EDILGRAPPA 230DE T10 Operation instructions

2

CONCRETE CRUSHER 230DE T10

USE AND MAINTENANCE

INSTRUCTIONS

MANUAL

2

3

HYDRAULIC TOOLS

ITEM

P/N

CONCRETE CRUSHER 230DE T10

1.50.2237

NOTE FOR THE USER:

THE USE OF THIS MACHINE IS ALLOWED PROVIDED IT IS CONNECTED TO A

HYDRAULIC POWER UNIT COMPLIANT WITH THE 2006/42/EC DIRECTIVE AND

WITH LEGISLATION IN FORCE AND IS SUITABLE FOR THE TECHNICAL FEATURES

OF THE MACHINE TO BE INSTALLED

4

INDEX

0 SAFETY AND DANGER STICKERS - CE PLATE.................................................................5

0.01 LIST OF ACCESSORIES SUPPLIED WITH THE TOOL................................6

1 TECHNICAL FEATURES.................................................................................................7

1.01DESCRIPTION ......................................................................................................7

1.02 TECHNICAL FEATURES....................................................................................7

2 DELIVERY AND HANDLING ..........................................................................................8

2.01 HANDLING, TRANSPORT AND LIFTING ........................................................9

3 COMMISSIONING .......................................................................................................9

3.01 PRELIMINARY CHECKS ....................................................................................9

3.02 HYDRAULIC CONNECTION............................................................................10

4 USE ...........................................................................................................................13

6.01 OPERATIVE DEMOLITION STAGE................................................................13

5 ROUTINE MAINTENANCE..........................................................................................15

5.01 CLEANING THE MACHINE ..............................................................................16

5.02 CHECKING THE SCREWS...............................................................................16

5.03 GREASING..........................................................................................................16

6 PROBLEMS AND REMEDIES........................................................................................17

7 STORAGE AND RE-COMMISSIONING .........................................................................18

7.01 STORAGE ...........................................................................................................18

7.02 RE-COMMISSIONING.......................................................................................18

8 MACHINE DISPOSAL ..................................................................................................18

9 SPARE PARTS AND ACCESSORIES CATALOGUE...........................................................19

9.01 ORDER INSTRUCTIONS..................................................................................19

5

0 SAFETY AND DANGER STICKERS - CE PLATE

CAUTION!! FIRST READ PART 1 OF THE MANUAL REGARDING THE GENERAL

AND SAFETY REGULATIONS!

Position of plate and safety and danger stickers on the machine:

6

0.01 LIST OF ACCESSORIES SUPPLIED WITH THE TOOL

Protective cover, if appropriate

Manual: Safety and use and maintenance instructions

Declaration of conformity

Warranty certificate

Simple repair keys, if appropriate

Observe the warnings on the plates and stickers. Failure to do so could lead

to injury or death. Make sure the plates and stickers are attached and

legible. If not, apply them or request the maker for replacements.

7

1 TECHNICAL FEATURES

1.01DESCRIPTION

The machine mainly consists of a stem actuator (piston) activated by pressurised oil

delivered by a hydraulic power unit. Figure 1 shows the main parts of the equipment, in

particular:

1. Cylinder;

2. Jaws;

3. Tips:

4. Handle;

5. Mechanically activated grip;

6. Twin hose with quick couplings;

7. Guard.

Fig. 1

1.02 TECHNICAL FEATURES

Maximum output force from rod [ t ]

21.8

Maximum force at the tip [ t ]

10

Maximum operating pressure [ bar ]

700

Maximum input flow rate [ l/min ]

6

Dimensions: Length X Width X Height [ mm ]

( with fully open jaws )

801 X 510 X 212

Maximum opening of the jaws [ mm ]

230

Mass [ kg ]

