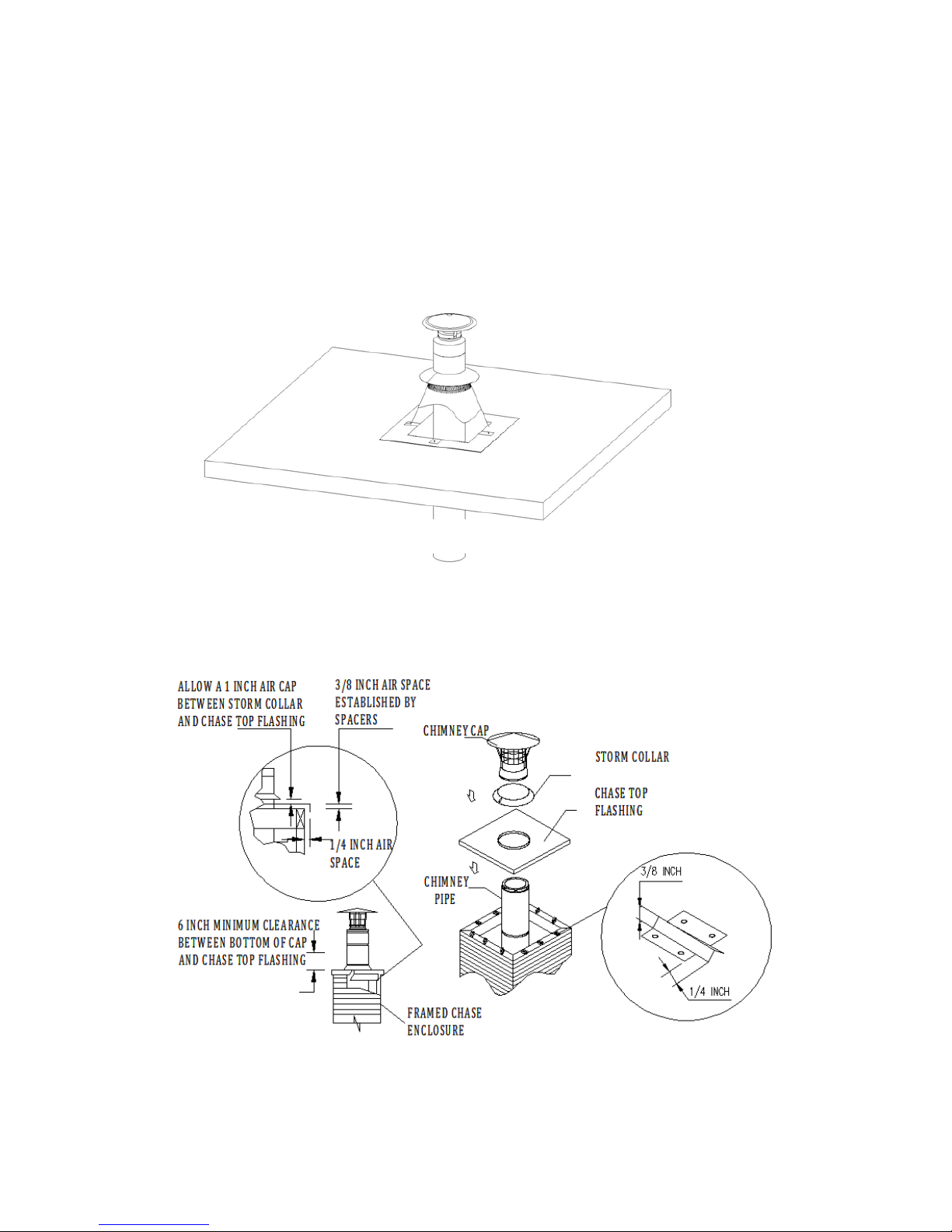

6. Install Chase Top Flashing: It is recommended that a Tee Supported

Chimney be enclosed in a chase. If a chase enclosure has been constructed,

you can either use a standard flat-roof flashing, or you can use a Chase Top

17"

Flashing. Using a Chase Top Flashing allows for a lower profile for the

chimney. The Chase Top Flashing has an opening that is 3" larger in diameter

than the EV-HST chimney. If the Chase Top Flashing can fit over your chase

enclosure as required (Fig 26) then install as directed, or trim as needed.

However, if the Chase Top Flashing is smaller than your chase enclosure, you

will need to provide a galvanized sheet capable of covering your chase and

overhanging the sides by 1/2 - 3/4 inch. Attach the Chase Top Flashing to the

Fig"25"

Fig"26"

18"

galvanized sheet using appropriate sheet metal screws and non-hardening

waterproof sealant. Use the Chase Top Flashing Spacers to allow the proper

air-gap clearances on the galvanized sheet. The Chase Top Flashing Spacers

are available to insure that the proper air-gap is maintained. Figure 26 displays

in some detail, how these air gaps are established using the Spacers and

Chase Top Flashing. Secure the Chase Top Flashing to the chase using a

sufficient number of #8, 1-1/2" wood screws, being careful to insure the air gap

is maintained between the flashing and the chase. Seal the screw heads with

non-hardening sealant. When installing the Storm Collar, allow a 1" air space

between the bottom of the Storm Collar and the Chase TopFlashing.

MASONRY FIREPLACE INSTALLATIONS

1. Determine Chimney Size: Use Table 3 to determine the correct diameter

chimney for your fireplace.

2. Mount Anchor Plate: Chimneys for masonry fireplaces begin with an

Anchor Plate. Make sure the surface of the masonry chimney has a level

surface on which to attach the Anchor Plate. If the top of the masonry does not

have a level surface, then you will need to modify the masonry accordingly.

Center the Anchor Plate over the masonry flue opening, and seal the Anchor

Plate with a high-temperature (10000F) sealant. Secure Anchor Plate with (4)

1/4" x 2" masonry anchors (Fig 27). It is very important that the Anchor Plate is

level. Be sure to maintain a 1" min. clearance to combustibles from the Anchor

Plate.

3. Attach Chimney: Twist lock the first Chimney Section clockwise onto the

Table"3"

Table of contents