Edbro PTO 01-01 User manual

SETTING THE INDUSTRY STANDARD

Edbro plc

Nelson Street, Bolton BL3 2JJ, UK

Tel: +44 (0) 120 4528888 Fax: +44 (0) 120 4531957

Spares fax: +44 (0) 120 4393561

Web: www.edbro.com

Technical specificaons are subject to change without noce.

Rev1, July 2011

General Installaon Guide for PTO’s PTO 01-01

1 - ATTENTION: SAFETY INFORMATION

- The PTOs should be mounted by qualied personnel.

- Use suitable tools and measurement instruments.

- Use personal protection and precautions set out by current regulation on safety in the workplace.

- Ensure the system or the PTO cannot involuntarily be started up.

- Do not assemble the PTO or parts of the PTO or conduct maintenance work when the engine is on.

- Ensure all the components have been assembled properly and the level of oil in the gear box has been topped up before starting up the

vehicle: Incorrect assembly of the PTO may cause the PTO and/or the gearbox to break and damage other parts of the vehicle.

- The splined shaft (male or female) protruding from the PTO rotates with no protection when the pump has not been assembled.

Avoid any contact between the shaft and any object and, more importantly, protect the working area to prevent contact with body parts or

clothing.

- Install the pump or the cardan shaft only when the engine is o and the PTO has been disconnected.

- The gearbox or the PTO may attain high very temperatures after prolonged use of the vehicle or the PTO. It is therefore necessary to take

all the necessary precaution measure to prevent burns. Wait for the mechanical parts to cool down to temperatures appropriate for skin contact

- Some PTOs are considerably heavy and to assemble and disassemble them it is necessary to use adequate lifting or resting sys

prevent crushing hazards, it may be necessary for two people to carry out the operation.

- Any waste oil that has not been used should be processed according to the directives included in the current regulation on the disposal of special waste.

MOST COMMON PTO SHAFT

OUTLET VERSION

Male shaft 6x21x25 (ISO14)

Rear outlet

Male shaft 6x21x25 (ISO14)

Front outlet

VERSION 13 VERSION 14

VERSION 15

Male shaft 8x32x36 (ISO14) Rear outlet

This version always requires

the ange (114...)

Female hub 8x32x36 (ISO14)

Rear outlet

VERSION 17

ASSEMBLY OF THE RIGHT SIDE

ASSEMBLY OF THE LEFT SIDE

ASSEMBLY OF THE REAR

ASSEMBLY OF THE UPPER PART

ASSEMBLY OF THE LOWER PART

2 - INDICATIVE ASSEMBLY POSITIONS OF THE PTOS

OUTLET REAR SHAFT

CLOCKWISE

ANTICLOCKWISE

CLOCKWISE rotation

Application - LEFT pump

ANTICLOCKWISE rotation

Application - RIGHT pump

RULES APPLYING TO THE DIRECTION

OF ROTATION OF THE PTO

OUTPUT SHAFT

OUTLET FRONT SHAFT

SETTING THE INDUSTRY STANDARD

Edbro plc

Nelson Street, Bolton BL3 2JJ, UK

Tel: +44 (0) 120 4528888 Fax: +44 (0) 120 4531957

Spares fax: +44 (0) 120 4393561

Web: www.edbro.com

Technical specificaons are subject to change without noce.

Rev1, July 2011

General Installaon Guide for PTO’s PTO 01-01

3 - GENERAL INFORMATION TO MOUNT POWER TAKE-OFFS

- Carefully follow these general assembly instructions, both as far as the safety precautions and the assembly stages of the PTOs are concerned.

- The general indications do not replace specic instructions contained in the PTOs, in the assembly kit or in the various assembly accessories

(adapters, auxiliary shafts, etc).

- It is necessary to also follow any instructions related to the vehicle gearbox.

- Install the PTO with the vehicle placed on a at surface, so that oil levels in the gearbox can be checked correctly.

- Only use the components contained in the PTO packaging and related accessories (assembly kit, auxiliary shafts, adapters).

- Only use gaskets supplied.

- Do not use sealing paste, unless explicitly indicated in the specic instructions.

- It is advisable to use a medium-strength threadlocker to tighten the studs and screws.

- Before assembling the PTO, check that the vehicles clutch and transmission work correctly and that the gearbox does no produce any

anomalous noises or issues in selecting gears.

TIGHTENING TORQUE (see note)

Thread diameter - Screw (mm) M8 M10 M12 UNC 3/8 UNC 7/16

Screws and nuts torque (Nm) 25 50 80 25 60

Studs torque (Nm) 6 10 18 10 20

For some aluminium gearboxes the tightening torque needs to be reduced

by 30%.

Note on the tightening torque: the tightening torques reported are only

means as a guide and do not replace the indications given by the vehicle’s

manufacturer of the gearbox manufacturer.

TABLE 3

4.5 - If the PTO needs to be mounted

with studs, insert them (with the

short thread side) in the threaded

holes of the gearbox, using a

medium-strength threadlocker (LOC-

TITE 243, LOXEAL 55-03 or similar).

