EDILGRAPPA MU 22N Operation instructions

MACHINE BODY

WITH INTERCHANGEABLE HEADS

USE AND MAINTENANCE

INSTRUCTIONS

MANUAL

2

MACHINE BODY

WITH INTERCHANGEABLE HEADS

MU22N

USE AND MAINTENANCE

INSTRUCTIONS

MANUAL

MU 22N

2

MU22N MACHINE BODY WITH INTERCHANGEABLE HEADS

AVAILABLE IN THE FOLLOWING VERSIONS:

·MU22N SINGLE-PHASE ELECTRIC MOTOR 230 V 50 Hz P/N 1.50.1952

AVAILABLE HEADS NAME P/N

T22 CUTTING HEAD 1.50.117

P22 CUTTING HEAD 1.50.1915

TS 500 STONE CUTTING HEAD 1.50.106

TW19 CUTTING HEAD 1.50.118

TF32 CUTTING HEAD 1.50.064

TR40 CUTTING HEAD 1.50.061

RD26 NUT-CRACKING HEAD 1.50.115

D180 SPREADING HEAD 1.50.112

MU 22N

3

INDEX

0 DESCRIPTION OF THE MACHINE......................................................5

0.01 MACHINECOMPONENTS......................................................................................................5

0.02 SAFETYAND DANGERSTICKERS -CE PLATE ...................................................................6

0.03 LIST OF ACCESSORIES INCLUDED IN THE SUPPLY...........................................................6

1 TECHNICAL FEATURES.....................................................................7

1.01 HYDRAULIC, MECHANICAL AND ELECTRICAL SPECIFICATIONS....................................7

2 DELIVERY, COMMISSIONING AND SET-UP......................................8

2.01 DELIVERY...............................................................................................................................8

2.02 ELECTRIC MOTOR.................................................................................................................8

2.02.01 ELECTRICAL CONNECTIONS......................................................................................8

2.02.02 COMMISSIONING .........................................................................................................8

2.03 MANUAL RETURN LEVER.....................................................................................................9

2.04 MOUNTING THE TOOL HEADS..............................................................................................9

2.05 EQUIPMENT OPERATION....................................................................................................10

2.05.01 STARTING...................................................................................................................10

2.06 FORESEEN USEAND RESIDUAL RISKS............................................................................10

3 ROUTINE MAINTENANCE.................................................................12

3.01 CHANGING AND TOPPING UP THE OIL..............................................................................12

3.02 CHECKING SCREWS...........................................................................................................14

3.03 HYDRAULIC COMPONENTS................................................................................................14

3.03.01 MANUAL RETURN VALVE DOES NOT CLOSE..........................................................14

3.03.02 MAX. PRESSURE VALVE INCORRECTLY ADJUSTED..............................................14

3.03.03 MAIN CHECKS ON THE MOTOR................................................................................14

4 POTENTIAL PROBLEMS AND MEASURES TO BE ADOPTED

.................15

4.01 GENERAL.............................................................................................................................15

4.02 TROUBLESHOOTING THE MOTOR.....................................................................................15

4.03 TROUBLESHOOTING THE HYDRAULIC COMPONENTS ...................................................16

5 STORAGE AND RESTARTING..........................................................17

5.01 STORAGE.............................................................................................................................17

5.01.01 ELECTRIC MOTOR.....................................................................................................17

5.01.02 CYLINDER AND HYDRAULIC COMPONENTS...........................................................17

5.02 RESTARTING .......................................................................................................................17

