Edge Technologies Patriot Series User manual

Patriot 338 & 551

OPERATIONS MANUAL

PATRIOT SERIES 338&551

HYDRODYNAMIC AUTOMATIC BAR FEEDER

PATRIOT

MANUAL FOR USE AND MAINTENANCE

REV. 5 DATE:2015/10/01 COD:BPA102032

S/H

Table of contents Patriot Series

I

1. General Information

Section Page

1.1 Contents of the Manual -------------------------------------------------------------------------------------- 1

1.2 Machine Data Plate ------------------------------------------------------------------------------------------- 2

1.3 Technical Support --------------------------------------------------------------------------------------------- 2

2. Technical Information

2.1 Description of the Machine --------------------------------------------------------------------------------- 3

2.2 Machine Footprint --------------------------------------------------------------------------------------------- 4

2.3 Capacities and Requirements ----------------------------------------------------------------------------- 4

2.4 Compressed Air Supply ------------------------------------------------------------------------------------- 5

2.5 Electrical Supply ---------------------------------------------------------------------------------------------- 6

2.6 Guide Channel Specifications ----------------------------------------------------------------------------- 6

2.7.1 Bar Stock Straightness Requirements ---------------------------------------------------------------- 7

2.7.2 Procedure for Checking Bar Stock Straightness -------------------------------------------------- 7

2.7.3 Bar Stock Preparation ------------------------------------------------------------------------------------ 8

2.7.4 RPM Limiting Factors ------------------------------------------------------------------------------------- 8

3. Transportation and Handling

3.1 Packaging of the Bar Feeder ------------------------------------------------------------------------------ 9

3.2 Transporting the Bar Feeder ------------------------------------------------------------------------------- 9

3.3 Installation Area --------------------------------------------------------------------------------------------- 10

4. Installation

4.1 Lathe Preparation ------------------------------------------------------------------------------------------- 11

4.2 Distance From Lathe -------------------------------------------------------------------------------------- 11

4.3 Height Adjustment ------------------------------------------------------------------------------------------ 12

Table of contents Patriot Series

II

4.4 Leveling -------------------------------------------------------------------------------------------------------- 12

4.5 Alignment ------------------------------------------------------------------------------------------------------ 13

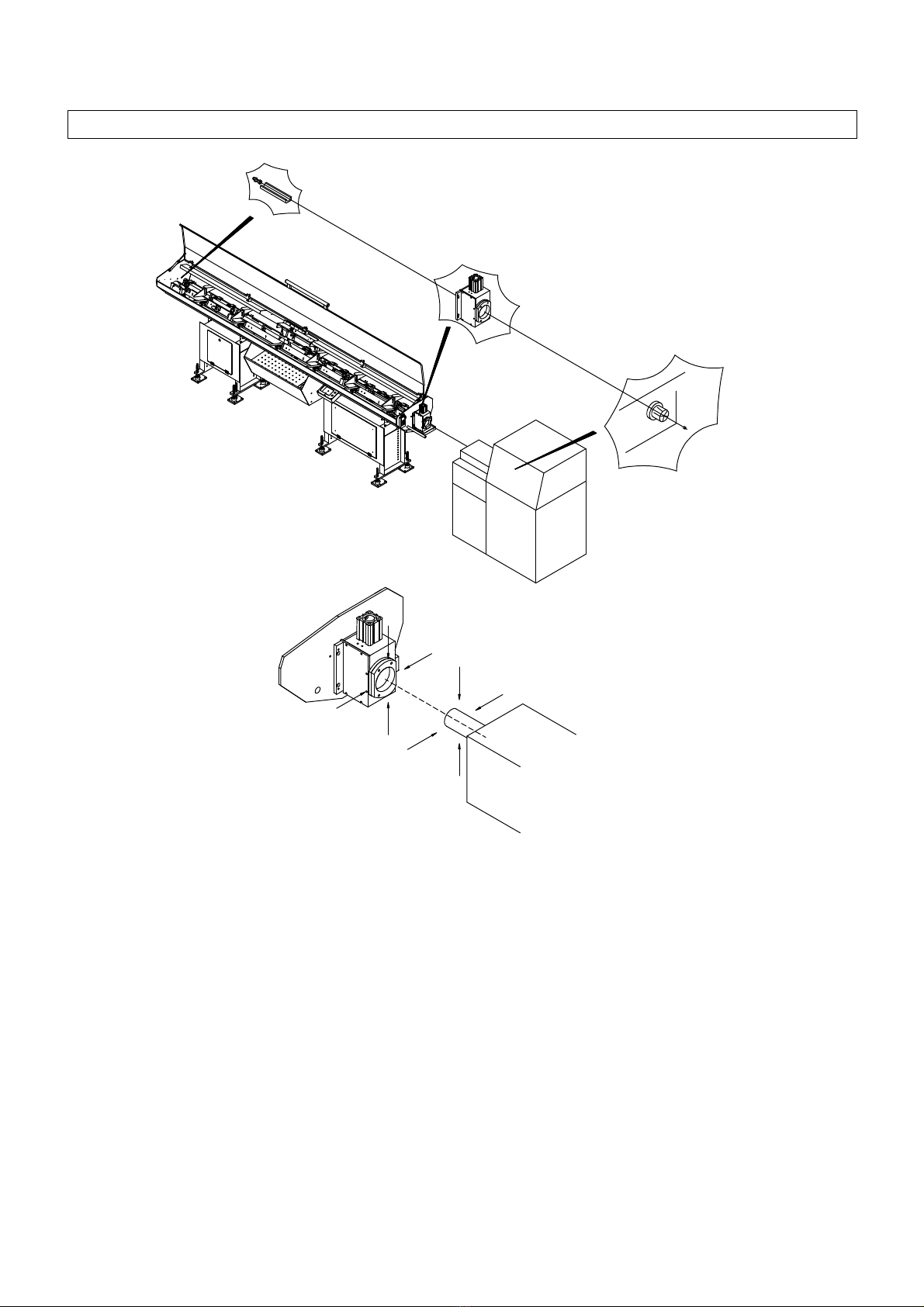

4.5.1 Preparing the Bar Feeder ------------------------------------------------------------------------------- 13

4.5.2 Aligning the Center Lines ------------------------------------------------------------------------------- 14

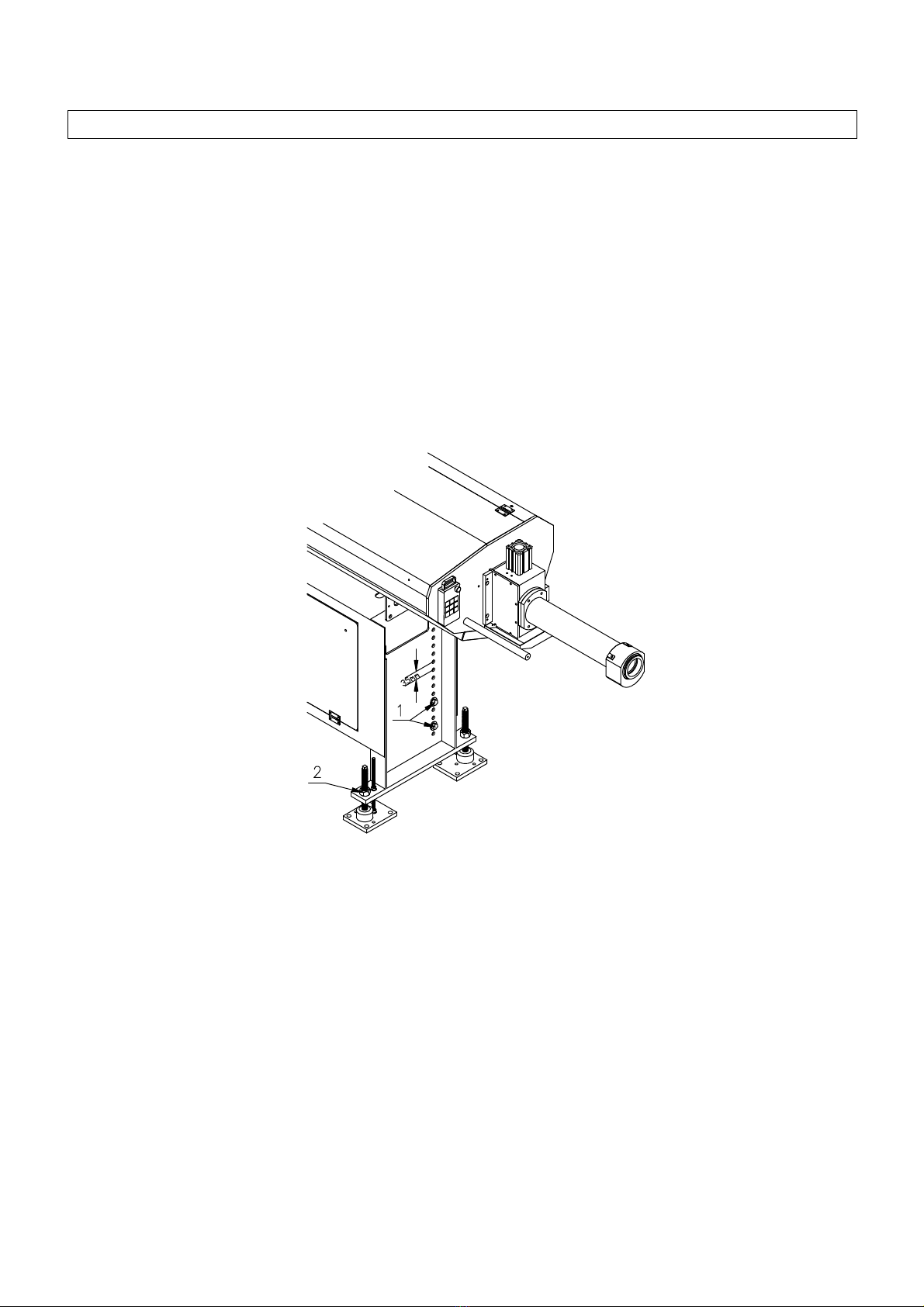

4.5.3 Anchoring the Bar Feeder ------------------------------------------------------------------------------ 15

4.6 Installation of Accessories -- ----------------------------------------------------------------------------- 16