Tighten the studs using a torque like

the one indicated in TABLE 3 Chap.3 .

If the gearbox has feed-through

threaded holes, the threadlocker

should also have a sealing action

and it is necessary to check that the

studs do not interfere with the gea-

ring of with parts inside the gearbox.

4.1 - Unscrew the drain plug

and remove the oil from the gear-

box. Screw the drain plug back

with the tightening torque indicated

in the gearbox’s operating manual.

4.2 - Identify the suitable gearbox

opening to mount the PTO and remo-

ve the cover with the related gasket.

4 - INSTALLATION OF SIDE MOUNT PTOS

4.3 - Check that the gearing is compa-

tible with the PTO’s gearing in terms of

position, inclination of the tooth and te-

ethsize.Thisneedstobecarriedoutasan

additional check that the right PTO has

been selected for the specied gearbox.

4.4 - Clean the surface of the ope-

ning, make sure no foreign mat-

ter is introduced in the gearbox.

4.6 - Position the sealing gasket.

4.7 - Install the PTO and tighten the nuts

with lower torque compared to the

nd xing torque.

4.9 - Once the optimal clearance

has been dened

tighten the nuts or the screws of the

PTO fully home with the tightening

torque shown in TABLE 3 Chap.3 .

4.10 - Top up the oil in the gearbox

bearing in mind that usually a side

mount PTO uses up approximately

0.5–0.8litresofoil. Installthecontrol

system. Start up the vehicle and en-

gage the PTO. Conduct the checks as

illustrated in the paragraphs below.

(A)

4.8 - Check, through the inspection hole

(indicated by the arrow) the clearan-

ce between the gearings. The clearan-

ce should be between 0.15 and 0.3 mm

(A) . The clearance is controlled manually

and therefore it cannot be precise. This is

why it is necessary to proceed by attem-

pts until the optimal clearance is achieved.

SETTING THE INDUSTRY STANDARD

Edbro plc

Nelson Street, Bolton BL3 2JJ, UK

Tel: +44 (0) 120 4528888 Fax: +44 (0) 120 4531957

Spares fax: +44 (0) 120 4393561

Web: www.edbro.com

Technical specificaons are subject to change without noce.

Rev1, July 2011

General Installaon Guide for PTO’s PTO 01-01

5 - INSTALLATION OF REAR MOUNT PTOS

It is necessary to check and follow the specic instructions contained in the adapters and the auxiliary shafts.

tions contained in the adapters and the auxiliary shafts. The indications below are meant as a guide.

5.1 - Empty the oil of the gearbox (for some gearboxes there is no need to empty the oil as the level does not reach the rear appertue (check the gear box’s operating manual)

5.2 - Identify the rear opening and remove its cover and gasket. The gasket removed should not be used to assemble the PTO.

5.3 - Clean the surface of the apertue, make sure no foreign matter is introduced in the gearbox

5.4 - If necessary, install the auxiliary shaft and/or adapters following the specic instructions with special care for cases where it is necessary to adjust the bearings with

cone-shaped rollers.

5.5 - If the PTO needs to be assembled with studs, insert them (fron the short thread side) in the threaded holes using a medium-strength threadlocker

(LOCTITE 243, LOXEAL 55-03 or similar). Tighten the studs using a torque as indicated in TABLE 3 .

If the gearbox has feed-through threaded holes, the threadlocker should also have a sealing action.

5.6 - Install the PTO on the gearbox and tighten the nuts or screws with the tightening torque indicated in the table.

5.7 - Top up the oil in the gearbox bearing in mind the oil required by the PTO.

5.8 - Install the tting and the air coupling pipe.

For rear PTO with 2 wheel it is recommended, to optimise the lubrication of internal parts, to suit the assembly positions indicated.

PTO Vertical ASSEMBLY

-Low outlet

PTO Horizontal

ASSEMBLY

PTO Vertical ASSEMBLY

-High outlet

6 - PREPARATION OF REAR PTOS

Some PTOs feature an engaging coupling

separated from the PTO and which changes

according to the gearboxes where

it needs to be installed.

6.1 - Use the circlip pliers to remove

the circlip from the seat of the central pin.

Attention: DO NOT EXPAND THE CIR-

CLIP MORE THAN IT NEEDS TO BE

TO AVOID PERMANENT WARPING.

6.2 - Insert the coupling in the seat of the

PTO

6.3 - Use the pliers to reposition

the circlip in the seat of the pin,

checking that this is secure.

Attention: DO NOT EXPAND THE CIR-

CLIP MORE THAN IT NEEDS TO BE

TO AVOID PERMANENT WARPING

ATTENTION: incorrect positioning of the cir-

clip or warping of the circlip during assem-

bly may cause the PTO to fail to disengage.

6.4 - Proceed to install the PTO, as il-

lustrated in the previous paragraph.

