Edison Autoslide User manual

Installation Manual

(For Sliding Garage Doors)

Edison Autoslide™

2

Parts List

1. Connector Sleeve (1x)

2. Two-part channel and plasc chain (1x)

3. C-rail (2x)

4. Carriage (1x)

5. Door bracket (1x)

6. Control housing with cord (1x)

7. Tensioner, tensioning bolt M8 x 80mm, and spring (1x)

8. Angle bracket for rail mid-aachment (4x)

9. Thick washer 1-1/4” dia (4x)

10. U-ng long stud with collar (1x)

11. U-ng short bolt (1x)

12. Long pin and clips OR lock nut/bolt (2x)

13. Medium pin and clip OR lock nut/bolt (1x)

14. Short pin and clip OR lock nut/bolt (2x)

15. Lag bolt 5/16” x 1-1/2” (10x)

16. Carriage bolt M8 x 25mm, lock washer and nut (4x)

17. Release cord grip (1x)

18. Electric end (1x) *NOT USED*

19. Non-electric end (1x)

20. Electric end with cord (1x)

21. Photoeye set (1x)

22. Rail mid-aachment bracket (2x)

23. Wall buon (1x)

24. Remote transmier (2x)

25. Boomerang curved brace (1x)

26. Limit stop set (marked “H” and “V”) (1x)

27. Rail end bracket (2x)

123

45

6

78910 11

12 13 14 15 16

18

21 22 23

25 26

19

24

27

17

20

3

Assembly

The chain is inserted into a plasc guide channel. It is not

packaging material. Do not throw away! Unfold the two

secons of chain. You may leave the limit stops “H” and

“V” in the rail.

Aach release cord grip to the carriage cord by sliding it

on and knong the cord. Hang the chain out as shown

and thread it onto the sprocket on the underside of the

carriage. Note the posion of the chain with guide as

shown in the side view at le. If the sprocket does not

turn, pull the release cord one me. This unlocks the

carriage.

Slide the carriage and chain assembly onto one secon of

C-Rail to the approximate mid-posion.

4

Assembly

Slide both secons of rail into the connecng sleeve.

Thread the chain through the other limit stop in the

process.

Feed the rst link of the chain into the tensioner on the

‘electric end with cord.’ Turn the electric end by 90° to

lock into posion.

Push the electric end rmly into the end of the C-rail unl

its ange meets edge of the rail. Loosen the screw on

limit stop “H” and slide against the tensioner.

90°

XNote: the ‘electric end’ that ships in the assembly is not

used and may be discarded.

5

Assembly

At the other end of the C-rail assembly:

Disassemble tensioner, tensioning bolt, and spring from

the ‘non electric end’. Slide tensioner onto chain and

rotate 90° to lock.

Slide the ‘non-electric end’ into the end of the rail,

guiding the tensioner into the hole in the end. Seat the

end fully onto the end of the rail using rm pressure.

Thread the spring onto the tensioning bolt and screw into

the tensioner by hand.

Using a socket wrench, ghten the tensioning bolt unl

the collar under the bolt head aligns with the arrow

marking on the non-electric end.

At the other end of the rail (electric end):

Do not adjust the factory posion of the tension bolt in

the embedded tensioner. Doing so could cause damage

to the tensioner.

90°

6

Assembly

Lock the carriage into place by pulling once on the release

cord, then sliding the carriage one direcon. There will be

an audible ‘click’ and the carriage will freeze its posion.

Insert two M8 x 25mm carriage bolts into rail mid-

aachment bracket as shown. Slide onto one end of the

rail, leaving at about the 1/3 posion. Repeat for the

opposite end of the rail.

Aach the angle brackets through the uppermost hole

with lock washer and nut. Repeat for other rail mid-

bracket.

7

Assembly

FOR CEILING MOUNTED APPLICATIONS:

Aach boomerang curved brace onto carriage as shown.

With thick washer and medium length pin and clip.

Posion end bracket on assembly as shown at le. Thread

long pin into end, then x into place with two clips.

Repeat for other end of rail assembly.

CEILING MOUNTED, CONTINUED

Aach U-ng with short pin and clip as shown.

8

Assembly

WALL (SIDE) MOUNTED, CONTINUED:

Slide boomerang curved brace into U-ng assembly and

ax with short length pin and clip. The secon of the

brace with 3 holes should be running parallel to the track.

Aach the other U-ng to the other end of the brace

with another short pin and clip.

