EDI TSG-416 User manual

EDI1020120

Revision0

December2012

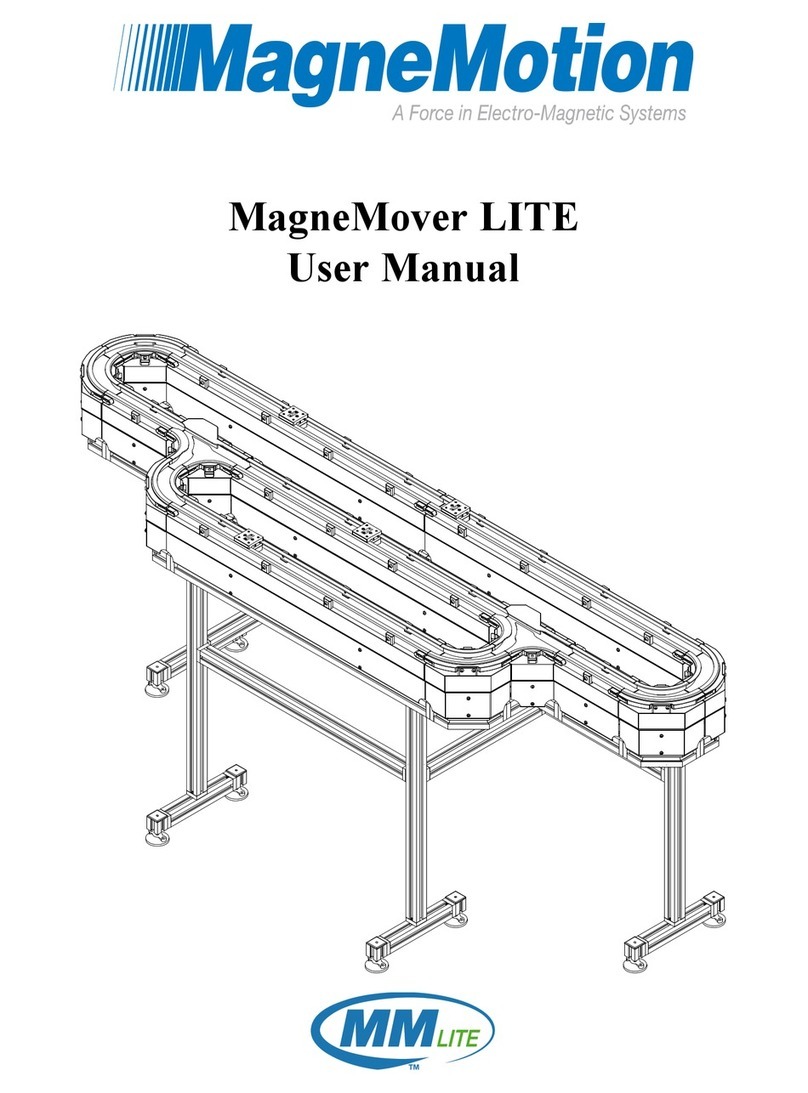

TSG‐416

1.6LITER

INDUSTRIALENGINESERVICEMANUAL

PowertrainAssemblies

&ComponentsProvided

ByFordComponentSales

EDI1020120

Revision0

December2012

Section

Index

Reproduction in any manner, in whole or in

part, is prohibited without the express

permission in writing from:

Engine Distributors Inc (EDI)

EDI policy is one of continuous improvement

and while every effort is made to ensure that this

publication is up to date and correct in all

respects, the right to change prices,

specifications and equipment at any time without

notice is reserved. Accordingly this publication is

not to be regarded as a final description of any

individual engine.

Section01GENERALINFO

Section02ENGINE

Section03IGNITION

Section04FUEL

Section05COOLING

Section06CHARGING

Section07STARTER

Section08ENG.CONTROLS

Section09METRICS

Section10DISTRIBUTORS

HEALTH & SAFETY

WARNING: THE FOLLOWING HEALTH AND SAFETY RECOMMENDATIONS SHOULD BE CAREFULLY

OBSERVED

WARNING: CARRYING OUT CERTAIN OPERATIONS AND HANDLING SOME

SUBSTANCES CAN BE DANGEROUS OR HARMFUL TO THE OPERATOR IF THE

CORRECT SAFETY PRECAUTIONS ARE NOT OBSERVED. SUCH PRECAUTIONS ARE RECOMMENDED

AT THE APPROPRIATE POINTS IN THIS BOOK. WARNING: WHILE IT IS IMPORTANT THAT THESE

RECOMMENDED SAFETY PRECAUTIONS ARE OBSERVED, CARE NEAR MACHINERY IS ALWAYS

NECESSARY, AND NO LIST CAN BE EXHAUSTIVE. ALWAYS BE CAUTIOUS TO AVIOD POTENTIAL

SAFETY RISKS.

The following recommendations are for general guidance:

1. Always wear correctly fitting protective clothing which should be laundered regularly. Loose or baggy clothing can be

extremely dangerous when working on running engines or machinery. Clothing which becomes impregnated with oil or

other substances can constitute a health hazard due to prolonged contact with the skin even through underclothing.

2. So far as practicable, work on or close to engines or machinery only when they are stopped. If this is not practicable,

remember to keep tools, test equipment and all parts of the body well away from the moving parts of the engine or

equipment—fans, drive belts and pulleys are particularly dangerous. The electric cooling fan used on some installations is

actuated automatically when the coolant reaches a specified temperature. For this reason, care should be taken to ensure

that the ignition/isolating switch is OFF when working in the vicinity of the fan as an increase in coolant temperature may

cause the fan suddenly to operate.

3. Avoid contact with exhaust pipes, exhaust manifolds and silencers when an engine is, or has recently been running;

these can be very hot and can cause severe burns.

4. Many liquids used in engines or vehicles are harmful if taken internally or splashed into the eyes. In the event of

accidentally swallowing gasoline (petrol), oil, diesel fuel, antifreeze, battery acid etc, do NOT encourage vomiting and

OBTAIN QUALIFIED MEDICAL ASSISTANCE IMMEDIATELY.

Wear protective goggles when handling liquids which are harmful to the eyes; these include ammonia and battery acid. If

any of these substances are splashed in the eyes, wash out thoroughly with clean water and OBTAIN QUALIFIED

MEDICAL ASSISTANCE IMMEDIATELY.

IMPORTANT SAFETY NOTICE

Appropriate service methods and proper repair procedures are essential for the safe, reliable operation of all industrial

engines as well as the personal safety of the individual doing the work. This Service Manual provides general directions

for accomplishing service and repair work with tested, effective techniques. Following them will help assure reliability.

