Model 242L Operations Manual

Eberle Design Inc. Page 6

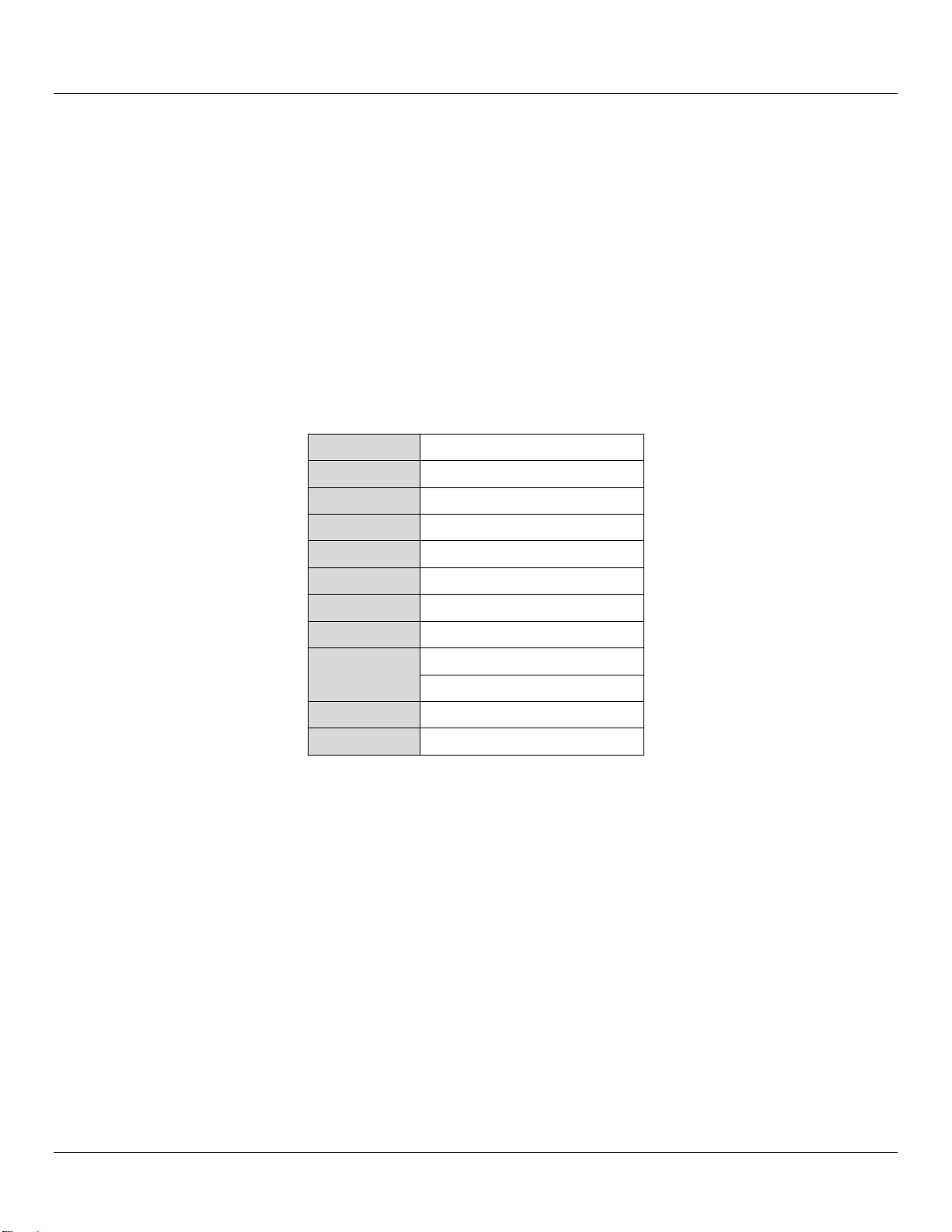

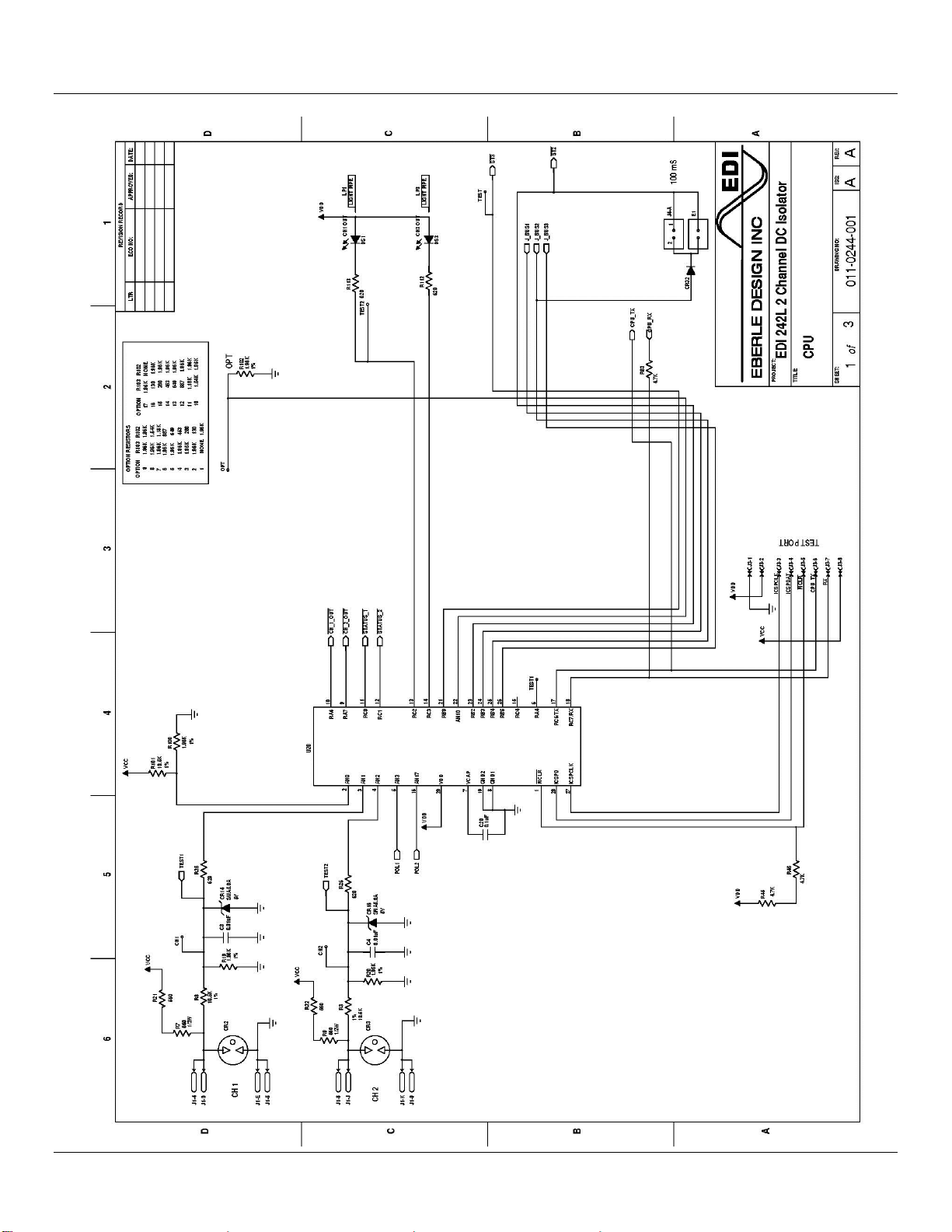

