CACG/CAHG & CACH/CAHH

Air Handlers

• Installation, Operation and Maintenance Manual •

Comfort where it counts 4P/N 240007756, Rev. A [051509]

Product description

The EMI AmericaSeries Cassette Air•

handlers are available in three cabinet

sizes with four output capacities from

9,000–24,000 Btuh, and two cooling only

capacities from 30,000–36,000 Btuh.

Key features include a condensate pump•

with safety switch and a 36” (0.9 m) li

(measured from the base or boom of

the unit), fresh air inlet and branch duct

knockouts, and motorized air vanes mod-

els 24 and 36 only).

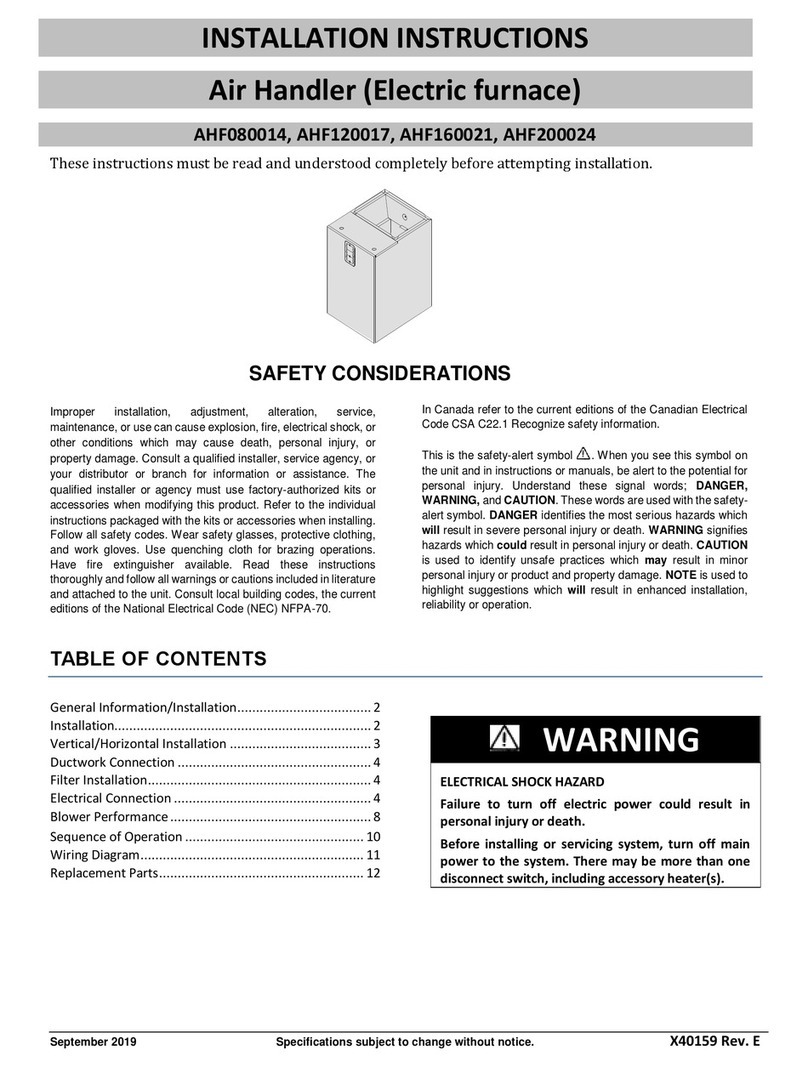

Electric heat is a factory-installed option•

ONLY(thereareno eldinstalledelectric

heat kits available). (See NOTICE on

next page.)

The cassette air handler accepts a 24•

volt thermostat control (thermostat not

included).

Designed for low noise levels, easy instal-•

lation and maintenance and a slim line

fascia, all ensure minimum intrusion into

the conditioned environment.

Due to ongoing product development, all•

designs and specications are subject to

change without notice.

ese American-made cassee air han-•

dlers produce system SEER’s meeting or

exceeding 13 when matched with EMI

outdoor units:

Single-zone condensing units –

S1CG/S1HG 09–24 and S1CG 30–

36.

Dual-zone condensing units –

S2CG/S2HG side discharge.

Multi-zone, top discharge condens-–

ing units T2CG/T2HG, T3CG/

T3HG, or T4CG/T4HG.

Refer to specications contained in–

this document.

All EMI air handlers arebackedby Enviro-•

master International LLC and are tested,

rated, and certied in accordance with

ARI standards 210/240 and UL 1995.

Verify Unit Before Installing

Standard features

CACG/CAHG units

“G” units require a remote thermostat•

for operation. They do not include an

onboard controller.

CACH/CAHH units

“H” units include an on-board micropro-•

cessor controller with infrared remote.

e remote is required to adjust seings•

and congure the controller.

Alsoincludedisabankof DIPswitchesfor•

seing operating behavior. ese can be

used to select operation by the on-board

controller or by a remote thermostat.

Whenoperatedbyremotethermostat,the•

controller oers limited options.

Materials of Construction

Galvanizedsteelcabinetwithre-resistant•

thermal and acoustic foam insulation.

Light grey high-impact ABS fascia.•

Expanded polystyrene drain pan with a•

tough, re-retardant thermoplastic liner.

Air Systems

Fans are backward-curved impeller•

centrifugal design; dynamically and stati-

cally balanced; and mounted on integral

mounting rails.

Single-fan models 9, 12 & 24 are–

designed with re-retardant plastic

or aluminum impellers.

Twin-fan model 36 is designed with–

re-retardant plastic impellers.

Motors are multispeed, enclosed type–

with thermal protection and sealed

lifetime bearings.

Permanent, washable lter (user acces-•

sible).

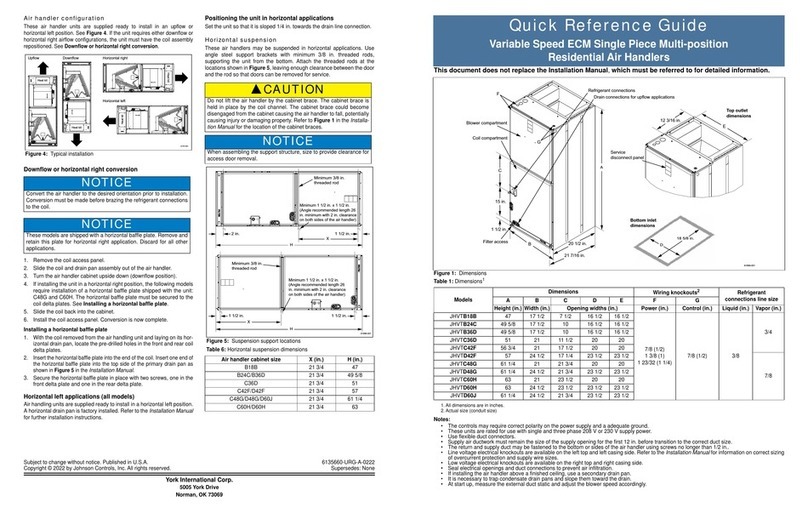

Branch duct knockouts on three sides•

for remote discharge locations (using no

more than two non-adjacent sides).

Freshairintakecapabilityonthreesidesof•

cabinet (only two on models 9–12).