TSG‐416GENERALINFORMATION

01‐1

INDEX

Subject

GeneralInformationPage

Introduction………………………………………………………………………………………………………………01–3

SafetyNotice…………………………………………………………………………….………………………………01–3

Notes,Cautions,andWarnings…………………………………………………………………………………01–3

BatteryHandlingandCharging……………………………………………….…………………………………01–4

Forward…………………………………….………………………………………………………………………………01–5

EngineIdentification………..………….……………………………………………………………………………01–5

PartsandService………………………………………….……………………………………………………………01–5

DescriptionandOperation……………………………………………………..…………………………………01–5

DiagnosisandTesting

SpecialTools…………….…………………………………………………………………………………………………01–6

InspectionandVerification…………………………………………………………………………………………01–7

SymptomChart…………………………………………………………………………………………………………..01–7

PCVSystemMalfunction…………………………………………………………………………………………….01–10

EngineOilLeaks………………………………………………………………………………………………………….01–10

CompressionTests……………………………………………………………………………………………………..01–12

CylinderLeakageDetection………………………………………………………………………………………..01–13

IntakeManifoldVacuumTest…………………………………………………………………………………….01–13

ExcessiveEngineOilConsumption……………………………………………………………………………..01–15

OilPressureTest…………………………………………………………………………………………………………01–16

ValveTrainAnalysis–Static………………………………………………………………………………………..01–17

ValveTrainAnalysis–Dynamic…………………………………………………………………………………..01–17

CamshaftLoveLift……………………………………………………………………………………………………….01–18

HydraulicValveLashAdjuster…………………………………………………………………………………….01–19

GeneralServiceProcedures

CamshaftJournalDiameter………………………………………………………………………………………..01–20

CamshaftJournalClearance……………………………………………………………………………………….01–20

CamshaftLobeSurface…..………………………………………………………………………………………….01–20

CamshaftLobeLift………………………………………………………………………………………………………01–21

CamshaftRunout……………………………………………………………………………………………………….01–21

CamshaftEndPlay……………………………………………………………………………………………………..01–21

CrankshaftMainBearingJournalDiameter……………………………………………………………….01–22

CrankshaftMainBearingJournalTaper…………………………………………………………………….01–22

CrankshaftMainBearingJournalClearance………………………………………………………………01–23

BearingInspection…………………………………………………………………………………………………….01–23

CrankshaftEndPlay…………………………………………………………………………………………………...01–24

CrankshaftRunout……………………………………………………………………………………………………..01–24

CylinderBoreTaper……………………………………………………………………………………………………01–24

CylinderBoreOut‐of‐Round……………………………………………………………………………………...01–25

PistonInspection……………………………………………………………………………………………………….01–25

PistonDiameter…………………………………………………………………………………………………………01–25

PistontoCylinderBoreClearance……………………………………………………………………………..01–25

TSG‐416GENERALINFORMATION

01‐2

INDEX(CONT.)

Subject

GeneralServiceProceduresPage

PistonSelection………………………………………………………………………………………………………….01–26

PistonRingEndGap…………………………………………………………………………………………………..01–26

PistonRing‐to‐GrooveClearance……………………………………………………………………………….01–27

CrankshaftConnectingRodJournalDiameter……………………………………………………………01–27

CrankshaftConnectionRodJournalTaper………………………………………………………………...01–27

ConnectingRodCleaning……………………………………………………………………………………………01–27

ConnectingRodLargerEndBore……………………………………………………………………………….01–28

PistonPinDiameter…………………………………………………………………………………………………..01–28

ConnectingRodBushingDiameter…………………………………………………………………………...01–28

ConnectingRodBend………………………………………………………………………………………………..01–28

ConnectingRodTwist………………………………………………………………………………………………..01–28

ConnectingRodPistonPinSideClearance………………………………………………………………..01–29

ConnectingRodJournalClearance…………………………………………………………………………….01–29

BearingInspection…………………………………………………………………………………………………….01–30

RollerFollowerInspection………………………………………………………………………………………...01–30

HydraulicLashAdjusterInspection……………………………………………………………………………01–30

ValveStemDiameter…………………………………………………………………………………………………01–31

ValveStem‐to‐ValveGuideClearance………………………………………………………………………01–31

ValveInspection……………………………………………………………………………………………………….01–31

ValveGuideInnerDiameter……………………………………………………………………………………..01–32

ValveGuideReaming………………………………………………………………………………………………..01–32

ValveSpringInstalledLength…………………………………………………………………………………….01–32

ValveSpringFreeLength…………………………………………………………………………………………..01–32

ValveSpringOut‐of‐Square……………………………………………………………………………………….01–32

ValveSpringCompressionPressure………………………………………………………………………….01–33

ValveandSeatRefacingMeasurements…………………………………………………………………..01–33

ValveSeatWidth………………………………………………………………………………………………………01–33

ValveSeatRunout……………………………………………………………………………………………………01–33

FlywheelInspection………………………………………………………………………………………………..01–34

OilPumpGearRadialClearance………………………………………………………………………………01–34

OilPumpRotorInspection………………………………………………………………………………………01–34

OilPumpSideClearance………………………………………………………………………………………….01–34

CylinderBoreHoning……………………………………………………………………………………………….01–35

CylinderBoreCleaning…………………………………………………………………………………………….01–35

CylinderBoreCorePlugReplacement…………………………………………………………………….01–36

CylinderBoreRepair–CastIronPorosityDefects………………………………………………....01–36

CylinderBlock–Distortion………………………………………………………………………………………01–36

SparkPlugThreadRepair………………………………………………………………………………………..01–38

ExhaustManifoldStraightness………………………………………………………………………………..01–39

SPECIFICATIONS…………………………………………………………………………………………………………….………...01–40

TSG‐416GENERALINFORMATION

01‐3

GENERAL INFORMATION

Introduction

This section covers various engine tests, adjustments,

service procedures and cleaning/inspection procedures.

Engine assembly and service specifications appear at

the end of the Section 02.

For engine disassembly, assembly, installation,

adjustment procedures and specifications, refer to

Section 02.

This engine incorporates a closed-type crankcase

ventilation system.

To maintain the required performance level, the fuel

system, ignition system and engine must be kept in good

operating condition and meet recommended adjustment

specifications.

Before replacing damaged or worn engine components

such as the crankshaft, cylinder head, valve guide,

valves, camshaft or cylinder block, make sure part(s) is

not serviceable.

WARNING: TO AVOID THE POSSIBILITY OF

PERSONAL INJURY OR DAMAGE, DO NOT

OPERATE THE ENGINE UNTIL THE FAN BLADE HAS

FIRST BEEN EXAMINED FOR POSSIBLE CRACKS

OR SEPARATION.

CAUTION: Use of abrasive grinding discs to remove

gasket material from the engine sealing surfaces

during repair procedures can contribute to engine

damage and wear. Airborne debris and abrasive grit

from the grinding disc may enter the engine through

exposed cavities causing premature wear

and eventual engine damage.

Engine Distributors Inc. (EDI) does not recommend

using abrasive grinding discs to remove engine gasket

material. Use manual gasket scrapers for removing

gasket material from the engine sealing surfaces.

Take added care to prevent scratching or gouging

aluminum sealing surfaces.

Safety Notice

There are numerous variations in procedures,

techniques, tools and parts for servicing equipment, as

well as in the skill of the individual doing the work. This

manual cannot possibly anticipate all such variations and

provide advice or cautions as to each. Accordingly,

anyone who departs from the instructions provided in

this Manual must first establish that neither personal

safety nor equipment integrity are compromised by the

choice of methods, tools or parts.

Notes, Cautions, and Warnings

As you read through the procedures, you will come

across NOTES, CAUTIONS, and WARNINGS. Each one

is there for a specific purpose. NOTES gives you added

information that will help you to complete a particular

procedure. CAUTIONS are given to prevent you from

making an error that could damage the equipment.

WARNINGS remind you to be especially careful in those

areas where carelessness can cause personal injury.

The following list contains some general WARNINGS

that you should follow when you work on the equipment.

GENERAL WARNINGS:

TO HELP AVOID INJURY:

ALWAYS WEAR SAFETY GLASSES FOR EYE

PROTECTION.

USE SAFETY STANDS WHENEVER A

PROCEDURE REQUIRES YOU TO BE UNDER THE

EQUIPMENT.