23.4

8

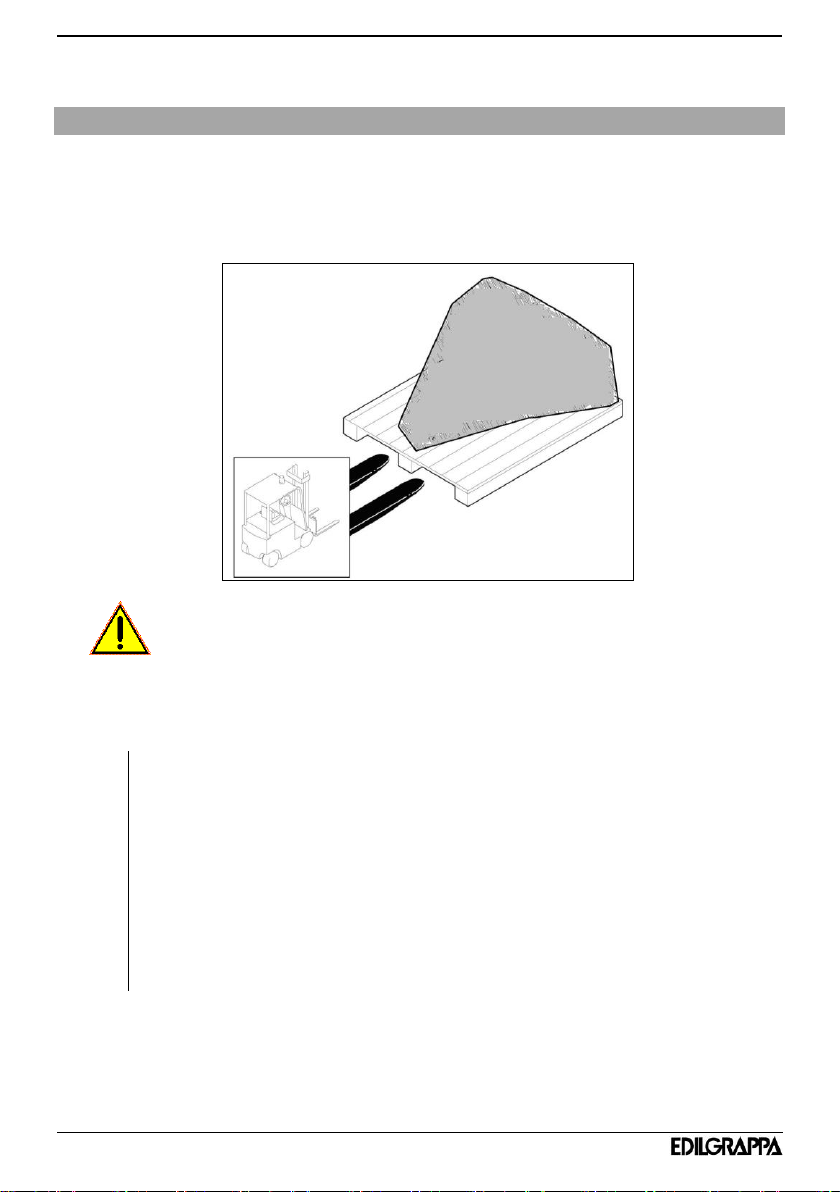

2 DELIVERY AND HANDLING

The crusher is usually shipped and delivered securely fixed onto a pallet, in a stable

position and appropriately wrapped in cellophane. The type of packaging can vary

according to the chosen means of transport and the destination. All the ordered

material is inspected before delivery to the customer.

CAUTION:

The packaging unloading must be performed with extreme care by means of a lifting

tool of appropriate capacity (e.g., forklift truck or other suitable means).

Then, the assembly must be positioned on a stable, horizontal surface.

Upon receipt, check the machine for any damage (breakages or major

denting) caused during transport. If so, it is necessary to immediately inform

the shipping company and to write on the Delivery note the “Accepted subject

to checking" clause.

In the event of damage, send a written complaint to the forwarder within 8

days of receipt.

Promptly inform Edilgrappa s.r.l. if major damage, caused during transport, is

found upon receipt, or if any parts are missing.

It is also necessary to check the delivered materials against the detailed

shipping list.

9

2.01 HANDLING, TRANSPORT AND LIFTING

The machine handling can be easily performed by gripping the machine itself by its

special grip and handle.

Handlingfor long distances:

Fix the crusher onto a pallet and handle it with the aid of a forklift truck or a pallet

truck in order to load it onto the means of transport (truck, train, etc...).