6 MACHINE DISPOSAL.........................................................................18

MU 22N

4

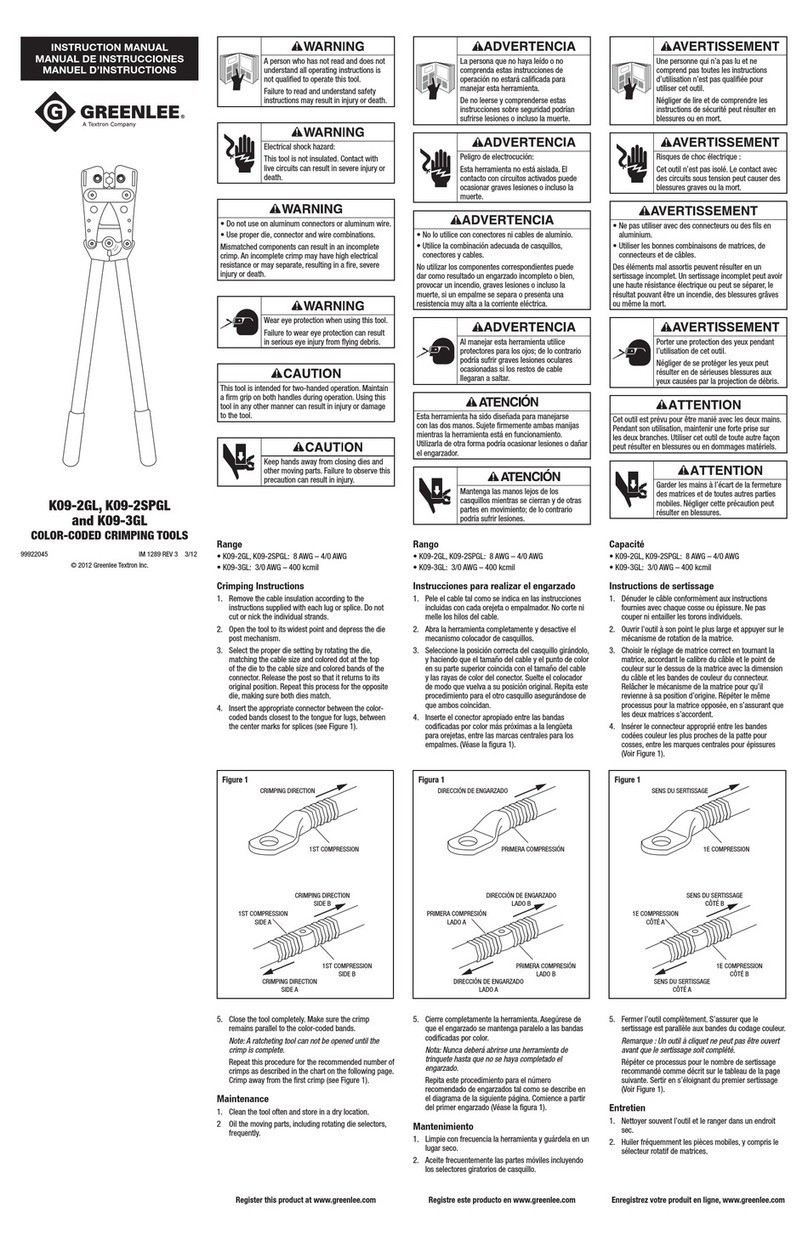

A brief legend indicating the most important symbols used in this manual is shown below.

THIS SYMBOL WARNS USERS TO PAY SPECIAL ATTENTION WHEN FOLLOWING

THE RELATIVE INSTRUCTIONS.

FAILURE TO OBSERVE THESE INSTRUCTIONS CAN CAUSE THE MACHINE TO

OPERATE INCORRECTLY.

THIS SYMBOL INDICATES POSSIBLE HAZARDS, TAKE ALL PRECAUTIONS TO

PREVENT THESE SITUATIONS FROM OCCURRING.

BEFORE WORKING ON THE MACHINE, CAREFULLY READ ALL THE

INSTRUCTIONS, ESPECIALLY THOSE CONTAINED IN BOXES.

“OPERATOR”: A person suitably trained and authorised to operate,

adjust, clean and transport the machine.

“MAINTENANCE MAN”: A person trained and authorised to perform routine

maintenance on the machine and replace certain

components.

“MACHINE BODY”: The equipment described in this manual.

“ELECTRIC TOOL”: Used in the safety precautions, it is a more general

definition of the machine in question as it refers to

mains-powered electric tools (with cable) or battery-

powered electric tools (cordless).

MU 22N

5

0 DESCRIPTION OF THE MACHINE

CAUTION!! FIRST READ THE MANUAL REGARDING THE GENERAL AND SAFETY

REGULATIONS!

0.01 MACHINE COMPONENTS

This machine is fitted with a single-phase alternating current motor.

The equipment comprises:

- a motor,

- a hydraulic pump driven by the motor,

- a rod actuator (piston) driven by the oil pressured by the pump,

- an interchangeable head with tool (purchased separately).