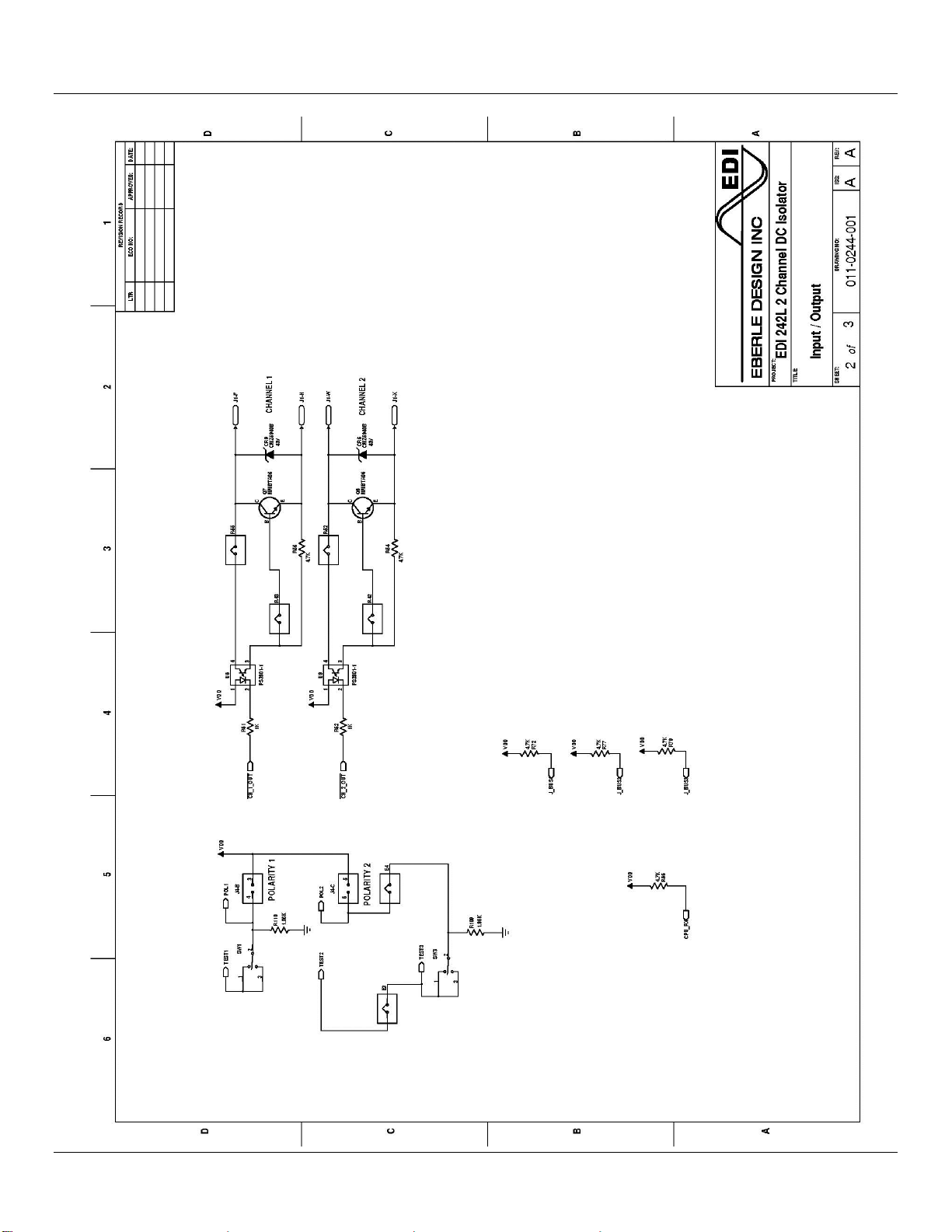

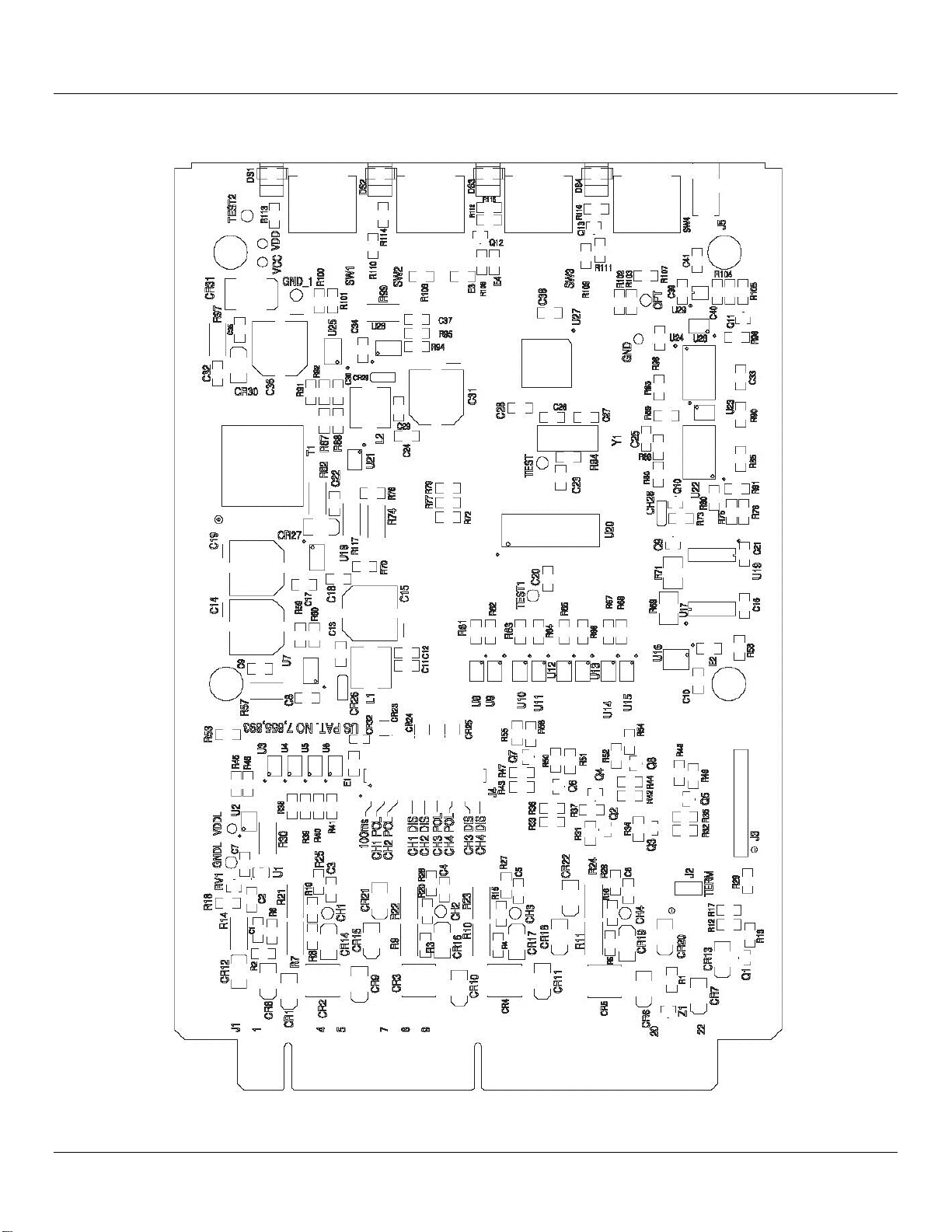

1.8 PARTS LIST AND SCHEMATIC

|------------------------------------------------------------------------------------------------------------------|

|Item|EDI Part Number|Qty|Description |Reference |Manufacturer |

|----+---------------+---+-------------------------------------------------+-------------------+-------------------|