Loads must be moved in compliance with current occupational

safety regulations

After each use, place the machine on a stable surface checking that it has the

appropriate capacity.

3 COMMISSIONING

CAUTION:

The installer is responsible for checking that the appropriate technical features of

the hydraulic power unit are met, according to the model of crusher applied (see

Par. 1.02).

The crusher can only be installed on a hydraulic power unit compliant with Directive

2006/42/EC.

3.01 PRELIMINARY CHECKS

Before connecting the crusher, perform the following checks on the hydraulic power

unit:

A. check the correct operation of the safety devices;

B. check the condition of the quick couplings and the other coupling

components both on the crusher and the hydraulic power unit.

10

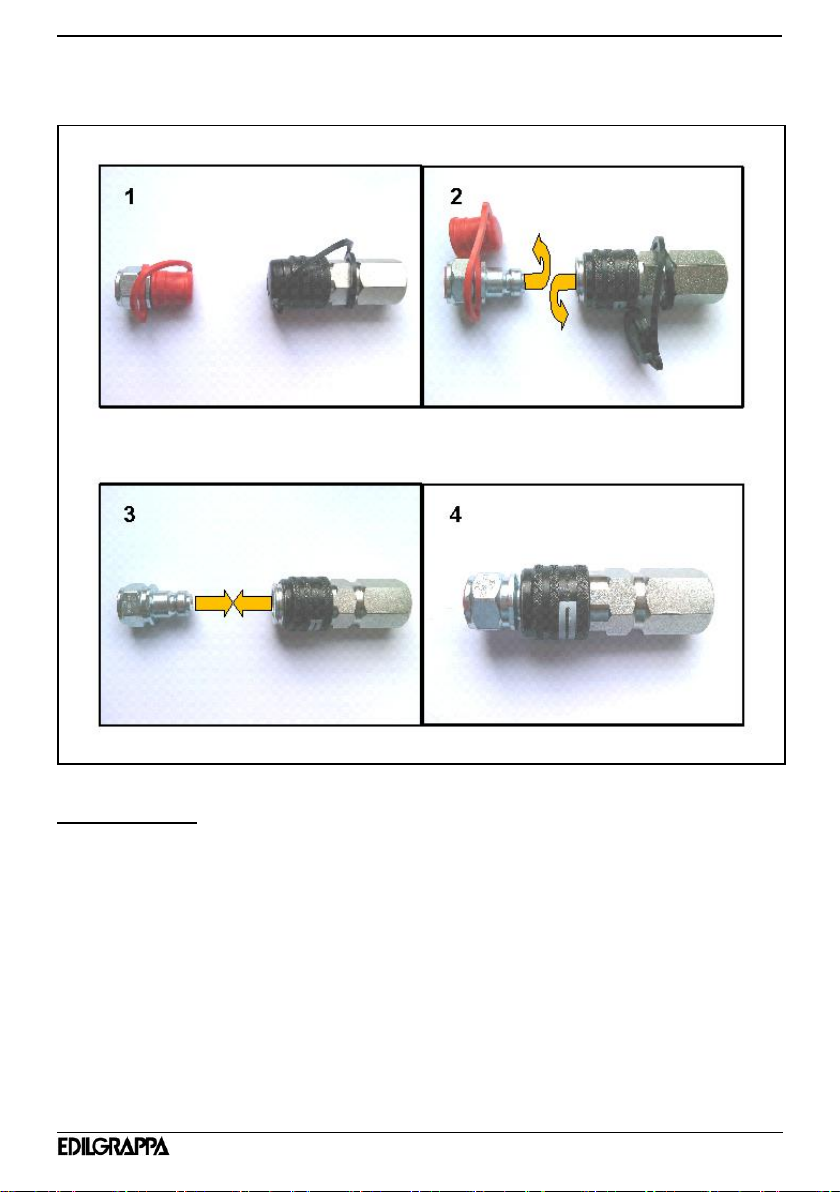

3.02 HYDRAULIC CONNECTION

To connect the crusher to the hydraulic power unit insert the quick coupling hoses (see

below) into the special attachments on the power unit.