Figure 1 shows the main parts of the equipment, in particular:

1. cylinder with hydraulic components

2. head supporting surface and centring guides

3. release lever or double-acting lever

4. grip with start button

5. electrical connecting cable complete with plug

6. electric motor

7. oil cap

8. head locking ring

MU 22N

6

0.02 SAFETY AND DANGER STICKERS - CE PLATE

Position of plate and safety and danger stickers on the machine:

Observe the warnings on the plates and stickers. Failure to do so could lead to

injury or death. Make sure the plates and stickers are attached and legible. If not,

apply them or request the maker for replacements.

0.03 LIST OF ACCESSORIES INCLUDED IN THE SUPPLY

·Case

·General safety rules, Use and maintenance instructions

·Declaration of conformity

·Warranty certificate

·Emergency key

DANGER

BEWARE OF

HANDS

3

DANGER

FLYING

SPLINTERS

MU 22N

7

1 TECHNICAL FEATURES

1.01 HYDRAULIC, MECHANICAL AND ELECTRICAL SPECIFICATIONS

Maximum cutting size and characteristics of material [ mm

and daN/mm2 ] Ø22 mm / R=65 daN/mm²

Maximum output force from rod [ t ] 24

Maximum operating pressure [ bar ] 580

Dimensions: Length X Width X Height [ mm ] 402 X 145 X 236

Weight [ kg ] 13.3

Guaranteed no-load LwA sound level (CEI EN 60745-1

and CEI EN 60745-2-8) [ dB ] 101

No-load operator Lpa (CEI EN 60745-1 and CEI EN

60745-2-8) [ dB ] 90

Vibrations when cutting diam. 22 mm rod (CEI EN 60745-1

and EN ISO 5349) 2.12 m/s²

Input voltage [ V ] 230

Frequency [ Hz ] 50

Electrical power [ W ] 1400

Input current [A] 6.8

Insulation class II

RPM 14000

MU 22N

8

2 DELIVERY, COMMISSIONING AND SET-UP

2.01 DELIVERY

The machine is normally shipped and delivered inside

a special hard case, well secured and in a stable

position (see adjacent figure). All the ordered material

is inspected before delivery to the customer.

Upon receipt, check the machine for any damage (breakages or major denting)

caused during transport. If so, immediately inform the shipping company and write

the “Accepted subject to checking" clause on the Delivery note.

In the event of damage, send

a written complaint to the forwarder within 8 days of

receipt.

Promptly inform Edilgrappa s.r.l. if major damage, caused during transport, is

found upon receipt, or if any parts are missing.

Also check the delivered materials against the detailed

shipping list.

The machine can be moved easily both when it is inside its special rigid case, using the

upper handle, and by gripping its upper or lower handle.

Loads must be moved in compliance with current occupational safety regulations.

After

use, put the machine back into its case or place it on a stable surface, making sure

this can withstand its weight.

2.02 ELECTRIC MOTOR

2.02.01 ELECTRICAL CONNECTIONS

THE USER SYSTEM AND THE RESPECTIVE CONNECTIONS MUST BE MADE IN

STRICT OBSERVANCE O

F THE REGULATIONS IN FORCE, BY COMPETENT

PERSONNEL QUALIFIED TO DO THE JOB.

BEFORE CONNECTING THE APPLIANCE USING THE PLUG SOCKETS, TURN THE

MAIN SWITCH TO ITS OPEN POSITION "O".

2.02.02 COMMISSIONING

Upon receipt, check the machine for any damage (breakages or major denting)

caused during transport. If so, immediately inform the shipping company and write

the “Accepted subject to checking" clause on the Delivery note.

a written complaint to the forwarder within 8 days of

Promptly inform Edilgrappa s.r.l. if major damage, caused during transport, is

shipping list.

The machine can be moved easily both when it is inside its special rigid case, using the

Loads must be moved in compliance with current occupational safety regulations.

use, put the machine back into its case or place it on a stable surface, making sure

THE USER SYSTEM AND THE RESPECTIVE CONNECTIONS MUST BE MADE IN

F THE REGULATIONS IN FORCE, BY COMPETENT

BEFORE CONNECTING THE APPLIANCE USING THE PLUG SOCKETS, TURN THE

MU 22N

9

These machines do not need any adjustment or particular precautions before

commissioning.

The only controls to perform concern:

- Machine integrity:

make sure that nothing happened during transport that could damage the insulation or

mechanical parts.

- Completeness of supply:

check that all the supplied accessories are fitted.

- Oil level:

check the oil level and top up if necessary as per the instructions in Para 3.01.

IMPORTANT: Before loosening the oil cap carefully read the instructions in Para

3.01.