SETTING THE INDUSTRY STANDARD

Edbro plc

Nelson Street, Bolton BL3 2JJ, UK

Tel: +44 (0) 120 4528888 Fax: +44 (0) 120 4531957

Spares fax: +44 (0) 120 4393561

Web: www.edbro.com

Technical specificaons are subject to change without noce.

Rev1, July 2011

General Installaon Guide for PTO’s PTO 01-01

7 - CHECKS

7.1 - Checking the coupling

Connect and disconnectthePTOafew times (follow the paragraph HOW TO USE THE PTO) to check the coupling system is working properly

Any anomalous noise produced during couplingis only dueto thefact that the PTO’s gearings are not completely still and therefore to the fact that the vechile’s

clutch isnot workingproperly. Eitherthe clutchpedal hasnot beenfully pressedor onehas notwaited thetime necessaryfor thegearbox’s gearings to stop.

7.2 - Checking noise levels for lateral PTOs

- If the PTO does not produce anomalous noises or noises that are not that dierent from those of the clutch, this means that the assembly and

the teeth clearance are correct;

- If the PTO produces a screeching noise (whistle) this means that the PTO has been assembled with insucient clearance between the teeth.

In this case it is necessary to disassemble the PTO and add a gasket between the surface of the PTO and that of the gear box;

- If the PTO produces a beating, this means that the PTO has been assembled with excessive clearance between the teeth. In this case it is

necessary to disassemble the PTO and remove a gasket or use a thinner gasket.

For the purposes of the durability of the PTO it is generally preferable to have a slightly higher clearance between the teeth rather than a low one.

7.3 - Leak check

After it has been operating for a few minutes, stop the vehicle and check there are no oil leaks from the surface connecting the gearbox to the

PTO or from other parts of the PTO.

7.4 - Clamping check

After a few minutes of operation, check the that the threaded parts have been tightened.

Checks related to noise levels, leaks and clamping should also be conducted when the vehicle is hot.

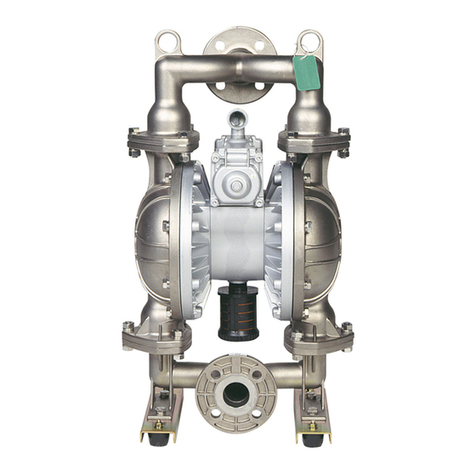

8 - PTO FOR DIRECT ASSEMBLY ON THE PUMP

shown in TABLE 3

2 - Move the pump away from

the PTO by 10mm.

3 - Screw the nuts a few mm. 4 - Push the pump against the

PTO and tighten the nuts fully

home. The tightening torque

1 - Install the pump on the PTO

with the sealing gasket supplied

with the assembly kit

To prevents splines from wear please grease pump shafts and / or couplings.

9 - HOW TO USE THE PTO

The procedure applies to PTOs installed on NON-automatic gearboxes.

For PTOs installed on automatic gearboxes, please refer to the related instructions.

PTO engagement procedure must be always carried with vehicle stationary and parking brake applied.

ATTENTION:

incorrect connection or disconnection causes premature damaging to the internal organs of the PTO.

Therefore CAREFULLY follow the indicated instructions.

9.1 CONNECTING THE PTO

-Press the clutch pedal and keep it pressed for a few seconds to stop the gears from turning.

- Activate the PTO control.

- The PTO engages (the actual coupling is conrmed when the related PTO CONNECTION indicator, if any, turns on).

- SLOWLY release the clutch pedal.

9.2 DISCONNECTING THE PTO

- Press the clutch pedal and keep it pressed for a few seconds.

- Bring the PTO control back to the o position.

- The PTO disengages (the actual coupling is conrmed when the related PTO CONNECTION indicator, if any, turns o).

- Release the clutch pedal.

WARNING: when the vehicle is on the move the PTO must be always OFF.

MOUNTING INSTRUCTIONS FOR ISO PUMPS ON ISO PTO’S WITHOUT BEARING

1 - Mount loose gear and circlip

on the pump’s shaft 2 - After mounting PTO on the gearbox, screw the studs

(pos.A) onto the PTO. Place the intermediate gasket and

then fit the PTO assembly (fig 1) onto the PTO. Fix the pump

applying the tightening torque indicated in TABLE 3.

Popular Water Pump manuals by other brands

GE

GE Monogram ZPK1 installation instructions

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 81 1/2B2-B Installation, operation, and maintenance manual with parts list

Daewoo

Daewoo DDP17000 user manual

HEISSNER

HEISSNER HFP7000-00 Instructions for use

Intex

Intex Quick-Fill Operation instructions

T.I.P.

T.I.P. GP 4500 INOX operating instructions