4.6.1 Moveable Anti-Vibration Device (MAVD) ----------------------------------------------------------- 16

4.6.2 Fixed Front Nose ----------------------------------------------------------------------------------------- 17

4.6.3 Telescoping Front Nose --------------------------------------------------------------------------------- 17

4.6.4 Synchronization Device --------------------------------------------------------------------------------- 18

4.7 Oil for Guide Channel -------------------------------------------------------------------------------------- 19

5. Adjustments and Settings

5.1 Structure of the Bar Feeder ------------------------------------------------------------------------------- 20

5.2 Adjustment of the Loading Device ---------------------------------------------------------------------- 21

5.3 Chain Adjustment and Lubrication ---------------------------------------------------------------------- 22

5.4 Moveable Anti-Vibration Device Adjustment --------------------------------------------------------- 23

6. Control Operations and Descriptions

6.1 Sequence to Manually Change Bars ------------------------------------------------------------------- 24

6.2 Start Up -------------------------------------------------------------------------------------------------------- 25

6.3 Clearing an Alarm ------------------------------------------------------------------------------------------- 25

6.4 Resetting the Zero Position ------------------------------------------------------------------------------- 26

6.5 Description of the Manual Screen ----------------------------------------------------------------------- 27

6.6 Description of the Automatic Screen ------------------------------------------------------------------- 28

6.7 Loading With the Bar On and Bar Off Buttons ------------------------------------------------------- 29

Table of contents Patriot Series

III

6.8 Entering a New Program ---------------------------------------------------------------------------------- 30

6.9 Selecting and Editing an Existing Program ----------------------------------------------------------- 33

7. General Maintenance

7.1 Periodic Maintenance -------------------------------------------------------------------------------------- 34

7.2 Rotating Tip and Collet ------------------------------------------------------------------------------------ 34

7.3 Air Filter/Regulator/Lubrication Unit -------------------------------------------------------------------- 34

Parameters

8. User Parameters ---------------------------------------------------------------------------------------------- 35

9. Factory Parameters ------------------------------------------------------------------------------------------ 47

10. Service Technician Parameters ------------------------------------------------------------------------- 58

Alarms

11. Error Alarms -------------------------------------------------------------------------------------------------- 62

Electrical Schematic

12. Machine Electrical Drawings ----------------------------------------------------------------------------------

Parts

13. Parts List -----------------------------------------------------------------------------------------------------------

1. General Information Patriot Series

1

1. General Information