BE SURE THAT THE IGNITION SWITCH IS

ALWAYS IN THE OFF POSITION, UNLESS

OTHERWISE REQUIRED BY THE PROCEDURE.

SET THE PARKING BRAKE (IF EQUIPPED) WHEN

WORKING ON THE EQUIPMENT. IF YOU HAVE AN

AUTOMATIC TRANSMISSION, SET IT IN PARK

(ENGINE OFF) OR NEUTRAL (ENGINE ON)

UNLESS INSTRUCTED OTHERWISE FOR A

SPECIFIC OPERATION. PLACE WOOD BLOCKS

(4”X 4” OR LARGER) TO THE FRONT AND REAR

SURFACES OF THE TIRES TO PROVIDE

FURTHER RESTRAINT FROM INADVERTENT

EQUIPMENT MOVEMENT.

OPERATE THE ENGINE ONLY IN A WELL

VENTILATED AREA TO AVOID THE DANGER OF

CARBON MONOXIDE.

KEEP YOURSELF AND YOUR CLOTHING AWAY

FROM MOVING PARTS WHEN THE ENGINE IS

RUNNING, ESPECIALLY THE FAN BELTS.

TO PREVENT SERIOUS BURNS, AVOID CONTACT

WITH HOT METAL PARTS SUCH AS THE

RADIATOR, EXHAUST MANIFOLD, TAIL PIPE,

CATALYTIC CONVERTER AND MUFFLER.

DO NOT SMOKE WHILE WORKING ON THE

EQUIPMENT.

ALWAYS REMOVE RINGS, WATCHES, LOOSE

HANGING JEWELRY, AND LOOSE CLOTHING

BEFORE BEGINNING TO WORK ON THE

EQUIPMENT. TIE LONG HAIR SECURELY BEHIND

THE HEAD.

KEEP HANDS AND OTHER OBJECTS CLEAR OF

THE RADIATOR FAN BLADES. ELECTRIC

COOLING FANS CAN START TO OPERATE AT

ANY TIME BY AN INCREASE IN UNDERHOOD

TEMPERATURES, EVEN THOUGH THE IGNITION

IS IN THE OFF POSITION. THEREFORE, CARE

SHOULD BE TAKEN TO ENSURE THAT THE

ELECTRIC COOLING FAN IS COMPLETELY

DISCONNECTED WHEN WORKING UNDER THE

HOOD.

TSG‐416GENERALINFORMATION

01‐4

Battery Handling and Charging

The handling and correct use of lead acid batteries is not

as hazardous provided that sensible precautions are

observed and that operatives have been trained in their

use and are adequately supervised.

NOTE: Observe all manufacturers’ instructions when

using charging equipment.

CAUTION: Batteries should not be charged in the

vehicle or equipment. May damage electrical

components.

It is important that all labeling on the battery is carefully

read, understood and complied with. The format of the

following symbols and labels is common to most brands

of lead acid battery.

TSG‐416GENERALINFORMATION

01‐5

Forward

This book contains service information for the engine(s)

listed on the title page.

The life of your engine unit and the delivery of the high

performance built into it will depend on the care it

receives throughout its life. It is the operator’s

responsibility to ensure that the engine is correctly

operated. We consider it to be in your interests to enlist

the aid of an authorized EDI Distributor, not only when

repairs are required but also for regular maintenance.

Distributors are listed at the back of this manual.

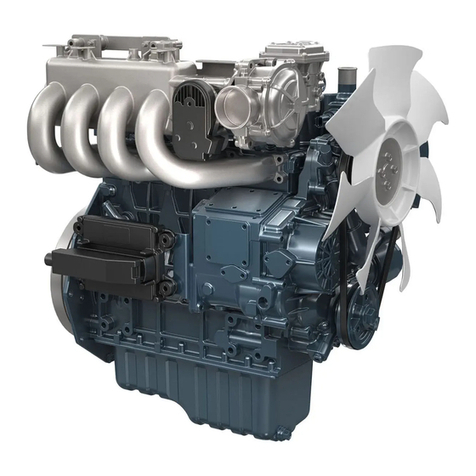

Engines manufactured by Ford Motor Company are

available through EDI Distributors. When in need of

parts or service, contact your local Authorized

Distributor. In overseas territories, in the event of

difficulties, communicate directly with the supervising

EDI affiliated Company in your area whose address

appears at the end of this book.

Where the terms “Right” or “Left” occur in this

publication, they refer to the respective sides of the

engine when viewed from the rear or flywheel end.

Pistons and valves are numbered from the front or timing

cover end of the engine commencing at No. 1.

You may find that your engine assembly includes

optional equipment not specifically covered in the

following text. Nevertheless, the service procedures

outlined in this book still apply to your engine.

