Shopsmith 555480 User manual

Jointer Feather

Guard Upgrade

555480

WARNING

Read this owner's manualand

follow the safety information.

Then read andfollow safety in-

formation in thejointer owners

manual.

lntroduction

The Jointer Feather Guard brings to your jointer the advantages of a feather board with the

safety of a guard. It guards just like the older style guardt plgs the Feather Guard presses- the

workpiece against the fence, which adds ease and control. This upgrades your jointer's older

style furard tb the new Feather Guard.

After you have followed the assembly instructions in this manual, read and follow the

operation instructions. The operations instruction in this manual tell how to adjust the Feather

Guard to be used in jointing or rabbeting. For other, more comprehensive instructions on

operations, see your jointer owner's manual.

JOINTER FEATHER GUARD UPGRADE 554180

w-

I

et-

,\

\b

\t8

+

*_g

u

F-,u

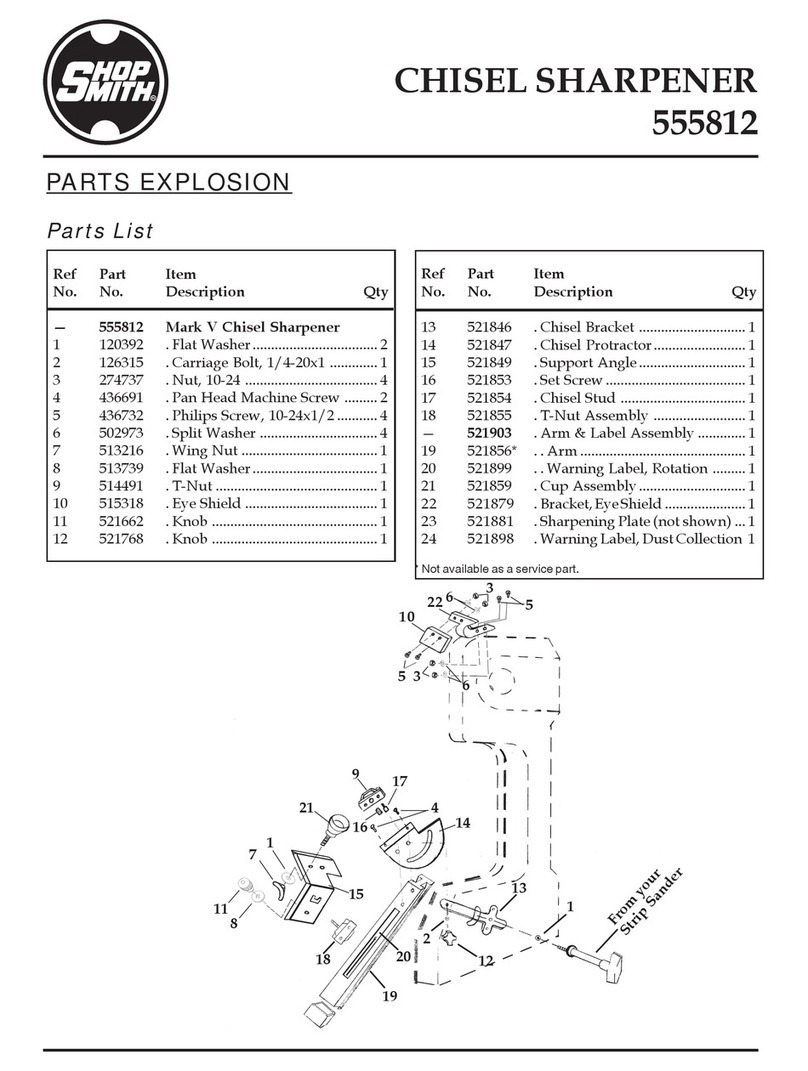

PARTS LIST

Ref.

No. Part No. ltem Description Oty.

55ilN JointerFeatherGuardUpgrade

1 51U23 .JointerFeatherGuardAssembly..... 1

2 516234 . . Warning Label .,....... ....... 1

3 516232 ..Logo ............ 1

4 51398901 . Adjuster Screw, 114"-20 x 114" ............ 1

5 516401 . Knob ............. 1

6 515847 . ThrustWasher..................................... 1

7 514196 . Spring .,.......... 'l

I 502909 . TorqueWasher.........................,.......... 1

9 514273 . Washer, 112" ............ ........ 1

10 514M9 . Retaining Ring ........... ....... 2

11 514272 .ThreadedStud..................................... 1

516315 . Hardware Bag (includes 12-171

12 120393 .. Washer, 11132"..-............................... 1

13 513857 .. Hex Nut, 5/16" - 18............................ 1

14 516221 .. Stop Pin ............. ............ 1

15 516222 .. Stop Knob .......... ............ 1

16 516226 . . Stop Stud Assembly 114 -28 Black.... 1

17 514274 .. SpecialWasher .............. 1

1B 516239 , DrillingTemplate.................................. 1

Fold Here //

THIS SIDE UP

Stud Insert Here _

- punsh HerP

Page2

555480 JOINTER FEATHER GUARD UPGRADE

Tools Neededt

tr 3/8" Drive Ratchet

tr 1./2" Socket

tr 7 /16'Wrench

tr 1/8" Allen Wrench (Optional)

tr Variable Speed Drill

tr 7 /32' (or #3) Twist Drill Bit

tr 1,/4-28 Drill Tap and Tap Handle

tr Precision Square

tr Piece of Scrap Cardboard

tr Hammer

tr Center Punch

El Installation Kit-555482 (Optional)