Please read and understand the Manual before operating the bar feeder

1.1 Contents of the Manual

The bar feeder manufacturer has provided this manual as an integral part of the machine.

Adherence to the instructions of the manual will help prevent injury to the operator and

damage to the machine as well as helping to realize the maximum potential of the bar

feeder and machine tool. Particularly important points of information are preceded by

the following symbols and text:

Warning Indicates a potential danger to life or risk of personal injury. Exercise

extreme caution.

Caution Indicates a possible hazardous condition. Take precautions according to the

instructions following these warnings to help prevent injury to personnel or damage to the

equipment.

Important Information precedes special or technical information. Additional

information can be located by using the table of contents of this manual.

Skilled Denotes operations that must be carried out by qualified and skilled personnel.

Other operations may be performed by qualified personnel or trained operators.

1. General Information Patriot Series

2

1.2 Machine Data Plate

A. Name of manufacturer

B. Model(Type)

C. Serial Number

D. Manufacture Date

E. Weight of Machine

F. Pneumatic Pressure

G. Rated Voltage

H. Control Voltage

I. Full Load Current

J. Power

K. Short Circuit Rating

L. Wiring Drawing Number

Important information When inquiring about or ordering parts please have the

machine model (type) and serial number on hand. Refer to the machine data plate

for this information.

1.3 Technical Support

For technical support please contact the Edge Technologies Service Department

Important information When calling for technical support please have the

machine model (type) and serial number on hand. Refer to the machine data plate

for this information.

2. Technical Information Patriot Series

3

2. Technical Information

2.1 Description of the Machine

The Patriot is a PLC controlled automatic bar feeder designed for both Swiss style and fixed

headstock lathes. The bar feeder is constructed to handle a wide variety of material profiles

from round to hex and square stocks and can be adapted to feed materials with a more unique

shape.

The bar feeder uses hydrodynamic design to dampen vibrations caused by bar stock rotation.

The bar stock spins within a polyurethane channel which is flooded with a high viscosity

circulating oil. This creates turbulence within the channel that serves to steady the material and

control vibration. The end of the bar stock is supported by a bearing unit on the end of the bar

pusher and the work holding system of the lathe.

An anti-vibration device is located at the front of the bar feeder. Polyurethane bushings

surround the bar, leaving a few millimeters clearance between the bar and the bushings.

This void is filled with oil to help further stabilize and support the stock. For Swiss style sliding

headstock lathes a moveable anti-vibration device is mounted on the rear of the lathe headstock

to provide even more support and vibration dampening.

Our touch screen control panel gives access to parameters that allow easy set up and operation.

Most job changeovers require only one or two parameter settings. While in the automatic mode

the screen displays helpful information.

