Notes:

• Air handler units have been tested to UL 60335-2-40 / CSA 22.2 No. 236 standards up to 0.6 in. W.C. external static pressure.

• Dry coil conditions only, tested without filters.

• For optimal performance, external static pressures of 0.2 in. W.C to 0.5 in. W.C are recommended. Heating applications tested at 0.5 in. W.C. external static pressure.

Above 0.5 in. W.C., CFM is reduced by 2% per 0.1 in. increase in static.

• Low speed cooling used only with two stage outdoor units. Speed is preset to 65% of high speed.

• Dehumidification speed is 85% of jumper selected cool tap.

• Any compressor operation uses HI COOL and LO COOL DIP switches. Indoor heating operates off the heatkit selection and the HEAT DIP switches.

• At some settings, low cool and/or low heat airflow may be lower than what is required to operate an airflow switch on certain models of electronic air cleaners. Consult

the instructions for the electronic air cleaner for further details.

• Airflow (CFM) indicator light (LED2) flashes once for every 100 CFM (for example, 12 flashes is 1200 CFM) - blinks are approximate ±10% of actual CFM.

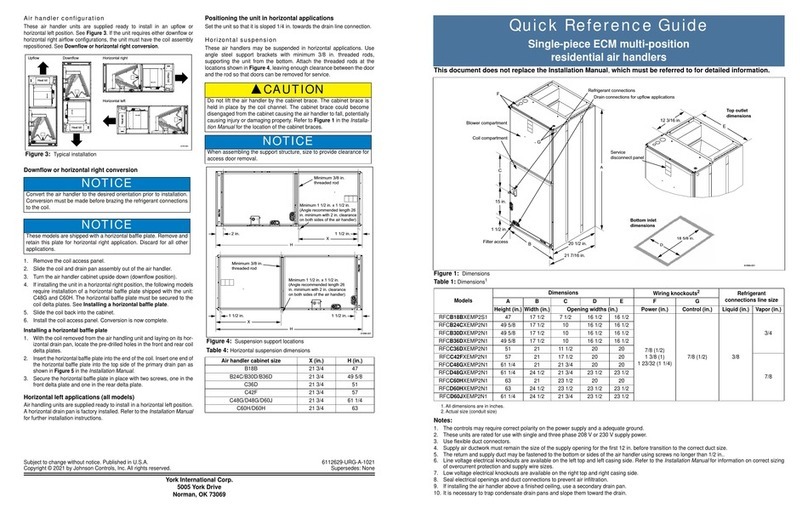

Airflow selection

When not using communicating functionality, you must set the airflow

and comfort setting selection switches correctly at the time of installation

for correct system operation. Place switches in the correct locations

based on the information shown in Table 2. An example of switch posi-

tions is shown below in Figure 2. 0 indicates the OFF position and 1 indi-

cates the ON position. The airflow configuration switches are located in

the SW4 switch bank.

Inputs to the air handler control board pass to the motor, which deter-

mines the target CFM to deliver. Refer to the Installation Manual for more

information on these inputs.

These variable speed air handlers are designed to deliver constant

airflow (CFM) regardless of the external static pressure (ESP) in the

ductwork. Therefore, if too many supply registers are closed, a filter

becomes clogged, or there is a restriction in the ductwork, the motor

automatically operates at a higher speed to compensate for the higher

ESP. This may result in a higher operating sound level and motor

damage.

Table 2: Airflow data (CFM)

DIP Switch B18B B24C B36D C36D C42F D42F

High cool Low cool High cool Low cool High cool Low cool High cool Low cool High cool Low cool High cool Low cool

000 575 400 700 475 800 550 825 600 1100 700 1125 675

001 625 450 725 525 900 600 900 650 1200 750 1225 875

010 675 475 800 575 975 650 1000 700 1300 800 1325 925

011 725 525 850 625 1075 700 1050 750 1400 850 1425 1000

100 775 550 925 650 1150 775 1150 825 1500 925 1550 1075

101 850 575 975 700 1250 825 1225 850 1625 975 1675 1150

110 900 625 1075 725 1325 900 1300 900 1725 1050 1775 1225

111 950 650 1100 775 1400 950 1350 950 1825 1100 1875 1275

DIP Switch C48G D48G C60H D60H D60J

High cool Low cool High cool Low cool High cool Low cool High cool Low cool High cool Low cool

000 1150 725 1125 700 1400 975 1400 975 1375 925

001 1250 775 1225 875 1525 1075 1550 1075 1475 1050

010 1350 850 1325 925 1650 1150 1700 1150 1750 1125

011 1450 900 1425 1000 1800 1250 1850 1250 1875 1225

100 1575 975 1550 1075 1925 1350 2000 1350 2000 1350

101 1675 1025 1675 1150 2050 1425 2125 1425 2000 1400

110 1775 1100 1800 1225 2050 1525 2125 1550 2000 1475

111 1875 1150 1900 1275 2050 1600 2125 1650 2000 1575

Figure 2: DIP-10

ON

DIP Switch example: 0101000110

12345678910

A1708-001

NOTICE

Incorrect airflow and comfort settings may result in decreased system

efficiency and performance.

