ECU Master Battery Isolator User manual

Ecumaster Battery Isolator

Manual

Revision 0.7

1 Device description

The Battery Isolator is a motorsport solid state device which can be used for FIA compliant battery

isolation and engine shutdown.

It is the most lightweight solution possible. The device is designed for harsh motorsport environment

and it weighs only 83g. The lack of mechanical components ensures long life and high reliability.

The device has a built in alternator load dump protection without need of external components. This

means there is no risk of damage to expensive electronic equipment during emergency shutdown. It is

controlled with two external switches and can be shut down with a CAN bus message. The message

can be sent from Ecumaster PMU16 unit in case of high impact or another event.

The device is configurable through CAN bus and the Light Client software. It also transmits diagnostic

information which can be used by other equipment and is valuable during device setup and diagnosis.

State of the device is transmitted over CAN bus and also is indicated with multi color led light.

It is fully protected for overheating and over current.

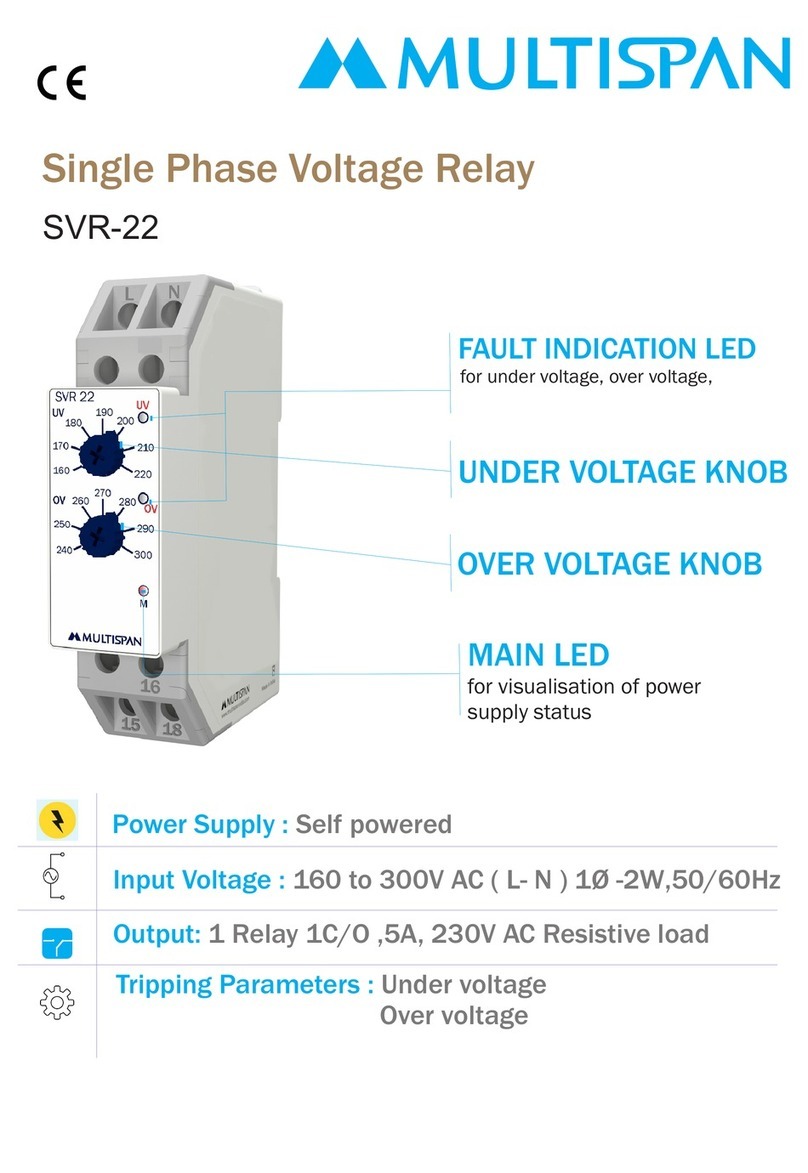

2 Specification

•Weight: 83g

•Dimensions: 50mm x 100mm x 38.5mm

•Voltage range: 6V 19V, 28V transient (12V automotive installations only)

•Current capability: 300A continuous, peak up to 1000A

•Current measurement resolution: 4A

•Current measurement range: 1000A to 1000A

•Current measurement accuracy: ±10%

•Inductive load switching capability: 600mJ

•Enclosure: Anodized billet aluminum, IP67 rated

•High current terminals: M8 nickel plated terminals or Radlok™ connectors

•Signal connector: Deutsch ASX202 06PN (mating plug ASX602 06SN included)

•Power save state current consumption: <1mA

•ON state current consumption: ~20mA

•Engine kill output: 3A, High (VBat), Low (GND) or Hi Z1

1* Hi Z high impedance output not connected to 12v nor ground

3 Installation

•To avoid damage, it is advised to disconnect any electrical equipment during welding on car

•Pay attention to correctly connect power terminals. Any attempt to crank the engine with

reverse terminal connection will most likely damage the device. Polarity is clearly

engraved on the case.