After connecting the hoses, activate the crusher 5-6 times and check for any oil leaks.

CAUTION

Residual risk of burns: hydraulic oil, hoses and fittings can reach very high

temperatures with or without the cylinder applied. Use suitable personal protective

equipment.

CONNECTION:

For connecting quick couplings, proceed as follows (for references see fig. 2):

Never use damaged quick couplings.

Never connect a quick coupling to the hydraulic power unit if the

hydraulic circuit is pressurised.

Make sure there is no residual pressure in the hydraulic circuit; otherwise, discharge

the pressure according to the instructions of the power unit manufacturer contained in

the relevant Use and maintenance manual.

Remove the anti-dust plugs from the couplings. The anti-dust plug can be easily

removed (see ref. 2 in fig. 2 );

Check for dust and any damage on the quick couplings and clean them if necessary;

Push the quick couplings against each other (see ref. 3 in fig. 2). The external ring nut

of the female coupling will automatically move in the opposite direction to that shown by

the arrows on the ring nut itself and will be locked in the correct position.

Check that the quick couplings cannot be easily separated and check that the external

ring nut of the female coupling is in the correct position.

Thoroughly clean all the quick couplings both on the cylinder and the power

unit before connecting them.

If, for any reason, pressure remains in the power unit hoses it will not be

possible to insert the male quick coupling into the female quick coupling.

Follow the instructions of the power unit manufacturer to remove pressure

11

Fig. 2

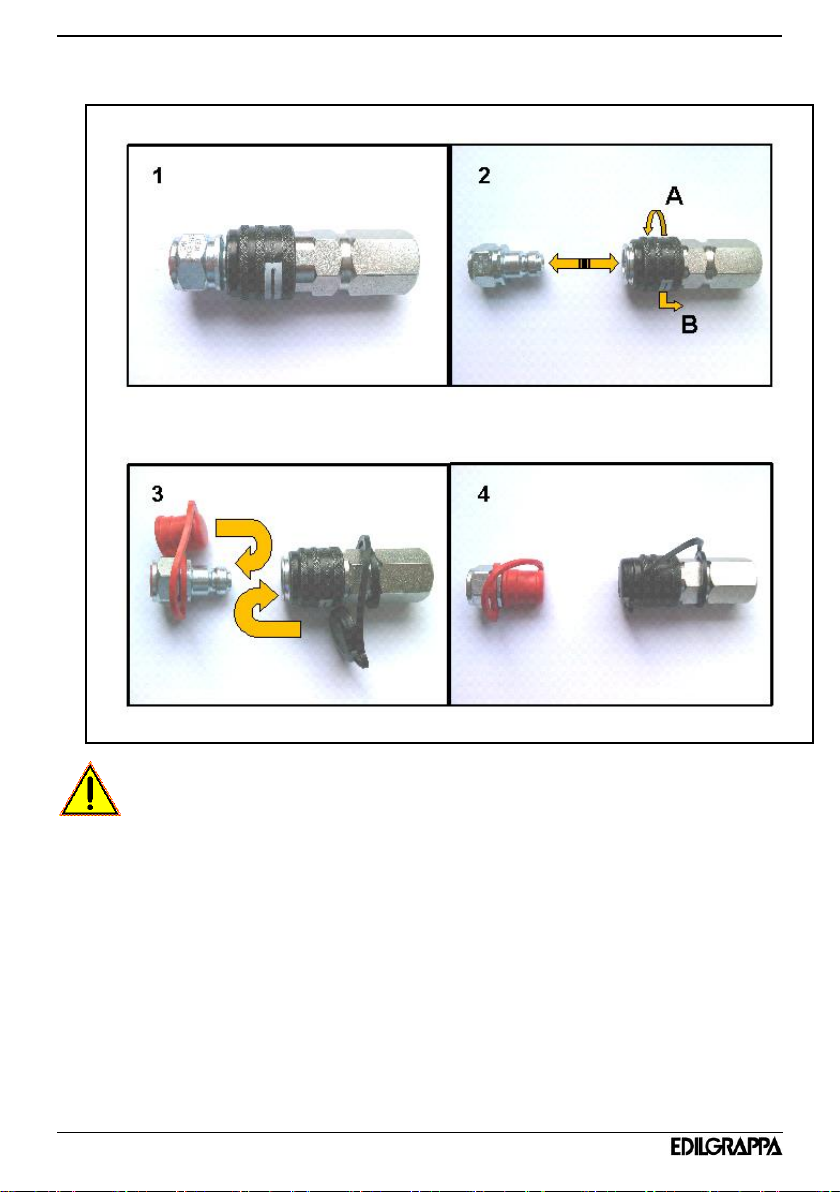

DISCONNECTION:

For disconnecting quick couplings, proceed as follows (for references see fig. 2A):

Make sure there is no residual pressure in the hydraulic circuit; otherwise,

discharge the pressure according to the instructions of the power unit

manufacturer contained in the relevant Use and maintenance manual.

Detach the quick couplings by rotating (A) the external ring nut of the female

coupling and making it slide (B) in the direction shown by the arrows; the male

coupling will come out of its position (see ref. 2 in fig. 2A).

Remove any dirt or oil residues from the quick couplings and the anti-dust plugs.

Replace the anti-dust plugs on the male and female quick couplings (see ref. 3 in

fig.2A).

12

Fig. 2A

CAUTION

After disconnecting the hoses, apply the anti-dust plugs to prevent impurities from entering

and protect the quick couplings.

13

4 USE

Controlled demolition crushers are designed to demolish concrete or brick walls depending

on the specific piece of equipment used for the dimensions indicated in the technical

characteristics, minimising noise, dust, vibrations and/or percussions.

The CRUSHER 230-DE T10 demolishes concrete walls (R=325 kg/cm²) with the maximum

dimensions indicated in the technical specifications.

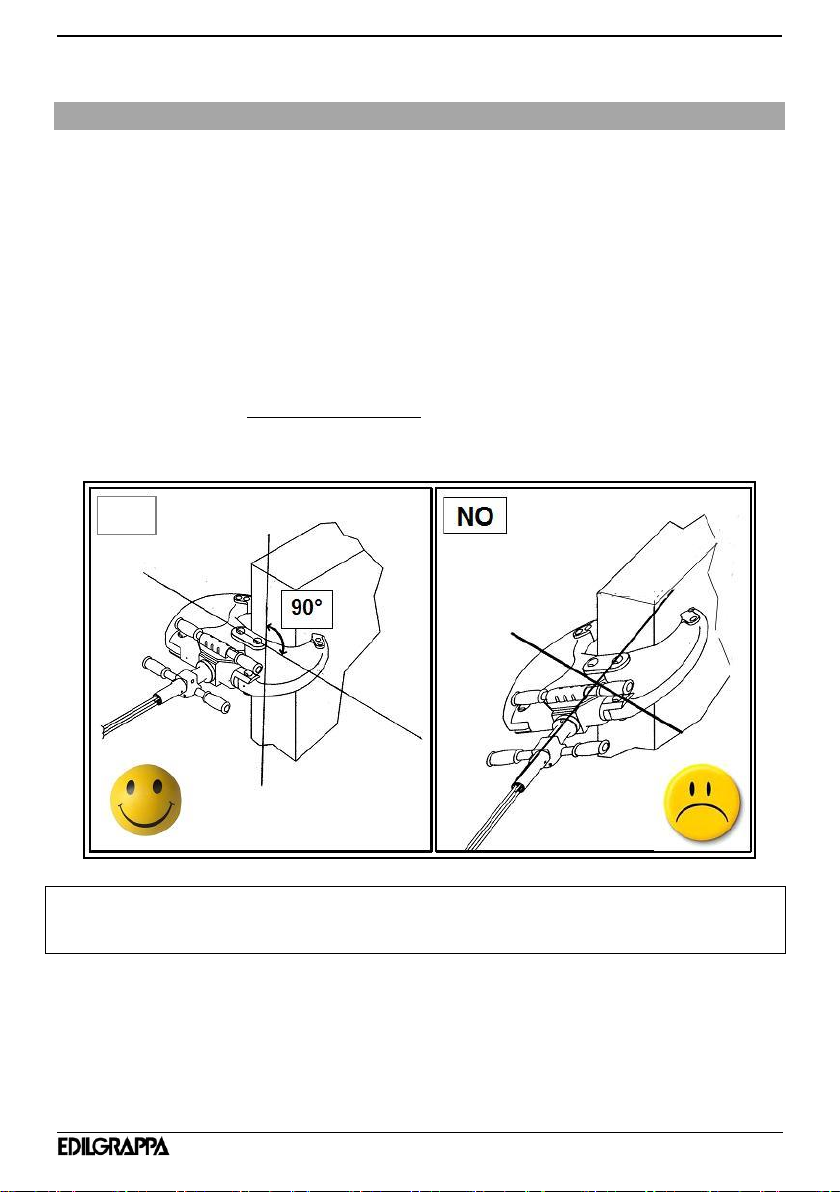

6.01 OPERATIVE DEMOLITION STAGE

Place the crusher jaws onto the object to be demolished so that it is perpendicular to the

axis of the object (fig. 3 shown as an example)

Fig. 3

If the crusher is in the wrong position, there can be damage to the tool due to the

significant thrust exerted by the cylinder.

-Place the jaws along the perpendicular line of the material to be demolished taking into

account the data shown in the technical features.

-After correctly positioning the jaws on the material to be demolished, move the

actuation handle in the direction of the "CLOSE” arrow until work is complete (see fig.

4).

YES

14

-Move it in the opposite direction “OPEN” to open the jaws and return to the original

position (see fig. 4).

-Make sure the actuation flange stops in the neutral position. This position can be

recognised by the alignment of the reference sign on the actuation flange with the