2. Technical Information Patriot Series

4

A

L

CB

H

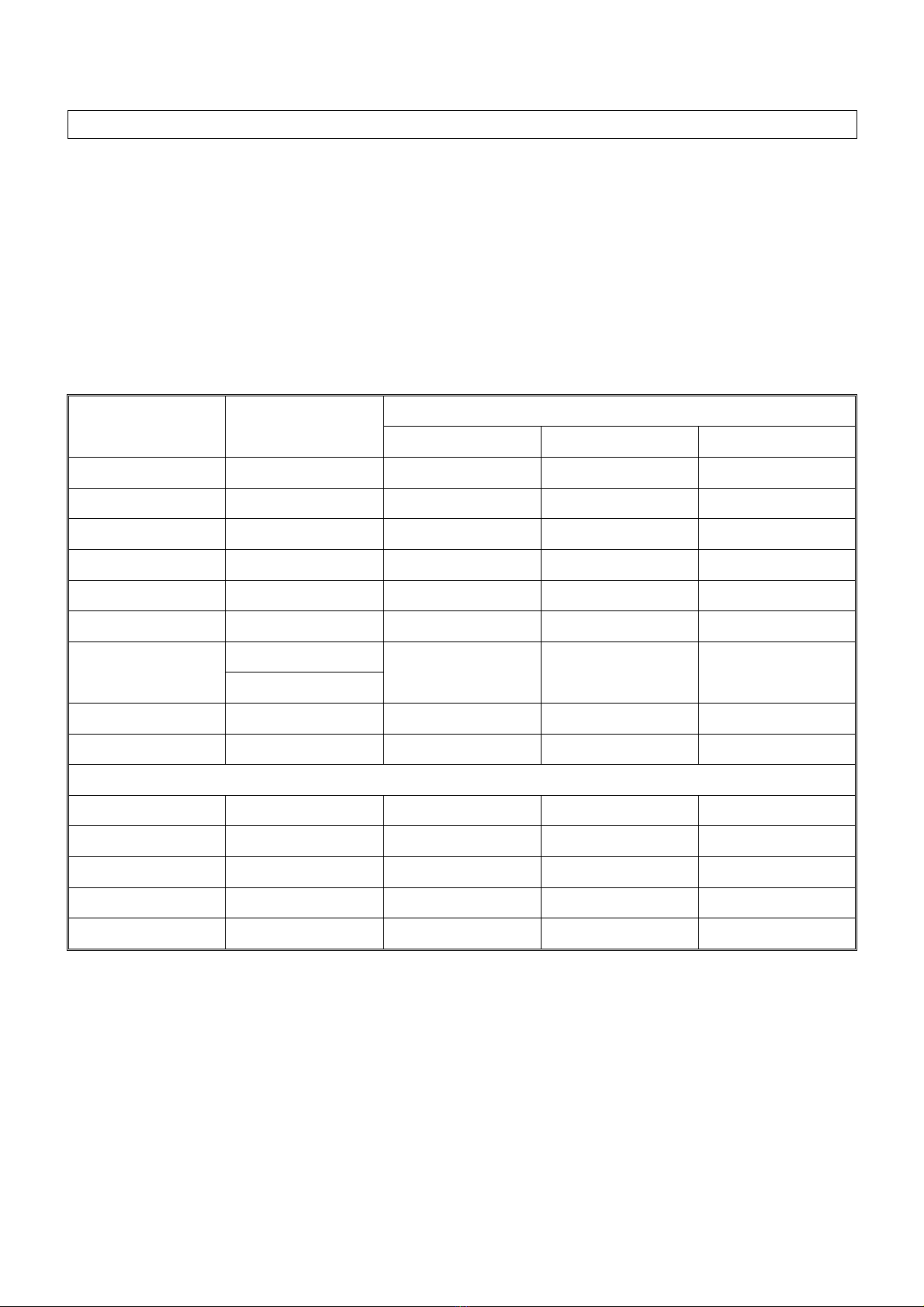

2.2 Machine Footprint

Model 25 32 37

L 3020 3680 4222

A (Max Bar Length) 2600 3260 3800

B 276 284 574

C 1309 1309 1559

H 850mm to 1300mm

Weight 850kg 900kg 950kg

2.3 Capacities and Requirements

Bar Diameter Capability 5mm (.196”) to 32mm (1.260”)

Available Channel Diameters 13, 21, 26, 28, 33, 36

Magazine Capacity (12” plane) Ø5 – 60 bars, ø32 – 9 bars

Oil Requirement 60 liters ISO CB 150

Electrical Requirement 3 phase 220VAC, 16A 50/620Hz

Air Requirement 6 Bar (85 PSI)

2. Technical Information Patriot Series

5

D

B

C

2.4 Compressed Air Supply

Air supply to the bar feeder must be supplied through a line having a minimum inside diameter

of 8mm. Pressure must be maintained at a minimum of 6 bar (85 PSI) for the bar feeder to

operate properly. An air pressure safety switch connected to the filter/regulator unit monitors air

pressure. A fault will be displayed on the bar feeder operator panel if the air pressure falls

below 6 bar. Air consumption is approximately 50L per hour.

2.4.1 Connect the air supply line to the fitting “A”. Pull the regulator control knob up and turn

the knob to set the air pressure to 6 bar (85 PSI).

2.4.2 The filter/regulator unit supplies lubricating oil to the various pneumatic system

components. The lubricator unit should be set at the factory but it may be adjusted as needed.

To adjust turn knob “C”. The proper setting supplies 1-2 drops of oil per 1000 liters of air used.

The lubricator oil level should be maintained between the high and low level marks on the

container. To fill the unit, first disconnect the air supply from fitting “A”. Remove the filler screw

“D” and fill the reservoir with one of the oils from the chart below or an equivalent.