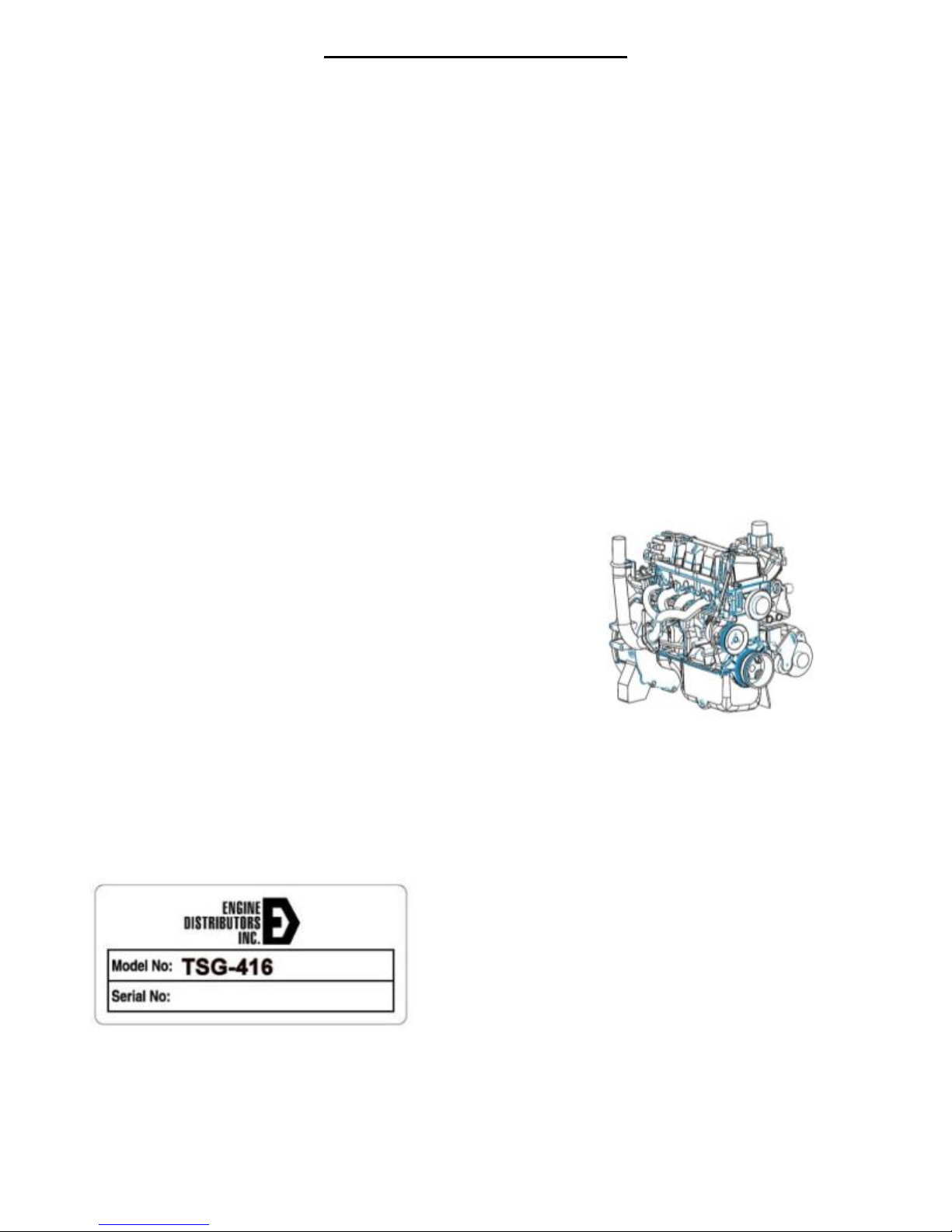

Engine Identification

Because Ford Power Products markets such a wide

range of industrial gasoline and diesel engines -

manufactured both in the U.S. and overseas - it is

important that you have as complete identification of the

engine as possible in order to provide the correct

replacement parts. Review the list in the back of this

book, for an EDI distributor in your area. You can obtain

a standard parts listing describing the parts. It remains a

distributor function to identify the part number.

An identification Decal is affixed to the valve cover of the

engine. The decal contains the engine serial number

which identifies this unit from all others. Use all numbers

when seeking information or ordering replacement parts

for this engine.

Parts and Service

Replacement parts can be obtained through your local

EDI Distributor listed in the back portion of this manual.

They also may be found in the yellow pages under

“Engines” or contact EDI directly at 1 800 220 2700.

EDI Distributors are equipped to perform major and

minor repairs. They are anxious to see that all of your

maintenance and service needs are quickly and

courteously completed.

Description and Operation

Section 01 of this manual covers general procedures

and diagnosis of the engine system, including base

engine repair procedures that would be common to most

engines. Refer to Section 02 for more specific service

information on the TSG-416 engine.

The TSG-416 engine incorporates a closed positive

crankcase ventilation system and an exhaust emission

control system.

The engine’s, fuel, ignition, emissions system and

exhaust system all affect exhaust emission levels and

must be maintained according to the maintenance

schedule. Refer to the Maintenance and Operator’s

Handbook or contact your nearest EDI distributor listed

in the back of this manual.

TSG‐416GENERALINFORMATION

01‐6

DIAGNOSIS AND TESTING

Special Tools

Special Service Tools called by the procedures can be

obtained by calling:

1-800-ROTUNDA (1-800-768-8632)

TSG‐416GENERALINFORMATION

01‐7

Inspection and Verification

1. Verify the customer concern by operating the

engine to duplicate the condition.

2. Visually inspect for obvious signs of mechanical

and electrical damage:

Engine coolant leaks.

Engine oil leaks.

Fuel leaks.

Damaged or severely worn pads.

Loose mounting bolts, studs, and nuts.

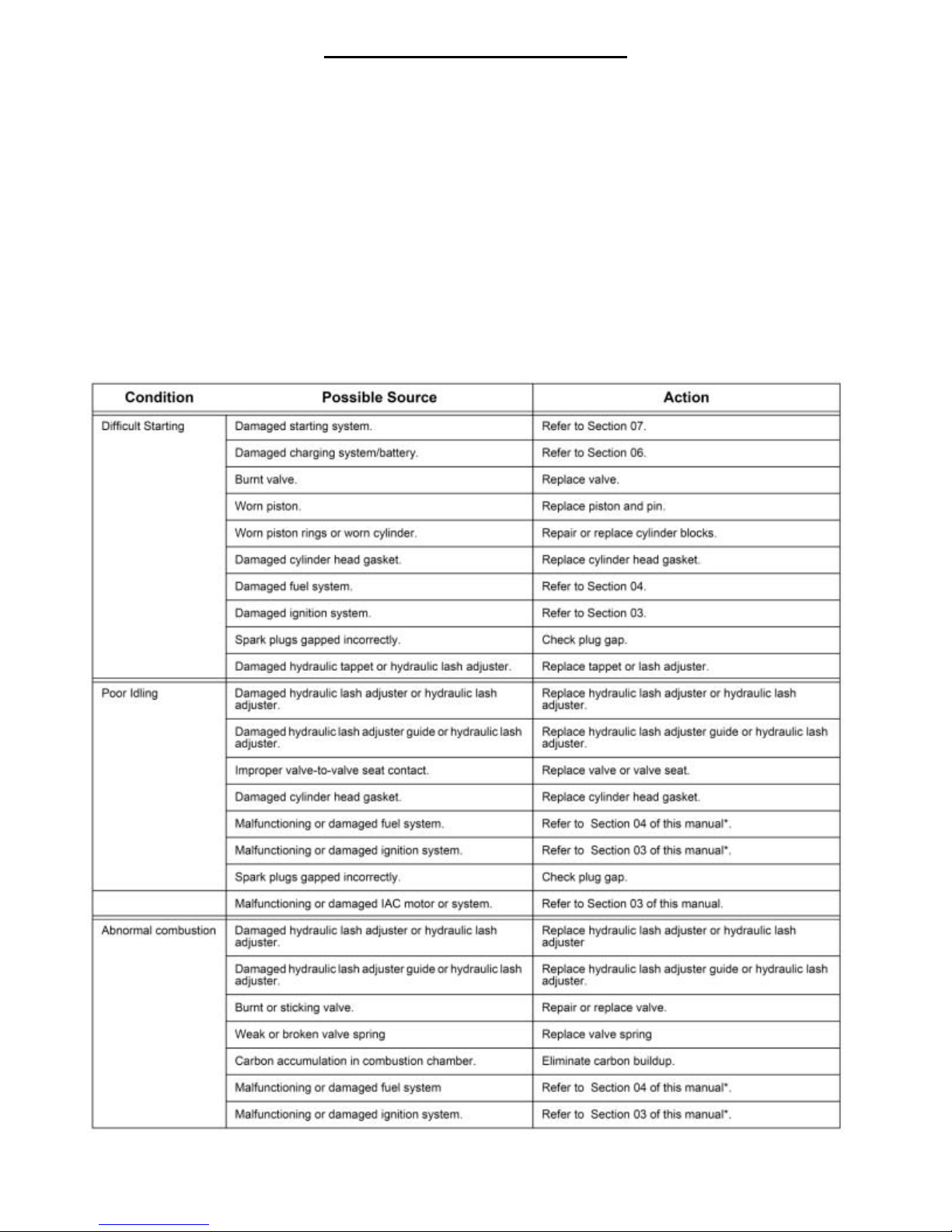

Symptom Chart

3. If the inspection reveals obvious concerns that

can be readily identified, repair as required.

4. If the concerns remain after the inspection,

determine the symptoms and go to the symptom

chart.

TSG‐416GENERALINFORMATION

01‐8

TSG‐416GENERALINFORMATION

01‐9

TSG‐416GENERALINFORMATION

01‐10

PCV System Malfunction

A malfunctioning Positive Crankcase Ventilation

System (closed type) may be indicated by loping or

rough engine idle. Do not attempt to compensate for this

idle condition by disconnecting the PCV system and

making an air bypass or idle speed adjustment.

CAUTION: The removal of the PCV system from the

engine will adversely affect fuel economy and

engine crankcase ventilation with resultant

shortening of engine life.

Engine Oil Leaks

NOTE: When diagnosing engine oil leaks, the source

and location of the leak must be positively identified prior

to service.

