Edic Aviator User manual

AVIATOR

owner’s manual

& parts list

This equipment is intended for commercial use only.

1753 Blake Avenue ❑Los Angeles, CA 90031 ❑(800) 338-EDIC Or (323) 660-1635 ❑Fax (323) 667-0144

3009AF

3009AF-W

Order Parts Here:

www.ivie-ent.com/parts

Ph:(918)254-5161

BEFORE OPERATING THE MACHINE

Read the manual carefully and completely before attempting to operate the unit. This manual has

important information for the use and safe operation of the machine. Keep this manual handy at all

times. This machine will assure years of satisfactory service if operated and maintained according

to recommendations in this manual. If additional information is needed, please contact your local

distributor or write to:

EDIC

1753 Blake Avenue

Los Angeles, CA 90031-1006

Electrical 115 Volt

This machine is designed to operate on a standard 15 amp., 115 volt, 60 Hz, AC circuit. Voltages

below 105 volts AC or above 125 volts AC could cause serious damage to the motor.

Electrical 240 Volt

This machine is designed to operate on a standard 10 amp., 230 volt, 50 Hz, AC circuit.

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS BEFORE USING

DANGER

• Improper connection of the equipment’s grounding conductor can result in a risk of re, electric

shock or injury to person.

• Check with a qualied electrician or service person if you are in doubt as to whether the outlet is

properly grounded. Do not modify the plug provided with the air mover if it will not t the outlet.

Have a proper outlet installed by a qualied electrician.

WARNING

• This equipment is not designed to handle or use combustible/volatile substances such as

gasoline or kerosene, in, on, or near the machine. The use of such materials will cause an extreme

hazardous condition.

• Do not immerse or use this machine in standing water. Such use may cause electric shock.

• Disconnect the power cord from the outlet before servicing.

• Ensure that children do not have access to the equipment. Do not allow children to play with or

near the unit or in its air flow.

• Do not use with damaged cord or plug. If air mover is not working as it should, has been dropped,

damaged, left outdoors, or dropped into water, return it to an authorized service center.

• Repairs are only allowed by a qualied service center. Do not attempt to disassemble or repair

the unit if you are not qualied to do so. For information about authorized repair, call EDIC at

(800) 338-3342.

• When using an extension cord, use only a 3-prong conductor grounding cord 12 ga. wire or

heavier.

• Check GFCI protection before each use by pushing the “test” button. If operating properly the

“reset” button will pop out.

• Never operate with the safety grills removed. Personal injury may result.

• Do not plug more than 9.0 amps total into the GFCI outlet.

• To avoid electric shock, do not expose the unit to rain. Store it indoors only.

• Do not expose machine to freezing temperatures.

• Do not move or carry the unit when it is turned on.

• Do not pull or carry by the cord, use cord as a handle, close a door on the cord, or pull cord around

sharp edges or corners.

• Keep cord away from heated surfaces.

• Do not unplug by pulling on cord. To unplug the unit, grasp the plug, not the cord.

• Do not handle plug or air mover with wet hands.

• Do not put object into openings. Do not use with any opening blocked; keep free of dust, lint, hair

and anything that may reduce air flow.

• Keep hair, loose clothing, ngers and all parts of the body away from openings and moving parts.

• Turn off all controls before unplugging.

• Connect to a properly grounded outlet only. See grounding instructions.

• Operate unit on level and stable surface to prevent it from falling and possibly causing injury.

• Do not drop or throw the unit. Treatment of this type can cause damage to the components and

create a hazardous condition.

• To reduce the risk of re or electric shock, do not use this air mover with any solid-state speed

control devices.

FAILURE TO COMPLY WITH THE ABOVE WARNING INSTRUCTION

WILL VOID THE WARRANTY.

GROUNDING INSTRUCTIONS:

The 120 V. A/C and the 220 V. A/C models have been outtted with the appropriate grounded

connectors. Make sure the machine is connected to a grounded outlet having the same conguration

as the grounded plug. No adaptor should be used with this machine. Any modication to the

connectors will void the warranty.

INTENDED USE:

The Aviator is designed to blow air across wet surfaces for speed drying. The high-volume airflow

from the Aviator increases the rate of evaporation, helps prevent mold growth, and reduces the risk of

additional moisture damage.

POSITION SWITCH:

The 3-position drying mode selector switch is used to select the Aviator’s mode of operation. The 3

modes of operation are OFF, LOW or HIGH.

GFCI Protection and the OnBoard Duplex Vac Outlet:

The standard AC voltage outlet GFCI (Ground Fault Circuit Interrupter) protection promotes operator

safety in wet applications. GFCI devices trip when a fault to electrical “ground” is sensed.