2.03 MANUAL RETURN LEVER

The manual return lever has two positions (see fig. 2)

-Position 1: valve closed. The piston work and return stroke takes place

automatically.

-Position 2: valve open. To interrupt the work stroke or in case of emergency

move the lever to position 2 to return the piston to

its home position.

IMPORTANT: If the machine does not work make sure the manual return lever is in

position 1.

2.04 MOUNTING THE TOOL HEADS

1

CLOSED

2

OPEN

MU 22N

10

IMPORTANT: Before mounting any head on the machine body,

piston rod (n° 1, 2, 3, 4, 5 in the following figure), the supporting surfaces and the

centring guides.

To mount the head, follow the instructions in the “

Commissioning

Maintenance Instructions relative to the specific head.

2.05 EQUIPMENT OPERATION

2.05.01 STARTING

Insert the plug in a suitable power socket and follow the instructions below, depending on

the kind of machine involved.

2.05.02 OPERATING PHASE

The operating phase is strictly connected to the type of head applied to the machine

body. Follow the instructions in the “Operating”

section of the Use and Maintenance

Instructions relative to the specific head.

IMPORTANT: Before starting work, scrupul

ously follow the general precautions for

use and carefully consider the conditions of use bearing in mind the technical

specifications.

2.06 FORESEEN USE AND RESIDUAL RISKS

IMPORTANT: Before mounting any head on the machine body,

carefully clean the

piston rod (n° 1, 2, 3, 4, 5 in the following figure), the supporting surfaces and the

Commissioning

” section of the Use and

Insert the plug in a suitable power socket and follow the instructions below, depending on

The operating phase is strictly connected to the type of head applied to the machine

section of the Use and Maintenance

ously follow the general precautions for

use and carefully consider the conditions of use bearing in mind the technical

MU 22N

11

Follow the indications concerning foreseen use and residual risks contained in the

use and maintenance manual of the work head attached to the machine.

The machine must only be used with heads that are compatible with the machine body in

question, as indicated on page 2 of this manual. The heads must be EDILGRAPPA s.r.l.

and purchased from an authorised dealer. The machine has been designed and

developed to operate in fields, such as building and industry, and for emergency/rescue

operations.

The machine may only be used if powered by an electrical system compliant with

legislation and current law (suitably connected to an earth system and protected from

current surges and short circuits).

Any use other than that expressly indicated shall be considered as improper and

therefore not permitted.

Edilgrappa S.r.l. declines all liability for any improper use of the machine and for any

modification or change made to it.

Operators must observe the instructions in this manual and in the manual of the head

fitted to the machine in order to minimise the risk of accidents. In particular, they must pay

attention when working in conditions that could cause:

- Possible burns from overheated metal parts;

- Injury due to incorrect positioning or inadequate lifting or moving

- Injury caused by splinters discharged from the work piece.

People remaining in the vicinities of the machine while it is working are subject to the

following risks:

- flying debris (dangerous objects, etc…);

Operating temperature -40° ÷ +50° C

·It is strictly forbidden to use the machine for purposes other than those

indicated in this installation and maintenance manual.

·It is forbidden to use the machine in areas subject to the risk of explosion.

MU 22N

12

3 ROUTINE MAINTENANCE

1.All maintenance, inspection and cleaning operations must be performed

with the power supply disconnected and the machine cool (see the person

responsible in the maintenance schedule);

2. Maintenance operations must be performed in a suitable place according to

current safety regulations;

3. Before any maintenance intervention, thoroughly clean the machine (see

Paragraph 5.01);

4. Wear suitable personal protective equipment while performing maintenance

work.

AFTER MAINTENANCE WORK, MAKE SURE THE GUARDS ARE PUT BACK INTO

THEIR CORRECT PLACE.

Periodic maintenance schedule

Frequency Operation Method Person

EVERY 8 HOURS

·

CHECK THE INTEGRITY OF THE

MACHINE Visual Operator

/ ·CLEAN THE PISTON Para 3.04.01

Operator

EVERY 1600

HOURS ·CHANGE THE OIL Para 3.01 Maintenance

man

EVERY 8 HOURS

·

CHECK THE TIGHTNESS OF NUTS AND

BOLTS Para 3.02 Operator

If you have any doubts about ordering spare parts or performing complex

maintenance work, contact your authorised dealer.

3.01 CHANGING AND TOPPING UP THE OIL

When changing or topping up the oil, make sure no impuritiescontaminate the oil or enter

the tank. Impurities in the oil can irreparably damage the hydraulic components.