Prior to performing this procedure, clean the cylinder

block, cylinder heads, valve covers, oil pan and flywheel

with a suitable solvent to remove all traces of oil.

Fluorescent Oil Additive Method

Use a 12 Volt Master UV Diagnostic Inspection Kit, such

as the Rotunda Oil Leak Detector Y112-R0021 or

equivalent, to perform the following procedure for oil leak

diagnosis.

1. Clean the engine with a suitable solvent to

remove all traces of oil.

2. Drain engine oil crankcase and refill with

recommended oil, premixed with Diesel Engine

Oil Dye 164-R3705 meeting Ford specification

ESEM9C103- B1 or equivalent. Use a minimum

14.8 ml (0.5 ounce) to a maximum 29.6 ml (1

ounce) of fluorescent additive to all engines. If

the oil is not premixed, fluorescent additive must

first be added to crankcase.

3. Run the engine for 15 minutes. Stop the engine

and inspect all seal and gasket areas for leaks

using the 12 Volt Master UV diagnostic

Inspection Kit. A clear bright yellow or orange

area will identify the leak. For extremely small

leaks, several hours may be required for the

leak to appear.

4. If necessary, pressurize the main oil gallery

system to locate leaks due to improperly sealed,

loose or cocked plugs.

5. Repair all leaks as required.

Pressure Method

The crankcase can be pressurized to locate oil leaks.

The following materials are required to fabricate the tool

to be used:

air supply and air hose

air pressure gauge that registers pressure in 4

kPa (1 psi) increments

airline shutoff valve

appropriate fittings to attach the above parts to

oil fill, PCV grommet hole and crankcase

ventilation tube

appropriate plugs to seal any openings leading

to the crankcase

a solution of liquid detergent and water to be

applied with a suitable applicator such as a

squirt bottle or brush

Fabricate the air supply hose to include the airline

shutoff valve and the appropriate adapter to permit the

air to enter the engine through the crankcase ventilation

tube. Fabricate the air pressure gauge to a suitable

adapter for installation on the engine at the oil filler

opening.

CAUTION: Use extreme caution when pressurizing

crankcase. Applying air pressure above specified

pressure risks damage to seals, gaskets and core

plugs. Under no circumstances should pressure be

allowed to exceed 27 kPa (4 psi)

TSG‐416GENERALINFORMATION

01‐11

Testing Procedure

Open the air supply valve until the pressure

gauge maintains 20 kPa (3 psi).

Inspect sealed or gasketed areas for leaks by

applying a solution of liquid detergent and water

over areas for formation of bubbles which

indicates leakage.

Leakage Points - Above Engine

Examine the following areas for oil leakage.

valve cover gaskets

intake manifold gaskets

cylinder head gaskets

oil filter

oil pump (if external)

oil level indicator tube connection

oil pressure sensor

Leakage Points - Under Engine

oil pan gaskets

oil pan sealer

oil pan rear seal

engine front cover gasket

crankshaft front seal

crankshaft rear oil seal

Leakage Points - with Flywheel Removed

NOTE: Air leakage in the area around a crankshaft rear

oil seal does not necessarily indicate a crankshaft rear

oil seal leak. However, if no other cause can be found for

oil leakage, assume that the crankshaft rear oil seal

is the cause of the oil leak.

NOTE: Light foaming equally around valve cover bolts

and crankshaft seals is not detrimental; no repairs are

required.

rear main bearing cap and seals

flywheel mounting bolt holes (with flywheel

installed)

camshaft rear bearing covers or pipe plugs at

the end of oil passages (except for overhead

cam)

Oil leaks at crimped seams in sheet metal parts and

cracks in cast or stamped parts can be detected when

pressurizing the crankcase.

TSG‐416GENERALINFORMATION

01‐12

Compression Tests

Compression Gauge Check

1. Make sure the oil in the crankcase is of the

correct viscosity and at the proper level and that

the battery is properly charged. Operate until the

engine is at normal operating temperature. Turn

the ignition switch to the OFF position, then

remove all the spark plugs.

2. Set the throttle plates in the wide-open position.

3. Install a Compression Tester such as Rotunda

Compression Tester 059-R0009, or equivalent,

in the No. 1 cylinder.

4. Install an auxiliary starter switch in the starting

circuit. With the ignition switch in the OFF

position, and using the auxiliary starter switch,

crank the engine a minimum of five compression

strokes and record the highest reading. Note the

approximate number of compression strokes

required to obtain the highest reading.

5. Repeat the test on each cylinder, cranking the

engine approximately the same number of

compression strokes.

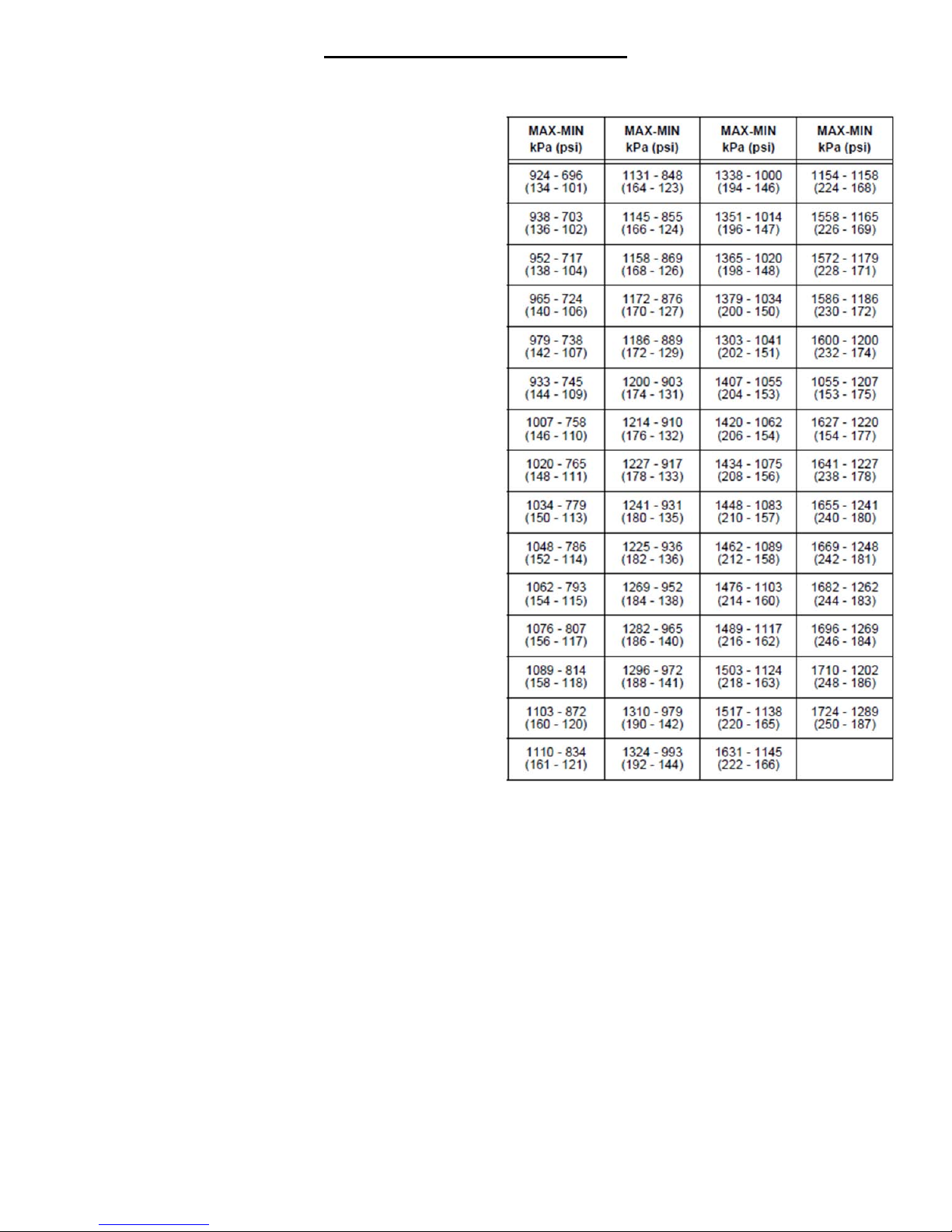

Test Results

The indicated compression pressures are considered

within specification if the lowest reading cylinder is within

75 percent of the highest reading. Refer to the

Compression Pressure Limit Chart.