3.1 Mountin

The device automatically shuts down at 90°C internal temperature. Temperature warning for the device

is set at 80°C. It is advised to install the device in cool, well ventilated place on a flat metal piece of

chassis.

The device will provide specified continuous current when firmly installed on flat metal piece of

chassis in an ambient temperature of 30°C. Device performance will vary depending on how much heat

dissipation you provide.

After installation you should verify that during normal operation the device has enough temperature

headroom not to fail during racing conditions.

3.2 Electrical connection

The device is connected between battery positive (+) terminal and rest of vehicle installation.

The device has two switch inputs:

•Power save switch input. When this input is connected to ground the device shuts down the

engine and turns off to very low current consumption level <1mA. It is also required to reset the

device after a fault condition occurs. The input has an internal pull up resistor and is not active

when disconnected. The switch connected to this input must be latching and have two stable

positions.

•Emergency switch input. When this input is disconnected from ground the device shuts

down the engine and turns off car power supply but it is still powered on itself. Normally closed

emergency switches should be connected to this input in series. The input has an internal pull

up resistor and is active when disconnected. The switch for this input must be momentary with

normally closed configuration.

The device has one output used to kill the engine in case of emergency. This output is fully

programmable and can have VBat, GND or High Z independently when active and not active. For the

system to work, engine must shut down when engine kill output is active. If the engine keeps running,

alternator will provide power supply to car installation. If current is drawn from kill output, GND

High Z combination is preferred for best performance on drained battery. PLEASE NOTE O TP T

IS ONLY 3AMP SO CAN’T BE SED AS DIRECT FEED FOR IGNITION, CORRECT RELAY

NEED TO BE SED IF ISOLATOR IS NOT SED WITH POWER DISTRIB TION DEVICE

The connector used for signals is Deutsch ASX 6 way. AWG 24 (0.2mm²) is maximum usable wire

size. Crimping the contacts requires a special tool (M22520/2 01 with K1586 positioner) for

motorsport or military size 24 terminals. If you're not equipped with such a tool or suitable gauge wire,

please contact Ecumaster dealer sales department for a premade wiring loom.

4 Operation principles

The device operation can be best explained with state machine diagram:

•Relay: state of main relay, on or off

•Output: state of ECU/PMU output: run or kill

•Hold: state of internal power supply hold. When hold is off, power save switch will turn device

off immediately.

When the device is turned on, it goes to ON state. From that it can be turned off by the power save

switch or emergency switch. Each switch will start an entry procedure which the duration of can be set

by using light client software. It is used to give time for other CAN devices to shut down properly and

for the engine to shut down.

If the device detects that engine is still running it will stay in LOAD D MP state until the engine shuts

down.

When the device is in OFF state it can be reset only by toggling the power save switch.

The state of the device is indicated with an LED light in following way:

Device states:

•green relay ON

•red relay OFF

•toggling green POWER SAVE ENTRY PROC device countdown to Power Save mode

•toggling red EMERGENCY ENTRY PROC device countdown to Relay OFF mode

Additional warnings (only in ON state):

•yellow overheat (temperature > 80°C)

•short green flash undervoltage (VBat < Battery Saver Threshold Voltage)

•short red flash overvoltage (VBat > 19V)

•short blue flash CAN bus error (also when nothing is connected to CAN bus)

Additional warnings will add up in a sequence. For example:

Short red flash, then short blue flash, then yellow means overvoltage with overheat and CAN error.

4.1 Under Volta e Lock Out

The device has built in Under Voltage Lock Out function to protect itself from invalid operation when

the supply voltage is too low.

If the battery voltage drops below 6V the device will instantly turn off power to the car.

4.2 Battery saver

Battery saver function is used to protect car battery from deep discharge.

If the battery voltage is below the threshold voltage for a defined time the isolator will disconnect the

battery by going to EMERGENCY ENTRY PROC.

Keep in mind that the total time from voltage dropping below threshold to isolator cutting of power is

equal to Battery saver timeout + Emergency kill timeout.

5 Confi uration

The Battery Isolator is configured through the Ecumaster Light Client software. The device CAN BUS

must be accessed with a USBtoCAN interface or other compatible devices. For general Light Client

usage refer to Light Client software manual.

5.1 Properties

•CAN ID CAN BUS first message ID for the device output data stream

•Timeouts delay times for transition between device states

◦Power save timeout from POWER SAVE ENTRY PROC to POWER SAVE (complete

device turn off)

◦Emerg. kill timeout from EMERGENCY ENTRY PROC to OFF

•PM /EC output configuration of output used to shut down the engine

◦Run mode state of output during normal device operation (12v (max 3Amp), 0V (max 3

amp) or High Z)

◦Kill mode state of output when engine shutdown is desired ("kill: on" on state machine

diagram)

•Current limit – current value, if exceeded that will turn device to go to OFF state immediately

•Emerg. kill ID CAN ID for receiving emergency shutdown information from CAN BUS

•Battery saver - function to disconnect battery if voltage drops below threshold for long time

◦Enable enables battery saver functionality

◦Threshold voltage - voltage below which Timeout starts counting. If voltage rise above

threshold voltage during timeout, the timeout timer resets.