It is recommended to check the GFCI protection prior to operation. To check, push the “TEST” button

located of the GFCI duplex outlet. If operating properly, the “RESET” button on the GFCI will pop out.

This duplex AC outlet allows the Interconnection of the other AC powered devices. The sum total

amperage of all devices plugged into the receptacle must not exceed 9 amps.

DAISY CHAINING:

The Aviator draws 2.3 amps. The 12 amp onboard circuit breaker will allow four (4) Aviators on one

circuit. Five (5) is too many for one circuit. When daisy chaining the Aviator, turn on one Aviator at a

time to prevent excessive current inrush caused by four units starting at once.

A ground fault in the Aviator or anywhere on the circuit will cause the Aviator’s GFCI to trip. After

rectifying the ground fault, reset the GFCI by pressing the reset button.

OPERATING PROCEDURES:

Plug the Aviator into a standard grounded outlet with correct voltage and amperage. Turn on the

switch and check that the unit operates properly before leaving it unattended. Do not carry or move

the Aviator when it is running.

MAINTENANCE:

1. Disconnect the power cord from the outlet before performing this maintenance procedure.

2. Inspect the electrical cord and wiring for damage or discoloration.

3. Inspect for loose fasteners.

4. Clean screens on the side and front of the unit.

5. Listen for abnormal sounds.

6. Keep unit clean.

7. Motor does not require lubrication.

PERIODIC MAINTENANCE:

Use compressed air or a vacuum to remove lint, etc, from the motor, screen or blower. Do not wet the

motor or the wiring. Do not use a pressure washer to clean the unit.

TROUBLESHOOTING

…MOTOR WON’T RUN

POSSIBLE CAUSE SOLUTION

No power to unit… Plug in the unit; check circuit breaker or fuse.

Switch not turned on… Turn on the switch.

Switch is defective… Call your local distributor for a replacement.

Defective power cord… Call you local distributor for a replacement.

Capacitor is defective… Call your local distributor for a replacement.

Fan blade jammed… Turn machine off, remove material jamming blade.

Intake or exhaust grill blocked… Turn machine off, allow to cool, remove blockage.

Loose wiring… Check wiring and tighten as needed.

…MOTOR RUNS BUT BLADE SCRAPES

POSSIBLE CAUSE SOLUTION

Severe jolt has caused motor mount

to bend and fan blade to rub…

Remove motor from housing, then replace or repair bent

motor mount.

…UNIT VIBRATES EXCESSIVELY

POSSIBLE CAUSE SOLUTION

Accumulation of soil on fan blade… Clean fan blade.

Fan blade has lost balance… Balance or replace fan blade.

Fan blade has been bent… Replace fan blade.

Bent motor shaft… Replace motor.

…DOES NOT OPERATE AT ALL SPEEDS

POSSIBLE CAUSE SOLUTION

Switch is defective… Call your local distributor for a replacement.

Capacitor is defective… Call your local distributor for a replacement.

…UNIT MAKES ABNORMAL SOUNDS

POSSIBLE CAUSE SOLUTION

Defective motor… Call your local distributor for a replacement.

Foreign object stuck… Remove material jamming blade.

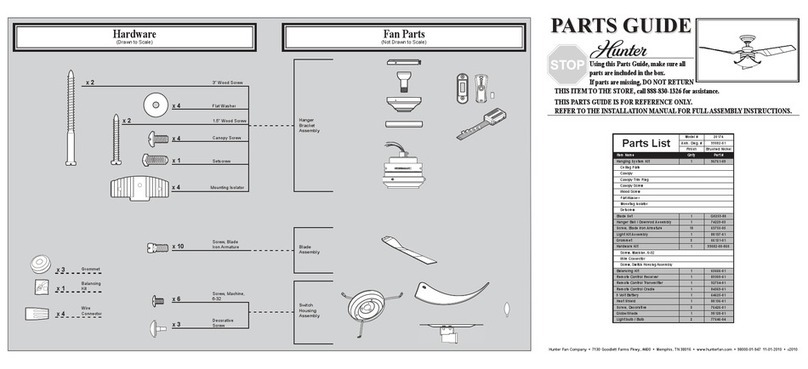

1 2 5 6 7 8 9 10

11

12

13

1819

23

14

27

28

29

30

32

21

34 33

20

22

262524

353637384041

4

3009AF-W

7-7-08

3009AF-W

7-7-08

3

15

1617

39

31

ITEM

NO.

PART NUMBER

DESCRIPTION

QTY.