If one or more cylinders reads low, squirt approximately

one tablespoon of clean engine oil meeting Ford

specification ESE-M2C153-E on top of the pistons in the

low-reading cylinders. Repeat the compression pressure

check on these cylinders.

Example Readings

If, after checking the compression pressures in all

cylinders, it was found that the highest reading obtained

was 1351 kPa (196 psi), and the lowest pressure

reading was 1069 kPa (155 psi), the engine is within

specification and the compression is considered

satisfactory.

Compression Pressure Limit Chart

Interpreting Compression Readings

1. If compression improves considerably, with the

addition of oil, piston rings are faulty.

2. If compression does not improve with oil, valves

are sticking or seating improperly.

3. If two adjacent cylinders indicate low

compression pressures and squirting oil on each

piston does not increase compression, the head

gasket may be leaking between cylinders.

Engine oil or coolant in cylinders could result

from this condition.

Use the Compression Pressure Limit Chart when

checking cylinder compression so that the lowest

reading is within 75 percent of the highest reading.

TSG‐416GENERALINFORMATION

01‐13

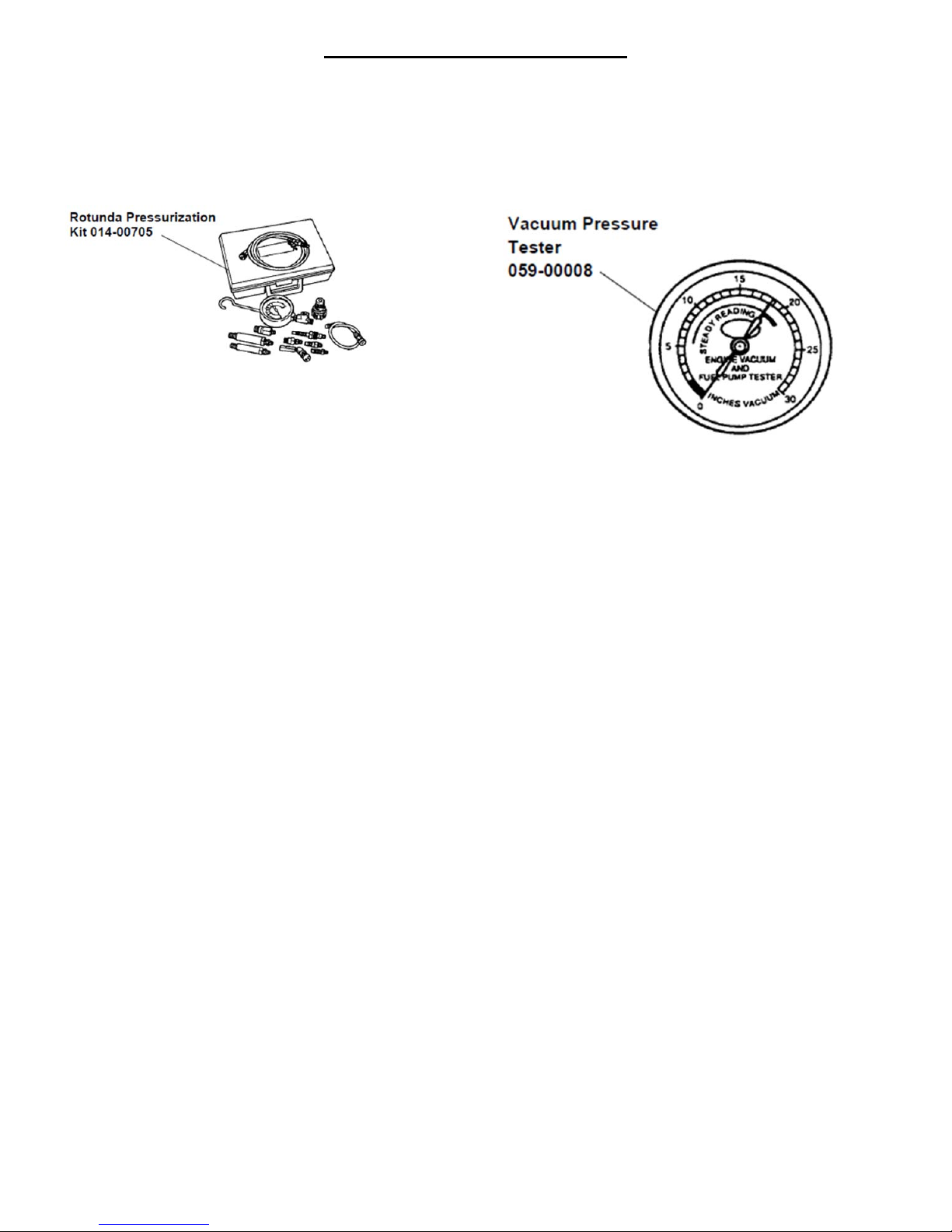

Cylinder Leakage Detection

When a cylinder produces a low reading, use of the

Engine Cylinder Leak Detection/Air Pressurization Kit,

such as the Rotunda Pressurization Kit 014-00705, or

equivalent, will be helpful in pinpointing the exact cause.

The leakage detector is inserted in the spark plug hole,

the piston is brought up to dead center on the

compression stroke, and compressed air is admitted.

Once the combustion chamber is pressurized, a special

gauge included in the kit will read the percentage of

leakage. Leakage exceeding 20 percent is excessive.

While the air pressure is retained in the cylinder, listen

for the hiss of escaping air. A leak at the intake valve will

be heard in the throttle body. A leak at the exhaust valve

can be heard at the tail pipe. Leakage past the piston

rings will be audible at the positive crankcase ventilation

(PCV) connection. If air is passing through a blown

head gasket to an adjacent cylinder, the noise will be

evident at the spark plug hole of the cylinder into which

the air is leaking. Cracks in the cylinder blocks or gasket

leakage into the cooling system may be detected by a

stream of bubbles in the radiator.

Oil Leak and Valve Stem Seal Test

The cylinder leakage detector tests for engine oil leaks

and checks the valve stem seals for leakage.

1. Plug all crankcase openings except the one

used for connecting the leakage detector.

2. Connect the Engine Cylinder Leak Detection/Air

Pressurization Kit to a crankcase opening (an oil

level indicator tube is convenient). Adjust the air

pressure to approximately 34 kPa (5 psi).

3. Using a solution of liquid soap and water, brush

the solution along the gasket sealing surfaces

and bearing seals. Look for bubbles or foam.

4. Remove the spark plugs and rotate the

crankshaft slowly with a wrench. Check for large

amounts of air escaping into the cylinders as

each intake valve and exhaust valve opens.

5. The spark plugs on the leaking cylinders will

probably show deposits of burned oil.