◦Timeout - time which needs to pass with voltage below Threshold voltage to activate

function.

CAN Bus shutdown function is activated when the message with first data byte is different from 0x00

is received. Other message bytes are irrelevant. If the first byte is equal to 0x00 the function is not

activated. For reliable operation only one device on CAN-B S can transmit with a particular ID.

To be able to be shut down by different devices, Battery Isolator will listen to four message IDs

starting from Emerg. kill ID.

For example, Emerg. kill ID is 0x0FC. The device will shut down when receiving messages with IDs

0x0FC, 0x0FD, 0x0FE, 0x0FF with first data byte will be set to anything from 0x01 to 0xFF.

•General options

◦Dis. emerg. switch disables emergency switch input

◦Dis. CAN LED warn. disables blue warning flash when CAN BUS is not connected

◦Ena. CAN terminator enables CAN BUS internal 120Ohm terminator available from

hardware RevD

5.2 Channels

•Voltage in voltage on battery side

•Voltage out voltage on car side

•Current load current flowing through the relay. Positive values: battery to car, negative: car to

battery (charging). Current load is not intended for precise current measurements but for general

information on device load and charging. Have in mind the measurement accuracy when

interpreting results.

•Temperature – device internal temperature

•Flags:

FLAG SET condition RESET condition

Overvoltage Battery voltage > 19V Battery voltage <= 19V

Undervoltage Battery voltage < battery saver threshold

voltage

Battery voltage >= battery saver

threshold voltage

Overheat Temperature > 80°C Temperature <= 80°C

Overheat kill Temperature > 90°C Device reset

Overcurrent kill Current > current limit Device reset

Emergency kill Emergency switch activated Device reset

Powersave kill Power save switch activated Power save switch deactivated

CAN kill CAN kill message received Device reset

UVLO kill Battery voltage < 6V Device reset

Load dump occurred Alternator is still charging when isolator

disconnects

Device reset

Battery saver kill Battery saver function turned off power Device reset

Overvoltage kill Voltage exceeded device specification for

too long

Device reset

•Device state refer to Operation principles

•Kill countdown time remaining to go from POWER SAVE ENTRY PROC to POWER SAVE

or from EMERGENCY ENTRY PROC to OFF

•Heartbeat counter indicating that device is running, incremented with every CAN message

sent

6 Troubleshootin

Finding the reason why the isolator disconnected the battery is mainly based on reading device flags.

Flags can be read via Light Client software. Possible options are listed below:

•Device turned off and there are no flags active.

◦Power save switch was activated.

◦Supply voltage dropped below 6V.

•overvoltage warn warning only, doesn't turn off the device.

•undervoltage warn warning only, doesn't turn off the device.

•overheat warn warning only, doesn't turn off the device.

•overheat kill internal device temperature exceeded 95°C

◦Reduce device current load.

◦Install device in colder environment.

◦Install device on chassis with thermal conductive material to spread the heat.

•overcurrent kill current limit was exceeded.

◦check car wiring and devices for shorts or malfunctions

◦increase Current limit

•emergency kill emergency switch was activated

◦If this wasn't intended, check emergency switch circuit for continuity.

•powersave kill flag is active when power save switch is active. It leads to device turning off

completely.

•CAN kill device was turned off with CAN bus message

◦it this wasn't intended, check if there aren't any devices sending messages on ID set up in

Emerg. kill ID field, or on the following 3 id's.

•VLO kill supply voltage dropped below specification.

◦Check if battery is sufficiently charged.

◦Check if supply wires are properly fastened.

•load dump occurred current was flowing to the battery, while device was disconnecting the

battery.

◦PMU/ECU output doesn't shut down engine properly.

◦Timeouts are too short. Engine should stop before disconnecting battery.

◦Supply voltage exceeded the device specification.

•battery saver kill battery saver function was activated.

◦Check battery saver setup.

◦Check if alternator is charging the battery when the engine is running.

•overvoltage kill supply voltage exceeded the device specification.

◦Check the alternator for proper operation.

◦Check if battery is properly connected to chassis and the isolator.

7 Revision history

Revision Date Changes

0.2 14.06.2019 Initial revision

0.3 17.07.2019 Battery saver and UVLO added

0.4 11.10.2019 Switch type and kill output hints added

0.5 28.11.2019 Drawing for lug and Radlok versions

0.6 12.12.2019 Text revised

0.7 16.06.2020 Troubleshooting, firmware 3.0

Table of contents