ALWAYS MAKE SURE THE OIL CONTAINS NO IMPURITIES

DO NOT USE DIRTY TOOLS

DO NOT WORK IN DUSTY AREAS

CHANGING THE OIL:

USING A SUITABLE DISPENSER, PREPARE THE CORRECT QUANTITY OF OIL (0.6

l) TO POUR INTO THE TANK.

LEAKING OIL CAN CAUSE SHORT CIRCUITS, FIRE AND EXPLOSIONS.

1. Place the machine horizontally in a stable position on a work surface with the magnetic

cap (fig. 3) facing upwards. Place a basin under the machine to catch any oil leaks;

2. Unscrew the magnetic cap (fig. 4) and remove any residues with the piston in its

retracted position;

3.

Totally drain the oil tank using a suitable extraction system (used oil extraction pump)

so that no oil can leak into the machine;

4. Loosen the vent screw (fig. 5);

5.

Slowly pour in the correct quantity of oil (0.6 l) using suitable equipment (e.g. as shown

in fig. 6). Only use new or clean recommended oil (as indicated on the next page);

6. Fill up to the upper rim of the hole;

7. Put back the oil cap and the vent screw and tighten slightly;

8. Perform some piston strokes to vent the large air bubbles;

9.

Move the piston to its maximum extension and rapidly start and stop the motor several

times (before the piston automatically retracts);

10.Complete filling;

11.

Put back the oil cap and vent screw and tighten (figs. 4 and 5).

TOPPING UP THE OIL:

Before unscrewing the magnetic cap to check the oil level, make sure the piston is

fully

extended and, if necessary, pull it out. If this is not done the oil may leak, air

bubbles may form and/or the oil level may be incorrectly measured, thus causing

the machine to operate incorrectly.

Only after completing the above operations, proceed as

shown below:

1.

Place the machine horizontally in a stable position on a work surface with the filling

hole facing upwards. Place a basin under the machine to catch any oil leaks;

2.

Move the piston to its maximum extension and rapidly start and stop the motor s

times (before the piston automatically retracts);

3.

Unscrew the magnetic cap (see fig. 4) and remove any residues;

4. Check the amount of missing oil;

5.

Loosen the vent screw (fig. 5) and slowly top up to the upper rim of the hole with

recommended new and

clean oil using suitable equipment (e.g.: as indicated in fig. 6);

6. Put back the oil cap and vent screw and tighten (figs. 4 and 5).

VENT SCREW

MAGNETIC CAP

MU 22N

13

Totally drain the oil tank using a suitable extraction system (used oil extraction pump)

Slowly pour in the correct quantity of oil (0.6 l) using suitable equipment (e.g. as shown

in fig. 6). Only use new or clean recommended oil (as indicated on the next page);

Move the piston to its maximum extension and rapidly start and stop the motor several

Put back the oil cap and vent screw and tighten (figs. 4 and 5).

Before unscrewing the magnetic cap to check the oil level, make sure the piston is

extended and, if necessary, pull it out. If this is not done the oil may leak, air

bubbles may form and/or the oil level may be incorrectly measured, thus causing

shown below:

Place the machine horizontally in a stable position on a work surface with the filling

hole facing upwards. Place a basin under the machine to catch any oil leaks;

Move the piston to its maximum extension and rapidly start and stop the motor s

everal

Unscrew the magnetic cap (see fig. 4) and remove any residues;

Loosen the vent screw (fig. 5) and slowly top up to the upper rim of the hole with

clean oil using suitable equipment (e.g.: as indicated in fig. 6);

MU 22N

14

Maximum quantity: 0.6 l.

Type of hydraulic oil: ESSO NUTO H46 or

homologated equivalents HLP46

according to DIN 51 524 MIL-

H 17672 C

When demolishing the machine or parts of it (oil, plastic, etc.) observe the

regulations in force in the country in which this operation is performed.

3.02 CHECKING SCREWS

Periodically, or every day in the event of frequent or

prolonged work, make sure that all

the screws are perfectly tight.

FAILURE TO TIGHTEN LOCKING SCREWS CAN CAUSE SERIOUS DAMAGE.

3.03 HYDRAULIC COMPONENTS

3.03.01 MANUAL RETURN VALVE DOES NOT CLOSE

If the piston is unable to perform another stroke

make sure the manual return lever is

closed.