reference sign on the handle (see ref. 1 in fig. 4 ).

The following picture is only an example.

Fig. 4

CAUTION: TO AVOID BREAKING THE JAWS AND PINS AND TO OPTIMISE THE

FORCE OF THE TOOL, IT IS IMPORTANT TO OBSERVE THE INSTRUCTIONS ON

HOW TO POSITION THE MACHINE ON THE MATERIAL:

PLACE THE EQUIPMENT ONTO THE MATERIAL SO THAT IT IS PERPENDICULAR

TO AXIS OF THE MATERIAL ITSELF (fig. 3).

It is expressly forbidden to use the tool for purposes other than that indicated above

The Manufacturer declines responsibility for damage caused to people, animals or

property if the above machine is used for purposes other than those it was designed

for.

15

5 ROUTINE MAINTENANCE

1. All maintenance, inspection and cleaning interventions on the machine

must be performed with the machine disconnected from the hydraulic

power unit and cold (see the person in charge in the maintenance

intervals table);

2. Maintenance operations must be performed in a suitable place

according to current safety regulations;

3. Before any maintenance intervention, thoroughly clean the machine

(see Paragraph 5.01);

4. Wear suitable personal protective equipment while performing

maintenance work.

AT THE END OF EACH MAINTENANCE INTERVENTION ON THE

MACHINE, CHECK THAT ALL GUARDS HAVE BEEN CORRECTLY

REPLACED AND REINSTALLED.

Periodic maintenance schedule

Frequency

Operation

Method

Person

EVERY 8

HOURS

CHECKING THE INTEGRITY OF

THE MACHINE

Visual

Operator

EVERY 8

HOURS

MACHINE CLEANING

Para 5.01

Operator

EVERY 8

HOURS

TIP WEAR CHECK

Visual

Operator

/

TIP REPLACEMENT

/

Authorised

personnel

EVERY 8

HOURS

CHECK THE TIGHTNESS OF

NUTS AND BOLTS

Para 5.02

Operator

EVERY 8

HOURS

PIN GREASING

Para 5.03

Operator

16

In case of doubts during the maintenance interventions, to order spare parts or for

complex maintenance work, contact your authorised retailer.

5.01 CLEANING THE MACHINE

The cleaning operations must be performed using a dry cloth or compressed air. For

plastic surfaces the use of a cloth slightly dampened with water is allowed.

5.02 CHECKING THE SCREWS

Periodically, or every day in the event of frequent or prolonged work, make sure that all the

screws are perfectly tight.