Air Unit Lubricating Oil – ISO VG32

BP Castrol Chevron Mobil Shell

Energol HLP 32

Hyspin VG32 Regal R&O 32 DTE 24 or Light

Tellus 32

2. Technical Information Patriot Series

6

2.5 Electrical Supply

The Patriot draws electrical voltage from the lathe through the interface cable. Standard power

input is 220VAC 3 Phase, 16 Amps. The transformer in the bar feeder cabinet has multiple

input voltage taps to accommodate most lathe configurations without using an additional

external transformer.

2.6 Guide Channel Specifications

Guide Channel

Diameter Bar Pusher

Diameter Permissible Diameter of Bar Stock

Minimum ¹ Maximum Max. Special ²

ø13mm 12.5mm 5mm (.196”) 10mm (.393”) 12mm (.472”)

ø17mm 16.5mm 5mm (.196”) 15mm (.591”) 16mm (.629”)

ø21mm 20.5mm 8mm (.315”) 16mm (.630”) 20mm (.787”)

ø26mm 25.5mm 8mm (.315”) 21mm (.827”) 25mm (.984”)

ø28mm 27.5mm 10mm (.393”) 25.4mm (1.00”) 27mm (1.062”)

ø33mm 32.5mm 10mm (.393”) 28.5mm (1.125”)

32mm (1.259”)

ø36mm 34mm 12.7mm (.500”) 32mm (1.260”) 35mm (1.377”)

34.5mm

ø36mm 35.5mm 12.7mm (.500”) 32mm (1.260”) 35mm (1.377”)

ø38mm 37.0mm 15.8mm (.625”) 33.3mm (1.312”)

37mm (1.456”)

Channel sizes below can be used ONLY with the Patriot 551

ø39mm 38.0mm 15.8mm (.625”) 33.3mm (1.312”)

38mm (1.500”)

ø43mm 42.5mm 19mm (.750”) 38mm (1.500”) 42mm (1.653”)

ø46mm 45.5mm 22.2mm(.875”) 41.2mm (1.625”)

44.5mm (1.750”)

ø52mm 51.0mm 25.4mm (1.00”) 44.5mm (1.750”)

50.5mm (2.00”)

ø56mm 55.0mm 25.4mm (1.00”) 50.8mm (2.00”) 50.5mm (2.145”)³

¹ Although the guide channel is capable of running the minimum diameter listed, the increasing

difference between the stock OD and channel ID allows greater potential for vibration. Spindle RPM

may need to be reduced accordingly.

² Bar stock larger than the standard maximum diameter up to the collet diameter may be used if the bar

end diameter is reduced to fit a standard collet. An ejection collet may also be used if the end of the

material is chamfered to match the angle of the ejection collet.

³ Diameter can only be run with a front ejection collet.

2. Technical Information Patriot Series

7

Important Information The outer diameter of the bar collet must be at least 0.5mm

smaller than the bar pusher outer diameter.

2.7 Bar Stock Preparation and Straightness Requirements

2.7.1 Straightness Requirements

Optimum performance of the bar feeder can only be achieved if the material to be run meets

specifications for straightness. The maximum allowable bend in a bar is 0.5mm T.I.R. in a 1

meter section (.02” T.I.R per 3 foot section). This tolerance assumes a curvature over the

length of the section and not a short kink in the bar. This tolerance is not accumulative. The

tolerance for the entire length of the bar is 1.7mm TIR.