Assembly

REMOVE THE OLD JOINTER GUARD

WARNING

Make suretheJolnte/s powersource (MARK

V, Power StaUon or other) ls turned off and

unplugged.

WARNING

Be carefu I notto cutyourself on theJolnter

Hades.

5.

Fig. 2

Again grasp the jointer's power coupler

while you insert the cardboard into the

cutter opening, as shown in Fig. 3 Use a

thin stick to help you tuck the cardboard

into the opening.

1. Remove the fence from the jointer, and as

you remove the fence, hold the cutterhead

guard. to prevent its spring fIoT] ryryp-

ping the guard around uncontrolled. See

Fig. 1 \ \

Guide the guard as it completely un-

winds, which will be about two revolu-

tions.

Grasp the jointer's power coupler and

rotate the cutter head so no blade is ex-

posed in the opening. See Fig. 2

Cut a 2-1,/2' x4-1,f 2" piece of cardboard. 8.

Fig. 3

Remove the guard's knob, as shown in

Fig.4.

Then remove the guard and the flat

washer.

Fig.4

Set all three pieces aside until later,leave

post from guard in table.

6.

7.

,

4.

Fig. 1

PageS

JOINTER FEATHER GUARD UPGRADE

Re-install the fence on the jointer, as shown

in Fig. 5.

DRILL A HOLE IN THE JO'NTER

TABLE

9. Re-install the fence on theiointer. as s

Fig. 5

Fold the template (18) along the serrated

line.

Place the template in the jointer table and

insert the guard stud through the tem-

plate hole.

Fis. 6

L2. Locate the fence so it touches the fold in

the template. See Fig.6. This will ensure

that the folded template flap is square

with the jointer base. Important: Make

sure the fence contacts the entire width of

the template. This is critical for exactly

placing the indentation in Step 13.

Remove the template.

Use a 7/32" (or #3) twist drill bit and

variable speed drill to drill a hole through

the table at the punch mark, as illustrated

in Fig. 8. Use a square to make sure that

you drill the hole perpendicular to the

surface of the table.

T

Fig. 8

Use a 1/4-28 Tap to cut threads in the

drilled hole, as seen in Fig.9. Follow this

process: Start the tap straight in the hole.

Make a full turn. Back up a quarter turn.

Add traro drops of any kind of oil into the

hole. Repeat this process until you have

tapped threads through the entire hole.

Fig. 9

Use a ratchet with a 1/2" socket to remove

the old guard stud post, as shown in Fig.

1.0, and re-assemble your old jointer

guard. Save it.

14.

L5.

10.

71..

1.6.

17.

13. Use a hammerand center punchto punch

through the template where it says "Cen-

ter Punch Here". This will leave an inden-

tation in the table. See Fig. 7.

Fig.7

Page4

Fig.10

JOINTER FEATHER GUARD UPGRADE

INSTALL THE NEW FEATHER

GUARD

18. Thread the stop stud (16) into the jointer

table, as shown in Fig. 1L.

Use a 7 /1.6' wrench to securely tighten

the stop stud's hex nut.

Remove the fence from the jointer.

Insert the feather guard's stud (11) into

the table's hex hole. See Fig. 12.

23. Starting with the feather guard parallel

w.ith the jointer, as demonstrateci in Fig

L4., rotate the feather guard counter-clock--

wise1.-l/ ).turns. Hold the guard by hand

(or use a clamp as a stop).

24. Fig.14

Install the stop pin (1a) in the feather

g1.rald by inserting its shaft through the

slot in the.guard, as in Fig. 15. The long,

flat side of the stop pin (14) must face th"e

side with the feather guard "fingers".

19.

20.

21.

Fig.12

NOTE

The Special Washer (J71must be installed

with its bevel facing up and the flat side

against the casting..

25. Attach the stop pin to the feather guard

(1a) with a washer (12) and knob (15), as

NOTE

This knob will be tight when threaded on

the stop pin. This tightness is to prevent the

knob from loosening during operations.

22. Attach a special washer (17) and hex nut

(13) to the stud, as shown in Fig. 13. Use a

1.f 2" socket wrench to securely tighten

the hex nut (13).