FAILURE TO TIGHTEN LOCKING SCREWS CAN CAUSE SERIOUS DAMAGE.

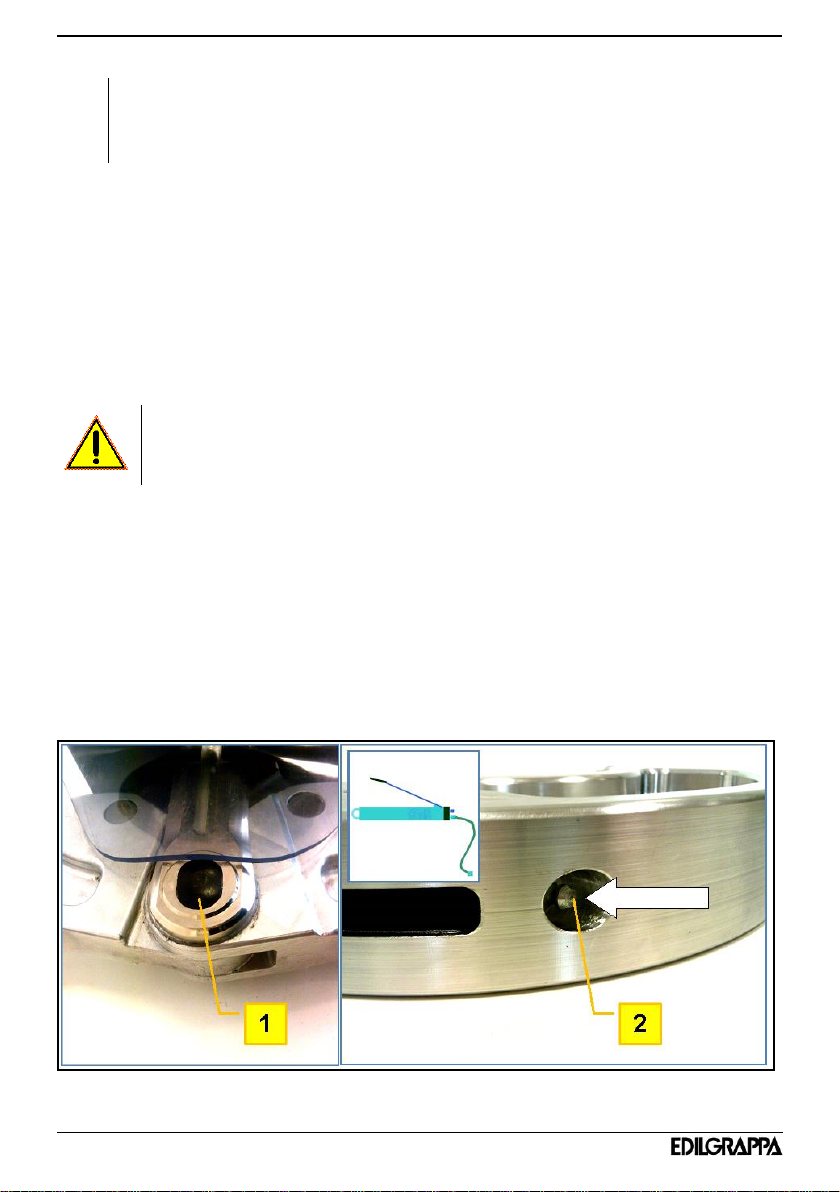

5.03 GREASING

Periodically or daily (in the event of frequent or extended works) check that the central pin (

see ref. 1 in fig. 5 ) is appropriately lubricated.

To grease the pin, use lithium-based water-repellent grease and apply it with a manual

grease gun (see example in fig. 5), pumping the grease into the grease nipple located on

one of the two jaws (see ref. 2 in fig. 5).

Fig. 5

17

6 PROBLEMS AND REMEDIES

The aim of this paragraph is to provide the user with the solutions to the problems (faults)

which occur most frequently. Do not perform any maintenance or repair interventions which

could compromise the safety of the machine.

The remedies marked by the letter Prequire the intervention of authorised personnel. Remedies

marked with the letter Mrequire the assistance of the maintenance man. Remedies marked with the

letter Ocan be performed by the operator.