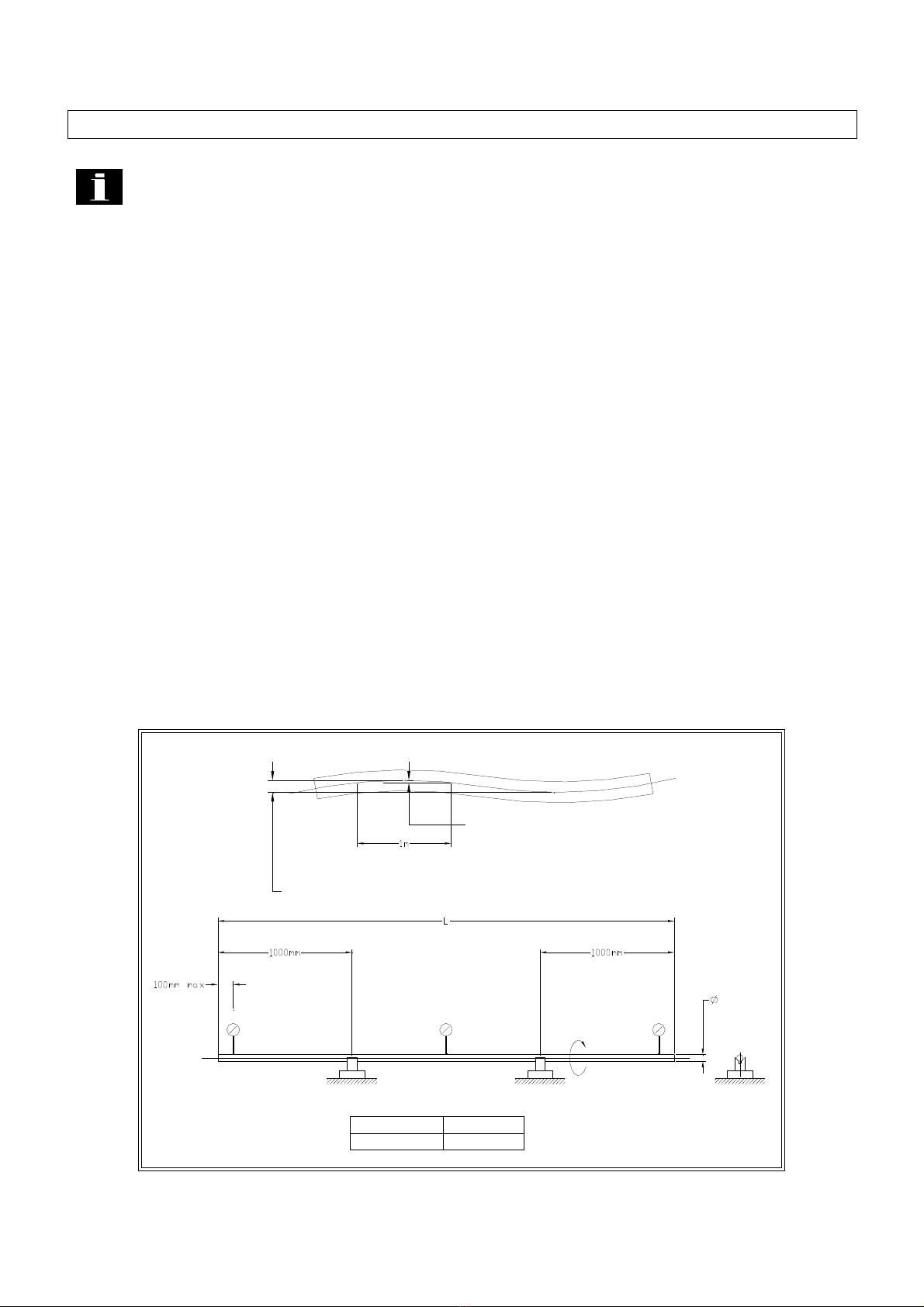

2.7.2 Procedure for checking bar straightness (Reference ASTM B249)

1. Find a suitable surface to allow the bar to rest on V-blocks without any rocking movement.

2. Rotate the bar 360°. Record the dial indicator readings at each location.

3. Calculate both the tolerance for each meter increment and also the tolerance over the entire

length of bar. Compare the recorded values to the required tolerances to determine the bar

suitability for operation with a bar feeder.

ROTATE

BAR 360?

1.7mm GEOMETRIC

TOLERANCE ZONE OVER TOTAL LENGTH

INCREMENTS

0.5mm TOLERANCE ZONE FOR

EACH METER INCREMENT

? .7MM / 3800MM

? .5MM / METER ? .070" / 12 FT

? .020" / 36"

2. Technical Information Patriot Series

8

2.7.3 Bar Stock Preparation

The bar stock must be free of burrs, chips and excessive dirt. Clean bars will extend the life of

the channel guides and bearing unit of the pusher as well as the oil pump impeller. The bar

ends should be relatively square to the length of the bar.

Chamfers on the bar ends are generally not needed except when the stock OD is close to the

bar pusher OD. In this case the wall of the pusher collet is thin and has only a small lead-in

chamfer.

Profiled material such as hex and square stock should have a generous chamfer on the bar

feeder end of the bar. This chamfer will help negate the offset of the bar centerline to that of the

bar pusher when the stock falls differently into the channel (corners up versus flats up).

Chamfers on the lathe end of the bar are not usually required, only an edge break to ensure no

burrs remain to snag on the lathe collet.

2.7.4 RPM Limiting Factors

Certain conditions may limit the lathe to less than full speed rotation of the spindle. Among

these conditions are the following:

•Bent bars (bar stock with straightness of less than .5mm/1 meter.

•Bars with an irregular profile or shaped material.

•Improperly sized guide channel in relation to the bar stock diameter.

•Incorrect sizing of guide blocks or incorrect adjustment of steady rollers.

•Lack of support in the lathe spindle for the bar pusher.

•Characteristics of the bar stock (copper, brass, plastic ect.).

•Improper viscosity lubricant in the oil tank of the bar feeder.

•Unbalanced bar stock.

•Sheared bar ends.

•Non-concentric chamfered bar end when using an ejection collet.

These factors may work alone or in combination to cause a vibration that requires a reduction in

the lathe spindle speed.

3. Transportation and Handling Patriot Series

9

A.

C.

B.