Intake Manifold Vacuum Test

Bring the engine to normal operating temperature.

Connect a Vacuum/Pressure Tester, such as Rotunda

Vacuum/Pressure Tester 059-00008 or equivalent, to the

intake manifold. Run the engine at the specified idle

speed.

The vacuum gauge should read between 51-74 kPa

(15-22 in-Hg) depending upon the engine condition and

the altitude at which the test is performed. Subtract 5.5

kPa (1 in-Hg) from the specified reading for every 500

meters (1,000 feet) of elevation above sea level.

The reading should be quite steady. If necessary, adjust

the gauge damper control (where used) if the needle is

fluttering rapidly. Adjust the damper until the needle

moves easily without excessive flutter.

TSG‐416GENERALINFORMATION

01‐14

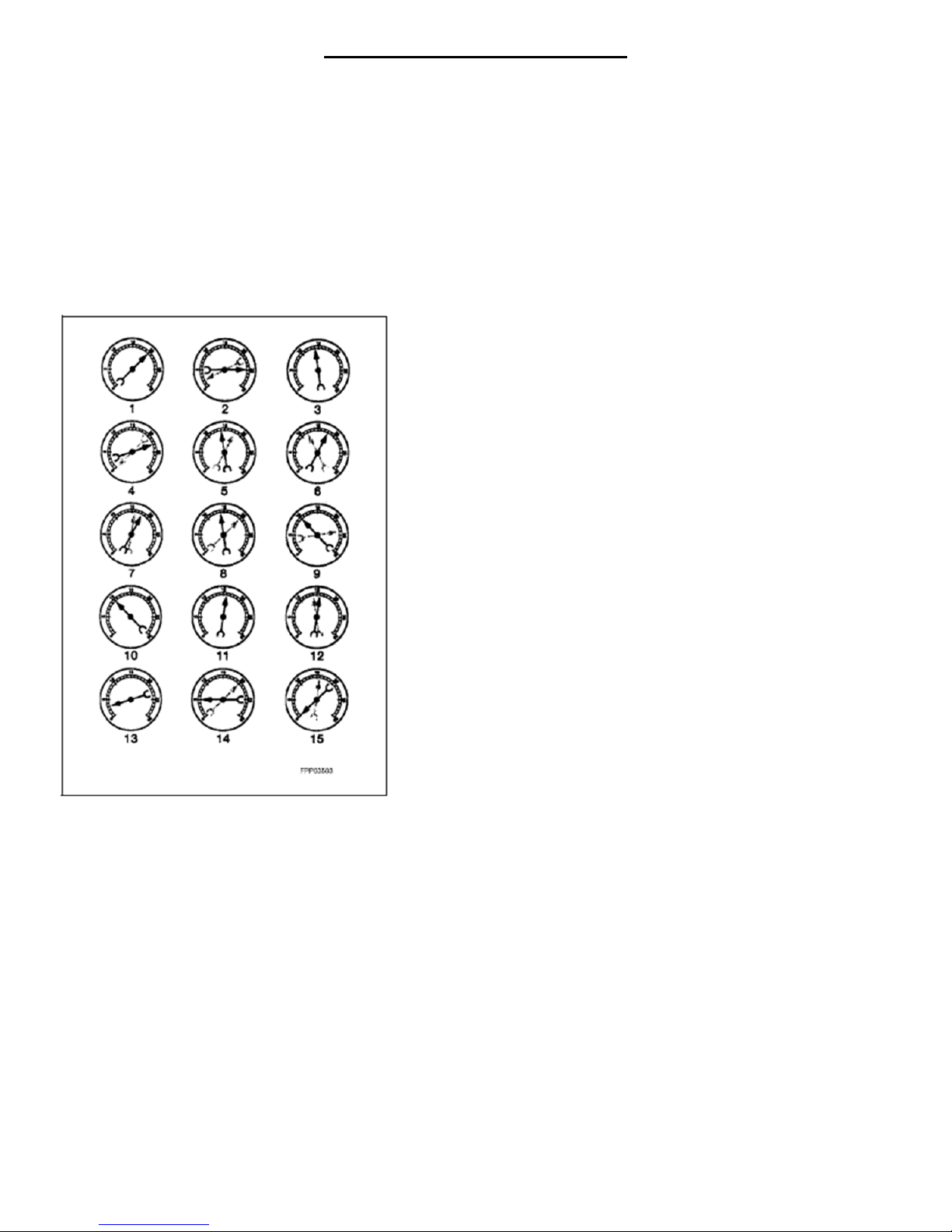

Interpreting Vacuum Gauge Readings

A careful study of the vacuum gauge reading while the

engine is idling will help pinpoint trouble areas. Always

conduct other appropriate tests before arriving at a final

diagnostic decision. Vacuum gauge readings, although

helpful, must be interpreted carefully.

Most vacuum gauges have a normal band indicated on

the gauge face.

The following are potential gauge readings. Some are

normal; others should be investigated further.

1. NORMAL READING: Needle between 51-74

kPa (15-22 in-Hg) and holding steady.

2. NORMAL READING DURING RAPID

ACCELERATION AND DEACCELERATION:

When the engine is rapidly accelerated (dotted

needle), the needle will drop to a low reading

(not to zero). When the throttle is suddenly

released, the needle will snap back up to a

higher than normal figure.

3. NORMAL FOR HIGH-LIFT CAMSHAFT WITH

LARGE OVERLAP: The needle will register as

low as 51 kPa (15 in-Hg) but will be relatively

steady. Some oscillation is normal.

4. WORN RINGS OR DILUTED OIL: When the

engine is accelerated (dotted needle), the

needle drops to 0 kPa (0 in-Hg). Upon

deceleration, the needle runs slightly above 74

kPa (22 in-Hg).

5. STICKING VALVES: When the needle (dotted)

remains steady at a normal vacuum but

occasionally flicks (sharp, fast movement) down

and back about 13 kPa (4 in-Hg), one or more

valves may be sticking.

6. BURNED OR WARPED VALVES: A regular,

evenly spaced, downscale flicking of the needle

indicates one or more burned or warped valves.

Insufficient hydraulic lash adjuster or hydraulic

lash adjuster (HLA) clearance will also cause

this reaction.

7. POOR VALVE SEATING: A small but regular

downscale flicking can mean one or more valves

are not seating.

8. WORN VALVE GUIDES: When the needle

oscillates (swings back and forth) over about a

13 kPa (4 in- Hg) range at idle speed, the valve

guides could be worn. As engine speed

increases, the needle will become steady if

guides are responsible.

9. WEAK VALVE SPRINGS: When the needle

oscillation becomes more violent as engine rpm

is increased, weak valve springs are indicated.

The reading at idle could be relatively steady.

10. LATE VALVE TIMING: A steady but low reading

could be caused by late valve timing.

11. IGNITION TIMING RETARDING: Retarded

ignition timing will produce a steady but

somewhat low reading.

12. INSUFFICIENT SPARK PLUG GAP: When

spark plugs are gapped too close, a regular,

small pulsation of the needle can occur.

13. INTAKE LEAK: A low, steady reading can be

caused by an intake manifold or throttle body

gasket leak.

14. BLOWN HEAD GASKET: A regular drop of

approx. 33-50 kPa (10-15 in-Hg) can be caused

by a blown head gasket or warped cylinder

head-to-cylinder block surface.