Clearances

It is essential to provide the following clearances:

• Refrigerant piping and connections - minimum 12 in.

• Maintenance and servicing access - minimum 36 in. from the front

of the unit for blower motor or coil replacement

• Condensate drain lines routed to clear filter and panel access

• Filter removal - minimum 36 in.

• The supply air ductwork connected to this unit is designed for 1 in.

clearance for the first 18 in. of combustible materials if an electric

heat kit accessory is installed.

• A combustible floor base accessory is available for downflow appli-

cations of this unit, if required by local code.

External duct static

Measure the supply air static pressure. Record this positive number.

Measure the return air static pressure. Record this negative number.

Treat the negative number as a positive and add the two numbers

together to determine the total external system static pressure. If a filter

rack is installed on the return air end of the air handler or indoor coil

section, make sure to measure the return air duct static between the filter

and the indoor coil.

Figure 3: Duct static measurements

Take measurements here if using

a filter rack.

Return air static must be taken

between the filter and indoor coil.

A1704-001

Table 3: Electrical heat: minimum fan CFM for single-phase heatkits

Heater kit

models1,2

Nominal

kW

at 240 V

Airflow

configuration

heat dip switch

setting*

Aux heat

configuration

heatkit

selection dip

switch setting

Air handler models (CFM3)

B18B B24C B36D C36D C42F D42F C48G D48G C60H D60H D60J

8HK(0,1)6500206 2.4 00 0001 625 650 625 825 825 825 825 825 825 825 825

8HK(0,1)6500506 4.8 00 0010 650 650 650 825 825 825 825 825 825 825 825

8HK(0,1)6500806 7.7 00 0011 750 800 750 1100 1100 1150 1100 1150 1100 1150 1150

8HK(0,1)6501006 9.6 00 0100 790 950 750 1100 1100 1500 1100 1500 1100 1500 1500

8HK(1,2)6501506 14.4 00 0101 —650,

950 650,

975 825,

1100 825,

1100 825,

1575 825,

1100 825,

1575 825,

1100 825,

1575 825,

1700

8HK(1,2)6502006 19.2 00 0110 ——

750,

975 1100,

1300 1100,

1300 1325,

1575 1100,

1300 1325,

1575 1100,

1300 1325,

1575 1500,

1700

8HK(1,2)6502506 24 00 0111 ———————

1325,

1650 —1325,

1650 1500,

1800

1.(0,1) - 0 = no service disconnect or 1 = with service disconnect.

2.(1,2) - 1 = with service disconnect, no breaker jumper bar or 2 = with service disconnect and breaker jumper bar.

3.For minimum fan CFM, if there are two values present, the first value is low-stage CFM (W1) and the second value is full-stage CFM (W1+W2). If higher kW/CFM is

needed for low-stage, see Table 5.

* To increase airflow by approximately 20%, adjust the HEAT DIP switches from 00 to 01.

Table 4: Electrical heat: minimum fan CFM for three-phase heatkits

Heater kit

models1,2

Nominal

kW

at 240 V

Airflow

configuration

heat dip switch

setting*

Aux heat

configuration

heatkit

selection dip

switch setting

Air handler models (CFM3)

B18B B24C B36D C36D C42F D42F C48G D48G C60H D60H D60J

8HK06501025 9.6 00 1000 790 950 1150 1150 1150 1500 1150 1500 1150 1500 1700

8HK06501525 14.4 00 1001 — 950 1150 1150 1150 1575 1150 1575 1150 1575 1700

8HK16502025 19.2 00 1010 — — 1150,

1150 1150,

1300 1150,

1400 1500,

1575 1150,

1300 1500,

1575 1150,

1300 1500,

1575 1700

8HK16502525 24 00 1011 — — —————

1575,

1650 —1575,

1650 1700,

1800

1.(0,1) - 0 = no service disconnect or 1 = with service disconnect.

2.(1,2) - 1 = with service disconnect, no breaker jumper bar or 2 = with service disconnect and breaker jumper bar.

3.For minimum fan CFM, if there are two values present, the first value is low-stage CFM (W1) and the second value is full-stage CFM (W1+W2). If higher kW/CFM is

needed for low-stage, see Table 5.

* To increase airflow by approximately 20%, adjust the HEAT DIP switches from 00 to 01.

Table 5: Aux heat configuration - stage 1 kW dip switch settings

W1 = W1 00, 01

W1 = W2 10

W1 = W1 + W2 11