3.03.02 MAX. PRESSURE VALVE INCORRECTLY ADJUSTED

In case of a pressure drop for a reason that cannot be directly identified, have

maintenance man or the maker

check the maximum pressure valve is clean and

calibrated.

3.03.03 MAIN CHECKS ON THE MOTOR

- Keep the motor surfaces clean, especially the fins on the head

- Keep the motor cooling slits clean and unobstructed

- Check the brushes for wear: replace them with

authentic spare parts when their length

is less than 5mm.

H 17672 C

When demolishing the machine or parts of it (oil, plastic, etc.) observe the

regulations in force in the country in which this operation is performed.

prolonged work, make sure that all

FAILURE TO TIGHTEN LOCKING SCREWS CAN CAUSE SERIOUS DAMAGE.

make sure the manual return lever is

In case of a pressure drop for a reason that cannot be directly identified, have

a

check the maximum pressure valve is clean and

authentic spare parts when their length

MU 22N

15

4 POTENTIAL PROBLEMS AND MEASURES TO BE ADOPTED

4.01 GENERAL

Faults can be divided into three sections:

1. faults on the motor

2. faults on the head

3. faults not closely connected with the machine

ALL OPERATIONS MUST BE PERFORMED BY QUALIFIED PEOPLE IN

OBSERVANCE OF SAFETY REGULATIONS.

WORK ON THE MACHINE DURING THE WARRANTY PERIOD MUST BE

PERFORMED AT THE MAKER'S FACILITY

Remedies marked with the letter R require the assistance of the Authorised dealer.

The remedies marked by the letter M require the intervention of the Manufacturer.

Remedies marked with the letter O can be performed by the Operator.

4.02 TROUBLESHOOTING THE MOTOR

FAULT POSSIBLE REASON

POSSIBLE REMEDY PERFORMED BY

MOTOR DOES NOT

START

Broken power cable Replace cable with one having

the same specifications M

Faulty plug Replace M

Stator windings Replace R

Rotor windings Replace R

Switch Replace R

No electric power Check the line and the cable

protections M

ELECTRIC MOTOR

OVERHEATED

Worn brushes Replace R

Worn manifold Replace or overhaul R

Insufficient power

supply

Check the line, the protections of

the electric panel and the

tightness of the connection

terminals

M

Partial fault of the

stator windings Replace R

Partial fault of the

rotor windings Replace R

Windings dirty Clean M

Ventilation slits

obstructed Clean O

Fan broken Replace R

Motor supports worn Replace R

Mechanical faults on

the head Overhaul R

MU 22N

16

FAULT POSSIBLE REASON

POSSIBLE REMEDY PERFORMED BY

ELECTROMAGNETIC

DISTURBANCES IN

LINE

Fault in anti-

disturbance filter Replace R

Manifold worn Replace R

Brushes worn Replace R

4.03 TROUBLESHOOTING THE HYDRAULIC COMPONENTS

FAULT POSSIBLE REASON POSSIBLE REMEDY

PERFORMED

BY

OUTWARD

STROKE DOES

NOT BEGIN

Return stroke incomplete Push back the piston O

Return spring broken (if present) Replace O

Max. pressure valve dirty

Consult the Maker

/

Manual return valve dirty Clean O

Manual return valve faulty Repair M

Oil tank empty Fill O

Valve remains open due to built-up

dirt

Clean O

MOTOR DOES

NOT STOP Earth cable interrupted Repair M

Earth cable rusted Clean O

OUTWARD

STROKE

INCOMPLETE No oil Top up O

OUTWARD

STROKE

DISCONTINUOUS

Air bubbles in the hydraulic

circuit Vent O

Max. pressure valve open due to

built-up dirt Consult the Maker /

Pump faulty or dirty Replace M

Piston gasket faulty Replace M

Pump O-ring Replace M

RETURN STROKE

INCOMPLETE Dirt between piston rod and tool Move the piston to its end-

of-stroke position and clean O

Return spring broken Replace O

NO FORCE

Oil hydraulic pump faulty Replace M

Dirt on oil hydraulic pump valve Replace M

Max. pressure valve open Replace M

Piston gasket worn Replace M

Pump O-ring broken Replace M

PISTON DOES

NOT

AUTOMATICALLY

REVERSE

STROKE

Automatic reverse valve faulty Replace M

OIL LEAKS ROM

TANK COVER Membrane faulty Replace O

MU 22N

17

5 STORAGE AND RESTARTING

5.01 STORAGE

In case of long periods of inactivity, proceed as follows:

5.01.01 ELECTRIC MOTOR

- Clean all the internal electrical parts (rotor, stator, cooling circuit) with compressed air

DO NOT USE CONDUCTIVE OR FLAMMABLE LIQUIDS TO CLEAN INTERNAL

ELECTRICAL PARTS

- To clean the outside of the machine, if necessary, use a cloth dampened in soapy

water and then dry thoroughly

- Check the following are in good condition:

• insulation

• power cable

• switches

• plug

• brushes and manifold

• clean the stator, rotor, cooling circuit and fan with compressed air

5.01.02 CYLINDER AND HYDRAULIC COMPONENTS

Before performing these operations, see the relative instructions in Chap. 3

·Check the hydraulic oil and top up or, if necessary, replace.

·Clean the magnetic cap and check the membrane.

·Check for any oil leaks.

·Tighten the screws.

Store the tool in a dry place that can only be accessed by authorised staff.

5.02 RESTARTING

Before performing these operations, see the relative instructions in Chap. 3

- Check the oil tank is full and top up if necessary

- Remove any traces of oil remaining after topping up or applied to protect metal parts

from the grip and other parts that can be gripped.

ELECTRIC MOTOR

- Ensure that the power cable, the plug and the machine body have not been damaged.

- Start the machine a few times and make sure no operating faults occur.

ELIMINATE ANY FAULTS BEFORE STARTING WORK.

MU 22N

18

6 MACHINE DISPOSAL

When disposing of themachine, the various materialsmust be separated.

The machine comprises the following groups of materials:

- ferrous materials

- copper

- plastic

Observe current legislation when sorting, storing, recycling or disposing of these materials.

Only for EU countries:

This electric tool features the following recycling symbol. Consistently with Directive 2002/96/EC on

waste electrical and electronic equipment (WEEE), at the end of its useful lifetime, this product must

be disposed of separately in suitable collection areas and not together with normal domestic waste. A

benefit for the environment and an advantage for all.

S.r.l.

Building, industrial and rescue machines and

equipment.

Via Callesello, 4 – 31030 BORSO DEL GRAPPA (TV)

Tel. (+39) 0423 910122 r.a.– Fax (+39) 0423 542122

www.edilgrappa.com

DECLARATION

OF CONFORMITY

Maker: EDILGRAPPA srl

Machines and equipment for the building trade, industry

and rescue

Via Callesello, 4

31030 Borso Del Grappa (TV)

Name and address of person

authorised to draw up

the technical brief: Giacomo Rorato

Via Callesello, 4

31030 Borso Del Grappa (TV)

Generic name:

Portable electric power tool (cordless)

Function: cutting metal rod Æmax 22 mm

Type: Electric shear

Model: MU 22N

Commercial name:

MU22N machine bodywith interchangeable heads

Serial number: ______________

Year of construction: ______________

DECLARES THAT THE ABOVE-

MENTIONED EQUIPMENT IS COMPLIANT WITH THE FOLLOWING

DIRECTIVES:

Machinery Directive 2006/42/EC (Proc. App. VIII)

EMC Directive 2004/108/EC

Low Voltage Directive 2006/95/EC

RoHS Directive 2011/65/EC

WEEE Directive 2002/96/EC

Place: Borso Del Grappa TV

Date....................

Signature

PAOLO MAZZARO

(legal representative)

Product Certified by ISET S.r.l. Notified body n° 0865:

MU 22N

19

Machines and equipment for the building trade, industry

Portable electric power tool (cordless)

MU22N machine bodywith interchangeable heads

MENTIONED EQUIPMENT IS COMPLIANT WITH THE FOLLOWING

Signature

PAOLO MAZZARO

(legal representative)

MU 22N

20

Srl

MACHINES AND EQUIPMENT FOR THE BUILDING TRADE,

INDUSTRY AND RESCUE

31030 BORSO DEL GRAPPA (TV) -ITALY -Via Callesello, 4

Tel. 0423 910122 – Fax 0423 542122

E-mail: cut@edilgrappa.com http: //www.edilgrappa.com

TRANSLATION OF THE ORIGINAL INSTRUCTIONS FROM ITALIAN LANGUAGE Revision 0 REPRODUCTION FORBIDDEN

Table of contents

Other EDILGRAPPA Power Tools manuals