|1 | |1 |(NO COMPONENT) |J1 | |

|2 | |1 |(no component) |J3 | |

|3 | |10 |(NO COMPONENT) |CH1-2 GND GND_1 OPT| |

| | | | |TEST TEST1-2 VCC | |

| | | | |VDD | |

|4 | |1 |(NO COMPONENT) |E1 | |

|5 | |2 | |M1-2 | |

|6 |215-0033-S |2 |RESISTOR, 1/2W, 0.33 OHMS, 5%, 2010 surface mount|R74 R99 | |

|7 |215-0180-S |1 |RESISTOR, 1/2W, 1.8 OHMS, 5%, 2010 surface mount |R14 | |

|8 |215-3310-S |1 |Resistor, 330 OHM, 1/2W, 5%, 2010 surf. mnt. |R117 | |

|9 |215-5610-S |4 |Resistor, 560 OHMS, 1/2W, 5%, 2010 surf. mnt. |R7 R9 R21-22 | |

|10 |215-5620-S |1 |Resistor, 5.6K OHMS, 1/2W, 5%, 2010 surf. mnt. |R82 | |

|11 |251-1052-S |3 |RESISTOR, 1/8W, 10.5K, 1%, 1206 surface mount |R3 R8 R101 | |

|12 |251-1211-S |3 |RESISTOR, 1/8W, 1.21K, 1%, 1206 surface mount |R70 R78 R92 | |

|13 |251-1961-S |7 |RESISTOR, 1/8W, 1.96K, 1%, 1206 surface mount |R19-20 R95 R100 | |

| | | | |R102 R109-110 | |

|14 |251-5901-S |1 |RESISTOR, 1/8W, 5.90K, 1%, 1206 surface mount |R94 | |

|15 |251-8061-S |1 |RESISTOR, 1/8W, 8.06K, 1%, 1206 surface mount |R91 | |

|16 |255-0000-S |6 |RESISTOR, 1/8W, 0 OHMS, 5%, 1206 surface mount |E3-4 R42-43 R52 R55| |

|17 |255-1020-S |3 |RESISTOR, 1/8W, 1K, 5%, 1206 surface mount |R61-62 R88 | |

|18 |255-4310-S |1 |RESISTOR, 1/8W, 430 Ohm, 5%, 1206 surface mount |R87 | |

|19 |255-4720-S |9 |RESISTOR, 1/8W, 4.7K, 5%, 1206 surface mount |R45-46 R54 R56 R72 | |

| | | | |R77 R79 R83 R86 | |

|20 |255-6210-S |4 |RESISTOR, 1/8W, 620 Ohm, 5%, 1206 surface mount |R25-26 R112-113 | |

|21 |261-1200-S |1 |RESISTOR, PULSE RATED, 3/4W, 12 OHMS, 5%, 2010 |R97 |SEI |

| | | |smt | | |

|22 |300-3370-035S |4 |CAPACITOR, ELECTROLYTIC, 330uF, 35V, LOW ESR, |C14 C19 C31 C36 |ILLINOIS |

| | | |20%, SMT | |337AXZ035MD10 |

|23 |320-1010-100S |2 |CAPACITOR, CER.MULT, 100pF, 100V, 5%, NPO,1206 |C32 C34 |Samsung |

| | | |CHIP | |CL31C101JCCNFNC |

|24 |320-1020-050S |2 |CAPACITOR, CER.MULT, 0.001uF, 50V, 10%, 1206 CHIP|C18 C30 | |

|25 |320-1030-100S |2 |CAPACITOR, CER.MULT, 0.01uF, 100V, 10%, 1206 CHIP|C3-4 | |

|26 |320-1040-050S |9 |CAPACITOR, CER.MULT, 0.1uF, 50V, 10%, 1206 CHIP |C9 C20 C22-25 C35 | |

| | | | |C37-38 | |

|27 |320-1060-025S |1 |CAPACITOR, CER.MULT, 10uF, 25V, 10%, 1206 CHIP |C29 |Samsung |