FAULT

PROBABLE CAUSE

REMEDY

LOW

PERFORMANC

E CRUSHER

INSUFFICIENT FLOW

AND/OR HYDRAULIC

PRESSURE

MAKE SURE YOU HAVE

PERFORMED ALL CONNECTIONS

REQUIRED FOR OPERATION

CORRECTLY.

CONTACT THE CUSTOMER

SERVICE OF THE HYDRAULIC

POWER UNIT CONTROLLING THE

FLOW AND THE HYDRAULIC

PRESSURE.

P

VIBRATIONS

LOOSE OR MISSING

SCREWS OR BOLTS

CHECK THE TIGHTENING TORQUE

OF THE SCREWS OR BOLTS.

REPLACE THE MISSING SCREWS.

P

THE CRUSHER

DOES NOT

OPEN/CLOSE

LACK OF HYDRAULIC

FLOW AND/OR

PRESSURE

CHECK THE HYDRAULIC POWER

UNIT

P

ELECTRIC CABLE

(IF FITTED)

CHECK THE CORRECT

CONNECTION OF THE ELECTRIC

CABLE

O

EXTERNAL OIL

LEAKS

LOOSE FITTINGS

TIGHTEN LOOSE FITTINGS

O

DAMAGED HOSES

REPLACE HOSES

P

DAMAGED

COUPLINGS

REPLACE COUPLINGS

18

7 STORAGE AND RE-COMMISSIONING

7.01 STORAGE

In case of long periods of inactivity, proceed as follows:

- Store the equipment in a clean and dry place accessible only to authorised personnel.

- Thoroughly clean the tool;

- Lubricate it with a thin layer of oil.

7.02 RE-COMMISSIONING

Before re-commissioning the machine after a long period of inactivity, perform the following

checks:

- check and if necessary eliminate any oil leaks;

- grease all parts which can be lubricated;

- check the hoses are intact;

- check for any missing, worn or badly positioned parts;

- check nuts and bolts are tightened.

8 MACHINE DISPOSAL

When disposing of the machine, the various materials must be separated.

The tool comprises the following groups of materials:

- ferrous materials

- copper

- plastic

Observe current legislation when sorting, storing, recycling or disposing of these materials.

Only for EU countries:

This electric tool features the following recycling symbol. Consistently with Directive

2002/96/EC on waste electrical and electronic equipment (WEEE), at the end of its useful

lifetime, this product must be disposed of separately in suitable collection areas and not

together with normal domestic waste. A benefit for the environment and an advantage for

all.

19

9 SPARE PARTS AND ACCESSORIES CATALOGUE

9.01 ORDER INSTRUCTIONS

For technical assistance and spare parts also after the warranty period, inform the

manufacturer of the identification data shown on the nameplate and the serial number

printed on the crusher body.

Orders for spare parts must be accompanied by the following information:

1. Type of equipment

2. Serial number

3. Part number or position in exploded drawing

4. Quantity

5. Revision status of the manual indicated on the cover.

The Manufacturer can only supply the appropriate spare part if the required data is

complete, since subsequent improvements may have entailed structural variations to the

equipment and therefore to the spare parts.

20

Declaration of conformity

Maker: EDILGRAPPA srl

Machines and equipment for the building trade, industry

and rescue

Via Callesello, 4

31030 Borso Del Grappa (TV)

Name and address of person

authorised to draw up

the technical brief: Giacomo Rorato

Via Callesello, 4

31030 Borso Del Grappa (TV)

Generic name: Demolition crusher

Function: Demolition of concrete items with a maximum thickness of 230

mm

Type: Crusher

Model: 230DE T10

Commercial name: CONCRETE CRUSHER 230DE T10

Serial number: ________________

Year of construction: ________________

DECLARES THAT THE ABOVE-MENTIONED EQUIPMENT IS COMPLIANT WITH THE FOLLOWING

DIRECTIVES:

Machinery Directive 2006/42/EC (Proc. App. VIII)

Place: Borso Del Grappa TV

Date.................... Signature

PAOLO MAZZARO

(Legal representative)

Table of contents

Other EDILGRAPPA Power Tools manuals