3. Transportation and Handling

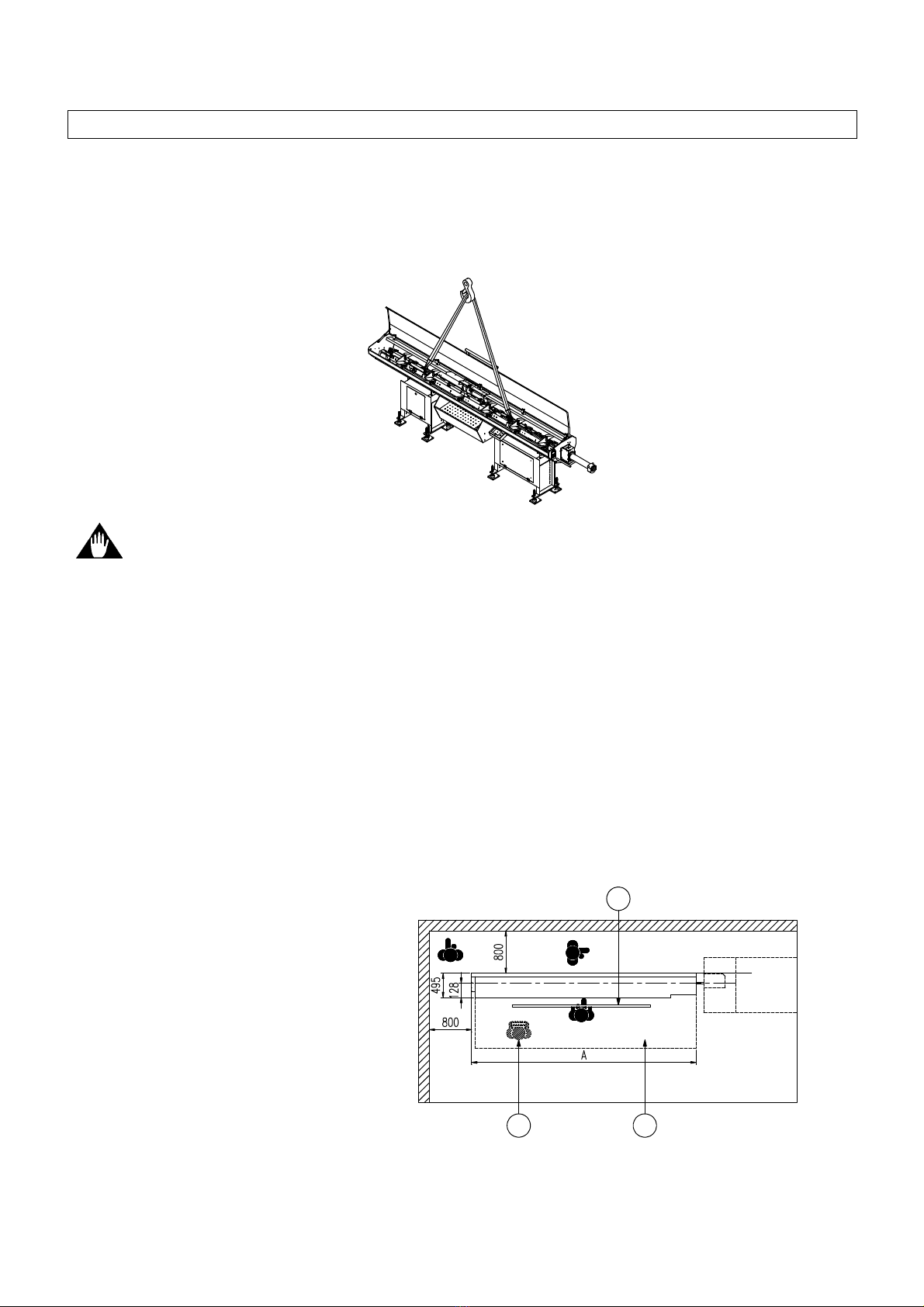

Warning The weight of the bar feeder without packaging is approximately 2100 lbs.

Verify the equipment to be used for moving the bar feeder is rated to safely lift the

weight of the bar feeder plus the packaging material. Make special note that the bar

feeder is top heavy and take proper precautions.

3.1 Packaging of the Bar Feeder

The bar feeder will arrive in one of three ways:

A: Without packaging.

B: Attached to a skid or pallet.

C: Crated in a wooden box.

3.2 Transporting the Bar Feeder

The bar feeder will usually arrive in configuration “B”, on a skid. In configurations B and

C the machine may be lifted by a fork truck having suitable capacity. The forks must be

spread as far as possible, ideally under the stands of the bar feeder. Lifting straps may

also be used to move machines in the B and C configurations.

3. Transportation and Handling Patriot Series

10

D

F

E

Machines in configuration “A” may be lifted only by the two 25mm eyebolts found under

the hood on the bar plane. These eyebolts must also be used to remove the bar feeder

from the skid.

Caution Lifting the bar feeder under the magazine with a lift truck or slings may cause

damage to the machine. Use the provided eyebolts with lifting straps or chains to

prevent damage to the bar feeder.

3.3 Installation Area

The bar feeder must be bolted to a sound, reasonably level floor using anchor bolts.

The area surrounding the machine must provide sufficient clearance the operator

access to both sides and the rear of the machine as shown in the diagram below.

Other necessities are suitable lighting and a compressed air supply. The bar feeder

is not suitable for and can not be adapted to use in an explosive surrounding.

A = 4400mm

D = Operator area

E = Material supply area

F = Remnant removal area

4. Installation Patriot Series

11

Maximum

Extension

A

B

Fixed Headstock

Sliding Headstock

4. Installation

Caution The following instructions should be carried out only by skilled, trained

personnel. Proper alignment and installation is crucial to achieve optimal performance

of the bar feeder. Improper alignment can cause poor finish quality and out of tolerance

conditions on machined parts, damage to the bar feeder channels, pusher and collet

and damage to the actuator and spindle bearings on the lathe.

4.1 Lathe Preparation

Prior to beginning the bar feeder installation the lathe must be properly leveled. It is

strongly recommended that the lathe be anchored to the floor to prevent it from shifting.

4.2 Distance From Lathe

The bar feeder must be set the proper distance from the lathe. This distance is measured from

the front of the anti-vibration device to the face of the lathe collet. In the case of a Swiss style

lathe the measurement is taken from the face of the lathe collet when the sliding headstock is in

over-travel condition nearest the guide bushing. Please refer to the diagram and chart below for

the correct dimension for bar feeder placement. The bar feeder is available in two pusher length

configurations, designated “L” for the shorter version and “LL” for the longer version.