FOR WALL (SIDE) MOUNTED APPLICATIONS:

Aach the U-ng with long stud and collar to carriage

as shown.

9

Installation

Plan your layout: The ‘closing’ end of the rail assembly should

be set back from the closed door by 1/2” minimum. The door

may be mounted on the exterior or the interior.

Aach rail assembly to wall or ceiling with 5/16” lag screws.

Note: Aachment must be to adequate framing or strapping.

Drywall aachment only is not permied. The track must not

come into contact with the door’s supporng sliding track at

any me. Curved brace may be rotated for maximum

exibility. Ceiling mounted clearance shown is from ceiling

plane to centerline of U-ng. Wall mounted clearance is

from boom of track to U-ng.

1/2” MIN

4” to 7” 4” to 7”

10

Installation

Posion door bracket in desired locaon. Nong the

clearances on previous page, swivel boomerang brace and

U-ng assembly to determine best placement. Mark the

locaon of the brace’s two mounng holes.

Cut door bracket to length (if desired). Plug end with plasc

end cap provided and install on door with 5/16” x 1-1/2”

lag bolts. Predrill through the bracket where the U-ng

meets it. Fasten securely with M10 x 40mm bolt.

11

Installation

Mount control enclosure to the wall and use the wiring diagram

on the following page to wire the components. WARNING: Do

not wire the 120V power unl all the wiring has been

completed. Plugging in the system is the last step in wiring.

Always disconnect the power source before adjusng or

rewiring the control panel.

Mount the photoeyes in the door jamb 6” to 8” from the oor.

The maximum distance between eyes must not exceed 20 feet.

Posion the wall pushbuon in an accessible locaon. Carefully

pry the buon’s switch cover o. Loosen the two exposed

screws, then carefully pry the buon base from the frame.

IMPORTANT:

Garage doors can cause harm to people and / or things. Never

allow children to play with the garage door. Do not use the

garage door as a pedestrian exit.

12

Wiring

The 120V power cord is prewired inside the enclosure. To exit the enclosure, slice the concentric

‘boot’ at the base of the enclosure, disconnect the plug from the terminals, and thread the cord

through the boot. Reconnect the terminals. IMPORTANT: Always have the power disconnected

when adjusng any wiring on the system.

Wire the accessories and safety photoeyes to the terminals numbers as shown. Polarity is not

observed with these devices.

To power the track, connect the RED wire to terminal 7 and the GREEN wire to terminal 8.

Wall Buon Photoeye set

123456

To 120V outlet

78

Wires exing

track

red

green

Table of contents

Popular Garage Door Opener manuals by other brands

Merlin

Merlin SilentDrive Pro Installation and operating instructions

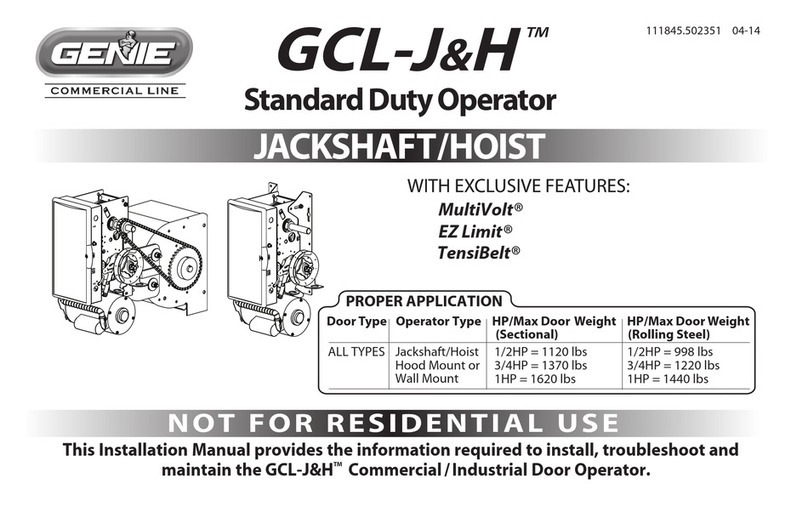

Genie

Genie GCL-J&H 1/2HP installation manual

Merlin

Merlin Commander Extreme MS125MYQ Installation and operating instructions

Craftsman

Craftsman 139.3043 owner's manual

Nice

Nice Spido Instructions and warnings for the fitter

Chamberlain

Chamberlain 8500 manual