15. RESTRICTED EXHAUST SYSTEM: When the

engine is first started and is idled, the reading

may be normal, but as the engine rpm is

increased, the back pressure caused by a

clogged muffler, kinked tail pipe or other

concerns will cause the needle to slowly drop to

0 kPa (0 in-Hg). The needle then may slowly

rise. Excessive exhaust clogging will cause the

needle to drop to a low point even if the engine

is only idling.

When vacuum leaks are indicated, search out and

correct the cause. Excess air leaking into the system will

upset the fuel mixture and cause concerns such as

rough idle, missing on acceleration or burned valves. If

the leak exists in an accessory unit such as the power

brake booster, the unit will not function correctly. Always

fix vacuum leaks.

TSG‐416GENERALINFORMATION

01‐15

Excessive Engine Oil Consumption

The amount of oil an engine uses will vary with the way

the equipment is driven in addition to normal engine to

engine variation. This is especially true during the first

340 hours or 16,100 km (10,000 miles) when a new

engine is being broken in or until certain internal engine

components become conditioned. Engines used in

heavy-duty operation may use more oil. The following

are examples of heavy-duty operation:

severe loading applications

sustained high speed operation

Engines need oil to lubricate the following internal

components:

cylinder block, cylinder walls

pistons, piston pins and rings

intake and exhaust valve stems

intake and exhaust valve guides

all internal engine components

When the pistons move downward, a thin film of oil is left

on the cylinder walls. As the engine is operated, some oil

is also drawn into the combustion chambers past the

intake and exhaust valve stem seals and burned.

The following is a partial list of conditions that can affect

oil consumption rates:

engine size

operator driving habits

ambient temperature

quality and viscosity of the oil

Operating under varying conditions can frequently be

misleading. An engine that has been run for short hours

or in below-freezing ambient temperatures may have

consumed a “normal” amount of oil.

However, when checking engine oil level, it may

measure up to the full mark on the oil level dipstick due

to dilution (condensation and fuel) in the engine

crankcase. The engine might then be run at high speeds

where the condensation and fuel boil off. The next time

the engine oil is checked, it may appear that a liter

(quart) of oil was used in about 3 to 3-1/2 hours.

This perceived 3 to 3-1/2 hours per liter (quart) oil

consumption rate causes customer concern even though

the actual overall oil consumption rate is about

50 hours per liter (quart).

Make sure the selected engine oil meets Ford

specification WSS-M2C153-F and the recommended

API performance category “SJ” or higher and SAE

viscosity grade as shown in the equipment Owner’s or

Operators Engine handbook. It is also important that the

engine oil is changed at the intervals specified. Refer to

the Engine Operator’s handbook.

Oil Consumption Test

The following diagnostic procedure is used to determine

the source of excessive internal oil consumption.

NOTE: Oil use is normally greater during the first 300

hours of service. As hours increase, oil use generally

decreases. Engines in normal service should get at least

31.7 hours per quart (900 miles per quart) after

300 hours of service. High speeds, heavy loads, high

ambient temperature and other factors may result in

greater oil use.

1. Determine customer’s engine load habits, such

as sustained high speed operation, extended

idle, heavy work loads and other considerations.

2. Verify that the engine has no external oil leak as

described under Engine Oil Leaks in the

Diagnosis and Testing portion of this section.

3. Verify that the engine has the correct oil level

dipstick.

4. Verify that the engine is not being run in an

overfilled condition. Check the oil level at least

five minutes after a hot shutdown with the

engine/vehicle parked on a level surface. In no

case should the level be above the top of the

cross-hatched area and the letter F in FULL. If

significantly overfilled, perform= steps 5 through

9. If not proceed to step 10.

5. Drain the engine oil, remove and replace the oil

filter and refill with one quart less than the

recommended amount.

6. Run the engine for three minutes (10 minutes if

cold), and allow the oil to drain back for at least

five minutes with the engine/vehicle on a level

surface.

7. Remove oil level dipstick and wipe clean.

CAUTION: Do not wipe with anything contaminated

with silicone compounds.

8. Reinstall the oil level dipstick, being sure to seat

it firmly in the oil level indicator tube. Remove

the oil level dipstick and draw a mark on the

back (unmarked) surface at the indicated oil

level. This level should be about the same as

the ADD mark on the face of the oil level

dipstick.

9. Add one quart of oil. Restart the engine and

allow to idle for at least two minutes. Shut off the

engine and allow the oil to drain back for at least

five minutes. Mark the oil level dipstick, using

the procedure above. This level may range from

slightly below the top of the cross-hatched area

to slightly below the letter F in FULL.

TSG‐416GENERALINFORMATION

01‐16

10. Record the vehicle mileage or hours.

11. Instruct the customer to run engine as usual and

perform the following:

Check the oil level regularly at intervals

of 3 to 3-1/2 hours.

Return to the service point when the oil

level drops below the lower (ADD) mark

on the oil level dipstick.

Add only full quarts of the same oil in an

emergency. Note the mileage at which

the oil is added.

12. Check the oil level under the same conditions

and at the same location as in Steps 7-9

Measure the distance from the oil level

to the UPPER mark on the oil level

dipstick and record.

Measure the distance between the two

scribe marks and record.

Divide the first measurement by the

second.

Divide the hours run during the oil test

by the result. This quantity is the

approximate oil consumption rate in

hours per quart.

13. If the oil consumption rate is unacceptable,

proceed to next step.

14. Check the positive crankcase ventilation (PCV)

system. Make sure the system is not plugged.

15. Check for plugged oil drain-back holes in the

cylinder heads and cylinder blocks.

16. If the condition still exists after performing the

above steps, proceed to next step.

17. Perform a cylinder compression test – Refer to

“Compression Tests” on page 12 or perform a

cylinder leak detection test with Engine Cylinder

Leak Detection/Air Pressurization Kit – Refer to

“Cylinder Leakage Detection” on page 13. This

can help determine the source of oil

consumption such as valves, piston rings or

other areas.

NOTE: After determining if worn parts should be

replaced, make sure correct replacement parts are used.

18. Check valve guides for excessive guide

clearances. REPLACE all valve stem seals after

verifying valve guide clearance.

19. Worn or damaged internal engine components

can cause excessive oil consumption. Small

deposits of oil on the tips of spark plugs can be

a clue to internal oil consumption. If internal oil

consumption still persists, proceed as follows:

Remove the engine from the vehicle and

place it on an engine work stand.

Remove the intake manifolds, cylinder

heads, oil pan and oil pump.

Check piston ring clearance, ring gap

and ring orientation. Repair as required.

Check for excessive bearing clearance.

Repair as required.

20. Perform the oil consumption test to confirm the

oil consumption concern has been resolved.

Oil Pressure Test

1. Disconnect and remove the oil pressure sensor

from the engine.

2. Connect the Engine Oil Pressure Gauge and

Transmission Test Adapter to the oil pressure

sender oil gallery port.

3. Run the engine until normal operating

temperature is reached.

4. Run the engine at 3000 rpm and record the

gauge reading.

5. The oil pressure should be within specifications.

6. If the pressure is not within specification, check

the following possible sources:

insufficient oil

oil leakage

worn or damaged oil pump

oil pump screen cover and tube

excessive main bearing clearance

excessive connecting rod bearing clearance

Table of contents

Popular Engine manuals by other brands

Briggs & Stratton

Briggs & Stratton Vanguard 10V300 Repair manual

Robin America

Robin America EX13 parts manual

Yamaha

Yamaha F150A Service manual

W&H

W&H EM-19 Instructions for use

Iveco

Iveco N60 ENT M37 Technical and repair manual

Briggs & Stratton

Briggs & Stratton Classic 100000 Series Operating & maintenance instructions