CONTENTS

1 - SAFETY CONSIDERATIONS .................................................................................................................................... 3

1.1 - General .................................................................................................................................................................. .3

1.2 - Applications ........................................................................................................................................................... .3

1.3 - Instruction types ..................................................................................................................................................... .3

1.4 - Disposal of parts/materials ..................................................................................................................................... .5

2 - TRANSPORT AND LIFTING INSTRUCTIONS.......................................................................................................... 5

2.1 - General .................................................................................................................................................................. .5

2.2 - Transport and storage ............................................................................................................................................ .5

2.3 - Offloading and hoisting ........................................................................................................................................... .5

2.4 - Horizontal transport ................................................................................................................................................ .6

2.5 - Storage .................................................................................................................................................................. .6

2.6 - Warranty ................................................................................................................................................................ .6

2

2.7 - Placement ............................................................................................................................................................... 6

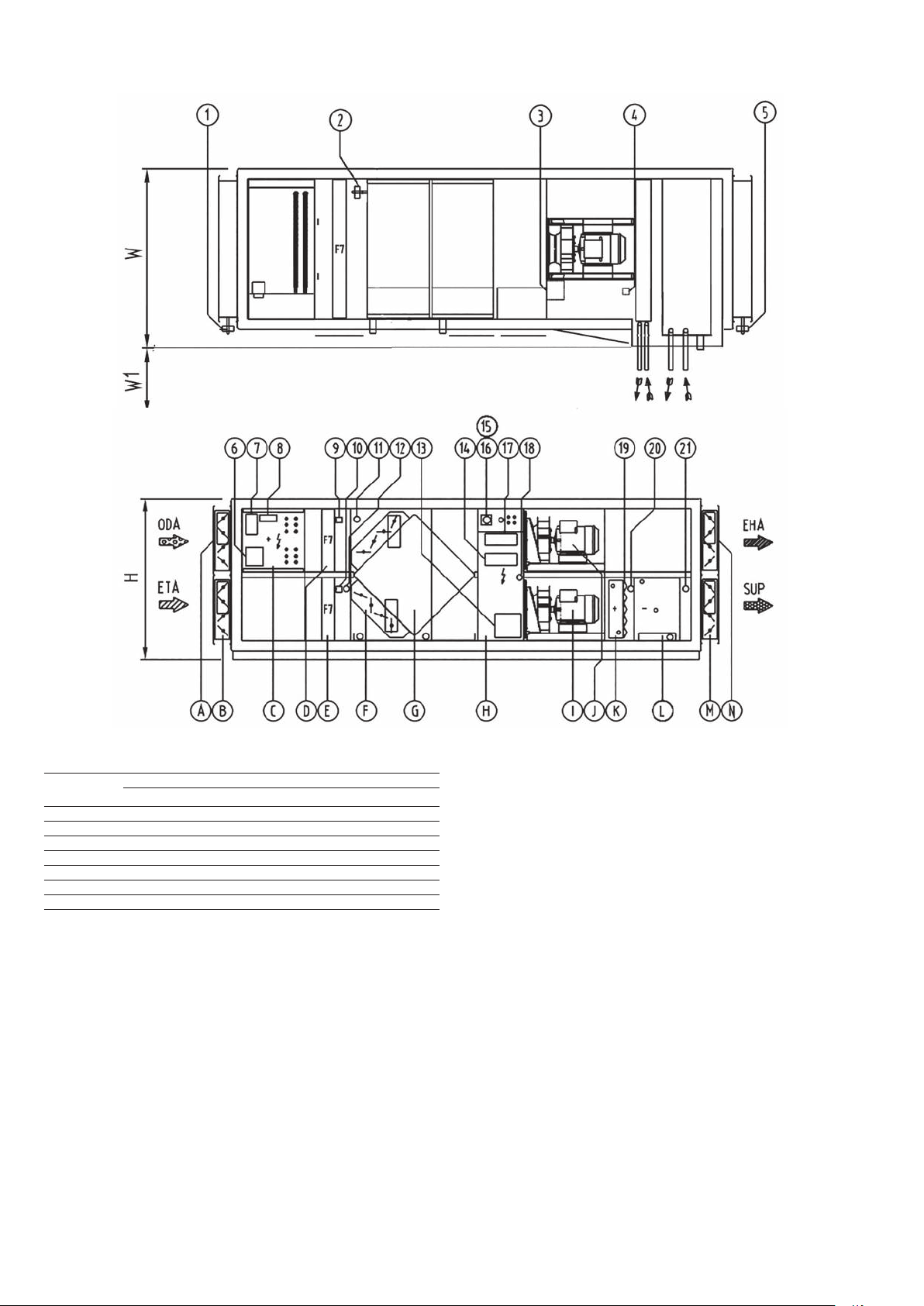

2.8 - Schematic diagram of an air handling unit ............................................................................................................... 6

3 - CHECKLIST OF START-UP CHECK POINTS .......................................................................................................... 9

3.1 - Checklist of start-up check points .......................................................................................................................... .9

4 - START-UP INSTRUCTIONS ................................................................................................................................... 10

4.1 - Casing ................................................................................................................................................................. .10

4.2 - Dampers .............................................................................................................................................................. .12

4.3 - Air filters ............................................................................................................................................................... .13

4.4 - Heaters ................................................................................................................................................................ .13

4.5 - Coolers ................................................................................................................................................................ .14

4.6 - DX Coils ............................................................................................................................................................... .15

4.7 - Heat recovery wheel ............................................................................................................................................. .15

4.8 - Plate heat exchanger ............................................................................................................................................ .16

4.9 - Recirculation damper ........................................................................................................................................... .16

4.10 - Fan .................................................................................................................................................................... .16

4.11 - Silencers ........................................................................................................................................................... .19

4.12 - Lighting .............................................................................................................................................................. .19

4.13 - Control panel ..................................................................................................................................................... .20

4.14 - Installation of external sensors included ............................................................................................................. .21

4.15 - Sensor Replecament ......................................................................................................................................... .22

5 - MAINTENANCE CHECKLIST ................................................................................................................................. 23

5.1 - Checklist of check points and maintenance intervals ............................................................................................ .23

6 - MAINTENANCE AND OPERATING INSTRUCTIONS ............................................................................................ 23

6.1 - General ................................................................................................................................................................ .24

6.2 - Casing panels ...................................................................................................................................................... .24

6.3 - Doors and access covers ..................................................................................................................................... .24

6.4 - Flexible connections ............................................................................................................................................. .24

6.5 - Earthing ............................................................................................................................................................... .24

6.6 - Dampers .............................................................................................................................................................. .24

6.7 - Outside air intake ................................................................................................................................................. .24

6.8 - Filters ................................................................................................................................................................... .24

6.9 - Heaters ................................................................................................................................................................ .24

6.10 - Coolers .............................................................................................................................................................. .25

6.11 - Heat recovery wheel ........................................................................................................................................... .25

6.12 - Plate heat exchanger .......................................................................................................................................... .26

6.13 - Recirculation damper ......................................................................................................................................... .26

6.14 - Fan .................................................................................................................................................................... .26

6.15 - Silencers ............................................................................................................................................................ .27

6.16 - Control ............................................................................................................................................................... .27

7 - OPEN AND CLOSED INSTRUCTIONS .................................................................................................................. 28

Abbreviations

AHU - Air handling unit

PED - Pressure Equipment Directive

SUP - Supply air

ETA - Extract air

BMS - Building management system

HMI - Human machine interface

ODA - Outdoor air

EHA - Exhaust air

rh - Relative humidity

6

7