1

F12111-1 Housing - Axial Fan

1

2

F00463-2 Corrugated Loom, .25 X 6 in

1

3

B13095 Bullet Splice, 16-10 AWG

2

4

B00185-40 Wire, 14GA Black, UL1015, 25 in

1

5

B00185-30 Wire, 14 Ga White, UL1015, 18 in

1

6

B00190 Nylon Tie, 4 in

3

7

C13122 10-24 X .375 SHCS, SS

8

8

D12133 Bracket, Motor Mount, Fan

4

9

C13025 Hex Nut, 10-32 W-Star

8

10

D12112 Grille, Axial Fan

2

11

C13093 #8 X .75 Phil, Flat

6

12

G12117 Motor, Axial Fan, 110V

1

13

B02214 Strain Relief Nut, (O)

1

14

C00310-38 Screw, 8-32 X .375 RH Mach

2

15

B00180-10-3 Ring Terminal, #10 Center

1

16

B11720 Flag Connector (yellow)

1

17

B10980 Flag Connector (blue)

7

18

B02212 Strain Relief W-Nut, (O)

1

19

H11831 Label, EDIC, Black-Silver

1

20

C13090 #6 X .375 Phil Pan

6

21

B12120 Circuit Breaker, 12 AMP

1

22

D13049 Switch Plate, Axial Fan

1

23

G12129 Fan, Axial, 40 Degree

1

24

C13119 Hex Nut, 6-32 KEP

2

25

B12976 Hour Meter, 110-220V

1

26

C13118 6-32 X .375 Phil

2

27

B12914 Ground Fault Interrupter

1

28

C13120 Hex Nut, 8-32 KEP

2

29

B11751 Switch, Rocker, DPDT, Black

1

30

B11756 Indicator Light, Green

1

31

H02548-2 Label, Important

1

32

B10719 Power Cord, 25', 16-3

1

33

B11821 Strain Relief, Aqua Dri

1

34

B11832 Strain Relief Nut

1

35

H13031 Label, Electric Shock

1

36

H03545 Cover, Serial # Label

1

37

H00565-5 Label, Serial Number

1

38

K13076 Bumper, Foot, w-Steel

8

39

C13092 10-24 X .75 Phil Pan Head

8

40

G13075 Socket for Swivel Caster

3

41

G13074 Caster, Swivel, 3 X .187 in

3

3009AF-W

ITEM # PART # DESCRIPTION QTY

1. F-12111-1 Green Housing - Axial Fan 1

2. F00463-2 Corrugated Loom, .25 x 6 in 1

3. B13095 Bullet splice, 16-10 AWG 2

4. B00185-40 Wire, 14GA Black, UL1015, 25 in 1

5. B00185-30 Wire, 14GA White, UL1015, 015,18 in 1

6. B00190 Nylon Tie, 4 in 3

7. C13122 10-24 X .375 SHCS, SS 8

8. D12133 Bracket, Motor Mount, Fan 4

9. C13025 Hex Nut, 10-32 W-Star 8

10. D12112 Grille, Axial Fan 2

11 C13093 #8 X .75 Phil, Flat 6

12 G12117 Motor, Axial Fan, 110V 1

13 B02214 Strain Relief Nut, (O) 1

14 C00310-38 Screw, 8-32 X .375 RH Mach 2

15 B00180-10-3 Ring Terminal, #10 Center 1

16 B11720 Flag Connector (Yellow) 1

17 B10980 Flag Connector (Blue) 7

18 B02212 Strain Relief W-Nut, (O) 1

19 H11831 Label, EDIC, Black-Silver 1

20 C13090 #6 X .375 Phil Pan 6

21 B12120 Circuit Breaker, 12 AMP 1

22 D13049 Switch Plate, Axial Fan 1

23 G12129 Fan, Axial, 40 Degree 1

24 C13119 Hex Nut, 6-32 KEP 2

25 B12976 Hour Meter, 110-220V 1

26 C13118 6-32 X .375 Phil 2

27 B12914 Ground Fault Interrupter 1

28 C13120 Hex Nut, 8-32 KEP 2

29 B11751 Switch, Rocker, DPDT, Black 1

30 B11756 Indicator Light, Green 1

31 H02548-2 Label, Important 1

32 B10719 Power Cord, 25’, 16-3 1

33 B11821 Strain Relief, Aqua Dri 1

34 B11832 Strain Relief Nut 1

35 H13031 Label, Electric Shock 1

36 H03545 Cover, Serial # Label 1

37 H00565-5 Label, Serial Number 1

38 K13076 Bumper, Foot, WSteel 8

39 C13092 10-24 X .75 Phil Pan Head 8

40 G13075 Socket for Swivel Caster 3

41 G13074 Caster, Swivel, 3 X .187 in 3

1753 Blake Avenue ❑Los Angeles, CA 90031 ❑(800) 338-EDIC Or (323) 660-1635 ❑Fax (323) 667-0144

ZF13167

This manual suits for next models

2

Table of contents