A Dimension B Dimension L B Dimension LL Max Extension L Max Extension LL

3800 2870 2540 1120 1450

4. Installation Patriot Series

12

4.3 Height Adjustment

Determine the distance from the floor to the center of the spindle of the lathe. Compare this

dimension to the distance from the bottom of the bar feeder stand to the center of the opening of

the steady device plus 75mm. If this distance is not within 25mm ± of the lathe center height

the bar feeder stands must be adjusted by repositioning the legs on the bar feeder stands. The

spacing between the holes of the legs are 35mm. The legs can be adjusted without use of a

crane or lift truck by supporting the stand with one set of legs while moving the opposite set.

The height adjustment need not be exact at this point. The final adjustment will be made during

the alignment to the lathe.

4.4 Leveling

Place steel anchor plates and spacers under the four outside corners of the bar feeder. Thread

the leveling bolt into the stand so the ball of the tip is in the matching socket of the spacer.

Assemble the 10mm hold down rod as shown below, nut – lock washer – flat washer. Be

careful not to extend the rod past the bottom of the anchor plate. Tighten the nut at the anchor

plate. Do not tighten the nuts on the top and bottom of the stand at this time. Leave sufficient

clearance to allow for height adjustment and leveling. Place a machine level on the leveling

bracket. Level the bar feeder side to side at the front stand. Move to the rear stand and level

from side to side, then adjust for level front to rear. The front to rear level is only a coarse

adjustment at this time. Raise or lower the bar feeder to match the lathe center height while

4. Installation Patriot Series

13

maintaining the side to side level while performing this step. Once the center height is roughly

the same as that of the lathe you are ready to align the bar feeder.

4.5 Alignment

The bar feeder is aligned to the lathe spindle by use of a nylon string which is stretched between

the lathe collet/chuck and the alignment fitting at the rear plate of the bar feeder. This string

indicates the centerline of the two machines. The procedure is detailed in the following steps.

4.5.1 Prepare the bar feeder

The bar feeder should be at the proper distance from the lathe, leveled from side to side and

adjusted to the approximate center height of the lathe as detailed in steps 4.2 – 4.4.

1. Open the guide channel and remove the bar pusher and pre-feed pusher.

2. Insert the nylon string through the hole in the supplied stepped plug and insert the plug into

the lathe collet.

3. Pull the string through the lathe spindle and the bar feeder and through the hole in the

alignment fitting in the rear plate of the bar feeder. Stretch the string as tightly as possible

and secure it to prevent slippage that would loosen the string.

4. Installation Patriot Series

14

C

D

B

A

4.5.2 Aligning the center lines

The bar feeder is aligned by moving the front and rear stands so that the distance from the

string to the centerline of the lathe spindle and the centerline of the opening of the anti-vibration

device is equal on all sides to within 0.15mm (approx. .005 inch).

1. Beginning with the rear stand, adjust the elevation by using the leveling screws so the rear of

the spindle is centered over the string between the 6 and 12 o’clock positions. A piece of

magnetic stock, such as that used in flat advertising magnets, attached to the spindle face

and positioned closely to the string will allow the spindle to be rotated 180 degrees to check

the position relative to the spindle bore. Once the string is centered to the spindle, move to

the front stands and repeat the procedure. To check the centering for the front of the bar

4. Installation Patriot Series

15

feeder check the position of the string relative to the bore of the anti-vibration device. It may

be necessary to alternate between the front and rear adjustments until both are centered.

When centered, tighten the jam nuts on the leveling screws.

2. Starting with the rear stand align the bar feeder to the lathe spindle from side to by using a

pry bar to shift the feeder. Small adjustments in position may be made by striking the anchor

plate with a soft faced hammer. When the string is centered to the spindle move to the front

stand and repeat the procedure, aligning the string to the bore of the anti-vibration device.

As with the elevation adjustment it may be necessary to alternate between the front and rear

adjustments until both are centered.

Important Information The bar feeder must be properly affixed to the floor to be

able to maintain alignment to the lathe. Bar feeders not anchored to the floor are subject

to damage to bar pushers, collets, anti-vibration blocks and guide channels as well as

possible damage to the machine tool.

4.5.3 Anchoring the bar feeder

The bar feeder is secured to the floor through hold down rods attached to the four leveling

plates which are bolted to the floor with concrete anchors. Please refer to the drawing in section

4.4. The anchor plates have 4 through holes for securing the plate to the floor. Only three holes

are used per plate.

1. Drill one hole through each of the four anchor plates using a rotary percussion

hammer drill equipped with a ½ inch diameter bit capable of drilling at least 8 inches

deep, preferably capable of drilling completely through the concrete. Drilling through

the concrete will make driving the anchors below flush possible if the machine is

to be relocated.

2. Drive an anchor bolt into each hole and tighten securely. Recheck the alignment to

verify that the feeder has not shifted (a small amount of shift is normal and may be

corrected later in the procedure).

3. Drill the remaining 2 holes per plate, insert and tighten the anchor bolts as above.

4. Tighten the top nut on each hold down rod.

5. Recheck the alignment. If the feeder has shifted loosen the hold down nut and ad-

just the leveling screw as required. Once the alignment is verified tighten the middle

Other manuals for Patriot Series

1

This manual suits for next models

2

Table of contents