Fig. 11

Fig. l5

shown in Fig. 16.

Fig. 16

PageS

JOINTER FEATHER GUARD UPGRADE 554$0

ADJUST THE FEATHER GUARD'S

TEirsroi,

26. Rotate the feather guard another haU turn

counter-clockwise.

27. Re-install the fence while holding the

feather guard in place, as illustrated in

Fig. 17. Guide the feather guard back

against the fence.

Fig.17

28. Remove the cardboard from the jointer's

blade opening.

ADJUST THE SPR'NG TENS'ON

NOTE

The spring pressure of the feather guard is

pre-adjusted atthe factory. Itshould notneed

any further adjustment. Test the spring pres-

sure by pulling the feather guard away from

the fence and letting go. It should snap back

against the fence quickly. If there is any hesi-

tation of movement, it should be readjusted.

29. If the spring action of the feather guard is

not sufficient follow these steps:

a. While holding the knob (5) so that it

will not rotate, use a 1/8" Allen

wrench to loosen the setscrew (4) 1o-

cated in the top of the knob (5) on the

feather guard, as shown in Fig. 18.

Fig. 18 5

b. Turn the knob (5) slightly counter-

clockwise (about L/4 turn) to adjust

the tension. See Fig. 19.

c. Hold the knob (5) in place while you

retighten the setscrew (4), see Fig. 20.

Fig.20

NOTE

Make sure thatyou do not adjust the feather

guard so ithas too much or too little pressure.

Too liftle pressure can cause the featherguard

to be ineffective in guarding you from injury

and applying applying lateral pressure to

keep the workpiece against the iointer fence.

Fig. 19

PageO

555480 JOINTER FEATHER GUARD UPGRADE

OPERATIOA'S

The sideways pressure exerted by the feather

guard fingers against the workpiece helps

keep the workpiece against the fence. Also,

the fingers are oriented so the workpiece is

prevented from kicking back horizontally.

This allows the operator to concentrate on

puching the stock through - enabling safer,

more convenient and more accurate jointer

operations.

All jointers which have the feather guard will

operate exactly the same as with the old style

guard, except for the instructions below on

how to adjust the feather guard to work with

each workpiece. Read and perform the fol-

lowing instructions for joining or rabbeting,

then see your jointer owner's manual for all

operation procedures and safety information.

Press the feather guard against the

workpiece until you have reached mild

pressure. You can tell this when the fin-

gers slightly flex.

Move the stop knob(15) and stop pin (1a)

away from the workpiece so it touches

the stop stud (16).

Tighten the stop knob (15), as inFig.22.

Follow the jointing operations procedures

found in the jointer owners manual. Fig.

23 shows the Jointer Feather Guard oper-

ating while a board is being joined.

3.

4.

5.

WARNING

Before performlng any step below, make

sure thejolnter's powersource (MARK V,

Power StaUon orothersource) isturned off

andunplugged.

For Jointing -

llow to Adjust the Feather Guard

to the Wo*piece

1. Loosen the stop knob (15) on the stop pin

(14).

Place the workpiece against the fence and

2. Placetheworkpieceagainsttt

between the fence and the fea guard.

See Fig. 21.

Fig.23

For Rabbeting -

How to Adjust the Feather Guard to

the Workpiece

1. Loosen the feather guard's stop knob (15)

with stop pin (14).

2. Adjust the fence so it is positioned to cut

the desired width rabbet and lock it in

position. (Consult your Jointer Owner's

Manual)

6.

Fig.22

Fig.21

PageT

Jointer FeatherGuard Upg rade 554n80

3. Insert the workpiece between the fence

and the feather guard, as shown inEig.24.

Fig.24

Press the feather guard against the

workpiece until you have reached mild

pressure.

Move the stop knob (15) with stop pin

(14) away from the workpiece so it touches

the stop stud.

Tighten the stop knob (15).

Follow the rabbeting operations proce-

dures found inthejointer owner's manual.

NOTE

The feather guard must always be used for

any jointer operation. DO NOT remove the

feather guard to perform any types of cuts.

Any width rabbet cut can be made on 3f 4"

stock with the feather guard. The maximum

width of a rabbet cut is 3/4". The maximum

depth of cut is 3/8".

NOTE

If you have any questions, please call our

Customer Service Department Toll-Free

800-762-7555 or visit our website

wwlry.shopsmith.com.

NOTES

4.

5.

6.

7.

Shopsrnihhc.

6530 Poe Avenue

Dayton, Ohio 45,414

U5286 RevA 9/01

@2001 Shopsmith,lnc.

AllRights Reserved

Printed In U.S.A.

IIIITIII.II.II-.IIIIIII.I--II

Fold Here

This Side UP

Locate on Stud

Here

Use Center -o-

51632e Rev B I

Punch Here

Table of contents

Other Shopsmith Power Tools manuals